Process Analyzer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428543 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Process Analyzer Market Size

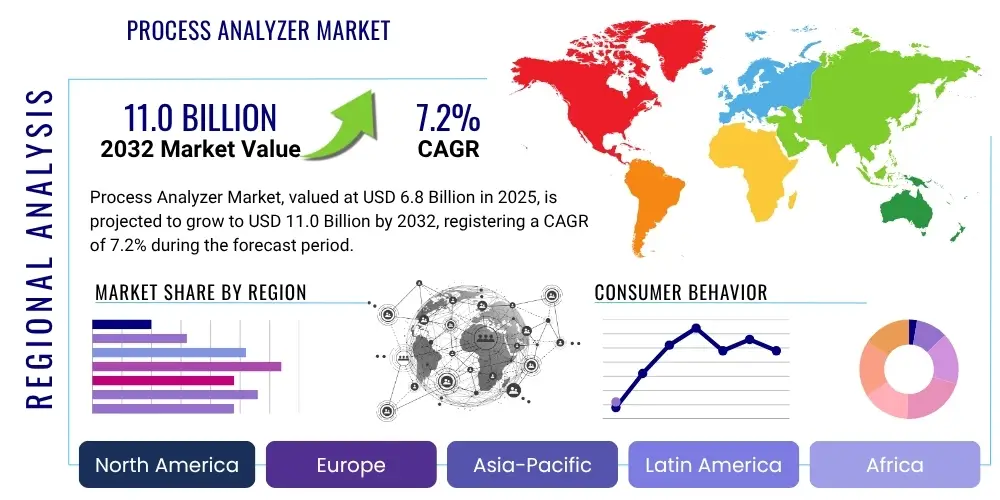

The Process Analyzer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at USD 6.8 billion in 2025 and is projected to reach USD 11.0 billion by the end of the forecast period in 2032.

Process Analyzer Market introduction

The Process Analyzer Market encompasses a wide range of analytical instruments and systems designed for real-time or near real-time measurement and control of chemical and physical properties within industrial processes. These advanced analytical solutions are crucial for monitoring various parameters such as composition, concentration, purity, and other critical process variables, ensuring optimal performance, product quality, and safety across diverse industries. The inherent complexity of modern manufacturing operations, coupled with stringent regulatory requirements and the continuous drive for operational efficiency, underscores the indispensable role of process analyzers in maintaining competitive advantage and achieving sustainability goals.

Process analyzers offer significant benefits by enabling proactive adjustments to process conditions, minimizing waste, reducing energy consumption, and preventing costly downtime. They are extensively utilized in major applications including oil and gas refineries for crude oil distillation and natural gas processing, chemical and petrochemical plants for reaction monitoring and product quality verification, and pharmaceutical manufacturing for ensuring drug purity and consistency. Furthermore, their application extends to environmental monitoring, food and beverage processing, and pulp and paper industries, where precise analytical data is essential for compliance and product integrity.

Key driving factors for the market's growth include the increasing adoption of industrial automation and digitalization initiatives, the growing emphasis on environmental protection and stricter regulatory mandates for emissions control and wastewater treatment, and the rising demand for high-quality, consistent products. The continuous technological advancements in sensor design, data analytics, and connectivity are further enhancing the capabilities and expanding the applicability of process analyzers, making them indispensable tools for modern industrial enterprises seeking to optimize their operations and respond effectively to dynamic market demands.

Process Analyzer Market Executive Summary

The Process Analyzer Market is experiencing robust growth, primarily driven by escalating automation trends across manufacturing sectors and an intensified focus on operational efficiency and stringent quality control. Businesses are increasingly investing in sophisticated analytical instrumentation to gain real-time insights into their processes, enabling them to reduce production costs, improve product consistency, and ensure regulatory compliance. The demand for advanced analyzers is particularly pronounced in high-growth industries suchses as pharmaceuticals, biotechnology, and specialty chemicals, where precise process monitoring is paramount for product integrity and safety. This market expansion is further fueled by the integration of emerging technologies like Artificial Intelligence and the Industrial Internet of Things (IIoT), transforming traditional process analysis into predictive and adaptive control systems.

Regional trends indicate significant dynamism, with Asia Pacific emerging as the fastest-growing market, propelled by rapid industrialization, increasing foreign direct investments in manufacturing, and rising infrastructure development, particularly in China and India. North America and Europe continue to hold substantial market shares, characterized by early adoption of advanced technologies, a strong regulatory environment, and a focus on upgrading existing facilities with more efficient and intelligent analytical solutions. Latin America, the Middle East, and Africa are also showcasing steady growth, driven by investments in oil and gas, petrochemicals, and water treatment projects, necessitating reliable process monitoring solutions to optimize resource utilization and meet evolving environmental standards.

From a segmentation perspective, the market is broadly categorized by analyzer type, application, and industry. Spectroscopic analyzers, including Near-Infrared (NIR), Raman, and UV-Vis, are witnessing high demand due to their non-destructive and rapid analysis capabilities. Chromatographic analyzers, such as Gas Chromatographs (GC) and Liquid Chromatographs (LC), remain critical for complex mixture analysis and impurity detection. By industry, the oil and gas sector remains a dominant segment, requiring extensive process monitoring for safety and yield optimization, closely followed by the chemicals and petrochemicals, and water and wastewater treatment industries. The ongoing trend towards modular, compact, and user-friendly analyzers, coupled with integrated software for data visualization and analysis, is shaping future product development and market competitive strategies across these segments.

AI Impact Analysis on Process Analyzer Market

Users are increasingly curious about how Artificial Intelligence will revolutionize process analyzer capabilities, enhance data interpretation, and contribute to predictive maintenance and anomaly detection. Common inquiries revolve around AI's role in improving measurement accuracy, reducing calibration frequency, enabling autonomous operation, and converting vast amounts of process data into actionable insights. There is a strong expectation that AI will address existing challenges such as false alarms, complex data analysis, and the need for highly specialized operators, ultimately leading to more efficient, reliable, and intelligent process control. The integration of machine learning algorithms for pattern recognition and deep learning for advanced diagnostics is viewed as a critical next step for the industry.

- AI algorithms enable enhanced data interpretation, uncovering subtle trends and correlations in complex process data that human analysis might miss.

- Predictive maintenance capabilities are significantly boosted, as AI can anticipate equipment failures or performance degradation based on analyzer data, optimizing maintenance schedules and reducing downtime.

- Improved anomaly detection, allowing for quicker identification of deviations from normal operating parameters, leading to faster issue resolution and prevention of product quality excursions.

- Reduced false alarms by differentiating between true process anomalies and benign variations, thereby increasing operational trust and efficiency.

- Enhanced calibration and self-validation routines, potentially reducing the frequency and complexity of manual calibration procedures and ensuring analyzer accuracy.

- Optimization of process control loops through real-time feedback and intelligent adjustments, leading to improved yield, reduced energy consumption, and higher product consistency.

- Development of autonomous analysis systems where AI manages data acquisition, interpretation, and even initial troubleshooting without direct human intervention.

- Facilitation of digital twin creation, allowing for virtual simulation and optimization of processes based on real-world analyzer data, leveraging AI for predictive modeling.

DRO & Impact Forces Of Process Analyzer Market

The Process Analyzer Market is primarily driven by the escalating demand for operational efficiency and productivity improvements across various industrial sectors. Industries are under constant pressure to optimize their manufacturing processes, reduce waste, and minimize energy consumption, all of which are significantly aided by real-time data provided by process analyzers. Furthermore, the increasing stringency of environmental regulations worldwide, particularly concerning emissions control, wastewater treatment, and air quality monitoring, mandates the deployment of advanced analytical solutions for continuous compliance. The globalization of supply chains also necessitates consistent product quality, driving the adoption of analyzers to ensure uniformity across different production sites and meet international standards. The rapid pace of industrial automation and the proliferation of Industry 4.0 initiatives, integrating advanced sensor technologies and data analytics, further accelerate market growth by creating demand for interconnected and intelligent analytical systems.

However, significant restraints impede market expansion. The high initial capital investment required for purchasing and installing sophisticated process analyzers, along with the associated costs for maintenance, calibration, and training skilled personnel, can be prohibitive for small and medium-sized enterprises (SMEs). The complexity of integrating these advanced analytical instruments into existing legacy control systems often presents technical challenges and requires specialized expertise, which can deter adoption. Additionally, the lack of standardization across different analytical technologies and the diverse regulatory landscapes across regions can create hurdles for manufacturers and end-users alike, complicating product development and market penetration strategies. The competitive pressure from laboratory-based analytical methods, which can offer higher precision for certain applications despite slower results, also poses a restraint.

Despite these challenges, substantial opportunities exist for market players. The rising demand for specialized and customized analytical solutions tailored to specific industry needs, particularly in emerging sectors like biotechnology and advanced materials, presents a fertile ground for innovation and market expansion. The growing focus on predictive maintenance and asset performance management, leveraging data from process analyzers, offers new avenues for value creation and service differentiation. Furthermore, the expansion into developing economies, characterized by rapid industrialization and increasing investments in infrastructure, provides significant growth prospects. Technological advancements in miniaturization, wireless connectivity, and AI-driven data analytics are creating opportunities for developing more compact, robust, and intelligent analyzers that can offer enhanced functionality at a potentially lower total cost of ownership, thereby addressing some of the key restraints and propelling future market growth.

Segmentation Analysis

The Process Analyzer Market is comprehensively segmented to address the diverse needs of various industries and applications, reflecting the wide range of analytical requirements in industrial processes. This segmentation typically covers aspects such as the type of analyzer technology employed, the specific end-user industry utilizing these analyzers, and the particular application areas within those industries. Understanding these segments is crucial for market participants to identify niche opportunities, tailor their product offerings, and develop targeted marketing strategies. Each segment represents distinct market dynamics, adoption rates, and technological preferences, influenced by factors such as regulatory pressures, process complexity, and budget constraints. The continued evolution of analytical technologies and industrial practices frequently leads to the emergence of new sub-segments and a redefinition of existing ones, highlighting the dynamic nature of this market landscape.

- By Analyzer Type

- Gas Chromatographs (GC)

- Liquid Chromatographs (LC)

- Spectrometers (NIR, UV-Vis, Raman, Mass Spectrometers)

- pH Analyzers

- Conductivity Analyzers

- Oxygen Analyzers

- Combustion Analyzers

- Moisture Analyzers

- Total Organic Carbon (TOC) Analyzers

- Sulfur Analyzers

- Infrared Analyzers

- Electrochemical Analyzers

- Others (Particle Size Analyzers, Density Analyzers, Viscosity Analyzers)

- By Application

- Process Optimization

- Quality Control and Assurance

- Safety Monitoring

- Environmental Monitoring and Compliance

- Yield Improvement

- Energy Management

- Asset Protection and Predictive Maintenance

- Product R&D

- By Industry Vertical

- Oil and Gas (Upstream, Midstream, Downstream)

- Chemical and Petrochemical

- Pharmaceutical and Biotechnology

- Water and Wastewater Treatment

- Food and Beverage

- Metals and Mining

- Pulp and Paper

- Power Generation

- Semiconductor

- Environmental Agencies

- Others (Textiles, Automotive, Academia)

- By System Type

- Standalone Analyzers

- Integrated Analyzer Systems

- By Measurement Type

- In-line/On-line Analyzers

- At-line Analyzers

- Laboratory (Off-line) Analyzers (for process support)

Value Chain Analysis For Process Analyzer Market

The value chain for the Process Analyzer Market is a complex ecosystem, starting from raw material suppliers and extending through various stages of design, manufacturing, distribution, and finally, end-user deployment and post-sales support. Upstream activities involve the procurement of specialized components such as sensors, detectors, optical components, electronic circuits, and software modules from a global network of suppliers. These components are critical for the functionality and precision of the analyzers, and relationships with reliable, high-quality component manufacturers are paramount. Research and development also represent a significant upstream activity, driving innovation in analytical techniques, miniaturization, and integration of new technologies like AI and IIoT, ensuring that products meet evolving industry demands and regulatory standards. Effective management of this upstream segment ensures cost-efficiency, quality, and timely availability of crucial parts, directly impacting the final product's competitiveness and performance.

Midstream activities primarily encompass the manufacturing, assembly, and testing of the process analyzer systems. This stage involves sophisticated engineering, precision manufacturing processes, and rigorous quality control to ensure that each analyzer meets specified performance parameters and reliability standards. Customization services are also offered at this stage, adapting standard products to specific customer requirements or unique process environments. After manufacturing, the products move into the distribution phase, which includes both direct and indirect channels. Direct distribution involves manufacturers selling directly to large industrial clients, often accompanied by comprehensive technical support and installation services. Indirect distribution utilizes a network of distributors, value-added resellers (VARs), and system integrators who provide local sales, technical support, and integrate analyzers into larger process control systems, particularly in regions where manufacturers do not have a strong direct presence. The choice of distribution channel often depends on the target market, customer size, and the complexity of the solution.

Downstream activities focus on the end-user deployment, operation, and maintenance of the process analyzers. This includes installation, commissioning, calibration, routine maintenance, troubleshooting, and repairs. Post-sales support, including technical assistance, training for operators, and software updates, is a crucial differentiator and a significant source of recurring revenue for market players. Direct channels enable manufacturers to maintain closer relationships with end-users, facilitating better understanding of their needs and faster feedback for product improvement. Indirect channels, through distributors and integrators, extend market reach and provide localized support, which is often essential for complex industrial installations. The entire value chain is interconnected, where efficiency and collaboration at each stage are critical for delivering high-quality, reliable, and cost-effective process analytical solutions to the global industrial market.

Process Analyzer Market Potential Customers

The primary potential customers for process analyzers are large-scale industrial operators across a diverse spectrum of sectors that rely on continuous process monitoring and control for operational integrity, product quality, and regulatory compliance. These end-users are typically characterized by complex manufacturing processes, high-volume production, and a significant economic impact from process inefficiencies or quality deviations. Key segments include the oil and gas industry, which uses analyzers extensively for refining, petrochemical production, and natural gas processing to ensure product specifications and optimize yields. Similarly, the chemical and petrochemical sectors are heavy consumers, utilizing analyzers for reaction monitoring, purity analysis, and process safety in the production of bulk chemicals, specialty chemicals, and polymers. The need for precise, real-time data to manage complex chemical reactions and ensure consistent output drives their demand.

Another significant customer base resides within the pharmaceutical and biotechnology industries, where process analyzers are critical for ensuring drug purity, consistency, and compliance with stringent Good Manufacturing Practice (GMP) regulations. These industries demand highly accurate and reliable analytical solutions for in-process control and final product verification, often involving specialized applications for biopharmaceutical production. The water and wastewater treatment sector also represents a substantial market, with analyzers used for monitoring water quality, detecting contaminants, and optimizing treatment processes to meet environmental discharge standards and public health requirements. Municipalities, industrial facilities with their own treatment plants, and utility companies are key buyers in this segment, driven by increasing regulatory scrutiny and public demand for clean water.

Furthermore, the food and beverage industry increasingly adopts process analyzers to ensure product safety, quality, and consistency, monitoring parameters such as sugar content, acidity, moisture, and potential contaminants across various stages of production. Manufacturers in the pulp and paper, metals and mining, and power generation industries also constitute important customer segments, leveraging process analyzers to optimize their respective operations, manage resources efficiently, and comply with environmental standards. Overall, any industrial entity seeking to enhance productivity, reduce operational costs, improve product quality, ensure worker safety, and meet environmental or industry-specific regulatory requirements is a potential customer for process analyzer solutions, with a strong focus on industries undergoing automation and digitalization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.8 Billion |

| Market Forecast in 2032 | USD 11.0 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Emerson Electric Co., Yokogawa Electric Corporation, Honeywell International Inc., Endress+Hauser Group Services AG, AMETEK Inc., Thermo Fisher Scientific Inc., Agilent Technologies Inc., Spectris PLC (through Malvern Panalytical), Applied Analytics Inc., HORIBA, Ltd., Anton Paar GmbH, Servomex Group Ltd. (a Spectris company), Process Insights Inc. (Galaxy Analyzers, Extrel, COSA Xentaur), METTLER TOLEDO, Analytik Jena AG, Focused Photonics Inc., Shimadzu Corporation, Hitachi High-Tech Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Process Analyzer Market Key Technology Landscape

The Process Analyzer Market is characterized by a dynamic and continuously evolving technology landscape, driven by the imperative for increased accuracy, speed, robustness, and connectivity in industrial monitoring. Spectroscopic techniques remain foundational, with Near-Infrared (NIR), Raman, and UV-Vis spectroscopy gaining prominence due to their ability to provide rapid, non-destructive, and in-situ analysis of chemical composition. These technologies are being enhanced with advanced optical components and sophisticated data processing algorithms to improve signal-to-noise ratios and expand their application range. Mass spectrometry, particularly process mass spectrometry, offers unparalleled sensitivity and selectivity for complex gas and vapor analysis, finding critical applications in petrochemicals and environmental monitoring where precise component identification is essential. These spectroscopic methods are instrumental in reducing laboratory sample analysis frequency, thereby speeding up process adjustments.

Chromatographic methods, primarily Gas Chromatography (GC) and Liquid Chromatography (LC), continue to be vital for separating and quantifying components in complex mixtures, particularly for impurity analysis and precise product quality control. Innovations in GC involve miniaturization, faster analysis times, and enhanced detector technologies, making them more suitable for on-line applications. Process LC is also advancing, offering robust solutions for analyzing non-volatile compounds and complex liquid streams in industries such as pharmaceuticals and specialty chemicals. Beyond these, electrochemical sensors for pH, conductivity, and dissolved oxygen, as well as flame ionization detectors (FIDs) and thermal conductivity detectors (TCDs), are continually being refined for improved stability, reduced drift, and longer operational lifetimes in harsh industrial environments, ensuring consistent and reliable performance.

A major technological trend shaping the market is the integration of advanced digital technologies, including the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and cloud computing. IIoT enables process analyzers to be networked and remotely monitored, facilitating centralized data collection and analysis. AI and machine learning algorithms are being embedded into analyzer software to enhance data interpretation, provide predictive maintenance insights, reduce false alarms, and even enable autonomous calibration and control. This shift towards smart, connected, and self-optimizing analytical systems is transforming process analysis from simple measurement into intelligent process management. Furthermore, advancements in micro-electromechanical systems (MEMS) are leading to smaller, more rugged, and cost-effective sensor solutions, expanding the deployment possibilities of process analyzers into remote or space-constrained applications, thereby broadening their market appeal and utility.

Regional Highlights

The global Process Analyzer Market demonstrates significant regional disparities in adoption and growth, influenced by industrial development, regulatory frameworks, technological maturity, and investment patterns. Each region presents unique market dynamics and opportunities for manufacturers and service providers. Understanding these regional nuances is essential for market players to formulate effective strategies, allocate resources judiciously, and capitalize on emerging trends. The mature markets of North America and Europe, for instance, are characterized by high technological adoption and stringent environmental regulations, driving demand for advanced and compliance-focused solutions. Conversely, the Asia Pacific region is rapidly industrializing, fostering a burgeoning demand for process analyzers across a wide range of expanding manufacturing sectors.

- North America: This region holds a significant market share due to the early adoption of advanced process analytical technologies, a strong emphasis on industrial automation, and stringent environmental and safety regulations, particularly in the oil and gas, chemical, and pharmaceutical sectors. The U.S. and Canada lead in innovation and investment in high-end analytical solutions.

- Europe: Europe is another mature market, characterized by robust manufacturing bases, strong regulatory push for environmental monitoring and process optimization, and a high degree of industrial digitalization. Countries like Germany, the UK, and France are major contributors, with a focus on sustainable production and energy efficiency.

- Asia Pacific (APAC): Expected to be the fastest-growing region, driven by rapid industrialization, increasing foreign direct investment in manufacturing infrastructure, and growing awareness of process optimization in countries like China, India, Japan, and South Korea. The expansion of chemical, petrochemical, and power generation industries fuels demand.

- Latin America: This region is experiencing steady growth, primarily fueled by investments in the oil and gas industry, mining, and water and wastewater treatment projects. Countries such as Brazil and Mexico are key markets, focusing on improving operational efficiency and meeting environmental standards.

- Middle East and Africa (MEA): Growth in MEA is largely concentrated in the oil and gas sector, where extensive investments in refining and petrochemical capabilities necessitate advanced process analytical instrumentation for safety, quality control, and maximizing yield. Industrial diversification efforts also contribute to demand in other sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Process Analyzer Market.- ABB Ltd.

- Siemens AG

- Emerson Electric Co.

- Yokogawa Electric Corporation

- Honeywell International Inc.

- Endress+Hauser Group Services AG

- AMETEK Inc.

- Thermo Fisher Scientific Inc.

- Agilent Technologies Inc.

- Spectris PLC (through Malvern Panalytical)

- Applied Analytic

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Standard Process Analyzer Market Statistics 2025 Analysis By Application (Oil and Gas, Chemical, Power Generation and Transmission, Pharmaceutical, Mining, Food and Beverages), By Type (Portable Process Analyzer, Stationary Process Analyzer), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- NIR Process Analyzer Market Statistics 2025 Analysis By Application (Pharmaceutical, Food and Feed, Chemical), By Type (Miniature Spectrometer, Benchtop Spectrometer), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager