Production Logistics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430426 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Production Logistics Market Size

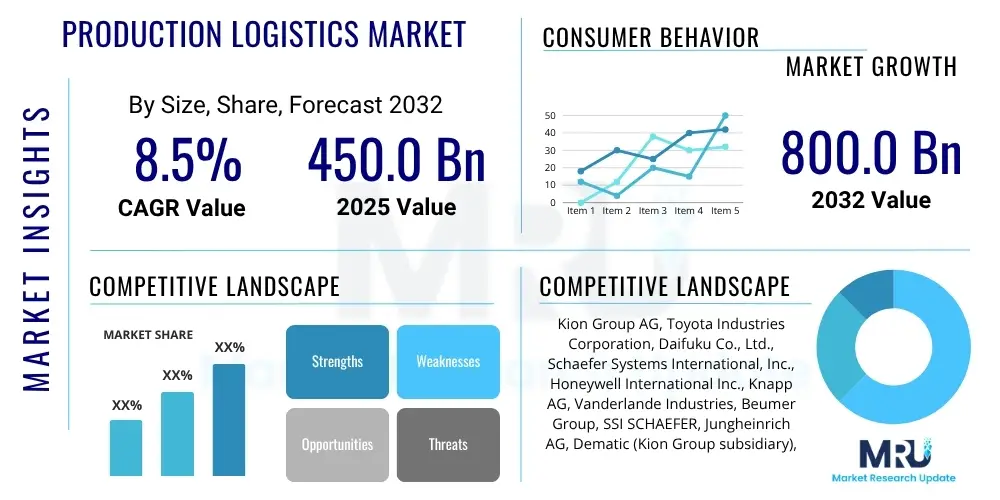

The Production Logistics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at $450.0 billion in 2025 and is projected to reach $800.0 billion by the end of the forecast period in 2032.

Production Logistics Market introduction

Production logistics encompasses the strategic planning, implementation, and control of the flow of raw materials, semi-finished goods, and information within a manufacturing process or facility. It aims to optimize the internal supply chain, ensuring that materials are available at the right place, at the right time, and in the right quantity to support efficient production. This involves managing internal transport, warehousing, material handling, and information systems to minimize bottlenecks, reduce waste, and enhance operational efficiency from the point of raw material intake through to the completion of finished products ready for outbound distribution. The ultimate goal is to achieve seamless integration between various production stages, fostering a lean and agile manufacturing environment that can respond effectively to market demands and production schedules.

The product offerings within the production logistics market are diverse, including advanced material handling equipment such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), sophisticated Warehouse Management Systems (WMS), and real-time tracking solutions. These technologies facilitate major applications across numerous industrial sectors, including the automotive industry for just-in-time component delivery, electronics manufacturing for precise assembly line feeding, and pharmaceuticals for stringent inventory control. The primary benefits derived from robust production logistics include significant reductions in operational costs, improved inventory accuracy, enhanced production throughput, and greater flexibility in manufacturing processes. Furthermore, it contributes to a safer working environment by automating repetitive tasks and reducing manual handling errors.

Several driving factors are propelling the growth of this market. The global push towards Industry 4.0 and smart manufacturing initiatives necessitates integrated and data-driven logistics solutions. Increasing labor costs and a growing scarcity of skilled manual labor are compelling manufacturers to invest in automation and robotics for internal logistics. The exponential growth of e-commerce has heightened consumer expectations for faster delivery, which in turn demands more efficient and responsive production processes. Additionally, the inherent complexities of modern supply chains, characterized by global sourcing and intricate product customization, underscore the critical need for sophisticated production logistics to maintain competitive advantage and operational resilience.

Production Logistics Market Executive Summary

The Production Logistics Market is experiencing robust growth, driven by an accelerating adoption of advanced automation and digital solutions within manufacturing sectors worldwide. Key business trends indicate a significant shift towards integrated systems that combine artificial intelligence, IoT, and robotics to create highly efficient, flexible, and responsive internal supply chains. Companies are increasingly investing in smart factories, digital twins, and predictive analytics to optimize material flow, reduce operational costs, and enhance production agility. This digital transformation is not only improving efficiency but also enabling greater visibility and control over complex manufacturing processes, fostering a more resilient and adaptable production ecosystem in the face of market volatilities.

Regional trends reveal Asia Pacific as the leading and fastest-growing market, propelled by rapid industrialization, expansion of manufacturing bases, and government initiatives supporting technological advancements in countries like China, India, and Japan. North America and Europe are mature markets, characterized by high adoption rates of advanced logistics technologies, driven by labor cost pressures and a strong emphasis on Industry 4.0 paradigms. These regions are focused on refining existing systems, enhancing sustainability, and integrating cutting-edge AI and machine learning capabilities to further optimize their production logistics infrastructure. Latin America, the Middle East, and Africa are emerging markets, showing increasing investment in modernizing their industrial capacities and adopting automated solutions to improve global competitiveness.

Segment trends highlight substantial growth across both hardware and software components. The automation segment, particularly involving AGVs, AMRs, and robotic handling systems, is witnessing rapid expansion due to its direct impact on labor efficiency and safety. Simultaneously, the software segment, including Warehouse Management Systems (WMS) and Manufacturing Execution Systems (MES), is growing as manufacturers seek comprehensive control and real-time visibility over their operations. Furthermore, the services segment, encompassing consulting, system integration, and maintenance, is crucial for successful deployment and sustained optimization of complex production logistics solutions. The automotive, electronics, and food and beverage industries remain key application areas, consistently demonstrating high demand for sophisticated and tailored production logistics capabilities to meet stringent quality, cost, and delivery requirements.

AI Impact Analysis on Production Logistics Market

User inquiries concerning AI's influence on the Production Logistics Market predominantly center on its capacity for optimization, predictive capabilities, and integration challenges. Users seek to understand how AI can reduce costs, improve efficiency, and enhance decision-making in real-time, while also expressing concerns about data security, initial investment, and the potential for workforce displacement. Key themes include the implementation of predictive maintenance for logistics equipment, demand forecasting for raw materials, and dynamic route optimization for internal transport. Expectations are high for AI to deliver significant operational benefits, enabling a more autonomous and adaptive manufacturing environment, though there is a clear demand for clear pathways to ROI and strategies for effective integration with legacy systems. The potential for AI to bridge the gap between fragmented data sources and provide actionable insights is a recurring point of interest.

- Enhanced Demand Forecasting: AI algorithms analyze historical data, market trends, and external factors to predict material and product demands with greater accuracy, optimizing inventory levels and production schedules.

- Optimized Internal Transport: AI-powered route optimization for AGVs and AMRs minimizes travel times, reduces congestion, and improves the flow of materials within the factory floor.

- Predictive Maintenance: AI monitors the performance of logistics equipment and machinery, predicting potential failures before they occur, thus reducing downtime and maintenance costs.

- Real-time Decision Making: AI systems process vast amounts of data from sensors and operational systems, providing real-time insights for dynamic adjustments to production and logistics processes.

- Automated Quality Control: AI-driven vision systems can identify defects in materials or products during production, ensuring higher quality output and reducing waste.

- Inventory Optimization: AI models recommend optimal stock levels, storage locations, and replenishment strategies, minimizing holding costs and preventing stockouts.

- Energy Efficiency: AI analyzes energy consumption patterns of logistics operations and suggests optimizations to reduce power usage for equipment and facilities.

DRO & Impact Forces Of Production Logistics Market

The Production Logistics Market is significantly shaped by a confluence of influential factors, encompassing robust drivers that fuel its expansion, persistent restraints that temper growth, and compelling opportunities that promise future avenues for development. The primary drivers include the global imperative for operational efficiency, spurred by escalating competition and the widespread adoption of Industry 4.0 principles, which advocate for smart, connected, and automated manufacturing environments. This digital transformation often translates into significant investments in advanced material handling systems and sophisticated software. However, growth is concurrently restrained by factors such as the substantial upfront capital investment required for implementing these advanced solutions, the inherent complexities associated with integrating new technologies into existing legacy systems, and a prevalent shortage of skilled personnel capable of managing and maintaining these sophisticated logistics infrastructures. Moreover, the increasing sophistication of cyber threats poses a significant risk to interconnected operational technologies, requiring robust cybersecurity measures.

Despite these challenges, numerous opportunities are emerging that are poised to accelerate market expansion. The increasing demand for customized products and shorter product lifecycles necessitates highly agile and flexible production logistics systems capable of rapidly adapting to changing manufacturing requirements. Furthermore, the growing focus on environmental sustainability is driving innovation in green logistics solutions, promoting energy-efficient equipment and optimized transport routes to reduce carbon footprints. The proliferation of IoT devices and advancements in artificial intelligence and machine learning are creating new possibilities for predictive logistics, enabling real-time optimization, and fostering more resilient supply chains. This technological evolution provides fertile ground for companies to differentiate themselves and capture new market shares by offering cutting-edge, data-driven solutions that address evolving customer needs and operational complexities.

The market is also subject to various external impact forces that can profoundly influence its trajectory. Technological advancements, particularly in robotics, automation, and data analytics, are continuously reshaping the landscape, introducing new capabilities and efficiency benchmarks. Economic shifts, including global recessions or periods of rapid industrial growth, directly affect investment capacities and manufacturing output, thereby influencing demand for production logistics solutions. Geopolitical factors, such as trade policies, regional conflicts, and regulatory changes pertaining to manufacturing standards or environmental compliance, can introduce volatility and compel companies to re-evaluate their production logistics strategies. Lastly, shifts in consumer behavior, such as the increasing preference for personalized products and expedited delivery, place immense pressure on manufacturers to adopt more responsive and efficient production logistics systems to remain competitive in a dynamic global marketplace.

- Drivers:

- Growing adoption of Industry 4.0 and smart manufacturing initiatives.

- Increasing demand for operational efficiency and cost reduction in manufacturing.

- Rising labor costs and shortage of skilled workforce pushing automation adoption.

- Expansion of e-commerce driving need for faster and more agile production.

- Increasing complexity of global supply chains and demand for visibility.

- Restraints:

- High initial investment costs for advanced automation and software solutions.

- Challenges in integrating new technologies with existing legacy systems.

- Lack of standardized protocols and interoperability between different systems.

- Cybersecurity risks associated with interconnected industrial systems.

- Shortage of skilled personnel to manage and maintain advanced logistics technologies.

- Opportunities:

- Emerging economies investing in industrial infrastructure and modernization.

- Growing demand for customized products requiring flexible production logistics.

- Advancements in sustainable logistics solutions and green manufacturing practices.

- Integration of Artificial Intelligence (AI) and Internet of Things (IoT) for predictive logistics.

- Development of digital twin technology for virtual optimization and simulation.

- Impact Forces:

- Technological advancements in robotics, automation, and data analytics.

- Economic shifts influencing manufacturing output and investment capacities.

- Geopolitical factors affecting trade routes and supply chain stability.

- Regulatory changes related to industrial safety, environmental standards, and data privacy.

- Shifting consumer expectations for product customization and rapid fulfillment.

Segmentation Analysis

The Production Logistics Market is comprehensively segmented to provide a detailed understanding of its diverse components, applications, industry verticals, and technological adoptions. This segmentation allows for precise market analysis, identifying key growth areas and niche opportunities across the global landscape. By categorizing the market based on these critical dimensions, stakeholders can gain insights into specific product demands, technological preferences, and industry-specific challenges, enabling targeted strategic planning and investment. The delineation into hardware, software, and services components reflects the integrated nature of modern logistics solutions, while application and industry vertical segments highlight the wide-ranging utility and tailored requirements across different manufacturing environments.

- By Component:

- Hardware:

- Material Handling Equipment (Conveyors, Cranes, Forklifts)

- Robotics (Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), Robotic Arms)

- Sensors

- Barcode Scanners and RFID Systems

- Software:

- Warehouse Management Systems (WMS)

- Transportation Management Systems (TMS)

- Inventory Management Software

- Production Planning Software

- Analytics and Reporting Tools

- Manufacturing Execution Systems (MES)

- Services:

- Consulting

- System Integration

- Maintenance and Support

- Managed Logistics Services

- Hardware:

- By Application:

- Inbound Logistics (Raw material receipt, storage, and internal delivery)

- In-production Logistics (Material flow on assembly lines, work-in-progress handling)

- Outbound Logistics (Finished goods handling, packaging, and dispatch to distribution)

- By Industry Vertical:

- Automotive

- Electronics

- Pharmaceuticals & Healthcare

- Food & Beverage

- Retail & E-commerce

- Heavy Industry

- Aerospace & Defense

- Chemicals

- By Technology:

- Automation (Robotics, AGVs, AMRs, Automated Storage and Retrieval Systems (AS/RS))

- Internet of Things (IoT)

- Artificial Intelligence (AI) & Machine Learning (ML)

- Cloud Computing

- Blockchain

- Big Data Analytics

- Digital Twin

Value Chain Analysis For Production Logistics Market

The value chain for the Production Logistics Market is intricate, involving a series of sequential activities that transform raw inputs into finished products, ultimately delivering value to the end-user. The upstream segment of this value chain is dominated by suppliers of essential components and raw materials crucial for the manufacturing of logistics equipment and the development of software solutions. This includes producers of robotics components, sensor technologies, automation hardware, and specialized software development kits. These upstream partners play a vital role in determining the quality, innovation, and cost-effectiveness of the core technologies that underpin modern production logistics. Relationships with these suppliers are often long-term and strategic, focusing on collaborative innovation and secure supply lines to ensure the continuous advancement and availability of logistics solutions.

Moving downstream, the value chain encompasses the integrators, solution providers, and end-users who deploy and leverage production logistics systems. Integrators are crucial as they tailor generic logistics components and software into bespoke solutions that meet the specific operational requirements of individual manufacturing facilities. These solutions are then adopted by a wide array of manufacturing enterprises across various industries, from automotive to pharmaceuticals, where they facilitate efficient material flow, inventory management, and overall production optimization. The downstream segment is characterized by strong customer relationships, ongoing support, and continuous adaptation of solutions to meet evolving production challenges. Value is generated through enhanced operational efficiency, reduced costs, and improved responsiveness for the end-user, directly impacting their competitive position in the market.

The distribution channel for production logistics solutions is multifaceted, employing both direct and indirect approaches. Direct sales channels typically involve specialized logistics solution providers or original equipment manufacturers (OEMs) who engage directly with large enterprise clients, often providing highly customized systems and extensive post-sales support. This approach allows for direct negotiation, deeper understanding of client needs, and a more integrated implementation process. Indirect channels, conversely, involve a network of value-added resellers (VARs), system integrators, and third-party logistics (3PL) providers who offer bundled solutions and services to a broader range of customers, including small and medium-sized enterprises (SMEs). These indirect partners often provide regional expertise, localized support, and specialized integration capabilities, extending market reach and facilitating broader adoption of production logistics technologies. The choice of channel often depends on the complexity of the solution, the target market segment, and the level of customization required by the end-user.

- Upstream Analysis:

- Raw Material Suppliers: Providers of metals, plastics, electronic components for hardware manufacturing.

- Component Manufacturers: Suppliers of motors, sensors, vision systems, control units, software modules for logistics equipment.

- Technology Developers: Companies specializing in AI, IoT platforms, cloud infrastructure, and analytics engines.

- Downstream Analysis:

- Manufacturing Companies: Automotive, electronics, food & beverage, pharmaceuticals, heavy industries.

- System Integrators: Firms that customize and implement logistics solutions for end-users.

- Consulting Firms: Advisors on logistics strategy, process optimization, and technology adoption.

- Distribution Channel:

- Direct Sales: OEMs and solution providers selling directly to large enterprises.

- Value-Added Resellers (VARs): Companies offering bundled solutions with added services.

- System Integrators: Specialized firms installing and configuring complex logistics systems.

- Third-Party Logistics (3PL) Providers: Companies managing logistics operations for other businesses.

Production Logistics Market Potential Customers

The primary beneficiaries and key potential customers of advanced production logistics solutions are diverse manufacturing enterprises operating across a wide spectrum of industrial verticals. These organizations are typically characterized by their need to manage complex internal material flows, optimize inventory levels, and enhance the efficiency and responsiveness of their production lines. From large-scale automotive assembly plants requiring precise just-in-time component delivery to pharmaceutical manufacturers necessitating stringent tracking and temperature-controlled handling, the demand for sophisticated production logistics is universal among entities striving for operational excellence. These customers are driven by a continuous need to reduce operational costs, minimize waste, shorten lead times, and improve the overall quality of their manufactured goods, making them ideal candidates for investing in these transformative solutions.

Beyond traditional manufacturing, the expansion of e-commerce and the increasing consumer demand for highly customized products have broadened the customer base to include companies engaged in high-mix, low-volume production or those with rapidly fluctuating demand patterns. These businesses require exceptionally agile and flexible production logistics systems that can quickly reconfigure to accommodate new product variants or sudden shifts in production volumes without incurring significant downtime or cost overruns. The ability to integrate seamlessly with order fulfillment and last-mile delivery systems is also a critical consideration for these customers, highlighting a demand for end-to-end supply chain visibility. Therefore, businesses prioritizing adaptability, scalability, and integration with broader supply chain operations represent a significant and growing segment of potential customers for advanced production logistics solutions.

Furthermore, organizations focused on sustainability and workplace safety are increasingly becoming potential customers for modern production logistics. Automated material handling systems, for instance, not only improve efficiency but also reduce the risk of workplace injuries associated with manual labor. Similarly, optimized internal transport routes and energy-efficient equipment contribute to a reduced carbon footprint, aligning with corporate sustainability goals. Companies seeking to achieve certifications for environmental management or improve their social responsibility profile find value in logistics solutions that support these objectives. This segment includes industries with strict regulatory compliance requirements, such as food and beverage or healthcare, where robust tracking, traceability, and safety protocols are paramount. The long-term benefits in terms of compliance, reputation, and employee well-being make these businesses prime candidates for investment in comprehensive production logistics strategies.

- Automotive Manufacturers: Seeking just-in-time delivery, assembly line optimization, and complex component handling.

- Electronics Manufacturers: Requiring precision handling of delicate components, high-volume production efficiency, and swift product changeovers.

- Pharmaceutical and Healthcare Companies: Demanding stringent temperature control, batch tracking, regulatory compliance, and secure inventory management.

- Food & Beverage Processors: Needing hygienic handling, rapid throughput, shelf-life management, and efficient distribution.

- Heavy Industry (e.g., Construction, Machinery): Managing large, bulky, and heavy components, requiring robust material handling and complex assembly logistics.

- Retail and E-commerce Fulfillment Centers: Aiming for high throughput, efficient inventory management, and quick order fulfillment for diverse product ranges.

- Aerospace & Defense Sector: Ensuring precise component traceability, long-term storage, and specialized handling for high-value parts.

- Small and Medium-sized Enterprises (SMEs) in Manufacturing: Increasingly adopting modular and scalable solutions to enhance competitiveness.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $450.0 billion |

| Market Forecast in 2032 | $800.0 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kion Group AG, Toyota Industries Corporation, Daifuku Co., Ltd., Schaefer Systems International, Inc., Honeywell International Inc., Knapp AG, Vanderlande Industries, Beumer Group, SSI SCHAEFER, Jungheinrich AG, Dematic (Kion Group subsidiary), Murata Machinery, Ltd., Hyster-Yale Materials Handling, Inc., Mitsubishi Logisnext Co., Ltd., Fortna, Inc., Swisslog (KUKA Group subsidiary), TGW Logistics Group, Zebra Technologies Corporation, SAP SE, Oracle Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Production Logistics Market Key Technology Landscape

The Production Logistics Market is undergoing a profound transformation, heavily influenced by a rapidly evolving technological landscape. At its core, the adoption of advanced automation plays a pivotal role, manifested through the widespread deployment of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). These intelligent mobile platforms are revolutionizing internal transport, efficiently moving materials between workstations, warehouses, and assembly lines with minimal human intervention. Complementing these are robotic arms for picking, packing, and sorting, as well as sophisticated Automated Storage and Retrieval Systems (AS/RS) that maximize storage density and retrieval speed. These automation technologies are foundational to creating lean and agile manufacturing environments, significantly reducing manual labor requirements and enhancing operational throughput.

Beyond physical automation, the integration of digital technologies is critical for optimizing production logistics. The Internet of Things (IoT) forms the backbone of real-time data collection, with sensors embedded in equipment, materials, and infrastructure providing continuous insights into operational status, inventory levels, and environmental conditions. This vast stream of data is then processed and analyzed using Artificial Intelligence (AI) and Machine Learning (ML) algorithms. AI-driven predictive analytics enable accurate demand forecasting, proactive maintenance scheduling for logistics equipment, and dynamic route optimization for internal material flows. Furthermore, Machine Learning capabilities allow systems to learn from operational data, continuously improving their efficiency and adaptability over time, leading to more intelligent and self-optimizing logistics processes.

The proliferation of cloud computing platforms provides the scalable infrastructure necessary to host and manage the massive amounts of data generated by these connected systems, enabling remote access, collaborative planning, and seamless integration across disparate organizational units. Digital Twin technology is also gaining traction, creating virtual replicas of physical production logistics systems to simulate, test, and optimize processes before real-world implementation, thereby reducing risks and accelerating deployment. Emerging technologies like Blockchain are being explored for enhanced transparency and traceability within the supply chain, particularly for high-value goods or those requiring stringent regulatory compliance. This comprehensive technological suite is collectively enabling manufacturers to achieve unprecedented levels of efficiency, responsiveness, and resilience in their production logistics operations, paving the way for the fully interconnected and intelligent factories of the future.

- Automation & Robotics:

- Automated Guided Vehicles (AGVs)

- Autonomous Mobile Robots (AMRs)

- Robotic Arms for material handling, picking, and packing

- Automated Storage and Retrieval Systems (AS/RS)

- Internet of Things (IoT):

- Sensor networks for real-time tracking of inventory and assets

- Smart devices for environmental monitoring (temperature, humidity)

- Connected equipment for performance monitoring and predictive maintenance

- Artificial Intelligence (AI) & Machine Learning (ML):

- Predictive analytics for demand forecasting and equipment maintenance

- Optimized route planning and scheduling for internal transport

- AI-driven vision systems for quality control and inventory verification

- Reinforcement learning for autonomous decision-making in complex logistics scenarios

- Warehouse Management Systems (WMS) & Manufacturing Execution Systems (MES):

- Advanced software for managing inventory, labor, and order fulfillment within production facilities

- Integration with ERP systems for holistic operational oversight

- Cloud Computing:

- Scalable infrastructure for data storage and processing

- Facilitates remote access, collaboration, and integration of diverse logistics applications

- Digital Twin:

- Virtual models of physical logistics systems for simulation, optimization, and predictive analysis

- Big Data Analytics:

- Processing and interpreting large datasets to identify patterns, inefficiencies, and opportunities for improvement.

- Blockchain:

- For enhanced transparency, traceability, and security of supply chain transactions and material provenance.

Regional Highlights

- North America: This region stands as a significant market for production logistics, characterized by early adoption of advanced technologies and a strong focus on innovation. The presence of major manufacturing hubs, coupled with increasing labor costs, drives investment in automation, AI, and IoT solutions to enhance efficiency and competitiveness. The United States, in particular, leads in research and development and hosts numerous technology providers, contributing to the rapid evolution of production logistics solutions.

- Europe: European countries are at the forefront of Industry 4.0 initiatives and smart factory concepts, significantly impacting the production logistics market. There is a strong emphasis on sustainability, energy efficiency, and regulatory compliance, leading to the adoption of sophisticated, environmentally friendly logistics solutions. Germany, with its robust automotive and machinery sectors, and the Nordic countries, known for technological innovation, are key contributors to market growth and advancements in the region.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market for production logistics, fueled by rapid industrialization, expanding manufacturing capabilities, and significant foreign direct investment. Countries like China, India, and Southeast Asian nations are emerging as global manufacturing powerhouses, driving demand for efficient internal logistics to support high-volume production. Government support for manufacturing modernization and the increasing adoption of robotics further propel market expansion in this dynamic region.

- Latin America: This region is experiencing a growing demand for production logistics solutions as its manufacturing sectors, particularly automotive and electronics, expand and seek to improve operational efficiency. Investments in infrastructure development and the increasing awareness of advanced logistics benefits are contributing to market growth. Brazil and Mexico are leading the adoption of automation and modern logistics practices to enhance their global competitiveness and streamline production processes.

- Middle East and Africa (MEA): The MEA region represents an emerging market with significant growth potential, driven by economic diversification efforts, industrialization initiatives, and large-scale infrastructure projects. As countries in the GCC and parts of Africa invest in establishing new manufacturing capabilities, the demand for efficient production logistics to support these operations is steadily increasing. The focus is on adopting robust and scalable solutions to build resilient and modern industrial ecosystems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Production Logistics Market.- Kion Group AG

- Toyota Industries Corporation

- Daifuku Co., Ltd.

- Schaefer Systems International, Inc.

- Honeywell International Inc.

- Knapp AG

- Vanderlande Industries

- Beumer Group

- SSI SCHAEFER

- Jungheinrich AG

- Dematic (Kion Group subsidiary)

- Murata Machinery, Ltd.

- Hyster-Yale Materials Handling, Inc.

- Mitsubishi Logisnext Co., Ltd.

- Fortna, Inc.

- Swisslog (KUKA Group subsidiary)

- TGW Logistics Group

- Zebra Technologies Corporation

- SAP SE

- Oracle Corporation

Frequently Asked Questions

What is production logistics and why is it important?

Production logistics refers to the management of material and information flow within a manufacturing facility, from raw material intake to finished goods ready for shipment. It is crucial for optimizing production efficiency, reducing operational costs, ensuring timely material availability, and enhancing overall supply chain resilience in a competitive manufacturing landscape.

How does automation contribute to production logistics efficiency?

Automation, through technologies like AGVs, AMRs, and robotic systems, significantly boosts efficiency by streamlining material handling, reducing manual labor, minimizing errors, and accelerating throughput on the factory floor. It ensures precise and consistent movement of goods, leading to optimized production schedules and improved workplace safety.

What are the primary challenges faced in implementing production logistics solutions?

Key challenges include high initial investment costs for advanced technologies, complexities in integrating new systems with existing legacy infrastructure, a shortage of skilled personnel for management and maintenance, and ensuring robust cybersecurity for interconnected operational technologies. Overcoming these requires strategic planning and phased implementation.

What role does AI play in optimizing production logistics processes?

AI optimizes production logistics by enabling predictive maintenance for equipment, enhancing demand forecasting accuracy, and facilitating dynamic route optimization for internal transport. It processes real-time data to make intelligent decisions, leading to improved resource utilization, reduced downtime, and greater responsiveness to production demands.

Which industry verticals are leading the adoption of advanced production logistics?

The automotive, electronics, pharmaceuticals, and food & beverage industries are leading the adoption of advanced production logistics. These sectors inherently require high levels of precision, speed, efficiency, and traceability in their manufacturing processes, making sophisticated logistics solutions essential for maintaining competitive advantage and meeting stringent regulatory standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager