Push Pull Tools Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427717 | Date : Oct, 2025 | Pages : 244 | Region : Global | Publisher : MRU

Push Pull Tools Market Size

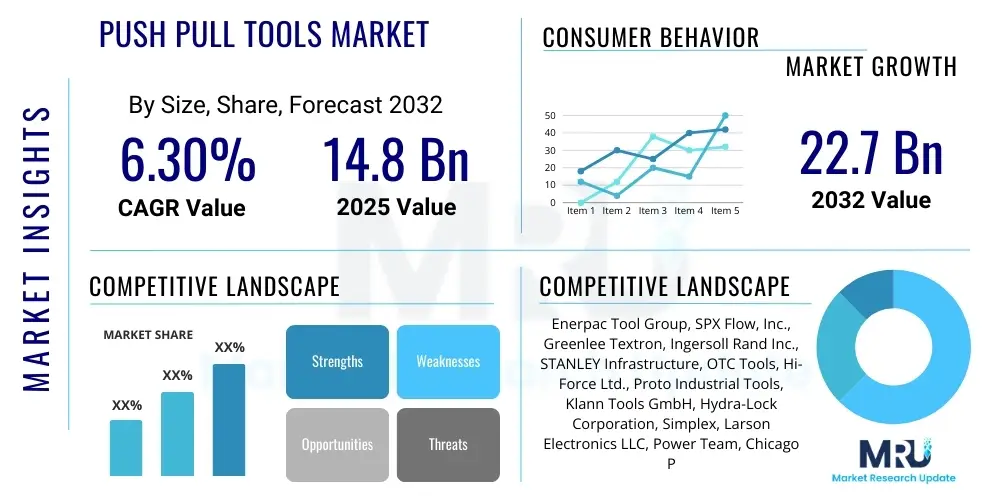

The Push Pull Tools Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.3% between 2025 and 2032. The market is estimated at USD 14.8 billion in 2025 and is projected to reach USD 22.7 billion by the end of the forecast period in 2032.

Push Pull Tools Market introduction

The Push Pull Tools market encompasses a diverse range of mechanical, hydraulic, pneumatic, and electric devices designed to apply precise forces for pushing, pulling, pressing, spreading, or lifting operations across various industrial applications. These tools are indispensable in tasks requiring controlled movement, assembly, disassembly, or positioning of components, ranging from delicate electronic parts to heavy machinery. Their fundamental utility lies in enabling efficient, safe, and accurate manipulation of objects, significantly reducing manual effort and minimizing the risk of damage or injury. The markets growth is inherently linked to global industrial output, infrastructure development, and the increasing complexity of manufacturing processes that demand higher precision and automation.

Major applications of push pull tools span across critical sectors such as automotive manufacturing, aerospace, heavy machinery, construction, energy, and maintenance, repair, and overhaul (MRO) operations. In automotive assembly, for instance, these tools are vital for engine installation, bearing removal, and chassis alignment, ensuring tight tolerances and structural integrity. Similarly, in the aerospace industry, they are crucial for assembling large airframe components, landing gear systems, and intricate engine parts where absolute precision is paramount. The adaptability and specialized nature of these tools allow for their deployment in environments ranging from cleanrooms to harsh outdoor construction sites, emphasizing their versatile design and robust engineering.

The primary benefits offered by push pull tools include enhanced operational safety, significant improvements in efficiency, superior accuracy, and ergonomic advantages for operators. By mechanically assisting or automating strenuous tasks, they mitigate the physical strain on workers, thereby reducing fatigue and the incidence of workplace injuries. This directly translates to improved productivity and reduced labor costs. Furthermore, the consistent and controlled force application ensures product quality, minimizes material waste, and extends equipment lifespan, making them a cost-effective solution in the long run. Driving factors for this market include the global push for industrial automation, stringent safety regulations, the rising demand for precision manufacturing, and substantial investments in infrastructure development, all of which necessitate advanced and reliable tooling solutions.

Push Pull Tools Market Executive Summary

The Push Pull Tools Market is experiencing robust growth driven by accelerating industrial automation, particularly in manufacturing and automotive sectors, alongside significant global infrastructure expansion. Business trends indicate a strong emphasis on smart tools integrated with IoT, offering real-time data and predictive maintenance capabilities, as well as a growing demand for customized solutions to meet specialized application requirements. Manufacturers are focusing on ergonomic designs, lightweight materials, and enhanced portability to improve user experience and operational efficiency. Sustainability is also emerging as a key factor, with a shift towards energy-efficient systems and recyclable materials in tool production, reflecting a broader industry commitment to environmental responsibility and operational longevity. The competitive landscape is characterized by innovation in hydraulic and pneumatic systems, alongside the increasing adoption of electric and battery-powered alternatives for greater flexibility and reduced environmental impact. Strategic partnerships and mergers are also prevalent as companies seek to expand their product portfolios and geographical reach, consolidating market presence and leveraging complementary expertise to offer comprehensive solutions.

Regionally, the Asia Pacific market is poised for the most significant expansion, fueled by rapid industrialization, burgeoning manufacturing hubs, and extensive infrastructure projects in countries like China, India, and Southeast Asian nations. This region benefits from a large labor force, expanding industrial base, and increasing adoption of advanced manufacturing techniques. North America and Europe, while mature markets, continue to demonstrate steady demand, propelled by continuous investment in advanced manufacturing, the aerospace and defense sectors, and a strong focus on worker safety and ergonomic compliance. These regions lead in the adoption of high-precision and automated push pull tools, driven by stringent quality standards and the pursuit of operational excellence. Emerging markets in Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, primarily due to rising foreign direct investment in industrial development and construction, which creates new avenues for tool adoption and market penetration.

Segmentation trends highlight a pronounced shift towards hydraulic and pneumatic push pull tools due to their high force capacity and precision, making them indispensable in heavy industrial applications. The mechanical segment retains its stronghold for cost-effectiveness and simplicity in lighter applications, while electric tools are gaining traction for their convenience, portability, and environmental benefits, especially in MRO and field service operations. By application, assembly and disassembly remain the largest segments, but specialized applications like material handling, lifting, and pressing are showing accelerated growth due to increasing complexity in industrial processes and materials. The end-user industry landscape sees the automotive, aerospace, and general manufacturing sectors as primary drivers, with construction and energy sectors exhibiting consistent demand due to ongoing project pipelines. This diversified demand across various segments underscores the markets resilience and adaptability to evolving industrial needs, necessitating continuous innovation in product design and functionality across the entire tool spectrum to maintain competitiveness and address niche requirements effectively.

AI Impact Analysis on Push Pull Tools Market

The integration of Artificial Intelligence (AI) is set to profoundly transform the Push Pull Tools market by enhancing operational efficiency, predictive capabilities, and design innovation. Users frequently inquire about how AI can make these tools smarter, more reliable, and ultimately more cost-effective. Key themes revolve around the potential for AI-driven predictive maintenance to minimize downtime, the ability of AI to optimize tool design for specific applications, and the role of AI in automating precision tasks. Concerns often include the initial investment required for AI integration, the need for skilled labor to manage advanced systems, and data security. Despite these considerations, there is a strong expectation that AI will lead to a new generation of intelligent push pull tools that offer unparalleled levels of accuracy, safety, and operational insights, fundamentally altering how these tools are conceived, manufactured, and deployed in industrial environments, ensuring optimal performance and extending their operational lifespan.

- Predictive Maintenance: AI algorithms analyze sensor data from tools to predict potential failures, enabling proactive maintenance and significantly reducing unexpected downtime and repair costs.

- Optimized Design and Manufacturing: AI-driven generative design and simulation tools can optimize tool geometries, material usage, and force distribution, leading to lighter, stronger, and more efficient designs and streamlined production processes.

- Enhanced Automation and Robotics Integration: AI facilitates seamless integration of push pull tools with robotic systems, allowing for adaptive control, precise force feedback, and autonomous task execution in complex assembly lines.

- Quality Control and Anomaly Detection: AI-powered vision systems and data analytics can monitor tool performance during operation, detecting subtle anomalies or deviations from standard, ensuring consistent output quality.

- Smart Manufacturing and Supply Chain Efficiency: AI optimizes production schedules, inventory management, and logistics for push pull tool components and finished products, leading to reduced lead times and improved supply chain resilience.

- Operator Assistance and Training: AI-driven augmented reality (AR) tools can provide real-time guidance and training for complex operations, improving operator efficiency and reducing errors, especially for intricate push-pull tasks.

DRO & Impact Forces Of Push Pull Tools Market

The Push Pull Tools market is significantly driven by the accelerating pace of industrial automation across various sectors, where precision and efficiency are paramount. The global emphasis on enhanced workplace safety standards also acts as a powerful driver, pushing industries to adopt tools that minimize manual handling risks and improve ergonomic conditions. Furthermore, the sustained growth in infrastructure development, including commercial, residential, and public works projects worldwide, continuously fuels demand for robust and reliable push pull tools for construction, installation, and maintenance activities. The increasing complexity of modern manufacturing processes, requiring high accuracy in assembly and disassembly of components, further solidifies the need for advanced and specialized push pull tools. Finally, the automotive and aerospace industries, with their stringent quality requirements and high-volume production, remain significant consumers, continually seeking innovative tooling solutions that support advanced materials and intricate designs, ensuring component integrity and operational reliability throughout the product lifecycle.

Despite the strong growth drivers, the market faces several restraints that could impede its expansion. The high initial capital investment required for advanced hydraulic, pneumatic, and electric push pull tools, especially those integrated with automation or IoT capabilities, can be a barrier for small and medium-sized enterprises (SMEs) with limited budgets. Additionally, the operation and maintenance of sophisticated push pull tools often necessitate a skilled workforce, and the shortage of adequately trained technicians can pose a significant challenge, particularly in developing regions. Economic downturns or geopolitical instabilities can lead to reduced industrial output and construction spending, thereby directly impacting the demand for these tools. Fluctuations in raw material prices, such as steel, aluminum, and specialized alloys, can also affect manufacturing costs, potentially leading to higher product prices and reduced market accessibility, thereby influencing purchasing decisions and market growth trajectories. Moreover, the long lifespan of some heavy-duty tools means replacement cycles can be extended, leading to slower incremental sales.

Opportunities within the Push Pull Tools market are abundant and diverse, pointing towards sustained innovation and expansion. Emerging markets, particularly in Asia Pacific, Latin America, and Africa, present vast untapped potential due to ongoing industrialization, urbanization, and infrastructure projects. The growing demand for customized and application-specific tools offers manufacturers a chance to differentiate their products and cater to niche industrial requirements, fostering innovation in design and functionality. The integration of smart technologies, such as IoT sensors, AI, and connectivity features, to enable predictive maintenance, real-time feedback, and remote diagnostics, represents a significant avenue for value addition and market differentiation. Furthermore, the development of lightweight, ergonomic, and battery-powered tools is opening up new possibilities for mobile maintenance and field service applications, enhancing portability and user convenience. The focus on sustainability and energy efficiency also provides opportunities for developing environmentally friendly tool solutions and manufacturing processes, aligning with global environmental objectives and consumer preferences, which could drive future market penetration and brand loyalty.

Segmentation Analysis

The Push Pull Tools market is comprehensively segmented to address the diverse needs of various industrial applications and end-user requirements. These segmentations allow for a granular understanding of market dynamics, identifying specific growth areas, technological preferences, and regional consumption patterns. Understanding these segments is crucial for manufacturers to tailor their product offerings, develop targeted marketing strategies, and allocate resources effectively. The market is typically analyzed based on various characteristics, including the type of mechanism employed, the specific application it serves, the end-user industry leveraging these tools, and even the material composition and force capacity, reflecting the broad spectrum of product sophistication and utility available to industrial consumers worldwide.

- By Type:

- Mechanical Push Pull Tools

- Hydraulic Push Pull Tools

- Pneumatic Push Pull Tools

- Electric/Battery-Powered Push Pull Tools

- Manual Push Pull Tools

- By Application:

- Assembly and Disassembly

- Bearing Removal/Installation

- Lifting and Lowering

- Pressing and Spreading

- Alignment and Positioning

- Material Handling

- By End-User Industry:

- Automotive

- Aerospace and Defense

- Manufacturing (General, Heavy, Precision)

- Construction

- Energy (Oil & Gas, Power Generation)

- Railways and Marine

- Maintenance, Repair, and Overhaul (MRO)

- By Force Capacity:

- Low Force (Up to 10 tons)

- Medium Force (10-50 tons)

- High Force (Above 50 tons)

- By Portability:

- Stationary/Fixed

- Portable/Handheld

Push Pull Tools Market Value Chain Analysis

The value chain for the Push Pull Tools market begins with upstream activities, primarily involving the sourcing of raw materials and the manufacturing of specialized components. This stage is critical as it determines the fundamental quality, durability, and performance characteristics of the final product. Key raw materials include high-strength steel alloys, aluminum, various composites, and engineering plastics, which are selected for their specific properties such as resistance to wear, corrosion, and extreme forces. Suppliers of hydraulic pumps, pneumatic cylinders, electric motors, batteries, and advanced sensor technologies also form a crucial part of the upstream segment. These component manufacturers often work closely with tool designers to ensure compatibility and optimal integration, emphasizing precision engineering and material science to meet stringent industry standards. The cost and quality of these upstream inputs significantly impact the final products pricing and competitive positioning, necessitating robust supply chain management and strategic procurement practices to ensure consistent supply and cost efficiency.

Moving downstream, the value chain encompasses the manufacturing, assembly, and quality assurance processes, followed by distribution and sales. Manufacturers invest heavily in precision machining, heat treatment, surface finishing, and assembly lines to produce a wide array of push pull tools. Rigorous testing and quality control procedures are implemented at various stages to ensure adherence to performance specifications, safety standards, and regulatory requirements. Once manufactured, the tools reach end-users through a combination of distribution channels. These include a global network of industrial distributors, wholesalers, and specialized tool retailers who cater to a broad customer base, from large industrial enterprises to individual contractors. Online sales platforms and e-commerce channels are also gaining prominence, providing wider market access and convenience for buyers, especially for standard and less complex tools. The effectiveness of this downstream segment relies on efficient logistics, strong channel partnerships, and responsive customer service to ensure timely delivery and post-sales support.

The distribution channel landscape for Push Pull Tools is typically bifurcated into direct and indirect channels, each serving distinct market needs. Direct channels involve manufacturers selling their products directly to large industrial clients, original equipment manufacturers (OEMs), or governmental agencies, often through dedicated sales teams or key account managers. This approach allows for customized solutions, direct technical support, and deeper client relationships, particularly for high-value or highly specialized tools. Indirect channels, on the other hand, leverage a network of third-party intermediaries. This includes authorized distributors who maintain inventory, provide local sales and technical support, and cater to a broader range of smaller and medium-sized enterprises. Value-added resellers (VARs) might integrate push pull tools into larger solutions or systems, offering comprehensive packages. Additionally, the proliferation of online marketplaces and e-commerce websites has opened new avenues for distribution, enabling manufacturers and distributors to reach a global customer base efficiently. The choice of distribution strategy often depends on market maturity, product complexity, target customer segments, and the desired level of market penetration and support.

Push Pull Tools Market Potential Customers

The potential customers for Push Pull Tools represent a broad spectrum of industries, primarily characterized by operations that require precise force application, assembly, disassembly, or controlled movement of components. At the forefront are the automotive and aerospace manufacturing sectors, where these tools are indispensable for critical tasks such as engine installation, chassis alignment, bearing removal, and the assembly of complex airframe structures. These industries demand tools that offer exceptional accuracy, reliability, and safety to meet stringent quality standards and high-volume production schedules. Heavy machinery manufacturers, involved in producing agricultural equipment, construction vehicles, and industrial machinery, also constitute a significant customer base, relying on push pull tools for the assembly of large, heavy components and critical maintenance tasks. The need for robust, high-force capacity tools is particularly pronounced in these segments, ensuring structural integrity and operational efficiency of the final products.

Beyond traditional manufacturing, the construction industry is a substantial end-user for push pull tools, especially for civil engineering projects, bridge construction, and commercial building developments. Here, tools are utilized for tasks like post-tensioning, structural alignment, demolition, and the installation of heavy components, contributing to the safety and efficiency of large-scale operations. The energy sector, encompassing oil and gas, power generation, and renewable energy, also represents a critical customer segment. Push pull tools are essential for the maintenance and repair of pipelines, turbines, generators, and other heavy equipment, often in challenging and remote environments where durability and reliability are paramount. Furthermore, general manufacturing industries, including those producing electronics, consumer goods, and industrial equipment, require a diverse range of push pull tools for various assembly, testing, and packaging processes, reflecting the broad utility of these instruments across the industrial landscape.

Maintenance, Repair, and Overhaul (MRO) operations across all industrial sectors form another vital customer segment. MRO activities frequently involve the removal of seized components, bearing extraction, shaft alignment, and other tasks where controlled force application is necessary to prevent damage to expensive machinery. This segment often seeks portable, versatile, and ergonomically designed tools that can be easily deployed in the field or within repair workshops. Service technicians, independent mechanics, and small-scale fabrication shops also comprise a significant part of the customer base, requiring cost-effective yet reliable push pull solutions for their everyday operations. The ongoing trend towards industrial automation and smart factory initiatives further expands the customer landscape, as automated assembly lines and robotic systems necessitate specialized push pull end-effectors and intelligent tools capable of seamless integration, real-time data feedback, and adaptive force control, thereby creating new demand for advanced, AI-compatible tooling solutions that enhance precision and efficiency in automated environments.

Push Pull Tools Market Key Technology Landscape

The technology landscape for the Push Pull Tools market is characterized by continuous innovation aimed at enhancing precision, power, safety, and user ergonomics. A fundamental aspect involves advancements in material science, with manufacturers increasingly employing high-strength steel alloys, lightweight aluminum, and advanced composite materials. These materials contribute to the development of tools that are not only more durable and resistant to wear and corrosion but also lighter and easier to handle, improving operator comfort and reducing fatigue. Precision machining techniques, such as CNC milling and additive manufacturing (3D printing), are becoming standard, enabling the creation of complex geometries and custom tool components with extremely tight tolerances. This level of precision is crucial for ensuring the reliable and accurate application of force, particularly in industries where even minor deviations can lead to significant structural or functional failures, thereby underpinning the overall quality and performance of the push pull tools.

The integration of sensor technology and IoT (Internet of Things) connectivity is rapidly transforming push pull tools into smart devices. Modern tools are increasingly equipped with embedded sensors that can measure force, torque, displacement, and temperature in real-time. This data can be wirelessly transmitted to control systems or cloud platforms, enabling operators and maintenance teams to monitor tool performance, track usage patterns, and perform predictive maintenance. This shift from reactive to proactive maintenance minimizes downtime, extends tool lifespan, and optimizes operational efficiency. Furthermore, the incorporation of artificial intelligence (AI) and machine learning (ML) algorithms allows these smart tools to analyze operational data, identify anomalies, and even suggest optimal settings for specific tasks, leading to more intelligent and adaptive force application. This technological evolution allows for greater control, accuracy, and repeatability, which are critical in high-precision manufacturing and automated assembly lines where consistency is paramount.

Ergonomic design principles are at the forefront of tool development, focusing on maximizing user comfort and minimizing the risk of musculoskeletal injuries. This includes features like anti-vibration handles, balanced weight distribution, intuitive controls, and adjustable components that cater to a wide range of operators. Advancements in hydraulic and pneumatic system design are also ongoing, leading to more compact, powerful, and efficient pumps and cylinders that deliver higher force capacities with reduced energy consumption. The development of electric and battery-powered push pull tools, featuring high-capacity lithium-ion batteries and brushless motors, addresses the need for greater portability, reduced noise, and zero emissions, making them ideal for field service, mobile applications, and environments with strict environmental regulations. These technological advancements collectively contribute to a new generation of push pull tools that are not only more powerful and precise but also safer, smarter, and more sustainable, addressing the evolving demands of modern industrial operations and enhancing overall productivity.

Regional Highlights

- North America: This region represents a mature yet robust market for Push Pull Tools, characterized by high adoption rates of advanced industrial automation and a strong emphasis on workplace safety standards. The substantial presence of the automotive, aerospace, and heavy machinery manufacturing sectors, coupled with significant ongoing investments in infrastructure development, fuels consistent demand for high-precision, reliable, and ergonomically designed push pull tools. Innovation in smart tool integration and stringent regulatory environments further drive market growth.

- Europe: Europe stands as a leading region for technological innovation in the Push Pull Tools market, driven by strict regulatory frameworks concerning worker safety and environmental protection. Countries like Germany, France, and the UK, with their advanced manufacturing capabilities and robust automotive and aerospace industries, demonstrate a high demand for high-quality, efficient, and specialized tools. There is a strong focus on ergonomic design, smart features, and sustainable solutions to meet evolving industrial requirements.

- Asia Pacific: Poised for the most significant growth, the Asia Pacific market is propelled by rapid industrialization, massive infrastructure development, and the emergence of new manufacturing hubs, particularly in China, India, Japan, and South Korea. The escalating demand for high-volume production, combined with increasing adoption of automation technologies, generates immense opportunities for push pull tool manufacturers. The region benefits from a large labor force and continuous investments in industrial capabilities.

- Latin America: This region is characterized by an emerging industrial landscape and increasing foreign direct investment in sectors such as mining, oil and gas, and construction. While relatively smaller than other markets, Latin America shows promising growth potential for Push Pull Tools as industrial processes modernize and local manufacturing capabilities expand. Demand is driven by new infrastructure projects and the need for efficient maintenance solutions across various industries.

- Middle East & Africa: The market in the Middle East & Africa is experiencing growth primarily due to substantial investments in infrastructure, particularly in the construction and energy sectors. Large-scale projects in oil & gas, urban development, and transportation drive the demand for heavy-duty and robust push pull tools. While still developing, increasing industrialization efforts and economic diversification initiatives across several countries are creating new opportunities for market penetration and expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Push Pull Tools Market.- Enerpac Tool Group

- SPX Flow, Inc. (OTC: SPXC)

- Greenlee Textron (a Textron Inc. Company)

- Ingersoll Rand Inc. (NYSE: IR)

- STANLEY Infrastructure (a Stanley Black & Decker, Inc. company)

- OTC Tools (a Bosch subsidiary)

- Hi-Force Ltd.

- Proto Industrial Tools (a Stanley Black & Decker, Inc. brand)

- Klann Tools GmbH

- Hydra-Lock Corporation

- Simplex (a Transor LLC company)

- Larson Electronics LLC

- Power Team (an SPX Flow brand)

- Chicago Pneumatic (a part of Atlas Copco Group)

- Donaldson Company, Inc. (NYSE: DCI)

Frequently Asked Questions

What are the primary applications of Push Pull Tools in industrial settings?

Push Pull Tools are primarily utilized across diverse industrial settings for critical tasks requiring controlled force application, including precision assembly and disassembly, bearing installation and removal, structural alignment, lifting, pressing, spreading, and general maintenance, repair, and overhaul (MRO) operations. These tools are indispensable in automotive, aerospace, heavy machinery manufacturing, construction, and energy sectors to enhance efficiency and safety.

How is technology influencing the Push Pull Tools market?

Technology is profoundly influencing the Push Pull Tools market through the integration of smart features, IoT connectivity, and advanced material science. This includes embedded sensors for real-time data feedback, AI-driven predictive maintenance, ergonomic designs for enhanced user comfort, and the development of lightweight, durable materials. Electrification with high-capacity batteries also improves portability and environmental performance.

What are the key factors driving the growth of the Push Pull Tools Market?

Key factors driving the markets growth include the escalating global trend towards industrial automation and robotics, which demands precise and integrated tooling solutions. Additionally, stringent workplace safety regulations, significant investments in infrastructure development, and the increasing complexity of manufacturing processes requiring high-accuracy force application are crucial drivers for market expansion.

Which regions are exhibiting the most significant growth in the Push Pull Tools market?

The Asia Pacific region is currently exhibiting the most significant growth in the Push Pull Tools market. This surge is attributed to rapid industrialization, burgeoning manufacturing sectors, extensive infrastructure development projects, and increasing adoption of advanced manufacturing technologies across countries like China, India, and Southeast Asian nations.

What are the main challenges faced by the Push Pull Tools market?

The main challenges faced by the Push Pull Tools market include the high initial capital investment required for advanced and smart tools, which can be a barrier for smaller enterprises. Other challenges include the need for a skilled workforce to operate sophisticated equipment, potential fluctuations in raw material prices, and the impact of economic downturns or geopolitical instabilities on industrial output and construction spending.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager