Radiation Hardened Electronics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428044 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Radiation Hardened Electronics Market Size

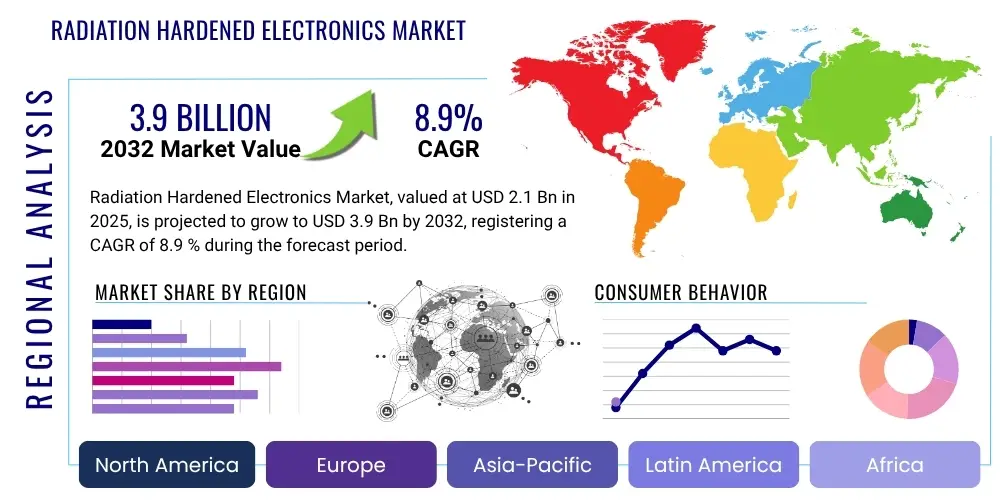

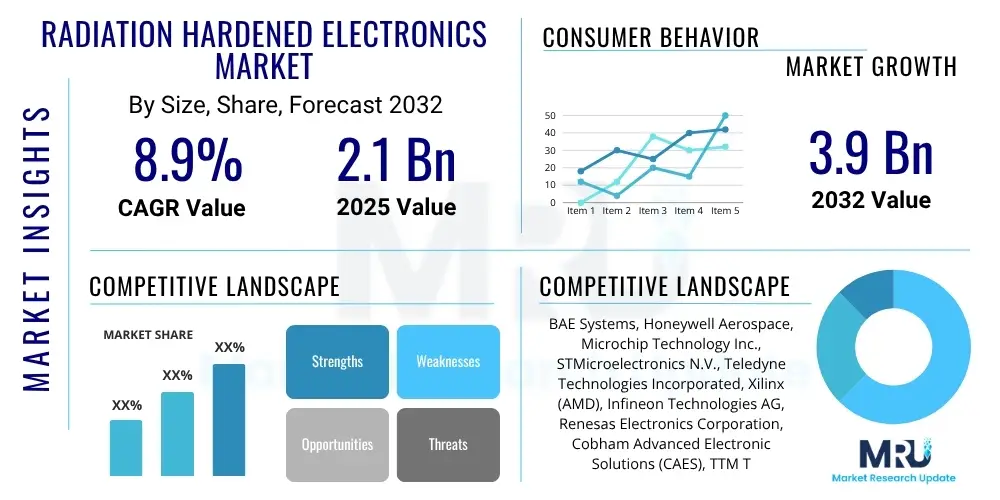

The Radiation Hardened Electronics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2025 and 2032. The market is estimated at USD 2.1 billion in 2025 and is projected to reach USD 3.9 billion by the end of the forecast period in 2032.

Radiation Hardened Electronics Market introduction

The Radiation Hardened (Rad-Hard) Electronics Market encompasses electronic components and systems specifically designed to operate reliably in environments exposed to high levels of ionizing radiation. These environments include outer space, nuclear power plants, defense and military applications, and high-energy physics research facilities. The fundamental purpose of these specialized electronics is to mitigate the damaging effects of radiation, such as Total Ionizing Dose (TID) effects, Single Event Effects (SEEs), and Displacement Damage (DD), which can lead to device malfunction, data corruption, or catastrophic failure in standard commercial-off-the-shelf (COTS) electronics.

Products within this market range from microprocessors, memory units, Field-Programmable Gate Arrays (FPGAs), and Application-Specific Integrated Circuits (ASICs) to power management devices, sensors, and discrete components. These components are critical for missions and operations where reliability and longevity under extreme conditions are paramount. For instance, satellites depend entirely on rad-hard electronics for their navigation, communication, and scientific instrumentation systems, as repair or replacement in space is prohibitively expensive or impossible. Similarly, military and defense systems, including avionics and ground support equipment, require hardened components to ensure uninterrupted operation during conflict or in harsh battlefield conditions, where electromagnetic pulses (EMPs) or other radiation threats might be present.

The primary benefits of radiation hardened electronics include enhanced reliability, extended operational lifespan in hostile environments, and reduced mission failure rates, which translates into significant cost savings and improved safety for critical applications. The market is primarily driven by the escalating demand for space-based services, including satellite constellations for communication and Earth observation, advancements in defense technologies requiring robust electronic systems, and the ongoing modernization of nuclear infrastructure. Additionally, a growing emphasis on deep space exploration missions and the development of new frontiers in quantum computing and AI for space applications are further propelling market expansion, necessitating ever more sophisticated and resilient electronic solutions.

Radiation Hardened Electronics Market Executive Summary

The Radiation Hardened Electronics Market is experiencing robust growth, primarily fueled by the accelerating pace of space exploration, the increasing deployment of satellite mega-constellations, and continuous advancements in defense technologies. Business trends indicate a shift towards higher integration levels and more advanced process nodes in rad-hard component manufacturing, aiming to deliver greater processing power and memory capacity within smaller, more energy-efficient packages. There is also a notable trend towards developing hybrid solutions that combine the cost-effectiveness of COTS components with targeted hardening techniques, seeking to strike a balance between performance, cost, and radiation tolerance. Strategic partnerships between traditional aerospace and defense contractors and commercial semiconductor manufacturers are becoming more common, fostering innovation and expanding the supply chain.

Regional trends highlight North America as a dominant market, largely due to significant government and private sector investments in space programs, military modernization, and advanced research initiatives. Europe also represents a substantial market, driven by its well-established space agencies (e.g., ESA) and defense industries, coupled with a focus on collaborative international space missions. The Asia Pacific region is emerging as a critical growth hub, propelled by the ambitious space programs of countries like China, India, and Japan, alongside rapidly expanding defense budgets. Latin America, the Middle East, and Africa are showing nascent but growing demand, particularly for satellite communication services and defense applications, suggesting future market expansion in these regions.

Segmentation trends indicate strong demand across all component types, with microprocessors and FPGAs witnessing significant growth due to the increasing complexity of on-board processing requirements in space and defense. Memory components, especially non-volatile memory, are also in high demand for robust data storage. Application-wise, the space segment remains the largest and most critical end-use, encompassing commercial, civil, and military satellites, as well as manned and unmanned space missions. Defense applications are also expanding, driven by the need for secure and reliable electronics in challenging operational environments. The nuclear power sector, while smaller, maintains a steady demand for instrumentation and control systems that can withstand harsh radiation exposures, ensuring safety and operational stability.

AI Impact Analysis on Radiation Hardened Electronics Market

User questions related to the impact of AI on the Radiation Hardened Electronics Market often revolve around how AI can enhance the design and testing of these components, whether AI processing capabilities can be effectively hardened for space or defense applications, and the potential for AI-driven autonomous systems in radiation-intensive environments. Users are keen to understand if AI can accelerate the development cycle, improve fault tolerance, or lead to entirely new classes of rad-hard systems. There's also curiosity about the challenges of deploying AI algorithms on current rad-hard hardware, which typically lags behind commercial counterparts in computational power. Key themes include the integration of AI for advanced mission capabilities, the necessity of radiation-tolerant AI hardware, and the potential for AI to optimize system performance and resilience in extreme conditions.

- AI can optimize the design and verification processes for radiation-hardened circuits, reducing development time and cost.

- Integration of AI processors and accelerators into rad-hard designs enables on-orbit data processing, reducing bandwidth requirements for ground communication.

- AI-powered fault detection, isolation, and recovery (FDIR) systems can enhance the resilience and autonomy of spacecraft and defense platforms.

- Machine learning models can analyze radiation effects data to predict component degradation and inform future hardening strategies.

- The demand for radiation-hardened AI hardware will surge with the increasing use of autonomous systems in space exploration and military intelligence.

- AI can enable adaptive radiation shielding, optimizing protection based on real-time environmental data and mission profiles.

- AI-driven image processing and data analysis on board satellites require significant radiation-hardened computational power, pushing technological boundaries.

DRO & Impact Forces Of Radiation Hardened Electronics Market

The Radiation Hardened Electronics Market is shaped by a complex interplay of drivers, restraints, and opportunities, each exerting significant influence on its trajectory and growth potential. Key drivers include the exponential increase in satellite launches, particularly for commercial constellations providing broadband internet and Earth observation services, which critically rely on highly reliable rad-hard components. Furthermore, intensifying geopolitical tensions are driving defense spending upwards globally, leading to greater demand for robust and secure electronics in military satellites, advanced avionics, and strategic weapon systems. The growing emphasis on deep space exploration, spearheaded by both national space agencies and private ventures, also necessitates sophisticated radiation-hardened solutions capable of withstanding prolonged exposure to harsh cosmic radiation environments, pushing the boundaries of current technological capabilities.

Conversely, significant restraints challenge market expansion. The high cost associated with the design, manufacturing, and extensive testing of radiation-hardened components remains a primary barrier, often making these solutions several times more expensive than their COTS counterparts. The extended development cycles and the specialized expertise required for radiation hardening also contribute to higher barriers to entry for new players, limiting competition and potentially slowing innovation. Moreover, the technological lag of rad-hard components, which often use older process nodes compared to cutting-edge commercial electronics, presents a performance challenge. This disparity can restrict the integration of advanced features and higher processing capabilities into systems where radiation tolerance is paramount, necessitating careful trade-offs between performance and resilience.

Despite these challenges, substantial opportunities exist for market growth and innovation. The miniaturization of satellites (e.g., CubeSats and SmallSats) is opening new avenues for more cost-effective rad-hard solutions, as these platforms still require a degree of radiation tolerance. Advancements in material science and packaging techniques are enabling the development of more resilient components without necessarily relying on older process nodes, potentially bridging the performance gap. Furthermore, the development of hybrid hardening techniques, which involve selectively hardening critical COTS components or using redundant COTS designs, offers a promising path to balance cost and radiation tolerance. The increasing integration of AI and machine learning into space and defense applications presents a significant opportunity for rad-hard AI processors, creating demand for entirely new product categories and capabilities within the market. This evolving landscape underscores the dynamic nature of the market, where innovation is key to overcoming existing limitations and capitalizing on emerging demands.

Segmentation Analysis

The Radiation Hardened Electronics Market is segmented to provide a granular understanding of its diverse components, applications, and end-user landscapes. This segmentation allows for precise market analysis, identifying key growth areas and niche opportunities across different technological and operational domains. The market can be broadly categorized by component type, application, and end-use, each reflecting distinct technological requirements and market demands. Understanding these segments is crucial for stakeholders to tailor their product offerings, R&D investments, and market strategies, ensuring they align with the specific needs of various industries operating in radiation-intensive environments.

- By Component

- Processors & Controllers (Microprocessors, Microcontrollers, DSPs)

- Memory (SRAM, MRAM, EEPROM, Flash Memory)

- Analog & Mixed-Signal ICs (ADCs, DACs, Amplifiers, Voltage Regulators)

- Power Management ICs (PMICs)

- FPGA & ASICs

- Sensors & Optoelectronics

- Discrete Devices (Diodes, Transistors)

- By Application

- Space

- Commercial Satellites

- Military Satellites

- Civil & Government Satellites

- Deep Space Probes

- Launch Vehicles

- Defense & Military

- Avionics

- Ground Systems

- Naval Systems

- Missile & Munition Systems

- Nuclear Power

- Reactor Control Systems

- Instrumentation & Monitoring

- Safety Systems

- Medical & Scientific Research (Particle Accelerators, Radiotherapy Equipment)

- Space

- By End-Use

- Aerospace & Defense

- Energy

- Industrial

- Medical

- Research

Value Chain Analysis For Radiation Hardened Electronics Market

The value chain for the Radiation Hardened Electronics Market is intricate, spanning from fundamental material science to sophisticated system integration and end-user deployment. Upstream activities involve the development and supply of specialized semiconductor materials, such as silicon-on-insulator (SOI) wafers or wide-bandgap materials like SiC and GaN, which inherently offer higher radiation tolerance. This stage also includes the design and intellectual property (IP) development for radiation-hardened architectures, which requires deep expertise in physics, electrical engineering, and radiation effects. Foundries capable of fabricating these specialized circuits, often using older, more stable process nodes or employing specific hardening techniques during manufacturing, form a critical part of the upstream segment. These specialized foundries are few and highly specialized, contributing to the high cost and long lead times associated with rad-hard components.

Midstream activities primarily focus on the manufacturing, assembly, and rigorous testing of the radiation-hardened components. After fabrication, components undergo extensive radiation testing, including Total Ionizing Dose (TID) testing, Single Event Effect (SEE) testing, and Displacement Damage (DD) testing, often at specialized facilities. This testing is crucial to verify the components' resilience against various radiation types and levels, ensuring they meet stringent performance and reliability specifications for their intended applications. Packaging, another critical step, also requires specialized, often hermetic, solutions to protect the sensitive electronics. Direct and indirect distribution channels then move these components to system integrators. Direct sales are common for large government contracts and prime contractors, while indirect channels involve specialized distributors catering to smaller integrators or specific industry niches.

Downstream activities involve the integration of these hardened components into complex systems, such as satellites, spacecraft, military aircraft, or nuclear reactor control systems. System integrators, often large aerospace and defense companies, take the rad-hard electronics and combine them with other subsystems, software, and mechanical structures to build the final product. The final stage involves the deployment and maintenance of these systems in their operational environments, requiring ongoing support and potentially further testing or upgrades over their lifecycle. The entire value chain is characterized by a strong emphasis on reliability, quality control, and adherence to rigorous industry standards and certifications, reflecting the mission-critical nature of radiation-hardened electronics.

Radiation Hardened Electronics Market Potential Customers

Potential customers for radiation hardened electronics primarily consist of entities involved in critical operations within radiation-intensive environments, where the reliability and longevity of electronic systems are paramount. The largest segment of end-users is the aerospace and defense industry, encompassing government space agencies such as NASA, ESA, Roscosmos, and ISRO, as well as private space companies like SpaceX, Blue Origin, and traditional aerospace giants like Lockheed Martin, Boeing, and Airbus. These organizations require rad-hard components for satellites (commercial, military, scientific), deep space probes, manned spacecraft, launch vehicles, and a wide array of military platforms including fighter jets, drones, missile systems, and secure communication devices. The need for uninterrupted operation and mission success in harsh radiation fields makes these entities the core consumers.

Beyond aerospace and defense, the energy sector, particularly nuclear power plant operators, represents another significant customer base. These facilities require radiation-hardened instrumentation, control systems, and safety monitoring equipment to operate reliably within reactor containment buildings, ensuring safe and efficient power generation. As nuclear plants age and undergo modernization, the demand for updated rad-hard electronics for control room upgrades and advanced sensor deployments is expected to persist. Research institutions and universities engaged in high-energy physics experiments, such as CERN with its particle accelerators, also procure specialized rad-hard electronics for their detectors and control systems, designed to withstand extreme radiation doses during experimental runs.

Emerging applications also point to other potential customers, including companies developing advanced medical radiotherapy equipment, where precise control systems operating in proximity to high-energy radiation sources are essential. Additionally, the industrial sector, particularly for specialized applications in hazardous environments like waste processing or certain extreme manufacturing processes, may represent a niche but growing demand for robust, radiation-tolerant electronics. Overall, any entity where electronics must function reliably under the threat of ionizing radiation, and where failure is not an option due to high costs, safety risks, or mission criticality, constitutes a potential customer for radiation hardened electronic solutions, driving the market forward.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.1 Billion |

| Market Forecast in 2032 | USD 3.9 Billion |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BAE Systems, Honeywell Aerospace, Microchip Technology Inc., STMicroelectronics N.V., Teledyne Technologies Incorporated, Xilinx (AMD), Infineon Technologies AG, Renesas Electronics Corporation, Cobham Advanced Electronic Solutions (CAES), TTM Technologies, Analog Devices Inc., Texas Instruments Incorporated, ON Semiconductor (onsemi), Leonardo DRS, Qorvo Inc., Thales Group, RTX Corporation (Raytheon), L3Harris Technologies, Inc., Skyworks Solutions, Inc., Kratos Defense & Security Solutions, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Radiation Hardened Electronics Market Key Technology Landscape

The technological landscape of the Radiation Hardened Electronics Market is characterized by continuous innovation aimed at enhancing resilience, performance, and efficiency while mitigating the effects of ionizing radiation. One prominent technology involves the use of Silicon-on-Insulator (SOI) fabrication processes, which significantly reduce parasitic leakage currents and improve single event effect (SEE) immunity compared to bulk silicon. SOI technology isolates active device regions with an insulating layer, leading to intrinsically more radiation-tolerant transistors. Beyond SOI, advancements in wide-bandgap (WBG) semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) are gaining traction, especially for power management applications. These materials offer superior electrical properties and intrinsic radiation hardness, enabling devices to operate at higher temperatures and voltages with greater efficiency in harsh environments, reducing the need for extensive external shielding.

Another crucial aspect of the technology landscape is the development of advanced circuit design techniques specifically for radiation tolerance. This includes using redundancy (e.g., Triple Modular Redundancy - TMR) at various levels (gate, flip-flop, block) to mask single event upsets (SEUs) and other transient faults. Error detection and correction codes (EDAC) are widely employed in memory components to prevent data corruption. Furthermore, specialized design methodologies focus on optimizing transistor sizing, layout geometries, and operating voltages to enhance resistance to Total Ionizing Dose (TID) effects. These design-for-radiation-hardness approaches are often combined with process hardening techniques at the foundry level, where specific manufacturing steps are modified to produce devices more resistant to radiation-induced damage.

The increasing complexity of modern space and defense systems also drives the demand for radiation-hardened Field-Programmable Gate Arrays (FPGAs) and Application-Specific Integrated Circuits (ASICs) with higher integration densities and processing capabilities. This has led to efforts to harden components at more advanced technology nodes, pushing the boundaries of what was traditionally considered feasible for rad-hard electronics. Technologies like 3D stacking and advanced packaging are also being explored to create more compact and robust multi-chip modules. Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) capabilities on-board space and defense platforms necessitates the development of radiation-tolerant AI processors and specialized hardware accelerators, representing a significant technological frontier within the market. These advancements collectively aim to deliver electronics that are not only resilient but also capable of meeting the computational demands of future missions.

Regional Highlights

- North America: Dominates the market due to significant investments by government agencies (NASA, DoD) and private companies in space exploration, satellite constellations, and military modernization programs. The region benefits from a robust ecosystem of research institutions, semiconductor manufacturers, and aerospace and defense contractors, driving innovation and technological leadership in radiation-hardened solutions.

- Europe: A substantial market propelled by established space agencies (ESA) and a strong defense industry. Countries like France, Germany, and the UK are key players, investing in collaborative space missions, advanced satellite technologies, and critical defense infrastructure. The region also emphasizes R&D in materials science and novel hardening techniques.

- Asia Pacific (APAC): Emerging as a high-growth region, driven by ambitious space programs in China, India, and Japan. Rapid expansion of commercial space activities, increasing defense budgets, and growing domestic manufacturing capabilities are fueling demand for radiation-hardened electronics across military, civil, and commercial applications.

- Latin America: Demonstrates nascent but growing demand, primarily for satellite communication services, Earth observation, and some defense applications. Investments in space infrastructure by countries like Brazil and Argentina, along with regional defense modernizations, are contributing to market development.

- Middle East and Africa (MEA): Shows increasing interest in satellite technology for communication, surveillance, and national security. Countries in the Gulf Cooperation Council (GCC) are investing in space programs and defense capabilities, leading to a gradual rise in demand for specialized radiation-hardened electronics in critical national infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Radiation Hardened Electronics Market.- BAE Systems

- Honeywell Aerospace

- Microchip Technology Inc.

- STMicroelectronics N.V.

- Teledyne Technologies Incorporated

- Xilinx (AMD)

- Infineon Technologies AG

- Renesas Electronics Corporation

- Cobham Advanced Electronic Solutions (CAES)

- TTM Technologies

- Analog Devices Inc.

- Texas Instruments Incorporated

- ON Semiconductor (onsemi)

- Leonardo DRS

- Qorvo Inc.

- Thales Group

- RTX Corporation (Raytheon)

- L3Harris Technologies, Inc.

- Skyworks Solutions, Inc.

- Kratos Defense & Security Solutions, Inc.

Frequently Asked Questions

Analyze common user questions about the Radiation Hardened Electronics market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are radiation-hardened electronics?

Radiation-hardened electronics are specialized electronic components and systems engineered to withstand and operate reliably in environments exposed to ionizing radiation, such as space, nuclear facilities, and defense applications. They are designed to prevent or mitigate radiation-induced damage, ensuring continuous functionality.

Why are radiation-hardened electronics essential for space missions?

Space environments expose electronics to high levels of cosmic rays, solar flares, and trapped radiation, which can cause severe damage, data corruption, or total system failure in standard commercial components. Rad-hard electronics ensure the long-term reliability and mission success of satellites, spacecraft, and deep space probes by resisting these destructive effects.

What are the main types of radiation damage mitigated by these electronics?

The primary types of radiation damage addressed include Total Ionizing Dose (TID) effects, which cause gradual degradation over time, and Single Event Effects (SEEs), which are transient, instantaneous faults caused by a single particle strike. Displacement Damage (DD) is also mitigated, particularly in optoelectronic and power devices.

How do radiation-hardened electronics differ from commercial-off-the-shelf (COTS) components?

Rad-hard electronics differ from COTS in their design, materials, manufacturing processes, and rigorous testing. They often use specialized fabrication processes (like SOI), redundant circuit designs, and shielding, undergoing extensive radiation testing to meet stringent reliability standards for harsh environments, unlike COTS which are optimized for cost and performance in terrestrial conditions.

What is the future outlook for the Radiation Hardened Electronics Market?

The market is poised for significant growth, driven by the proliferation of satellite constellations, increasing defense spending, and ambitious deep space exploration initiatives. Future trends include higher integration of AI capabilities, the development of more advanced and cost-effective hardening techniques, and the adoption of new materials like SiC and GaN to enhance performance and resilience in extreme conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager