Rail Gangway Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430055 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Rail Gangway Market Size

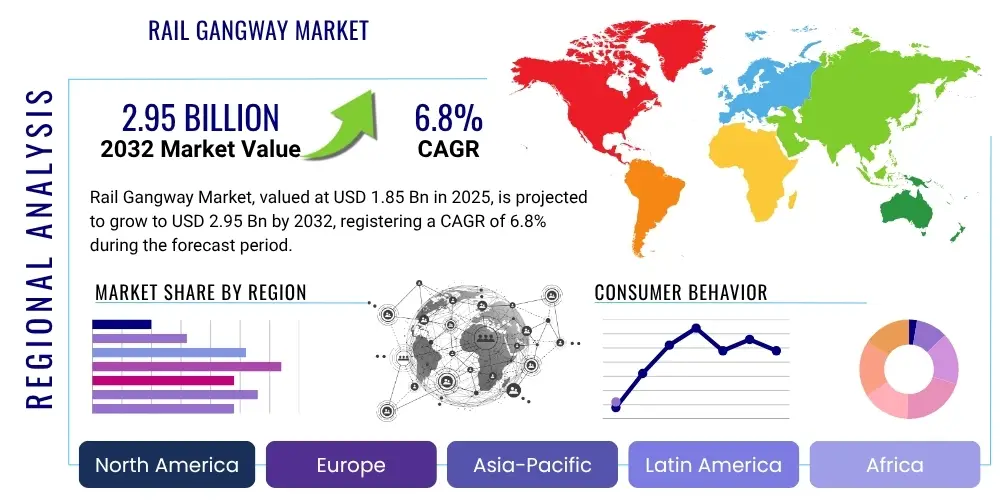

The Rail Gangway Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.85 Billion in 2025 and is projected to reach USD 2.95 Billion by the end of the forecast period in 2032.

Rail Gangway Market introduction

The Rail Gangway Market encompasses the design, manufacturing, and distribution of flexible connecting elements that allow passengers and crew to move safely and comfortably between railway carriages. These critical components ensure structural integrity, weather protection, and acoustic insulation within train sets, ranging from urban metro systems to high-speed intercity lines. The ongoing expansion of global railway networks, coupled with stringent safety and comfort standards, underpins the market's continuous growth.

Rail gangways are sophisticated systems that comprise various materials like rubber, metal, and specialized fabrics, engineered to withstand extreme temperatures, vibrations, and dynamic stresses encountered during train operations. Their primary applications span high-speed trains, regional and commuter trains, metro systems, and trams, facilitating seamless passenger flow and enhancing overall travel experience. Key benefits include improved passenger safety through secure connections, enhanced comfort by reducing noise and vibration, protection from environmental elements, and compliance with accessibility regulations for diverse passenger needs.

Driving factors for this market include significant investments in public transportation infrastructure globally, particularly in developing economies, the modernization of existing rail fleets, and the increasing demand for high-speed rail networks. Furthermore, evolving regulatory mandates for passenger safety and comfort, alongside technological advancements aimed at enhancing gangway durability and performance, are compelling factors stimulating market expansion. The continuous need for efficient and reliable inter-carriage passage remains a core driver.

Rail Gangway Market Executive Summary

The Rail Gangway Market is characterized by robust business trends focusing on innovation in material science, modular design, and enhanced integration with train control systems. Manufacturers are increasingly investing in research and development to produce lightweight, fire-resistant, and more durable gangway solutions that can withstand harsh operating conditions and reduce maintenance overheads. A notable trend involves the development of smart gangways equipped with sensors for real-time condition monitoring, moving towards predictive maintenance models and improved operational efficiency across railway fleets.

Regional trends indicate significant market expansion in Asia Pacific, driven by extensive urbanization and massive investments in new railway infrastructure projects, including high-speed rail and metro expansions in countries like China, India, and Japan. Europe continues to be a mature market with steady growth, primarily fueled by fleet modernization, stringent environmental regulations, and the expansion of cross-border high-speed rail networks. North America is experiencing growth through the replacement of aging infrastructure and investment in commuter rail upgrades, while Latin America, the Middle East, and Africa represent emerging opportunities with planned new railway developments.

Segmentation trends highlight a growing demand for gangways optimized for high-speed rail, emphasizing aerodynamic design and advanced vibration dampening capabilities. The metro and tram segments are focusing on durability, low maintenance, and design adaptability for high-frequency operations. Material-wise, there is a shift towards hybrid solutions combining the resilience of rubber with the structural integrity of metal and advanced fabrics, offering improved performance and longevity. Customization based on train type and specific operational environments is also becoming a key differentiator in the market.

AI Impact Analysis on Rail Gangway Market

Common user questions regarding AI's impact on the Rail Gangway Market frequently revolve around how artificial intelligence can enhance safety, optimize maintenance, and improve the design and manufacturing processes of these critical components. Users are keen to understand if AI can lead to more resilient and efficient gangways, reducing operational costs and downtime for railway operators. There is significant interest in AI's role in proactive problem identification and the integration of intelligent features within gangway systems.

The key themes emerging from this analysis indicate a strong expectation that AI will revolutionize predictive maintenance by enabling real-time monitoring and anomaly detection, thus preventing failures before they occur. Concerns often touch upon data security, the complexity of AI integration into existing infrastructure, and the need for skilled personnel to manage these advanced systems. Users anticipate that AI will facilitate the creation of more adaptive and durable gangways, significantly contributing to the overall reliability and safety of rail transport.

- AI-powered predictive maintenance: Utilizing sensor data from gangways to forecast potential failures, optimizing maintenance schedules and reducing unexpected downtime.

- Enhanced safety monitoring: AI algorithms processing video and sensor inputs to detect unusual wear, tear, or structural anomalies in real time, alerting operators to potential hazards.

- Optimized material and design: AI-driven simulations and generative design tools accelerating the development of lightweight, highly durable, and acoustically insulated gangway structures.

- Automated quality control: AI-vision systems identifying defects during the manufacturing process with higher precision and speed than manual inspection.

- Smart logistics and inventory management: AI forecasting demand for spare parts, optimizing supply chains for gangway components, and managing stock levels efficiently.

- Improved passenger experience: AI analyzing passenger flow patterns to inform gangway design, potentially influencing future layouts for faster boarding and disembarking.

DRO & Impact Forces Of Rail Gangway Market

The Rail Gangway Market is significantly influenced by a confluence of driving forces, inherent restraints, and emerging opportunities, all of which shape its trajectory and competitive landscape. Key drivers include the global push for sustainable transportation solutions, leading to substantial investments in new rail infrastructure and the expansion of existing networks, particularly in rapidly urbanizing regions. Strict safety regulations mandated by national and international railway authorities compel manufacturers to continuously innovate and upgrade gangway designs, ensuring passenger protection and operational reliability. Furthermore, the increasing demand for comfortable and high-speed rail travel directly translates into a need for advanced gangway systems that minimize noise, vibration, and improve overall ride quality.

However, the market also faces considerable restraints that temper its growth. The high initial capital expenditure associated with manufacturing complex gangway systems, which require specialized materials and precision engineering, can be a barrier for new entrants and can increase the cost of procurement for railway operators. Stringent certification processes and compliance with diverse international standards add to the complexity and cost of product development. Economic downturns or geopolitical instabilities can lead to delays or cancellations of major rail projects, impacting market demand. The long lifecycle of railway rolling stock also means replacement cycles for gangways are extended, often deferring new purchases.

Despite these challenges, numerous opportunities present themselves. The development of lightweight and advanced composite materials for gangway construction offers the potential for improved energy efficiency and reduced wear on railway tracks. The integration of smart technologies, such as sensors for real-time condition monitoring and predictive maintenance, represents a significant growth avenue. Moreover, the vast market for retrofitting and upgrading existing rail fleets with modern, more efficient gangways offers a steady stream of business. Emerging markets in Africa, Latin America, and parts of Asia are actively developing new railway networks, creating new demand for gangway solutions. The pursuit of enhanced passenger comfort and accessibility standards further fuels innovation and market expansion.

Segmentation Analysis

The Rail Gangway Market is comprehensively segmented based on various critical parameters, including the type of material used, the specific train type it serves, the application context, and the fundamental design characteristics. This segmentation allows for a detailed analysis of market dynamics, competitive landscapes, and specific consumer preferences within the diverse global railway industry. Understanding these segments is crucial for manufacturers to tailor their product offerings and for railway operators to select gangway solutions that best fit their operational requirements and fleet specifications.

The material segmentation highlights the evolving choices available, from traditional rubber-based solutions known for their flexibility to more rigid metal constructions offering enhanced durability, and advanced fabric composites that provide a balance of lightweight properties and robust performance. Train type segmentation differentiates needs for high-speed, metro, regional, and tram systems, each having distinct demands for speed, vibration, passenger capacity, and urban environment considerations. Application segmentation broadly distinguishes between passenger and specialized freight requirements, while design segmentation delves into structural forms like corrugated, articulated, or folding gangways, each suited for particular functionalities and aesthetic requirements. This granular analysis provides a clear picture of the market structure and avenues for innovation.

- By Material

- Rubber

- Metal

- Fabric/Textile

- Hybrid/Composite Materials

- By Train Type

- High-Speed Rail

- Metro/Subway

- Regional Trains

- Trams/Light Rail

- Commuter Trains

- By Application

- Passenger Rail

- Specialized Freight Rail (e.g., car carriers, maintenance trains)

- By Design

- Corrugated Gangways

- Articulated Gangways

- Folding Gangways

- Telescopic Gangways

- By End User

- Original Equipment Manufacturers (OEMs)

- Aftermarket (Maintenance, Repair, and Overhaul - MRO)

Value Chain Analysis For Rail Gangway Market

The value chain for the Rail Gangway Market is intricate, beginning with the sourcing of specialized raw materials and extending through complex manufacturing processes to final deployment and aftermarket services. Upstream analysis involves a diverse set of suppliers providing critical components such as various grades of rubber (e.g., EPDM, neoprene), specialized metals (e.g., aluminum, stainless steel), high-performance fabrics (e.g., fire-retardant textiles), and other components like sealing elements, fasteners, and sensor technologies. These suppliers are crucial for ensuring the quality, durability, and safety features of the final gangway product, often requiring adherence to strict industry standards and certifications.

Downstream analysis primarily focuses on the direct customers, which are predominantly Original Equipment Manufacturers (OEMs) of railway rolling stock, such as Alstom, Siemens, CRRC, and Hitachi Rail. These OEMs integrate the gangways into new train sets during the assembly phase. Beyond initial installation, the downstream segment also includes railway operators and maintenance service providers who purchase gangways for replacement, repair, and upgrade purposes throughout the operational life of their train fleets. The interaction between gangway manufacturers and these downstream entities often involves customized solutions and long-term supply agreements, emphasizing reliability and after-sales support.

Distribution channels in the Rail Gangway Market are predominantly direct, particularly for sales to major OEMs due to the highly specialized nature of the product and the need for close technical collaboration. Gangway manufacturers often work directly with train builders during the design and integration phases to ensure seamless compatibility and performance. For the aftermarket segment, sales can be both direct to railway operators or indirect through a network of authorized distributors, parts suppliers, and specialized maintenance, repair, and overhaul (MRO) service providers. Indirect channels become more prevalent for standard replacement parts or maintenance components, facilitating wider reach and faster delivery to diverse operational hubs globally.

Rail Gangway Market Potential Customers

The primary potential customers and end-users of rail gangways are entities deeply embedded within the global railway industry ecosystem, ranging from the manufacturers of trains themselves to the operators and maintainers of these vital transportation systems. Original Equipment Manufacturers (OEMs) of rolling stock constitute a significant segment of demand, as gangways are integral components of every new train set produced. These OEMs seek innovative, compliant, and cost-effective gangway solutions that meet their design specifications, safety standards, and overall train performance requirements for various applications, including high-speed, metro, and regional trains.

Beyond the initial manufacturing phase, national and private railway operators represent another substantial customer base. These operators procure gangways for their existing fleets, either as part of routine maintenance and replacement cycles due to wear and tear, or as part of comprehensive modernization and upgrade programs. For these customers, factors such as durability, ease of maintenance, availability of spare parts, and the total cost of ownership are paramount. Major players like Deutsche Bahn, SNCF, Indian Railways, and numerous metro authorities worldwide constantly require reliable gangway solutions to ensure continuous and safe service delivery.

Furthermore, specialized maintenance, repair, and overhaul (MRO) service providers, who often work under contract for railway operators, also serve as key purchasers of rail gangways and related components. These companies require a consistent supply of high-quality parts to conduct scheduled and unscheduled maintenance, ensuring the long-term operational integrity and safety of railway vehicles. The decision-making process for these customers is heavily influenced by regulatory compliance, product certifications, supplier reliability, and the availability of technical support, highlighting the specialized nature of the rail gangway procurement landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.85 Billion |

| Market Forecast in 2032 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hübner GmbH & Co. KG, Dellner Couplers AB, KTK Group Co., Ltd., Voith Group, Stemmann-Technik GmbH, Sumitomo Electric Industries, Ltd., CRRC Corporation Limited, Kawasaki Heavy Industries, Ltd., Hitachi Rail, Alstom S.A., Siemens AG, Wabtec Corporation, Knorr-Bremse AG, Trelleborg AB, Hutchinson S.A., Getzner Werkstoffe GmbH, Gummiwerk Kraiburg Elastik GmbH, P. C. Cox Ltd., Polytech S.A., Shandong Zhongda Electromechanical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rail Gangway Market Key Technology Landscape

The Rail Gangway Market is significantly influenced by a dynamic technological landscape that continually drives innovation in materials, design, and manufacturing processes. One of the primary technological advancements is in the area of advanced materials, where manufacturers are increasingly incorporating lightweight composites, high-performance rubbers, and fire-resistant fabrics. These materials not only enhance the durability and longevity of gangways but also contribute to overall train energy efficiency by reducing weight and improving fire safety compliance, which is a critical regulatory concern in the rail industry. The integration of these materials allows for gangways that can withstand extreme environmental conditions and rigorous operational stresses.

Another crucial technological development involves sensor integration and smart gangway solutions. Modern gangways are being equipped with various sensors, including strain gauges, temperature sensors, and vibration monitors, to enable real-time condition monitoring. This technology facilitates predictive maintenance strategies, allowing railway operators to identify potential issues before they escalate into failures, thereby reducing unplanned downtime and maintenance costs. The data collected from these sensors can also be used to optimize gangway performance, inform future design iterations, and enhance overall operational safety and reliability, moving towards more autonomous and data-driven maintenance regimes.

Furthermore, advancements in manufacturing technologies such as automated welding techniques, robotic assembly, and precision machining are leading to higher quality and more consistent gangway production. The use of advanced computational fluid dynamics (CFD) and finite element analysis (FEA) software in the design phase allows for virtual prototyping and optimization of aerodynamic properties, noise reduction, and structural integrity. Additive manufacturing (3D printing) is also gaining traction for prototyping complex gangway components, accelerating development cycles. These technological evolutions collectively contribute to the development of more sophisticated, safer, and economically viable rail gangway solutions that meet the evolving demands of modern railway systems.

Regional Highlights

- North America: This region is characterized by significant investments in the modernization and replacement of aging rail infrastructure, particularly in commuter and freight rail sectors. There is a growing emphasis on enhancing passenger comfort and safety standards, driving demand for advanced gangway solutions. The United States and Canada are undertaking projects to upgrade their networks, including proposals for new high-speed rail corridors, though progress can be gradual. The market here also benefits from a strong aftermarket segment focused on maintenance and upgrades of existing fleets.

- Europe: A mature market with a strong emphasis on high-speed rail and extensive urban transport networks. Europe leads in adopting stringent safety and environmental regulations, which mandates continuous innovation in gangway design, focusing on fire resistance, noise reduction, and energy efficiency. Countries like Germany, France, and the UK are consistently investing in expanding their high-speed networks and electrifying regional lines, creating a steady demand for state-of-the-art gangways. Cross-border connectivity projects further stimulate market growth.

- Asia Pacific (APAC): The APAC region stands out as the fastest-growing market for rail gangways, driven by unprecedented rates of urbanization and massive government investments in new railway infrastructure. China, India, and Japan are at the forefront of this expansion, with extensive high-speed rail projects, new metro lines, and intercity networks. The demand is not only for new installations but also for localized manufacturing and robust gangway solutions capable of handling high passenger volumes and diverse climatic conditions. Emerging economies in Southeast Asia are also contributing to this growth.

- Latin America: This region presents emerging opportunities with several countries planning and executing new railway projects to improve connectivity and facilitate economic development. Investments in urban rail transport and regional cargo lines are notable, though growth can be influenced by economic stability and government policies. Brazil, Mexico, and Argentina are key markets, with a focus on durable and cost-effective gangway solutions for both new builds and fleet upgrades, often requiring solutions adaptable to varying operating environments.

- Middle East and Africa (MEA): The MEA region is characterized by ambitious infrastructure development plans, including the construction of entirely new railway networks for both passenger and freight transport. Countries in the GCC (Gulf Cooperation Council) are investing heavily in modern high-speed and metro systems, while several African nations are working on cross-country rail links to bolster trade and connectivity. This region demands robust gangways capable of operating in harsh desert climates and often involves significant international partnerships for technology transfer and project execution.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rail Gangway Market.- Hübner GmbH & Co. KG

- Dellner Couplers AB

- KTK Group Co., Ltd.

- Voith Group

- Stemmann-Technik GmbH

- Sumitomo Electric Industries, Ltd.

- CRRC Corporation Limited

- Kawasaki Heavy Industries, Ltd.

- Hitachi Rail

- Alstom S.A.

- Siemens AG

- Wabtec Corporation

- Knorr-Bremse AG

- Trelleborg AB

- Hutchinson S.A.

- Getzner Werkstoffe GmbH

- Gummiwerk Kraiburg Elastik GmbH

- P. C. Cox Ltd.

- Polytech S.A.

- Shandong Zhongda Electromechanical Co., Ltd.

Frequently Asked Questions

What are rail gangways used for?

Rail gangways are crucial components in trains that provide a flexible, safe, and weather-protected passage between railway carriages, enabling passengers and crew to move across wagons while also reducing noise and vibration.

What materials are commonly used in rail gangways?

Common materials include various types of rubber (e.g., EPDM, neoprene) for flexibility and sealing, metals (e.g., aluminum, stainless steel) for structural integrity, and specialized fabrics for protective bellows, often combined in hybrid designs.

How do safety regulations impact gangway design?

Safety regulations heavily influence gangway design, requiring features like fire resistance, robust structural integrity to withstand dynamic forces, emergency egress capabilities, and adherence to specific impact absorption and anti-climbing standards to ensure passenger and operational safety.

What are the future trends in the rail gangway market?

Future trends include the integration of smart sensors for predictive maintenance, the use of advanced lightweight and composite materials for improved efficiency, enhanced acoustic and thermal insulation, and designs optimized for aerodynamic performance and modularity.

Which regions are major markets for rail gangways?

Asia Pacific, particularly China and India, is the largest and fastest-growing market due to extensive new rail infrastructure, while Europe remains a strong market driven by high-speed rail expansion and fleet modernization projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager