Rail Gearbox Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427332 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Rail Gearbox Market Size

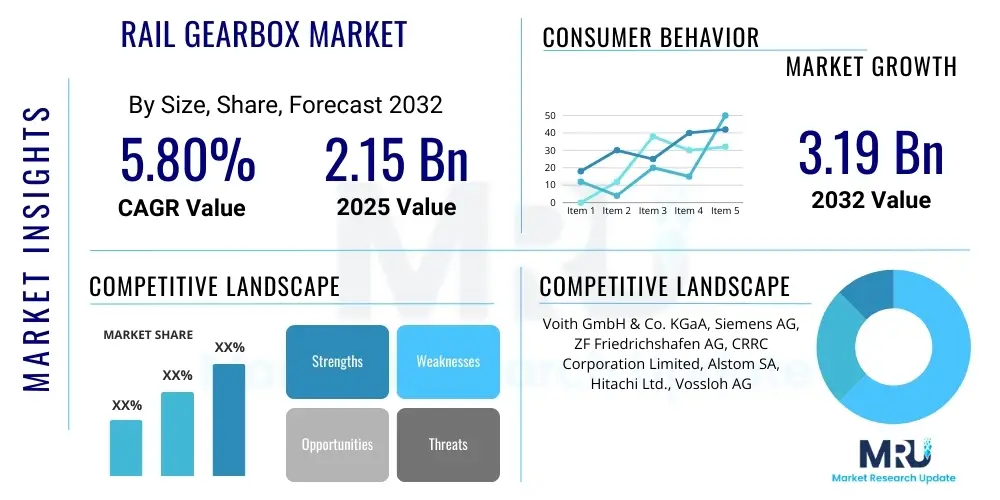

The Rail Gearbox Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 2.15 Billion in 2025 and is projected to reach USD 3.19 Billion by the end of the forecast period in 2032. This growth is driven by increasing investments in railway infrastructure, the expansion of high-speed rail networks, and the rising demand for efficient and sustainable transportation solutions globally. The markets robust expansion reflects the critical role gearboxes play in ensuring the operational efficiency and reliability of modern railway systems across freight and passenger segments.

Rail Gearbox Market introduction

The rail gearbox market encompasses the design, manufacturing, and distribution of specialized gear systems essential for the propulsion and auxiliary functions of railway rolling stock. These crucial components transmit power from traction motors to the wheels, enabling trains to move efficiently and reliably. The market includes gearboxes for various rail applications, ranging from high-speed passenger trains and urban metro systems to heavy-haul freight locomotives and light rail vehicles, each demanding specific performance characteristics in terms of torque, speed, noise reduction, and durability.

Major applications for rail gearboxes span across multiple railway segments, including passenger rail (high-speed rail, regional trains, metros, trams), freight rail, and specialized industrial rail. Key benefits derived from advanced rail gearboxes include enhanced energy efficiency, reduced operational noise, extended service life, and improved safety performance. Driving factors for market growth include significant global urbanization leading to increased demand for public transport, governmental initiatives promoting rail as an eco-friendly mode of transport, and continuous technological advancements in railway engineering aimed at higher speeds and greater payloads.

Rail Gearbox Market Executive Summary

The global rail gearbox market is experiencing robust growth, primarily fueled by extensive modernization programs for existing railway networks and the construction of new high-speed lines, particularly in Asia-Pacific and Europe. Business trends indicate a strong emphasis on smart rail solutions, integrating predictive maintenance capabilities and advanced sensor technologies within gearbox systems to optimize performance and reduce downtime. Manufacturers are focusing on lightweight designs, enhanced material science, and improved lubrication systems to meet stringent efficiency and environmental regulations, pushing the boundaries of durability and operational lifespan.

Regional trends reveal significant investment in rail infrastructure across developing economies, with China and India leading the expansion of urban and intercity rail networks. Europe continues to upgrade its extensive railway systems, focusing on cross-border connectivity and high-speed services, which drives demand for advanced gearboxes. Segment trends highlight a growing preference for modular and compact gearbox designs that offer easier maintenance and higher power density. The market also sees increasing adoption of gearboxes optimized for electric multiple units (EMUs) and diesel multiple units (DMUs), reflecting the shift towards more energy-efficient and low-emission rail transport.

AI Impact Analysis on Rail Gearbox Market

Common user questions regarding AIs impact on the Rail Gearbox Market often revolve around predictive maintenance, operational efficiency, and design optimization. Users are keen to understand how AI can transform traditional maintenance schedules into condition-based monitoring, anticipate component failures, and extend gearbox lifespan. There is also significant interest in AIs role in enhancing the real-time performance of rail systems, optimizing power transmission, and contributing to overall energy efficiency. Expectations include AI-driven design iterations that could lead to lighter, more durable, and cost-effective gearboxes, ultimately revolutionizing the manufacturing and operational paradigms within the rail industry.

- Predictive maintenance: AI algorithms analyze sensor data from gearboxes to predict potential failures, enabling proactive maintenance and reducing unscheduled downtime.

- Optimized performance: AI can fine-tune gearbox operations based on real-time track conditions, load, and speed, enhancing energy efficiency and reducing wear.

- Design and material innovation: AI-driven simulations accelerate the design process, allowing for the development of lighter, more robust, and more efficient gearbox components.

- Enhanced safety: Real-time monitoring and anomaly detection capabilities powered by AI contribute to safer rail operations by identifying potential issues before they escalate.

- Supply chain optimization: AI can improve inventory management for spare parts, ensuring timely availability of components for gearbox maintenance and repair.

DRO & Impact Forces Of Rail Gearbox Market

The Rail Gearbox Market is primarily driven by significant global investments in high-speed rail and urban transit projects, coupled with the increasing demand for sustainable and efficient transportation solutions. Governments worldwide are prioritizing rail infrastructure development to alleviate road congestion and reduce carbon emissions, thereby creating a sustained demand for advanced gearboxes. Restraints include the high initial investment costs associated with railway infrastructure projects and the long design and certification cycles for critical rail components like gearboxes. Moreover, geopolitical uncertainties and fluctuating raw material prices can also impede market growth and stability.

Opportunities for market expansion lie in the growing adoption of magnetic levitation (Maglev) trains and hydrogen-powered trains, which will necessitate new generations of specialized gearboxes or propulsion systems. Furthermore, the retrofitting and modernization of aging railway fleets across mature markets present a substantial opportunity for gearbox manufacturers to supply upgraded, more efficient components. The impact forces shaping this market include the rapid pace of technological innovation, particularly in materials science and lubrication technologies, which allow for the development of gearboxes with higher power density and extended service intervals. Stringent regulatory standards for safety, noise, and environmental performance also compel manufacturers to continuously innovate, further influencing market dynamics and product development.

Segmentation Analysis

The Rail Gearbox Market is segmented across various critical parameters, including product type, application, and train type, to provide a granular view of market dynamics. Understanding these segments is crucial for identifying specific growth areas, competitive landscapes, and evolving technological demands within the rail industry. Each segment presents unique challenges and opportunities, influencing material choices, design specifications, and performance requirements for rail gearboxes.

- By Product Type: Spur Gearboxes, Helical Gearboxes, Bevel Gearboxes, Planetary Gearboxes, Worm Gearboxes.

- By Application: Traction Systems, Auxiliary Systems (Doors, HVAC, etc.).

- By Train Type: High-Speed Trains, Freight Locomotives, Passenger Trains (Commuter & Regional), Metro & Urban Rail, Trams & Light Rail, Special Rail Vehicles.

- By Material Type: Steel Alloy, Cast Iron, Aluminum Alloy, Composite Materials.

- By Power Output: Low Power, Medium Power, High Power.

- By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa.

Rail Gearbox Market Value Chain Analysis

The value chain for the rail gearbox market begins with upstream analysis, which involves the sourcing of raw materials such as high-grade steel, aluminum alloys, and specialized lubricants from primary metal producers and chemical suppliers. Component manufacturers then transform these materials into precision-engineered parts like gears, shafts, bearings, and casings. The quality and availability of these upstream materials significantly impact the final products performance and cost. Key considerations at this stage include material purity, metallurgical properties, and sustainable sourcing practices.

Moving downstream, the value chain progresses through the manufacturing and assembly of the gearboxes, often involving complex machining, heat treatment, and quality control processes. This stage is dominated by specialized gearbox manufacturers who possess expertise in precision engineering and adhere to stringent rail industry standards. Following manufacturing, distribution channels play a critical role, ranging from direct sales to original equipment manufacturers (OEMs) of rolling stock (e.g., Alstom, Siemens, CRRC) to indirect sales through authorized distributors and service providers for aftermarket needs. The final stage involves installation, commissioning, and extensive aftermarket services, including maintenance, repair, and overhaul (MRO), which are crucial for extending product lifespan and ensuring operational continuity. Both direct and indirect channels are vital, with direct sales facilitating integrated solutions for new builds and indirect channels serving the diverse and fragmented MRO market.

Rail Gearbox Market Potential Customers

The primary potential customers and end-users of rail gearboxes encompass a broad spectrum of entities within the railway ecosystem. Original Equipment Manufacturers (OEMs) of rolling stock, such as locomotive and train manufacturers, represent the largest segment of direct buyers for new gearbox installations. These companies integrate gearboxes into their train designs, demanding highly customized solutions that meet specific performance, weight, and durability requirements for various train types, including high-speed, freight, and urban transit vehicles.

Beyond new builds, railway operators and maintenance companies constitute a significant customer base for aftermarket sales, including replacement units, spare parts, and overhaul services. These operators, whether state-owned railway companies or private freight carriers, prioritize reliability, longevity, and ease of maintenance to minimize operational disruptions and extend the service life of their existing fleets. Furthermore, independent MRO service providers and rail workshops also serve as key purchasers, acquiring gearboxes and related components for repair and refurbishment activities, ensuring the continuous and safe operation of railway assets.

Rail Gearbox Market Key Technology Landscape

The rail gearbox market is characterized by a continuous evolution in technological advancements aimed at enhancing efficiency, durability, and performance. One prominent technological trend is the adoption of advanced material science, utilizing high-strength steel alloys, surface hardened gears, and lightweight composite materials to reduce weight, improve wear resistance, and increase power density. These material innovations contribute significantly to energy efficiency and extended operational lifespans. Furthermore, advanced manufacturing techniques, such as precision grinding and additive manufacturing, are being employed to produce gear components with tighter tolerances and superior surface finishes, minimizing friction and noise.

Another crucial aspect of the technology landscape involves the integration of smart technologies and sensor-based monitoring systems. These systems enable real-time condition monitoring, allowing for predictive maintenance strategies that detect early signs of wear, temperature anomalies, or lubrication issues. Such proactive approaches significantly reduce unscheduled downtime and optimize maintenance schedules, enhancing overall operational reliability. Moreover, advancements in lubrication technologies, including synthetic lubricants and intelligent oil management systems, contribute to reduced friction, improved cooling, and longer service intervals. The drive towards modular designs and standardized interfaces also facilitates easier installation, maintenance, and interchangeability, making gearboxes more adaptable to diverse rail applications and improving their overall cost-effectiveness over the product lifecycle.

Regional Highlights

- Asia Pacific: Expected to be the fastest-growing region due to extensive investments in high-speed rail networks, urban metro projects, and freight corridor development, particularly in China, India, and Japan.

- Europe: A mature but continuously evolving market driven by the modernization of existing railway infrastructure, expansion of cross-border high-speed lines, and stringent environmental regulations promoting rail transport. Countries like Germany, France, and the UK are key contributors.

- North America: Dominated by heavy-haul freight rail, with increasing investments in locomotive modernization and the expansion of passenger rail services. Emphasis on robust and durable gearboxes for demanding conditions.

- Latin America: Emerging market with increasing railway infrastructure projects, particularly in countries like Brazil and Argentina, aiming to improve logistics and urban connectivity.

- Middle East & Africa: Significant growth potential due to new rail projects aimed at economic diversification, trade facilitation, and public transportation improvement, especially in GCC countries and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rail Gearbox Market.- Voith GmbH & Co. KGaA

- Siemens AG

- ZF Friedrichshafen AG

- CRRC Corporation Limited

- Alstom SA

- Hitachi Ltd.

- Vossloh AG

Frequently Asked Questions

Analyze common user questions about the Rail Gearbox market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a rail gearbox and its primary function?

A rail gearbox is a critical mechanical component in railway rolling stock that transmits power from the traction motor to the wheel axles, converting high-speed, low-torque motor output into low-speed, high-torque necessary for train propulsion. It ensures efficient power transfer and enables the train to move.

What are the key factors driving growth in the Rail Gearbox Market?

The market is primarily driven by increasing global investments in railway infrastructure, expansion of high-speed rail networks, rising demand for urban transit systems, and the imperative for more energy-efficient and sustainable transportation solutions worldwide.

How does AI impact the Rail Gearbox Market?

AI significantly impacts the rail gearbox market through predictive maintenance, optimizing operational performance by analyzing real-time data, accelerating design and material innovation, and enhancing overall safety and efficiency of rail systems.

What types of trains commonly use rail gearboxes?

Rail gearboxes are essential for a wide range of train types, including high-speed trains, freight locomotives, passenger trains (commuter and regional), metro systems, light rail vehicles, and trams, each requiring specialized gearbox designs.

Which regions are key contributors to the Rail Gearbox Markets growth?

The Asia Pacific region is a dominant contributor due to extensive infrastructure development, while Europe remains a strong market driven by modernization and high-speed rail expansion. North America is significant for freight rail, with emerging opportunities in Latin America and the Middle East & Africa.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager