Reciprocating Heat Pump Compressors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428077 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Reciprocating Heat Pump Compressors Market Size

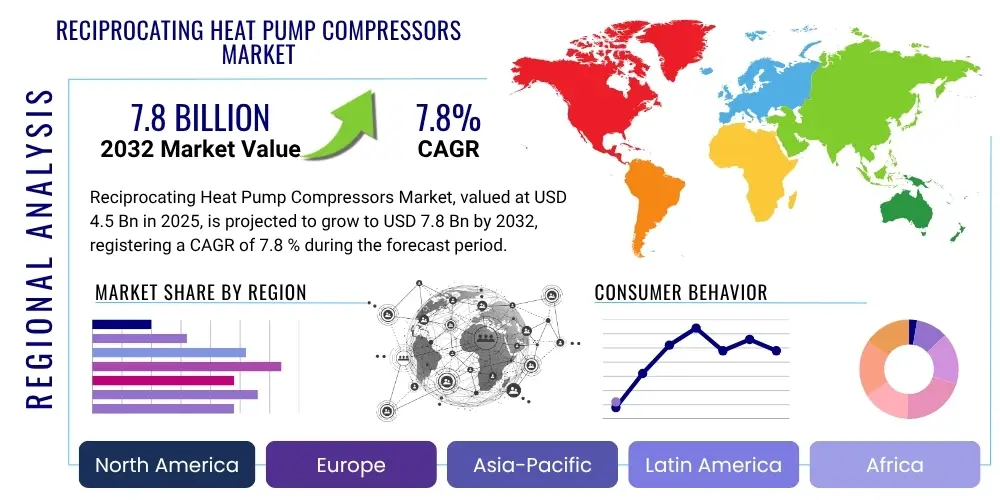

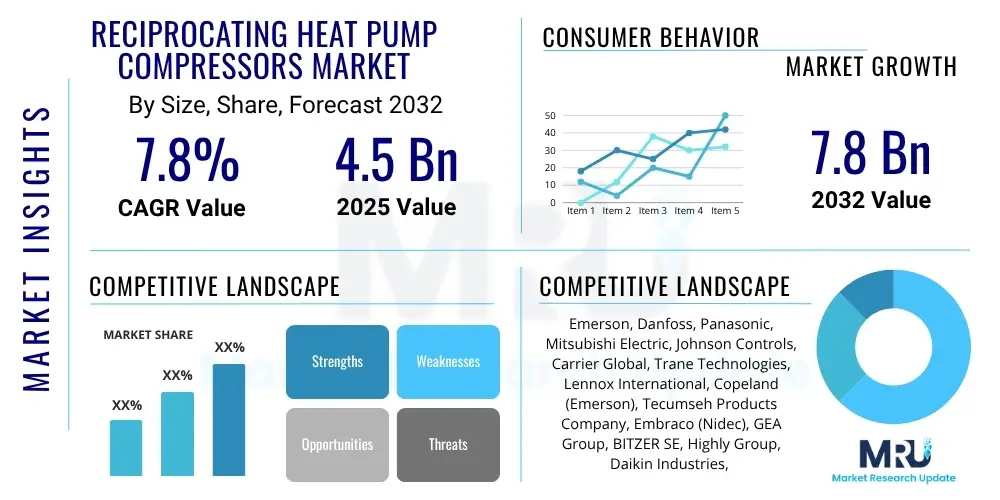

The Reciprocating Heat Pump Compressors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 4.5 billion in 2025 and is projected to reach USD 7.8 billion by the end of the forecast period in 2032.

Reciprocating Heat Pump Compressors Market introduction

The Reciprocating Heat Pump Compressors Market encompasses the design, manufacturing, and distribution of a crucial mechanical component central to the operation of heat pump systems globally. These compressors are essential for transferring thermal energy efficiently, facilitating both heating and cooling functions across diverse applications. Operating on the principle of positive displacement, they utilize a piston's cyclical motion within a cylinder to compress refrigerant gas, thereby elevating its temperature and pressure. This fundamental thermodynamic process is indispensable to the vapor-compression cycle, making reciprocating compressors foundational to the robust and reliable performance of modern heat pump technology. Their proven efficacy and adaptability have solidified their indispensable role within the broader Heating, Ventilation, and Air Conditioning (HVAC) industry. The market's trajectory is intimately tied to the increasing global emphasis on energy efficiency, environmental sustainability, and the electrification of heating systems across residential, commercial, and industrial sectors, driving continuous innovation and demand.

These specialized compressors are primarily characterized by their robust design and consistent performance across varying operating conditions. Key product attributes include their capability to manage a wide range of pressures and temperatures, often available in hermetic, semi-hermetic, or open-drive configurations to suit specific application requirements. The internal mechanism, consisting of a crankshaft, connecting rods, and pistons, is engineered for longevity and minimal wear. Advancements in material science and lubrication technologies have significantly improved their durability, reduced noise and vibration levels, and enhanced overall operational efficiency. Moreover, the integration of advanced electronic controls allows for precise modulation of refrigerant flow and capacity, optimizing energy consumption and ensuring stable indoor climate control. This continuous refinement makes them a preferred choice for systems requiring reliable and adaptable compression solutions, supporting the evolving needs of the HVAC sector for higher performance and environmental compliance.

Major applications for reciprocating heat pump compressors are predominantly found in residential and light commercial HVAC systems, where they are integral components of split systems, packaged units, multi-zone installations, and geothermal heat pump configurations. In residential settings, these compressors enable highly efficient space heating, cooling, and often domestic hot water generation, providing comprehensive climate control solutions. For commercial buildings such as offices, retail spaces, and educational institutions, they contribute to precise zoned comfort systems and smaller-scale industrial processes that necessitate regulated thermal management. The benefits derived from employing reciprocating compressors are substantial, including high volumetric efficiency, particularly under partial load conditions, making them well-suited for applications demanding variable capacity. Their relatively straightforward design ensures ease of maintenance and contributes to extended operational lifespans, offering a cost-effective and reliable solution for a broad spectrum of heating and cooling demands. This widespread utility underpins their continuous demand within the global market.

Reciprocating Heat Pump Compressors Market Executive Summary

The Reciprocating Heat Pump Compressors Market is experiencing dynamic shifts, largely influenced by pivotal business trends centered around energy efficiency, sustainability, and technological integration. A significant trend involves the accelerated electrification of heating systems globally, driven by ambitious decarbonization goals and the imperative to reduce reliance on fossil fuels. This transition fosters increased demand for high-efficiency compressors compatible with low Global Warming Potential (GWP) refrigerants. Manufacturers are strategically investing in research and development to optimize compressors for natural refrigerants like R290 (propane) and R32, aligning with stringent environmental regulations and consumer preferences for eco-friendly solutions. Furthermore, the market is witnessing a pronounced focus on integrating smart controls, IoT capabilities, and artificial intelligence for advanced energy management, predictive maintenance, and enhanced system diagnostics, which allows for remote monitoring and optimized performance. Strategic partnerships, mergers, and acquisitions are also prevalent as key players seek to expand market reach, consolidate technological capabilities, and leverage economies of scale in an increasingly competitive landscape, aiming to offer comprehensive and innovative heat pump solutions to a global clientele.

Regional trends significantly shape the market's growth trajectory and adoption patterns for reciprocating heat pump compressors. Europe currently stands as a leading market, propelled by robust environmental policies such as the F-Gas Regulation, high energy costs, and substantial government incentives promoting the widespread adoption of heat pumps. Countries like Germany, France, and Sweden are at the forefront of this transition, demonstrating strong market penetration in both new constructions and retrofitting projects. The Asia Pacific region, however, represents the largest and fastest-growing market, primarily driven by rapid urbanization, significant infrastructure development, and rising disposable incomes in economic powerhouses like China, Japan, and South Korea. Governmental support for energy-efficient appliances and improving air quality further fuels this growth. North America exhibits consistent growth, stimulated by federal and state-level incentives for electric heating solutions and a growing consumer preference for energy-efficient and environmentally responsible HVAC systems across residential and light commercial sectors. Emerging markets in Latin America, the Middle East, and Africa are also showing promising potential, albeit at an earlier stage of adoption, driven by increasing construction activities and a burgeoning awareness of energy efficiency benefits.

Segmentation trends within the reciprocating heat pump compressors market highlight the diverse applications and specific performance requirements driving demand. The residential applications segment continues to dominate the market, largely owing to the mass adoption of heat pumps for space heating, cooling, and domestic hot water. Within this segment, there is an increasing preference for compact, quiet, and high-efficiency units that can seamlessly integrate into modern homes. The commercial sector is also increasingly adopting heat pump technology for smaller to medium-sized buildings, including offices, retail outlets, and hospitality establishments, as well as for specific process heating and cooling needs. From a capacity perspective, lower capacity compressors (typically below 10 kW) are predominant in the vast residential market, whereas medium-capacity units (10 kW - 50 kW) are gaining traction in light commercial and multi-family residential applications. In terms of type, hermetic compressors remain the most popular choice due to their sealed design, which offers enhanced reliability, prevents refrigerant leakage, and minimizes maintenance requirements, making them ideal for a wide array of heat pump systems where long-term, trouble-free operation is paramount.

AI Impact Analysis on Reciprocating Heat Pump Compressors Market

Artificial intelligence is poised to profoundly transform the reciprocating heat pump compressors market by introducing unprecedented levels of operational efficiency, enabling sophisticated predictive maintenance, and optimizing design and manufacturing processes with remarkable precision. Market participants, including manufacturers, system integrators, and end-users, are keenly interested in understanding how AI can translate into tangible benefits such as significant energy savings, extended equipment lifespan, and streamlined supply chain management. There is also considerable anticipation regarding AI's crucial role in facilitating the challenging transition to new, environmentally friendly refrigerants, as well as its capacity to drastically improve system diagnostics and fault detection. Ultimately, AI's influence is expected to contribute to the development of more sustainable, reliable, and user-friendly heating and cooling solutions, thereby enhancing both environmental performance and customer satisfaction in this critical sector.

- Predictive Maintenance: AI algorithms analyze vast datasets from compressor operation, including temperature, pressure, vibration, and current draw, to identify subtle anomalies and predict potential component failures long before they occur. This proactive approach allows for scheduled maintenance, significantly reducing unexpected downtime and costly emergency repairs.

- Energy Efficiency Optimization: AI-driven control systems can dynamically learn and adapt to real-time operating conditions, ambient temperatures, occupancy patterns, and user preferences. By intelligently modulating compressor speed and capacity, these systems optimize energy consumption, ensuring the heat pump operates at its peak efficiency across varying loads and environmental factors, leading to substantial energy savings.

- Enhanced Design and Simulation: Machine learning models accelerate the research and development phase by simulating compressor performance under a multitude of operational scenarios and environmental conditions. This capability allows engineers to quickly iterate on designs, optimize component selection, and identify potential design flaws virtually, leading to faster product development cycles and superior, more efficient compressor designs.

- Quality Control in Manufacturing: AI-powered vision systems and sensor networks are integrated into the manufacturing line to meticulously inspect components and assembled compressors. These systems detect minute manufacturing defects with exceptional accuracy and speed, ensuring consistent product quality, reducing scrap rates, and upholding stringent industry standards, thereby improving overall production efficiency.

- Supply Chain Management and Logistics: AI can optimize complex supply chain operations by forecasting demand with greater accuracy, managing inventory levels more efficiently, and streamlining logistics for raw material procurement and finished product distribution. This leads to reduced lead times, lower warehousing costs, and a more resilient and responsive supply chain for reciprocating compressors.

- Remote Monitoring and Diagnostics: Leveraging IoT connectivity, AI enables advanced remote troubleshooting and performance monitoring of installed heat pump systems. Technicians can diagnose issues without on-site visits, receive alerts about potential problems, and even perform remote adjustments, which significantly reduces service costs, improves response times, and enhances customer satisfaction.

- Refrigerant Management and Transition: AI tools assist in optimizing refrigerant charge during installation and operation, detecting minute leaks, and managing the complex transition to lower Global Warming Potential (GWP) alternatives. By analyzing thermodynamic properties and system performance, AI can guide the selection and application of new refrigerants, ensuring compliance with evolving environmental regulations.

- Proactive System Protection: AI algorithms can identify unusual operational patterns that might indicate impending system stress or component degradation, triggering protective measures or alerts before severe damage occurs. This proactive safeguarding extends the overall lifespan of the heat pump system and its critical compressor components.

DRO & Impact Forces Of Reciprocating Heat Pump Compressors Market

The Reciprocating Heat Pump Compressors Market is dynamically shaped by a confluence of drivers, restraints, and opportunities, all influenced by various impact forces. A primary driver is the global push for enhanced energy efficiency, underscored by stringent regulatory frameworks, particularly in developed economies. These regulations, often accompanied by government incentives and subsidies for green building technologies, compel manufacturers to innovate and consumers to adopt more efficient heating and cooling solutions. The escalating demand for decarbonization and the electrification of heating systems across residential, commercial, and industrial sectors further amplify market growth. Growing environmental awareness among consumers and businesses, coupled with increasing concerns about climate change, is fostering a sustained shift towards sustainable technologies like heat pumps. Rapid urbanization and the expansion of residential and commercial infrastructure globally also contribute significantly to the demand for efficient HVAC systems, directly benefiting the reciprocating compressor market. These factors collectively create a robust and expanding demand landscape.

Despite these strong drivers, the market faces several notable restraints. The relatively high initial capital expenditure associated with the installation of heat pump systems, particularly for larger commercial applications or comprehensive residential retrofits, can be a significant barrier for some potential customers. While the long-term operational savings due to lower energy consumption are considerable, the upfront investment often requires substantial financial planning. Furthermore, the market is susceptible to the fluctuating prices of essential raw materials, including copper, steel, and specialized electronic components. These price volatilities directly impact manufacturing costs, subsequently influencing the final market price of compressors and overall heat pump systems. Another significant challenge is the limited availability of skilled labor for the installation, maintenance, and servicing of advanced heat pump systems in certain regions. The technical complexity of these systems necessitates specialized training, and a shortage of qualified professionals can hinder widespread adoption and market expansion, creating bottlenecks in the value chain and impacting customer satisfaction.

However, the market is rich with opportunities that can mitigate these restraints and propel future growth. Emerging markets in the Asia Pacific, Latin America, and parts of Africa present vast untapped potential, driven by rapid economic development, increasing disposable incomes, and growing construction activities. These regions are increasingly prioritizing energy efficiency and modern infrastructure, creating fertile ground for heat pump adoption. Technological advancements, including the pervasive integration of smart home systems, Internet of Things (IoT) connectivity, and Artificial Intelligence (AI) for enhanced control, diagnostics, and predictive maintenance, offer significant avenues for product differentiation and value addition. The development of compressors optimized for natural refrigerants, such as R290 (propane) and R744 (CO2), in response to environmental mandates, opens entirely new market segments and strengthens the industry's sustainable profile. Moreover, the increasing trend towards hybrid heating solutions, combining heat pumps with existing fossil fuel systems, expands market reach by offering flexible and cost-effective upgrade paths for a broader customer base. These opportunities allow for strategic market penetration and sustained innovation.

The impact forces exerting significant influence on the Reciprocating Heat Pump Compressors Market are multifaceted. Government policies and environmental regulations are paramount, shaping technological innovation, refrigerant choices, and market demand through mandates on energy efficiency standards, carbon emission limits, and incentives for renewable heating technologies. Economic factors, such as global economic growth rates, energy prices, and consumer disposable income levels, directly influence purchasing decisions for energy-efficient appliances and large-scale HVAC investments. Technological innovation is a continuous and powerful force, driving improvements in compressor efficiency, noise reduction, durability, and compatibility with new refrigerants and smart control systems. This relentless pursuit of advancement creates competitive differentiation and elevates market standards. Societal shifts towards sustainable living, amplified by increasing awareness of climate change and environmental stewardship, are fundamentally altering consumer preferences and corporate responsibility, thereby increasing the preference for eco-friendly heating and cooling solutions. Geopolitical events and trade policies can also impact supply chains and market access, adding another layer of complexity. These interwoven forces dictate the market's evolution and strategic direction.

Segmentation Analysis

The reciprocating heat pump compressors market is extensively segmented based on several critical parameters, allowing for a granular and nuanced understanding of its diverse applications, underlying dynamics, and specific market niches. This comprehensive segmentation provides invaluable insights for market players, enabling them to identify key growth areas, understand competitive positioning, and tailor their product development and marketing strategies. Analyzing the market across these various dimensions helps to decode consumer preferences, technological trends, and regional specificities, ultimately supporting more effective strategic planning and resource allocation. Each segment reflects distinct demand drivers and technological requirements, contributing to a multifaceted market landscape that requires detailed scrutiny for effective participation.

- By Type:

- Hermetic Reciprocating Compressors: Fully sealed units, preventing refrigerant leakage, ideal for residential and light commercial applications due to their reliability and low maintenance.

- Semi-Hermetic Reciprocating Compressors: Partially sealed units that allow for field servicing and motor replacement, commonly used in larger commercial and industrial refrigeration and heat pump systems requiring more flexibility.

- Open Reciprocating Compressors: Compressors with external motors and shaft seals, offering maximum serviceability and often used in very large industrial applications where external motor power is desired and maintenance access is critical.

- By Refrigerant Type:

- HFC (Hydrofluorocarbon): Includes refrigerants like R410A and R134a, widely used but facing phase-down due to high Global Warming Potential (GWP).

- HFO (Hydrofluoroolefin): Such as R1234yf, emerging low-GWP alternatives, increasingly adopted for their reduced environmental impact.

- Natural Refrigerants: Includes R290 (Propane), R744 (CO2), and R600a (Isobutane), gaining significant traction due to ultra-low GWP, requiring specialized compressor designs.

- Other (e.g., R32): A moderately low-GWP refrigerant, offering higher efficiency in certain applications and growing in popularity.

- By Application:

- Residential Heating and Cooling: The largest segment, covering space heating, cooling, and ventilation for single-family homes and multi-unit dwellings.

- Commercial Heating and Cooling: Encompasses offices, retail, hospitality, and educational buildings, requiring varying capacities and control sophistication.

- Industrial Process Heating: Applications in manufacturing and processing where heat pumps provide high-temperature hot water or steam for specific industrial processes.

- Water Heating: Dedicated heat pump water heaters for domestic hot water supply in residential and commercial settings, known for high efficiency.

- Other Applications: Includes specialized uses such as drying, agricultural heating, and district heating/cooling connections.

- By End-User Industry:

- Residential Buildings: Homeowners and property developers focused on energy-efficient and comfortable living spaces.

- Commercial Buildings: Owners and operators of offices, retail centers, healthcare facilities, and hotels seeking efficient HVAC solutions.

- Industrial Facilities: Manufacturers and process industries requiring reliable and cost-effective thermal management for their operations.

- Utilities: Energy providers and district heating/cooling networks incorporating heat pump technologies for grid-scale applications.

- By Capacity:

- Low Capacity (Below 10 kW): Predominantly for residential and small commercial heat pump units, emphasizing compactness and quiet operation.

- Medium Capacity (10 kW - 50 kW): Suited for light commercial applications, larger residential systems, and multi-zone climate control.

- High Capacity (Above 50 kW): Employed in large commercial buildings, industrial processes, and district heating systems where substantial thermal loads are required.

- By Sales Channel:

- Original Equipment Manufacturers (OEMs): Direct sales to manufacturers who integrate compressors into their finished heat pump products.

- Aftermarket: Sales of replacement compressors and components for existing heat pump systems through distributors and service providers.

- Distributors: Wholesalers and specialized distributors who supply compressors to HVAC contractors, installers, and smaller OEMs.

- Online Retail: Emerging channel for parts and smaller units, offering convenience and broader access to a diverse customer base.

Value Chain Analysis For Reciprocating Heat Pump Compressors Market

The value chain for the Reciprocating Heat Pump Compressors Market commences with the crucial upstream activities involving the sourcing of diverse raw materials and highly specialized components. This foundational stage includes the procurement of various metals such as high-grade steel and copper, which are essential for constructing compressor casings, crankshafts, pistons, and other internal mechanisms designed for durability and thermal efficiency. Additionally, specialized lubricants, advanced electronic components for motors and control systems, and innovative sealing materials are sourced from a global network of suppliers. The performance, cost-effectiveness, and environmental compliance of the final compressor are heavily dependent on the quality and sustainability of these upstream inputs. Therefore, establishing robust, resilient, and ethically sound supply chain relationships with reliable material and component providers is paramount for compressor manufacturers to ensure consistent production, maintain competitive pricing, and adhere to evolving industry standards and customer expectations regarding product integrity and environmental footprint.

Moving downstream, the value chain progresses through the manufacturing of the reciprocating compressors by Original Equipment Manufacturers (OEMs), followed by their meticulous integration into complete heat pump systems. This intricate process involves rigorous assembly, testing, and quality control to ensure that each compressor meets stringent performance and reliability standards before being incorporated into residential, commercial, or industrial heat pump units. Once integrated, these comprehensive heat pump systems are distributed through a sophisticated network that includes wholesalers, specialized HVAC distributors, and certified contractors. These downstream entities are not only responsible for logistics and sales but also play a critical role in providing expert installation, precise commissioning, and comprehensive after-sales service. The effectiveness of the downstream segment is highly customer-facing, emphasizing the importance of efficient logistical operations, robust technical support, and the widespread availability of skilled installation professionals to guarantee optimal system performance, maximize energy efficiency, and ensure paramount customer satisfaction throughout the entire lifecycle of the heat pump system. This collaborative ecosystem is vital for market penetration and sustained growth.

The distribution channel for reciprocating heat pump compressors primarily bifurcates into direct sales and indirect sales, each serving distinct market segments and strategic objectives. Direct sales typically involve strong, long-term relationships between compressor manufacturers and large-scale HVAC system manufacturers (OEMs). In this model, compressor producers supply units directly to these OEMs, who then integrate them into their final heat pump products. This channel is characterized by bulk orders, often involving customized specifications, dedicated technical support, and close collaborative development to ensure seamless integration and optimized system performance. The focus here is on high-volume efficiency, specialized requirements, and strategic partnerships. Conversely, indirect sales leverage an extensive network of third-party independent distributors and wholesalers. These intermediaries play a crucial role in reaching a more fragmented market comprising smaller HVAC installers, contractors, service companies, and regional system integrators. This model prioritizes broad market accessibility, localized support, and the ability to offer a diverse product portfolio to cater to the varied requirements of a wide array of customers, including aftermarket needs for replacement parts. Emerging online platforms are also supplementing these traditional channels, offering increased convenience and expanding market reach, particularly for standard products and spare parts, further diversifying the distribution landscape.

Reciprocating Heat Pump Compressors Market Potential Customers

The primary and most significant potential customers for reciprocating heat pump compressors are the Original Equipment Manufacturers (OEMs) of heat pump systems. These large-scale manufacturers, ranging from global HVAC giants to specialized regional producers, integrate the compressors as core components into their vast array of residential, commercial, and industrial heating and cooling units. Their purchasing decisions are critically driven by a multitude of factors, including the compressor's energy efficiency ratings, proven reliability and durability, cost-effectiveness over its lifecycle, compatibility with various refrigerant types (especially low-GWP alternatives), and the level of technical support and customization options offered by the compressor supplier. Establishing and maintaining strong, long-term strategic partnerships with these OEMs is absolutely crucial for reciprocating compressor manufacturers, as these relationships often involve collaborative R&D, bulk procurement contracts, and deep integration into the OEM's product development pipeline, ensuring a stable and significant revenue stream within the market.

Beyond the OEM segment, direct buyers often include large-scale commercial and industrial facility managers, as well as prominent property developers who are undertaking significant construction projects, such as multi-unit residential complexes, extensive commercial centers, or large industrial facilities. These customers typically require compressors in bulk quantities for integrated heating and cooling systems within their specific projects. They frequently engage in direct procurement to ensure that the compressors meet very specific performance criteria, adhere to rigorous building codes, and comply with various environmental certifications relevant to their developments. Their focus extends beyond initial cost to encompass the long-term operational savings achievable through superior energy efficiency, the projected longevity and reliability of the system, and the overall environmental impact of their HVAC installations. These buyers prioritize solutions that offer robust performance, contribute to sustainable building practices, and provide a strong return on investment over the system's operational lifespan, making them key direct purchasing entities in the market.

Furthermore, an extensive network of HVAC contractors, installers, and distributors constitutes another vital segment of potential customers for reciprocating heat pump compressors, particularly for aftermarket sales and replacement parts. These entities serve a diverse and fragmented base of end-users, which includes individual homeowners seeking to upgrade or replace their existing heat pump units, small business owners looking for efficient climate control solutions, and specialized maintenance companies managing building systems. Their purchasing decisions are primarily influenced by factors such as immediate product availability, competitive pricing, ease of installation, comprehensive warranty provisions, and the overall reputation of the compressor brand for consistent reliability and readily available technical support in the field. This segment relies heavily on the distribution network for timely access to components and often values suppliers who can offer strong logistical support and a broad product range. The aftermarket, driven by the need for repairs and replacements in a vast installed base, represents a continuous and essential revenue stream for compressor manufacturers, underscoring the importance of robust distribution and service networks to cater to these crucial indirect customers effectively.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 billion |

| Market Forecast in 2032 | USD 7.8 billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Emerson, Danfoss, Panasonic, Mitsubishi Electric, Johnson Controls, Carrier Global, Trane Technologies, Lennox International, Copeland (Emerson), Tecumseh Products Company, Embraco (Nidec), GEA Group, BITZER SE, Highly Group, Daikin Industries, Hitachi, LG Electronics, Samsung Electronics, Secop GmbH, Fusheng. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Reciprocating Heat Pump Compressors Market Key Technology Landscape

The technological landscape for reciprocating heat pump compressors is in a constant state of evolution, driven by an overarching imperative to enhance energy efficiency, minimize environmental impact, and improve overall system intelligence and reliability. A pivotal and transformative development in this domain is the widespread adoption and continuous refinement of variable speed drive (VSD) or inverter technology. VSDs enable compressors to operate at precisely varying speeds, allowing them to accurately match the heating or cooling load requirements of a building at any given moment. This dynamic adjustment significantly boosts energy efficiency, especially under partial load conditions which are common in real-world scenarios, and simultaneously improves occupant comfort by maintaining stable indoor temperatures without frequent on-off cycling. The integration of VSDs also contributes to an extended operational lifespan of the compressor by reducing mechanical stress and wear, fundamentally enhancing the performance envelope of heat pump systems. This technology is becoming a standard feature in high-performance units, responding directly to market demands for greater efficiency and adaptability.

Further advancements are evident in the sophisticated integration of electronic controls and an array of advanced sensors. These intelligent systems facilitate precise, real-time monitoring of critical operational parameters such as refrigerant temperature, pressure, and flow rates, alongside motor performance and vibration levels. Such granular data collection and analysis enable proactive diagnostics, allowing for early detection of potential issues and optimization of performance. Moreover, these smart controls are increasingly being integrated with Internet of Things (IoT) platforms, allowing for remote monitoring, management, and troubleshooting of heat pump systems. This connectivity not only reduces service costs and improves response times but also empowers predictive maintenance strategies, transitioning from reactive repairs to proactive asset management. Simultaneously, material science innovations are playing a crucial role, with the development and application of more durable, lightweight, and acoustically optimized materials for internal components. These advancements significantly contribute to enhanced compressor reliability, reduced noise levels, and minimized vibration, aspects that are particularly critical for residential applications where occupant comfort and quiet operation are paramount design considerations, further solidifying the market's trajectory towards quieter and more robust solutions.

The global shift towards lower Global Warming Potential (GWP) refrigerants is a monumental force reshaping compressor technology and driving significant research and development investments. Manufacturers are increasingly focusing on developing compressors specifically optimized for natural refrigerants such as R290 (propane), R744 (CO2), and R600a (isobutane), as well as synthetic alternatives like R32. This transition presents unique engineering challenges, including managing increased flammability risks for hydrocarbons and handling the very high operating pressures associated with CO2. Consequently, compressor designs are undergoing substantial revisions to accommodate these characteristics while maintaining or improving efficiency and safety. This includes the development of more robust internal components, advanced sealing technologies to prevent leakage, and improved electrical insulation and explosion-proof designs where necessary. Furthermore, the incorporation of advanced lubrication systems tailored to the specific properties of these new refrigerants is critical to ensuring the long-term safe and efficient operation of the next generation of reciprocating compressors. These technological adaptations are not merely incremental improvements but represent fundamental shifts, aligning the industry with ambitious global environmental objectives and evolving regulatory mandates while addressing the growing consumer demand for greener HVAC solutions, ultimately defining the future of the reciprocating heat pump compressor market.

Regional Highlights

- North America: This region is characterized by robust and steady growth in the reciprocating heat pump compressors market, primarily fueled by strong energy efficiency incentives from both federal and state governments, coupled with evolving building codes that favor sustainable heating solutions. The U.S. and Canada are significant contributors, with a growing consumer preference for electric heat pumps over traditional fossil fuel systems due to increasing awareness of environmental benefits and long-term cost savings. The residential sector, alongside light commercial applications, is a key driver, demonstrating a continuous shift towards electrified heating.

- Europe: A leading and mature market globally, Europe is driven by stringent environmental regulations, particularly the F-Gas Regulation targeting the phase-down of high-GWP refrigerants, and ambitious decarbonization targets across member states. Countries such as Germany, France, Italy, and the Nordic nations are at the forefront of adoption, heavily supported by substantial government subsidies and a robust regulatory framework promoting heat pump installations for both new constructions and extensive retrofitting projects in existing buildings. This strong policy support creates a highly favorable market environment.

- Asia Pacific (APAC): Representing the largest and fastest-growing market segment, the APAC region is primarily propelled by rapid urbanization, extensive industrialization, and steadily rising disposable incomes in economic powerhouses like China, Japan, and South Korea. Government initiatives aimed at promoting energy-efficient appliances, improving air quality, and curbing carbon emissions are significant accelerators of market expansion. The vast scale of new construction and infrastructure development across the region ensures sustained high demand.

- Latin America: An emerging market, Latin America is showcasing increasing potential, driven by growing awareness of energy efficiency and the environmental benefits of heat pumps. Brazil and Mexico stand out as key markets within the region, influenced by expanding construction activities, ongoing modernization of urban infrastructure, and a gradual, albeit accelerating, shift towards more modern and sustainable HVAC solutions. However, the pace of adoption can vary significantly across different countries, reflecting diverse economic conditions and policy landscapes.

- Middle East and Africa (MEA): This region is experiencing nascent growth in the reciprocating heat pump compressors market, primarily driven by significant infrastructure development projects and a strategic focus on diversifying energy sources away from traditional fossil fuels. While the current adoption rates are lower compared to more established regions, substantial opportunities exist in the hospitality sector, large commercial buildings, and industrial projects, particularly with a strong emphasis on efficient cooling solutions and domestic hot water heating, responding to the region's climate conditions.

- Japan: A technologically advanced market, Japan places a strong emphasis on high-efficiency heat pumps, inverter technology, and compact, quiet unit designs. This is driven by stringent energy conservation standards, a high population density, and a discerning consumer base that values innovative, space-saving, and eco-friendly solutions. Japanese manufacturers are global leaders in heat pump technology and continue to push boundaries in performance and integration.

- China: As the world's largest manufacturer and consumer of heat pumps, China is characterized by massive domestic demand and formidable export capabilities. The market is fueled by extensive government support for green technologies, large-scale residential and commercial development projects, and national policies aimed at reducing air pollution and energy consumption. This creates an unparalleled environment for growth and innovation within the reciprocating compressor market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Reciprocating Heat Pump Compressors Market.- Emerson

- Danfoss

- Panasonic

- Mitsubishi Electric

- Johnson Controls

- Carrier Global

- Trane Technologies

- Lennox International

- Copeland (Emerson)

- Tecumseh Products Company

- Embraco (Nidec)

- GEA Group

- BITZER SE

- Highly Group

- Daikin Industries

- Hitachi

- LG Electronics

- Samsung Electronics

- Secop GmbH

- Fusheng

Frequently Asked Questions

What is a reciprocating heat pump compressor and how does it work?

A reciprocating heat pump compressor is a core mechanical device that functions as the heart of a heat pump system. It operates by utilizing a piston moving within a cylinder to mechanically compress refrigerant vapor. This compression process significantly increases the refrigerant's pressure and temperature, enabling it to efficiently absorb thermal energy from one environment (e.g., outdoor air or ground) and release it into another (e.g., indoor space for heating). This cyclical action is fundamental to the vapor-compression refrigeration cycle, making it possible for heat pumps to provide highly efficient heating, cooling, and often domestic hot water by transferring heat rather than generating it directly. Its robust design ensures reliable and consistent performance across a broad spectrum of operating conditions, making it a foundational technology in modern HVAC systems.

What are the primary advantages of reciprocating compressors in heat pump systems?

Reciprocating compressors offer several key advantages that make them a preferred choice for many heat pump applications. Firstly, they boast high volumetric efficiency, particularly when operating at variable loads, which directly translates to superior overall system energy efficiency and reduced electricity consumption, especially in systems with variable speed drives. Secondly, their established and robust design contributes to a long operational lifespan and high reliability, ensuring consistent performance over many years with relatively straightforward maintenance. Thirdly, their ability to handle varying pressure ratios effectively allows for precise control over refrigerant flow, which enhances system stability, improves comfort levels by maintaining steady temperatures, and ensures adaptability to diverse operating conditions. Furthermore, their mature technology typically presents a cost-effective solution compared to some alternative compressor types, balancing initial investment with long-term operational benefits.

How do environmental regulations impact the reciprocating heat pump compressors market?

Environmental regulations exert a profound impact on the reciprocating heat pump compressors market, acting as a powerful catalyst for innovation and strategic shifts. Regulations such as the F-Gas Regulation in Europe, which mandates the phase-down of high Global Warming Potential (GWP) hydrofluorocarbon (HFC) refrigerants, are compelling manufacturers to redesign compressors for compatibility with lower-GWP alternatives. This drives significant investment in research and development for compressors optimized to operate with natural refrigerants like R290 (propane), R744 (CO2), and R600a (isobutane), as well as new synthetic HFO (hydrofluoroolefin) blends or R32. These regulatory pressures necessitate changes in compressor materials, internal components, sealing technologies, and safety protocols to ensure safe and efficient operation with new refrigerant types. Consequently, environmental mandates are fundamentally reshaping product development strategies, influencing market availability, and accelerating the industry's transition towards more sustainable and eco-friendly heating and cooling solutions globally, making compliance a key competitive differentiator.

What role does Artificial Intelligence (AI) play in the future of reciprocating heat pump compressors?

Artificial Intelligence (AI) is set to play a transformative role in the future of reciprocating heat pump compressors by introducing advanced capabilities that enhance performance, efficiency, and reliability. AI's integration enables sophisticated predictive maintenance strategies, where algorithms analyze vast amounts of operational data (e.g., vibration, temperature, pressure) to anticipate potential component failures, allowing for proactive servicing and minimizing costly downtime. Furthermore, AI-driven control systems can dynamically optimize energy efficiency by learning and adapting to real-time heating or cooling demands, weather patterns, and user preferences, ensuring the compressor operates at its peak performance across varying conditions. AI also accelerates product design and simulation phases, allowing engineers to rapidly iterate and refine compressor designs for improved efficiency and sustainability. Finally, AI enhances remote monitoring and diagnostics, offering quicker troubleshooting and improved customer service, thereby ushering in an era of smarter, more resilient, and more sustainable heat pump systems.

Which regions are leading the adoption of reciprocating heat pump compressors and why?

Europe stands as a leading region for the adoption of reciprocating heat pump compressors, primarily due to its stringent environmental policies, ambitious decarbonization targets, and high energy costs which incentivize energy-efficient heating. Countries such as Germany, France, and Sweden are pioneering markets, backed by substantial government subsidies and robust regulatory frameworks promoting the widespread installation of heat pumps in both new and existing buildings. The Asia Pacific (APAC) region, particularly China and Japan, is another significant leader, experiencing rapid growth driven by swift urbanization, massive infrastructure development, and increasing disposable incomes. Governmental support for energy-efficient appliances and initiatives to improve air quality are key accelerators in APAC. North America also demonstrates steady growth, propelled by various federal and state-level incentives for electric heating solutions and a growing consumer preference for energy-efficient and environmentally responsible HVAC systems across residential and light commercial sectors. These regional leaders are driven by a combination of regulatory impetus, economic incentives, and increasing environmental consciousness.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager