Reciprocating Power Generating Engine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430168 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Reciprocating Power Generating Engine Market Size

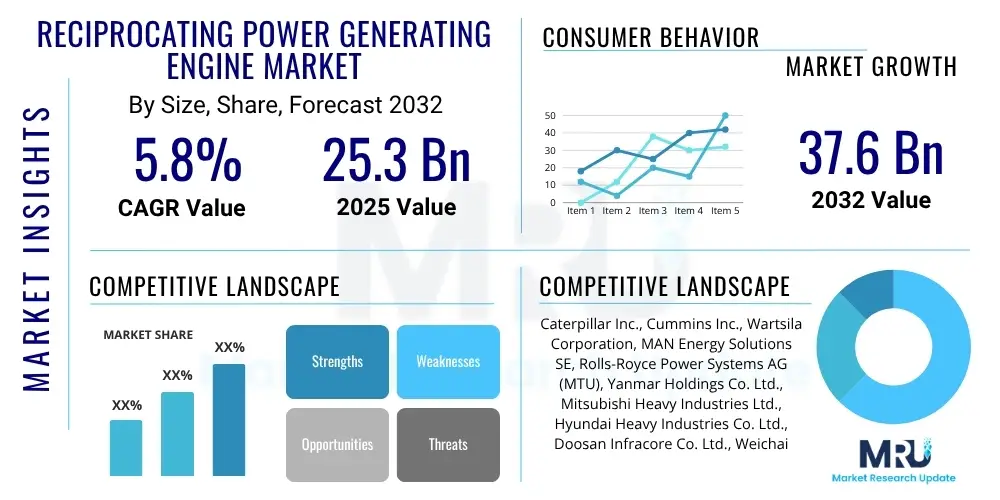

The Reciprocating Power Generating Engine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 25.3 Billion in 2025 and is projected to reach USD 37.6 Billion by the end of the forecast period in 2032.

Reciprocating Power Generating Engine Market introduction

The Reciprocating Power Generating Engine Market encompasses a wide array of internal combustion engines designed to convert chemical energy from fuel into mechanical energy, which is then used to generate electricity. These engines are fundamental to various power generation applications, serving as reliable sources for primary, standby, and peak-shaving power. Their versatility in fuel type, power output, and operational flexibility makes them indispensable across a multitude of industries.

Products within this market range from small gasoline or diesel generators for residential and commercial backup power to large industrial engines running on natural gas, biogas, or heavy fuel oil for grid support, marine propulsion, and oil and gas operations. Major applications span industrial facilities, data centers, hospitals, remote power stations, marine vessels, and distributed power generation units. The primary benefits include high reliability, quick start-up times, fuel flexibility, and the ability to operate independently of a central grid, offering crucial energy security. Key driving factors for market growth include increasing global electricity demand, rapid industrialization and urbanization in emerging economies, the need for robust backup power solutions, and the ongoing development of distributed power generation infrastructure.

Reciprocating Power Generating Engine Market Executive Summary

The Reciprocating Power Generating Engine Market is experiencing dynamic shifts driven by evolving energy landscapes and technological advancements. Business trends highlight a strong emphasis on fuel efficiency, reduced emissions, and the integration of smart technologies for enhanced operational control and predictive maintenance. Companies are increasingly investing in research and development to offer engines compatible with alternative fuels like natural gas and biogas, aligning with global sustainability goals and stringent environmental regulations. The move towards modular and containerized power solutions is also a notable trend, facilitating quicker deployment and greater flexibility.

Regional trends indicate significant growth in Asia Pacific due to burgeoning industrialization and urbanization, leading to increased energy demand and infrastructure development. North America and Europe, while mature markets, are focusing on engine upgrades, emission compliance, and the adoption of natural gas and dual-fuel engines for grid stability and combined heat and power (CHP) applications. Segment trends show a pronounced shift towards natural gas-fueled engines owing to their cleaner combustion and lower operational costs compared to diesel, particularly in stationary power generation. Additionally, there has been a growing demand for engines in the medium power output range (1 MW to 5 MW) to support distributed generation projects and microgrids, reflecting a broader trend towards decentralized energy systems and energy independence. The market is also witnessing innovations in engine control systems and digital integration, enhancing overall performance and longevity.

AI Impact Analysis on Reciprocating Power Generating Engine Market

Users frequently inquire about how artificial intelligence can transform the operation and maintenance of reciprocating power generating engines, with common themes revolving around enhancing efficiency, predicting failures, and optimizing fuel consumption. There is considerable interest in leveraging AI for real-time monitoring, diagnostic capabilities, and autonomous adjustments to engine parameters, aiming to reduce downtime and operational costs. Concerns often include the initial investment in AI infrastructure, data security, and the need for skilled personnel to manage these advanced systems. Overall, expectations are high for AI to significantly improve reliability, extend asset lifespans, and contribute to more sustainable and cost-effective power generation.

- AI-powered predictive maintenance reduces unplanned downtime by forecasting component failures.

- Optimized fuel efficiency through real-time monitoring and adaptive control algorithms.

- Enhanced operational performance by analyzing vast datasets for ideal engine settings.

- Automated fault diagnosis and rapid issue resolution, minimizing human intervention.

- Improved energy management and grid integration for distributed power systems.

- Reduced emissions by fine-tuning combustion processes and operational parameters.

- Extended asset lifecycle through proactive maintenance and optimized operational stress.

DRO & Impact Forces Of Reciprocating Power Generating Engine Market

The Reciprocating Power Generating Engine Market is shaped by a complex interplay of drivers, restraints, and opportunities, all influenced by various impact forces. Key drivers include the escalating global demand for electricity, fueled by industrial expansion, urbanization, and a growing population. The increasing need for reliable backup power solutions across critical infrastructure like data centers, hospitals, and manufacturing units also significantly propels market growth. Furthermore, the rising adoption of distributed power generation and microgrid solutions, especially in remote or underserved areas, provides a substantial impetus for engine deployment. The inherent reliability and operational flexibility of these engines, coupled with their ability to quickly adapt to varying load demands, positions them as crucial components in ensuring energy security.

However, the market faces significant restraints. Stringent environmental regulations aimed at reducing greenhouse gas emissions and air pollutants pose a considerable challenge, necessitating substantial investments in advanced emission control technologies and cleaner fuel alternatives. The accelerating shift towards renewable energy sources such as solar and wind power, which are often preferred for their lower environmental impact, also creates competitive pressure. Additionally, the relatively high initial capital expenditure for reciprocating power generating engines and associated infrastructure, alongside fluctuating fuel prices, can deter potential buyers. The noise pollution generated by larger engines and the ongoing maintenance requirements also represent practical limitations that stakeholders must address.

Despite these challenges, numerous opportunities exist for market expansion and innovation. The development and increasing adoption of hybrid power systems, which combine reciprocating engines with renewables and battery storage, offer a pathway to enhanced efficiency, reduced emissions, and greater grid stability. Opportunities also arise from the growing compatibility of engines with alternative and biofuels, including biogas and hydrogen, aligning with sustainability trends. The ongoing digitalization of power generation, encompassing remote monitoring, advanced analytics, and the integration of AI for predictive maintenance and operational optimization, presents a significant avenue for value creation. Furthermore, the expansion of oil and gas exploration activities, particularly in regions requiring localized power generation, continues to create demand for specialized reciprocating engines, providing a niche but impactful growth segment for manufacturers.

Segmentation Analysis

The Reciprocating Power Generating Engine Market is comprehensively segmented by various parameters, including fuel type, application, end-use, power output, and speed, to provide a granular understanding of market dynamics and cater to diverse industry needs. Each segment exhibits unique growth patterns and demand drivers, reflecting the broad utility and adaptability of these power generation solutions across different operational environments and economic contexts. This detailed segmentation enables market participants to identify lucrative niches, develop targeted product offerings, and formulate effective market entry and expansion strategies, ensuring tailored solutions for a wide range of customers.

- By Fuel Type

- Diesel

- Natural Gas

- Biogas

- Dual Fuel

- Gasoline

- By Application

- Power Generation

- Marine

- Oil & Gas

- Industrial

- Automotive

- Others (e.g., Agriculture, Construction)

- By End-Use

- Utilities

- Commercial

- Residential

- Data Centers

- Mining

- Manufacturing

- By Power Output

- Less than 1 MW

- 1 MW to 5 MW

- More than 5 MW

- By Speed

- Low Speed (less than 1000 rpm)

- Medium Speed (1000-1800 rpm)

- High Speed (greater than 1800 rpm)

Value Chain Analysis For Reciprocating Power Generating Engine Market

The value chain for the Reciprocating Power Generating Engine Market is a complex network, beginning with upstream activities focused on the sourcing and processing of raw materials and the manufacturing of intricate components. This phase involves suppliers of specialized metals like steel and aluminum, electronic components for control systems, and various other parts such as crankshafts, pistons, cylinder liners, and advanced fuel injection systems. Manufacturers often rely on a global network of specialized component providers, ensuring the quality and precision required for high-performance engines. Research and development activities also play a crucial upstream role in developing new engine designs, improving efficiency, and ensuring compliance with evolving emission standards.

Midstream activities involve the assembly of these components into complete engine units by original equipment manufacturers (OEMs). This stage often includes extensive testing, quality control, and customization to meet specific application requirements. Downstream activities focus on the distribution, sales, installation, and after-sales service of the engines. Distribution channels are varied, encompassing direct sales to large industrial customers and utilities, as well as extensive dealer networks that cater to smaller businesses and individual consumers. Third-party distributors and system integrators play a vital role in providing value-added services, such as packaging engines into complete power generation solutions or integrating them into complex energy systems. After-sales service, including maintenance, spare parts supply, and technical support, is a critical component of the downstream value chain, ensuring engine longevity and customer satisfaction.

The market employs both direct and indirect distribution channels. Direct sales are common for high-value, large-scale projects where OEMs engage directly with end-users like national utilities or major industrial clients, offering tailored solutions and direct technical support. Indirect channels, involving a network of authorized dealers, distributors, and value-added resellers, are essential for reaching a broader customer base, particularly in commercial and residential sectors. These indirect partners often provide localized sales, installation, and maintenance services, enhancing market penetration and customer accessibility. The efficiency and effectiveness of these distribution channels are paramount for market reach, customer relationship management, and ensuring timely delivery and support for critical power generation equipment.

Reciprocating Power Generating Engine Market Potential Customers

The potential customer base for the Reciprocating Power Generating Engine Market is exceptionally diverse, spanning a wide range of industries and sectors globally. These engines serve as essential power sources for various end-users or buyers who require reliable, flexible, and often independent electricity generation. A significant segment of customers includes utilities and independent power producers who utilize these engines for grid stability, peak shaving, and distributed generation, especially in areas with fluctuating energy demands or underdeveloped grid infrastructure. Their ability to quickly ramp up and down makes them ideal for balancing intermittent renewable energy sources.

Industrial facilities, such as manufacturing plants, mining operations, and construction sites, represent another major customer group. These sectors often require robust and continuous power for their heavy machinery and operational processes, making reciprocating engines critical for uninterrupted production and safety. The marine sector is a substantial consumer, employing these engines for propulsion in various vessels, from cargo ships and tankers to cruise liners, as well as for auxiliary power generation on board. Furthermore, the oil and gas industry relies heavily on these engines for powering drilling rigs, processing plants, and pipeline operations, particularly in remote and off-grid locations where a stable power supply is paramount.

Commercial and institutional end-users also form a vital part of the customer base. Data centers, hospitals, financial institutions, and large commercial buildings frequently invest in reciprocating engines for emergency backup power to ensure continuity of critical operations during grid outages. This demand is driven by the severe financial and operational consequences of power interruptions. Residential complexes and individual homeowners, particularly in regions prone to power cuts or those seeking energy independence, also represent a market for smaller generator sets. The versatility, reliability, and fuel flexibility of reciprocating power generating engines make them a preferred choice for a broad spectrum of buyers seeking resilient and efficient power solutions across multiple demanding applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 25.3 Billion |

| Market Forecast in 2032 | USD 37.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Caterpillar Inc., Cummins Inc., Wartsila Corporation, MAN Energy Solutions SE, Rolls-Royce Power Systems AG (MTU), Yanmar Holdings Co. Ltd., Mitsubishi Heavy Industries Ltd., Hyundai Heavy Industries Co. Ltd., Doosan Infracore Co. Ltd., Weichai Holding Group Co. Ltd., Kohler Co., Deutz AG, General Electric Co. (GE Power), John Deere (Deere & Company), Perkins Engines Company Limited, ABB Ltd. (for control systems), Innio Jenbacher GmbH & Co KG, Dresser-Rand (Siemens Energy), Himoinsa S.L., Atlas Copco AB |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Reciprocating Power Generating Engine Market Key Technology Landscape

The Reciprocating Power Generating Engine Market is characterized by continuous technological advancements aimed at improving efficiency, reducing emissions, and enhancing operational flexibility. A cornerstone of this landscape is the development of advanced combustion technologies, including lean-burn and pre-chamber designs, which optimize fuel-air mixture and ignition for more complete combustion and lower pollutant formation. Alongside this, sophisticated fuel injection systems, such as common rail direct injection for diesel and gas engines, ensure precise fuel delivery, leading to better fuel economy and reduced emissions. The drive for environmental sustainability has also spurred innovations in emission control technologies, including selective catalytic reduction (SCR) for NOx reduction, diesel particulate filters (DPF) for particulate matter, and exhaust gas recirculation (EGR) systems to meet increasingly stringent global regulatory standards.

Furthermore, engine management systems (EMS) or electronic control units (ECUs) have become central to modern reciprocating engines. These intelligent systems monitor and control various engine parameters in real-time, such as fuel injection timing, ignition, turbocharger boost, and exhaust gas treatment, to optimize performance, enhance reliability, and minimize fuel consumption under diverse operating conditions. The increasing digitalization of power generation assets has led to the widespread adoption of condition monitoring and remote diagnostics capabilities. These technologies utilize sensors and data analytics to track engine health, predict potential failures, and enable proactive maintenance, thereby reducing unplanned downtime and operational costs. Remote monitoring platforms allow operators to oversee engine performance from any location, facilitating efficient fleet management and rapid response to alerts.

Another significant technological trend is the growing capability for dual-fuel and multi-fuel operation, allowing engines to seamlessly switch between different fuel types, such as diesel and natural gas, or even incorporate biogas and hydrogen. This flexibility enhances energy security, reduces reliance on a single fuel source, and supports the transition towards cleaner energy mixes. The integration of advanced turbocharging, intercooling, and combined heat and power (CHP) or cogeneration systems further boosts overall system efficiency by recovering waste heat. The continuous evolution in material science for engine components also contributes to improved durability and extended service intervals, reinforcing the long-term economic viability and performance of reciprocating power generating engines in a dynamic energy landscape.

Regional Highlights

- North America: Characterized by a strong focus on natural gas engines due to abundant shale gas reserves and stringent environmental regulations. High demand for backup power in data centers, commercial facilities, and critical infrastructure. Emphasis on modernization and integration with smart grid technologies.

- Europe: Driven by strict emission standards and the push towards decarbonization. Significant adoption of combined heat and power (CHP) systems, often fueled by natural gas or biogas, supporting distributed generation. Focus on engine efficiency upgrades and hybrid solutions.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, urbanization, and burgeoning energy demand in countries like China, India, and Southeast Asian nations. Substantial investment in infrastructure development and increasing demand for both primary and backup power solutions across various sectors.

- Latin America: Growing market due to industrial expansion, infrastructure projects, and the need for energy security and grid stability in developing economies. Diesel and natural gas engines are vital for remote power generation and supporting mining and oil & gas operations.

- Middle East and Africa (MEA): Significant demand from the oil and gas sector for upstream and downstream operations, as well as for powering remote sites. Infrastructure development, urbanization, and efforts to expand electricity access drive market growth, particularly for robust and reliable power solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Reciprocating Power Generating Engine Market.- Caterpillar Inc.

- Cummins Inc.

- Wartsila Corporation

- MAN Energy Solutions SE

- Rolls-Royce Power Systems AG (MTU)

- Yanmar Holdings Co. Ltd.

- Mitsubishi Heavy Industries Ltd.

- Hyundai Heavy Industries Co. Ltd.

- Doosan Infracore Co. Ltd.

- Weichai Holding Group Co. Ltd.

- Kohler Co.

- Deutz AG

- General Electric Co. (GE Power)

- John Deere (Deere & Company)

- Perkins Engines Company Limited

- ABB Ltd. (for control systems and turbochargers)

- Innio Jenbacher GmbH & Co KG

- Dresser-Rand (Siemens Energy)

- Himoinsa S.L.

- Atlas Copco AB

Frequently Asked Questions

What are the primary applications of reciprocating power generating engines?

Reciprocating power generating engines are primarily used for grid power generation, standby and backup power, marine propulsion and auxiliary power, oil and gas operations, and various industrial applications requiring reliable and flexible electricity supply.

How do emission regulations impact the market for these engines?

Stringent emission regulations globally necessitate significant investment in advanced emission control technologies and encourage the shift towards cleaner fuels like natural gas and biogas, influencing engine design and operational costs for manufacturers and end-users.

What role do natural gas engines play in the current market?

Natural gas engines are playing an increasingly vital role, driven by abundant gas reserves, lower operational costs, and reduced emissions compared to diesel. They are widely adopted for distributed power generation, CHP applications, and as grid stability solutions.

How is digitalization influencing reciprocating engine technology?

Digitalization is transforming engine technology through advanced engine management systems, remote monitoring, predictive maintenance, and data analytics. This leads to improved efficiency, reduced downtime, optimized fuel consumption, and extended engine lifespan.

What are the key growth drivers for this market?

Key growth drivers include escalating global electricity demand, rapid industrialization and urbanization in emerging economies, the growing need for robust backup power solutions, and the expansion of distributed power generation infrastructure, particularly in remote areas.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager