Recombinant Protein Therapeutics CDMO Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428359 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Recombinant Protein Therapeutics CDMO Market Size

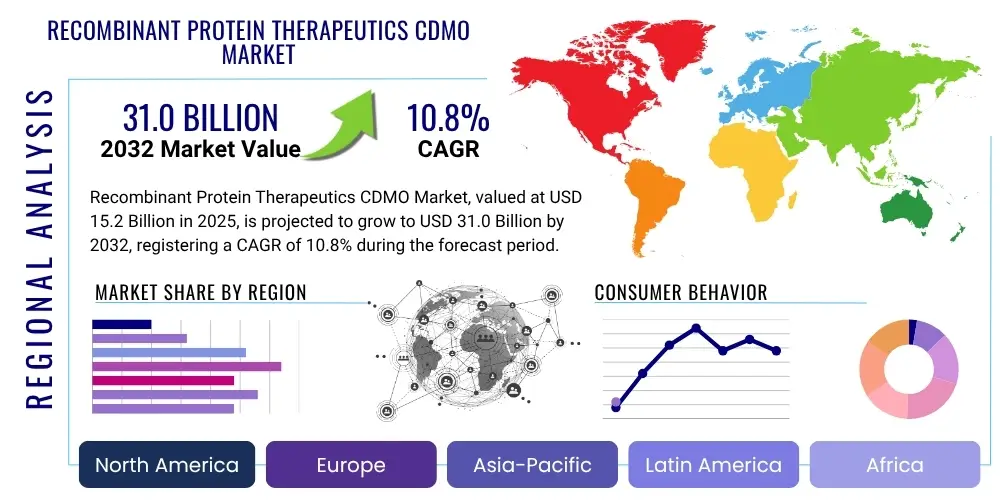

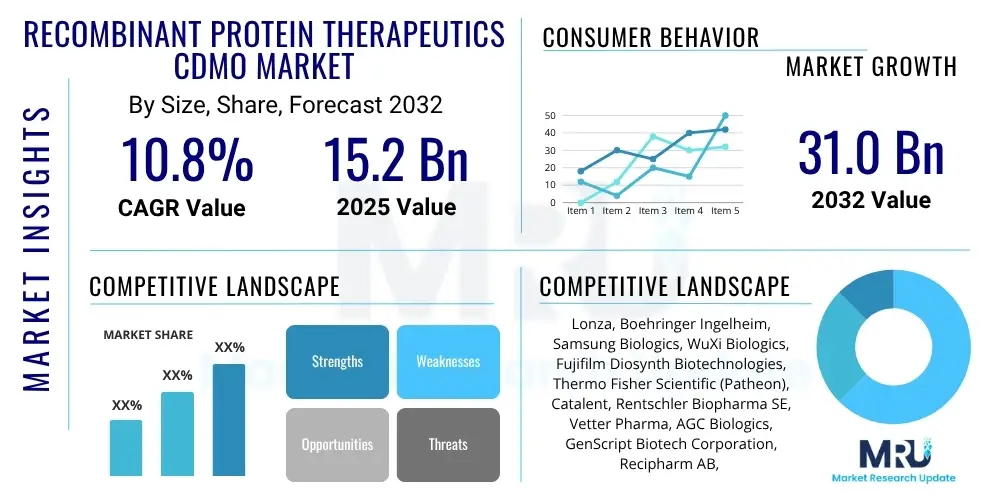

The Recombinant Protein Therapeutics CDMO Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.8% between 2025 and 2032. The market is estimated at USD 15.2 Billion in 2025 and is projected to reach USD 31.0 Billion by the end of the forecast period in 2032.

Recombinant Protein Therapeutics CDMO Market introduction

The Recombinant Protein Therapeutics Contract Development and Manufacturing Organization (CDMO) market encompasses specialized services offered by third-party organizations to biopharmaceutical companies for the development, manufacturing, and analytical testing of recombinant protein-based drugs. These therapeutic proteins, produced through genetic engineering, include a wide range of biological products such as monoclonal antibodies, vaccines, hormones, and enzymes, addressing various diseases like cancer, autoimmune disorders, and metabolic conditions. The product lifecycle typically involves cell line development, upstream and downstream processing, purification, and sterile fill and finish operations, all crucial for bringing complex biologics to market.

Major applications for recombinant protein therapeutics span across critical therapeutic areas, notably oncology, immunology, infectious diseases, and rare genetic disorders, where these advanced biologics offer targeted and often life-saving treatments. The benefits of leveraging CDMOs include access to specialized expertise, state-of-the-art facilities, advanced technologies, and a skilled workforce, all of which contribute to cost efficiencies, accelerated timelines, and reduced operational complexities for biopharma clients. This outsourcing model allows pharmaceutical companies, particularly small to mid-sized biotech firms, to focus on their core competencies like research and development, while entrusting the intricate manufacturing processes to experienced partners.

Key driving factors for the robust expansion of the Recombinant Protein Therapeutics CDMO Market include the rapidly expanding pipeline of biologic drugs, the increasing complexity of manufacturing advanced protein therapeutics, and the strategic imperative for biopharmaceutical companies to optimize their supply chains and reduce capital expenditure. Furthermore, the growing demand for personalized medicine and biosimilars, coupled with the rising prevalence of chronic diseases globally, continues to fuel investment in recombinant protein drug development. These dynamics collectively underscore the essential role of CDMOs in supporting the global biopharmaceutical industry's innovation and production needs.

Recombinant Protein Therapeutics CDMO Market Executive Summary

The Recombinant Protein Therapeutics CDMO Market is experiencing significant growth, driven by an escalating demand for complex biologics and a strategic shift towards outsourcing manufacturing processes by biopharmaceutical companies. Business trends indicate a focus on operational efficiency, technological advancement, and expansion of global manufacturing footprints, particularly through mergers, acquisitions, and strategic alliances to enhance service offerings and geographic reach. Companies are increasingly investing in single-use technologies, continuous manufacturing, and advanced analytical capabilities to meet stringent regulatory requirements and reduce time-to-market for novel therapies. This competitive landscape is characterized by both large, integrated CDMOs offering end-to-end solutions and specialized players focusing on niche areas like cell line development or fill-finish services.

Regionally, North America continues to dominate the market due to its robust biopharmaceutical industry, extensive R&D investments, and a supportive regulatory environment. Europe also holds a substantial market share, fueled by strong government funding for biotech research and a concentration of innovative biopharma companies. The Asia Pacific region is rapidly emerging as a high-growth market, driven by lower manufacturing costs, increasing government support for biotechnology, a growing pool of skilled labor, and expanding patient populations. Countries like China, India, and South Korea are becoming attractive hubs for CDMO operations, attracting significant foreign investment and fostering local capabilities. Latin America, the Middle East, and Africa represent nascent but promising markets, with increasing healthcare infrastructure development and growing interest in local drug production.

In terms of segments, monoclonal antibodies (mAbs) remain the leading product type driving CDMO demand, owing to their broad therapeutic applications and established clinical success. However, there is a burgeoning demand for CDMO services for recombinant vaccines, enzymes, and other complex protein formats, particularly with the rise of gene and cell therapies which often require recombinant proteins as critical components in their manufacturing processes. Service-wise, upstream and downstream processing, alongside analytical testing and fill-finish services, represent the largest segments, reflecting the critical need for specialized expertise in these areas. The trend towards integrated CDMO services that can manage a product from early-stage development through commercialization is also gaining traction, offering clients a streamlined and de-risked pathway to market.

AI Impact Analysis on Recombinant Protein Therapeutics CDMO Market

User questions regarding the impact of AI on the Recombinant Protein Therapeutics CDMO market often revolve around its potential to revolutionize drug discovery, optimize manufacturing processes, enhance quality control, and improve overall operational efficiency. Key themes include how AI can accelerate molecule design, predict protein folding, streamline bioprocess development, reduce costs, minimize human error, and ensure consistent product quality. Concerns frequently touch upon data privacy, the need for robust AI validation in regulated environments, integration challenges with legacy systems, and the evolving skill sets required for the workforce. Users also seek to understand AI's role in predictive maintenance, supply chain optimization, and accelerating regulatory submissions within the highly complex and regulated CDMO landscape, expecting tangible benefits in speed, cost, and quality.

- AI accelerates target identification and lead candidate selection in drug discovery.

- Predictive analytics optimize cell line development and fermentation parameters.

- Machine learning algorithms enhance bioprocess monitoring and control, reducing batch failures.

- Automated image analysis improves quality control and impurity detection.

- AI-driven data analysis identifies bottlenecks and optimizes downstream purification processes.

- Digital twins and simulations enable virtual process development and scale-up.

- Enhanced supply chain management through demand forecasting and logistics optimization.

- Faster development cycles for novel recombinant proteins and biosimilars.

- Improved intellectual property management and competitive intelligence.

- Facilitates personalized medicine by optimizing production for smaller, diverse batches.

DRO & Impact Forces Of Recombinant Protein Therapeutics CDMO Market

The Recombinant Protein Therapeutics CDMO Market is significantly shaped by a confluence of driving forces, inherent restraints, and emerging opportunities, all of which are subject to various impact forces. The primary drivers include the burgeoning global demand for biologics, particularly monoclonal antibodies and advanced protein therapies, which necessitate specialized manufacturing expertise and substantial capital investment often best managed by CDMOs. The increasing prevalence of chronic and infectious diseases fuels a continuous pipeline of new therapeutic proteins. Furthermore, the rising trend of outsourcing by biopharmaceutical companies, driven by cost-efficiency, access to cutting-edge technologies, and the desire to focus on core R&D, remains a powerful market accelerant. The complexity of recombinant protein manufacturing, requiring sophisticated infrastructure and skilled personnel, further solidifies the reliance on CDMO partners.

Despite robust growth, the market faces notable restraints. High upfront investment costs for facility expansion and advanced equipment can be prohibitive for some CDMOs, while stringent regulatory requirements from agencies like the FDA and EMA necessitate extensive compliance efforts, adding to both timelines and expenses. Concerns over intellectual property (IP) protection when outsourcing sensitive manufacturing processes can deter some biopharma clients. Additionally, capacity constraints within the CDMO landscape for specialized services, along with a shortage of highly skilled technical personnel, can create bottlenecks. The long development timelines and high failure rates associated with biologic drug development also introduce inherent risks for CDMOs, as projects can be terminated before reaching commercial scale.

Opportunities for growth are abundant and strategically important for the market's future trajectory. The increasing focus on personalized medicine and cell and gene therapies presents new avenues for CDMOs to provide recombinant protein components essential for these advanced modalities. Expansion into emerging markets, particularly in Asia Pacific, offers significant untapped potential for manufacturing and market access. The adoption of advanced manufacturing technologies, such as single-use bioreactors, continuous processing, and digitalization, provides opportunities for CDMOs to enhance efficiency, reduce costs, and improve flexibility. Furthermore, strategic alliances, collaborations, and M&A activities allow CDMOs to expand their service portfolios, geographical reach, and technological capabilities, thus solidifying their competitive advantage and addressing evolving client needs. These factors collectively define the dynamic environment in which the Recombinant Protein Therapeutics CDMO Market operates.

Segmentation Analysis

The Recombinant Protein Therapeutics CDMO market is comprehensively segmented to address the diverse needs of biopharmaceutical clients and reflect the specialized nature of biologic drug development and manufacturing. This segmentation allows for a detailed analysis of market dynamics, competitive landscapes, and growth opportunities across different product types, services offered, scales of operation, and therapeutic areas. Understanding these segments is crucial for CDMOs to strategically position their offerings and for biopharmaceutical companies to identify the most suitable partners for their specific drug development programs, ensuring optimal resource allocation and successful product commercialization. Each segment highlights distinct technical requirements, regulatory considerations, and market demands.

- Product Type:

- Monoclonal Antibodies (mAbs)

- Recombinant Enzymes

- Recombinant Hormones

- Recombinant Vaccines

- Fusion Proteins

- Other Recombinant Proteins

- Service:

- Cell Line Development

- Process Development (Upstream & Downstream)

- Analytical & Quality Control (QC) Testing

- Biomanufacturing (Clinical & Commercial Scale)

- Fill and Finish

- Formulation Development

- Regulatory Support

- Stability Studies

- Scale of Operation:

- Clinical Scale

- Commercial Scale

- Therapeutic Area:

- Oncology

- Autoimmune Diseases

- Infectious Diseases

- Metabolic Disorders

- Neurological Disorders

- Cardiovascular Diseases

- Rare Diseases

- Other Therapeutic Areas

- End User:

- Pharmaceutical & Biopharmaceutical Companies

- Academic & Research Institutes

Value Chain Analysis For Recombinant Protein Therapeutics CDMO Market

The value chain for the Recombinant Protein Therapeutics CDMO Market is intricate, involving multiple stages from initial research to patient delivery, with CDMOs playing a pivotal role in the manufacturing and development phases. At the upstream analysis stage, the chain begins with raw material suppliers providing cell culture media, reagents, single-use consumables, and specialized equipment crucial for cell line development and bioprocess initiation. Technology providers also sit upstream, offering innovative solutions for bioreactors, purification systems, and analytical instruments that CDMOs integrate into their service offerings. Effective relationships with these upstream suppliers are critical for ensuring quality, cost-effectiveness, and supply chain resilience, directly impacting the CDMO's ability to deliver high-quality therapeutic proteins.

The core of the value chain involves the CDMOs themselves, which undertake various critical processes including cell line engineering, process development (upstream and downstream), cGMP manufacturing at clinical and commercial scales, analytical characterization, and quality control. These activities transform raw materials into purified, functional recombinant proteins. Downstream analysis of the value chain typically involves finished product packaging, storage, and distribution. Logistics providers, wholesalers, and distributors play a key role in ensuring that the final therapeutic products reach hospitals, clinics, and pharmacies globally, maintaining cold chain integrity where necessary. Regulatory bodies are also a crucial part of the downstream process, as they oversee approvals and market access.

Distribution channels for recombinant protein therapeutics manufactured by CDMOs can be broadly categorized as direct and indirect. Direct channels involve biopharmaceutical companies utilizing CDMO services for their proprietary drugs, then managing the direct distribution of the finished product to healthcare providers or through their established sales networks. Indirect channels often involve CDMOs manufacturing for smaller biotech companies or virtual pharma firms that may not have their own extensive distribution infrastructure, potentially relying on larger pharmaceutical partners or specialized third-party logistics (3PL) providers to manage market access. Both models require stringent adherence to regulatory guidelines and quality standards throughout the entire supply chain to ensure product efficacy and patient safety.

Recombinant Protein Therapeutics CDMO Market Potential Customers

The primary potential customers and end-users of the Recombinant Protein Therapeutics CDMO Market are diverse, primarily consisting of biopharmaceutical companies ranging from emerging biotech startups to large, established pharmaceutical giants. Small and medium-sized biotechnology companies, often operating with limited in-house manufacturing capabilities and capital, represent a significant segment, relying on CDMOs for cost-effective access to advanced facilities, specialized expertise, and regulatory guidance to advance their drug candidates through clinical development and commercialization. These companies frequently outsource the entire manufacturing process to mitigate risks and accelerate time-to-market, enabling them to focus their resources on R&D and clinical trials.

Large pharmaceutical corporations also constitute a crucial customer base for CDMOs, despite often possessing their own extensive manufacturing infrastructure. These larger entities strategically engage CDMOs to manage capacity fluctuations, handle specialized or niche product manufacturing, access specific advanced technologies not available internally, or expand their global manufacturing footprint without significant capital investment. This approach allows them to de-risk new product launches, diversify their supply chain, and gain flexibility in response to market demands or unexpected events, such as global health crises requiring rapid vaccine or therapeutic production. The pursuit of biosimilars and next-generation biologics further drives their engagement with CDMOs.

Beyond traditional biopharma, other potential customers include academic research institutions, government organizations, and non-profit foundations involved in drug discovery and early-stage development, particularly for rare diseases or neglected tropical diseases. These entities often require specialized protein production services for research-grade materials or preclinical studies. Contract Research Organizations (CROs) may also partner with CDMOs to offer integrated development services to their clients. The overarching appeal for all these customer segments is the ability of CDMOs to provide scalable, compliant, and expert-driven solutions that reduce overall costs, accelerate development timelines, and ensure the high quality and safety required for therapeutic recombinant proteins.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.2 Billion |

| Market Forecast in 2032 | USD 31.0 Billion |

| Growth Rate | 10.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lonza, Boehringer Ingelheim, Samsung Biologics, WuXi Biologics, Fujifilm Diosynth Biotechnologies, Thermo Fisher Scientific (Patheon), Catalent, Rentschler Biopharma SE, Vetter Pharma, AGC Biologics, GenScript Biotech Corporation, Recipharm AB, IDT Biologika GmbH, ProBioGen AG, KBI Biopharma, Albany Molecular Research Inc. (AMRI), Avid Bioservices, BioNTech, Eurofins Scientific, Sino Biological Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Recombinant Protein Therapeutics CDMO Market Key Technology Landscape

The Recombinant Protein Therapeutics CDMO Market is profoundly influenced by a rapidly evolving technological landscape, as CDMOs continually invest in cutting-edge innovations to enhance efficiency, reduce costs, accelerate timelines, and meet the growing demand for complex biologics. Single-use systems, including disposable bioreactors, mixing bags, and purification columns, have become foundational, offering increased flexibility, faster changeovers between batches, reduced cross-contamination risks, and lower capital investment compared to traditional stainless-steel facilities. These systems are particularly advantageous for multi-product facilities and clinical-scale manufacturing, allowing CDMOs to respond swiftly to diverse client needs and accelerate drug development phases.

Another transformative technology is continuous manufacturing, which contrasts with traditional batch processing by operating non-stop, potentially leading to smaller footprints, higher productivity, and more consistent product quality. While still maturing for biologics, its adoption in downstream processing and for certain upstream applications is gaining traction, promising significant economic and operational advantages. Advanced analytical technologies, such as mass spectrometry, biosensors, and high-throughput screening platforms, are critical for comprehensive product characterization, impurity detection, and real-time process monitoring, ensuring compliance with stringent regulatory requirements and maintaining high product integrity throughout the manufacturing lifecycle.

Furthermore, the integration of automation, robotics, and digitalization through Industry 4.0 principles is reshaping CDMO operations. This includes sophisticated process control systems, digital twins for predictive modeling, and extensive data analytics platforms that optimize bioprocesses, enable predictive maintenance, and facilitate robust quality by design (QbD) approaches. The application of artificial intelligence and machine learning in areas like cell line development, media optimization, and yield prediction is also emerging, driving further improvements in efficiency and reducing the empirical trial-and-error often associated with biologic manufacturing. These technological advancements collectively empower CDMOs to deliver highly specialized and efficient services for the intricate production of recombinant protein therapeutics.

Regional Highlights

- North America: This region maintains its dominance in the Recombinant Protein Therapeutics CDMO Market, primarily driven by a robust biopharmaceutical industry, extensive R&D investments, and a well-established ecosystem of biotech companies. The presence of leading CDMOs, coupled with substantial funding for life sciences and a favorable regulatory environment, positions North America as a hub for both innovation and advanced manufacturing. The United States, in particular, leads in drug development and commercialization, fostering a strong demand for outsourcing complex biologic production.

- Europe: Europe represents a significant market share, characterized by a strong emphasis on biotechnology research, a concentrated base of innovative biopharmaceutical companies, and supportive government initiatives. Countries like Germany, Switzerland, and the United Kingdom are key players, boasting advanced manufacturing capabilities and a skilled workforce. The European Medicines Agency (EMA) provides a mature regulatory framework, further encouraging investment and expansion in the region's CDMO sector.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market, propelled by increasing healthcare expenditure, a rapidly expanding patient population, and a growing focus on developing local biomanufacturing capabilities. Countries such as China, India, South Korea, and Singapore are emerging as attractive destinations for CDMO investments due to competitive operational costs, government incentives, and a rising pool of scientific talent. This region is increasingly becoming a strategic manufacturing hub for global biopharma companies.

- Latin America: This region is an emerging market for the Recombinant Protein Therapeutics CDMO sector, showing steady growth driven by improving healthcare infrastructure and an increasing demand for access to advanced therapeutics. While still smaller than established markets, countries like Brazil and Mexico are witnessing increased interest from CDMOs and biopharma companies looking to establish a regional presence and cater to local market needs.

- Middle East and Africa (MEA): The MEA region is at an nascent stage but holds significant potential, with rising awareness of advanced healthcare solutions and growing government initiatives to diversify economies through investments in the pharmaceutical and biotechnology sectors. As local drug manufacturing capabilities expand and regulatory frameworks mature, CDMO opportunities are expected to grow, particularly in areas focusing on local supply for prevalent diseases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Recombinant Protein Therapeutics CDMO Market.- Lonza

- Boehringer Ingelheim

- Samsung Biologics

- WuXi Biologics

- Fujifilm Diosynth Biotechnologies

- Thermo Fisher Scientific (Patheon)

- Catalent

- Rentschler Biopharma SE

- Vetter Pharma

- AGC Biologics

- GenScript Biotech Corporation

- Recipharm AB

- IDT Biologika GmbH

- ProBioGen AG

- KBI Biopharma

- Albany Molecular Research Inc. (AMRI)

- Avid Bioservices

- BioNTech

- Eurofins Scientific

- Sino Biological Inc.

Frequently Asked Questions

What drives the growth of the Recombinant Protein Therapeutics CDMO market?

The market growth is primarily driven by the expanding pipeline of biologics, increasing demand for outsourced manufacturing, the complexity of protein therapeutics, and the strategic need for biopharmaceutical companies to reduce costs and accelerate time-to-market.

What are the key services offered by Recombinant Protein Therapeutics CDMOs?

Key services include cell line development, process development (upstream and downstream), cGMP manufacturing (clinical and commercial), analytical testing, fill-finish operations, formulation development, and comprehensive regulatory support.

How is AI impacting the Recombinant Protein Therapeutics CDMO market?

AI is impacting the market by accelerating drug discovery, optimizing manufacturing processes through predictive analytics, enhancing quality control, improving supply chain efficiency, and enabling virtual process development, leading to faster and more cost-effective production.

Which regions are leading the Recombinant Protein Therapeutics CDMO market?

North America currently leads the market due to its robust biopharmaceutical industry and high R&D investment, followed closely by Europe. The Asia Pacific region is rapidly emerging as the fastest-growing market, driven by favorable economic conditions and increasing biomanufacturing investments.

What are the main challenges faced by CDMOs in this market?

Key challenges include high capital expenditure for advanced technologies, stringent regulatory requirements, potential capacity constraints, concerns over intellectual property protection, and the need for a highly skilled workforce to manage complex biologic manufacturing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager