Reconstituted Wood Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429677 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Reconstituted Wood Market Size

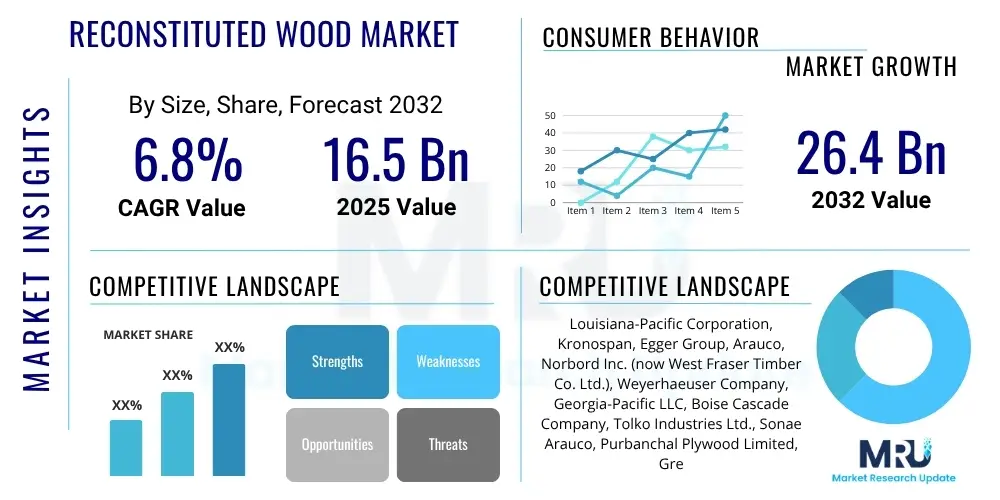

The Reconstituted Wood Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 16.5 Billion in 2025 and is projected to reach USD 26.4 Billion by the end of the forecast period in 2032.

Reconstituted Wood Market introduction

Reconstituted wood, often referred to as engineered wood or composite wood, is a manufactured product created by bonding together strands, particles, fibers, or veneers of wood with adhesives to form various composite materials. This process enhances the utilization of timber resources, often yielding products that surpass solid wood in terms of strength, dimensional stability, and resistance to warping. Key applications span the construction industry, including structural elements, flooring, and paneling, as well as extensive use in furniture manufacturing, cabinetry, and packaging. The primary benefits of reconstituted wood include its superior structural performance, environmental sustainability through efficient resource consumption, cost-effectiveness compared to traditional timber, and significant design flexibility. The market's growth is predominantly driven by the increasing global demand for sustainable building solutions, the expansion of the construction and furniture sectors, and continuous advancements in manufacturing technologies that improve product quality and expand application possibilities.

Reconstituted Wood Market Executive Summary

The reconstituted wood market is experiencing robust expansion, propelled by a global shift towards sustainable construction practices and ongoing innovations in material science. Key business trends include a heightened focus on developing eco-friendly adhesives, such as those with low formaldehyde emissions or bio-based formulations, and the introduction of high-performance products tailored for specific structural and aesthetic requirements across diverse applications. Regional dynamics indicate the Asia Pacific region as a dominant growth engine, fueled by rapid urbanization, significant infrastructure projects, and a burgeoning housing market, especially in countries like China and India. North America and Europe demonstrate steady demand, driven by renovation activities, green building initiatives, and a preference for advanced engineered wood solutions. From a segmentation perspective, product types like medium-density fiberboard (MDF) and plywood continue to hold substantial market shares, while oriented strand board (OSB) and laminated veneer lumber (LVL) are gaining traction due to their enhanced structural properties and cost-efficiency in various construction segments. This collective momentum signifies a market ripe with opportunities for innovation and strategic expansion.

AI Impact Analysis on Reconstituted Wood Market

Common inquiries regarding the influence of Artificial Intelligence (AI) on the reconstituted wood market frequently center on its potential to revolutionize operational efficiency, enhance product quality, optimize resource management, and foster innovation throughout the value chain. Users are particularly interested in how AI can contribute to predictive analytics for machinery maintenance, enabling proactive interventions that reduce downtime and improve production continuity. There is significant anticipation for AI-powered automated quality inspection systems that can detect defects with unprecedented precision, ensuring consistent product standards. Furthermore, stakeholders seek to understand AI's role in optimizing raw material utilization through advanced sorting and grading algorithms, minimizing waste, and maximizing yields. The integration of AI for supply chain optimization, from logistics and inventory forecasting to personalized product design, represents a key area of user expectation for driving both cost efficiencies and market responsiveness in the engineered wood sector.

- Optimized raw material grading and selection using computer vision and machine learning.

- Predictive maintenance for manufacturing equipment, reducing unexpected downtime and operational costs.

- Enhanced quality control through AI-driven automated defect detection and classification systems.

- Supply chain optimization, including demand forecasting, inventory management, and logistics routing.

- Development of smart manufacturing processes for improved energy efficiency and waste reduction.

- Customization and personalization of engineered wood products based on specific client requirements.

- Simulation and design optimization for new composite wood materials with enhanced properties.

- Data analytics for market trend identification and strategic business decision-making.

DRO & Impact Forces Of Reconstituted Wood Market

The reconstituted wood market is significantly shaped by a confluence of driving factors, restraints, and opportunities, all influenced by various impact forces. The primary drivers include the escalating global demand for sustainable and cost-effective building materials, alongside robust growth in residential and commercial construction activities and an increasing emphasis on green building practices. However, the market faces restraints such as the volatile pricing of raw timber and wood fibers, which can impact manufacturing costs and product affordability. Perceptions regarding the aesthetic and durability differences compared to solid wood, combined with regulatory concerns over formaldehyde emissions from certain adhesives, also pose challenges. Opportunities for growth are abundant, stemming from continuous technological advancements that yield stronger, more durable, and environmentally safer products, coupled with an expanding range of applications beyond traditional construction, particularly in furniture and interior design. Key impact forces include stringent environmental regulations promoting sustainable product development, global economic fluctuations affecting construction spending, and evolving consumer preferences favoring eco-friendly and high-performance materials.

Segmentation Analysis

The reconstituted wood market is comprehensively segmented to reflect the diverse nature of its products, applications, and end-users, providing a granular view of market dynamics. This segmentation helps in understanding specific demand patterns, technological preferences, and regional consumption trends. The market is primarily categorized by product type, which distinguishes between various engineered wood formats based on their manufacturing processes and structural characteristics. Further segmentation by application highlights the key industries and uses driving demand, while end-user segmentation identifies the primary consumer bases for these versatile materials, ranging from large-scale construction firms to individual consumers. This detailed breakdown facilitates targeted market strategies and product development efforts within the industry.

- By Product Type:

- Plywood

- Particleboard

- Medium-Density Fiberboard (MDF)

- Oriented Strand Board (OSB)

- Laminated Veneer Lumber (LVL)

- Glued Laminated Timber (Glulam)

- Cross-Laminated Timber (CLT)

- Others (e.g., hardboard, insulated panels)

- By Application:

- Construction

- Residential Construction

- Commercial Construction

- Industrial Construction

- Furniture Manufacturing

- Flooring

- Packaging

- Cabinetry

- Decorative Applications

- Other Industrial Uses

- Construction

- By End-User:

- Residential

- Commercial

- Industrial

Value Chain Analysis For Reconstituted Wood Market

The value chain for the reconstituted wood market encompasses a series of interconnected stages, beginning with upstream raw material sourcing and extending to downstream distribution and end-user consumption. Upstream activities are critical, involving sustainable forestry management, harvesting, and the procurement of various wood resources such as logs, wood chips, and recycled wood fiber, along with resins and other additives. These materials then proceed to manufacturing facilities for primary processing, where they are transformed into different types of engineered wood products through processes like drying, adhesive application, pressing, and finishing. Midstream operations often include further cutting, shaping, and specific treatment of panels and boards to meet application requirements. Downstream, the distribution network is complex, utilizing both direct sales channels to large construction companies, furniture manufacturers, and original equipment manufacturers (OEMs), as well as indirect channels through an extensive network of wholesalers, distributors, retailers, and building material suppliers to reach smaller contractors and individual consumers. The efficiency of these channels is crucial for market penetration and customer accessibility, with e-commerce platforms increasingly becoming a relevant direct-to-consumer avenue.

Reconstituted Wood Market Potential Customers

The potential customer base for reconstituted wood products is exceptionally broad and diverse, primarily centered within the construction, furniture, and packaging industries. In the construction sector, key buyers include residential homebuilders requiring durable and stable materials for framing, subflooring, wall sheathing, and roofing, alongside commercial developers utilizing engineered wood for structural components, interior finishes, and non-structural applications in offices, retail spaces, and institutional buildings. Industrial construction also represents a significant segment, especially for specialized structural elements. Furniture manufacturers are substantial consumers, leveraging the consistency, strength, and aesthetic versatility of products like MDF and particleboard for cabinetry, tables, chairs, and other furnishings. Furthermore, the packaging industry relies on reconstituted wood for manufacturing robust and cost-effective crates, pallets, and custom shipping solutions. Architects, interior designers, and DIY enthusiasts also form a growing segment of potential customers, valuing the sustainability, performance, and design flexibility offered by these engineered materials for various renovation and creative projects.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 16.5 Billion |

| Market Forecast in 2032 | USD 26.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Louisiana-Pacific Corporation, Kronospan, Egger Group, Arauco, Norbord Inc. (now West Fraser Timber Co. Ltd.), Weyerhaeuser Company, Georgia-Pacific LLC, Boise Cascade Company, Tolko Industries Ltd., Sonae Arauco, Purbanchal Plywood Limited, Greenply Industries Ltd., Century Plyboards (India) Ltd., Fantoni Spa, Masisa S.A., Unilin Group, Dongwha Group, Evergreen Fibreboard Berhad, West Fraser Timber Co. Ltd., Huber Engineered Woods LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Reconstituted Wood Market Key Technology Landscape

The reconstituted wood market is continuously evolving through significant technological advancements aimed at enhancing product performance, improving manufacturing efficiency, and addressing sustainability concerns. A critical area of innovation lies in advanced pressing technologies, including continuous presses and multi-opening platen presses, which ensure uniform density, strength, and reduced manufacturing cycles for various board types. The development of innovative adhesive systems is also paramount, with a strong industry shift towards formaldehyde-free, low-VOC (Volatile Organic Compound), and bio-based resins like soy-based or lignin-derived glues, driven by stricter environmental regulations and growing consumer demand for healthier indoor environments. Furthermore, automation and digitalization are transforming production lines; this includes the integration of IoT (Internet of Things) sensors for real-time monitoring of process parameters, robotic handling systems for increased precision, and AI-powered quality control systems for automated defect detection. Material science plays a key role in developing new composite formulations, incorporating alternative fibers, recycled plastics, or nanomaterials to create engineered wood products with enhanced properties such as superior fire resistance, improved moisture stability, and increased durability, thereby broadening their application scope.

Regional Highlights

- North America: This region demonstrates a mature and stable market, driven by a robust residential construction sector, significant renovation and remodeling activities, and an increasing embrace of green building standards. The United States and Canada are key contributors, with high demand for OSB and LVL in structural applications.

- Europe: Characterized by strong environmental regulations and a high awareness of sustainable materials, Europe represents a significant market. Countries such as Germany, France, and the UK lead in the consumption of MDF and particleboard for high-quality furniture and interior design applications.

- Asia Pacific (APAC): Positioned as the fastest-growing market globally, APAC's expansion is fueled by rapid urbanization, extensive infrastructure development projects, and a booming residential construction industry, particularly in emerging economies like China, India, and Southeast Asian nations. Plywood and MDF are highly consumed products in this region.

- Latin America: An emerging market with considerable growth potential, Latin America is seeing increased construction activities and a growing recognition of the benefits of engineered wood products. Brazil and Mexico are prominent countries contributing to the regional market share.

- Middle East and Africa (MEA): This region is a developing market, with growth primarily stemming from large-scale construction projects in the Gulf Cooperation Council (GCC) countries and a rising need for cost-effective and durable building materials across various African nations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Reconstituted Wood Market.- Louisiana-Pacific Corporation

- Kronospan

- Egger Group

- Arauco

- Norbord Inc. (now West Fraser Timber Co. Ltd.)

- Weyerhaeuser Company

- Georgia-Pacific LLC

- Boise Cascade Company

- Tolko Industries Ltd.

- Sonae Arauco

- Purbanchal Plywood Limited

- Greenply Industries Ltd.

- Century Plyboards (India) Ltd.

- Fantoni Spa

- Masisa S.A.

- Unilin Group

- Dongwha Group

- Evergreen Fibreboard Berhad

- West Fraser Timber Co. Ltd.

- Huber Engineered Woods LLC

Frequently Asked Questions

What is reconstituted wood?

Reconstituted wood, also known as engineered wood, is a product manufactured by binding together wood strands, particles, fibers, or veneers with adhesives to form composite materials, offering enhanced strength and stability.

Is reconstituted wood environmentally friendly?

Yes, it is often considered more sustainable than solid wood as it maximizes timber utilization, uses smaller or waste wood pieces, and can incorporate recycled content. Many manufacturers also use eco-friendly, low-VOC adhesives.

What are the main applications of reconstituted wood?

Its primary applications include residential and commercial construction (for structural components, flooring, and panels), furniture manufacturing, cabinetry, and packaging, due to its versatility and performance.

How does reconstituted wood compare to solid wood?

Reconstituted wood typically offers superior dimensional stability, greater consistency, and resistance to warping and splitting compared to solid wood. It can also be more cost-effective and allow for larger, more uniform panels.

What are the different types of reconstituted wood?

Key types include Plywood, Medium-Density Fiberboard (MDF), Particleboard, Oriented Strand Board (OSB), Laminated Veneer Lumber (LVL), Glued Laminated Timber (Glulam), and Cross-Laminated Timber (CLT, each with distinct properties and uses.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager