Recyclable Barrier Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430889 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Recyclable Barrier Packaging Market Size

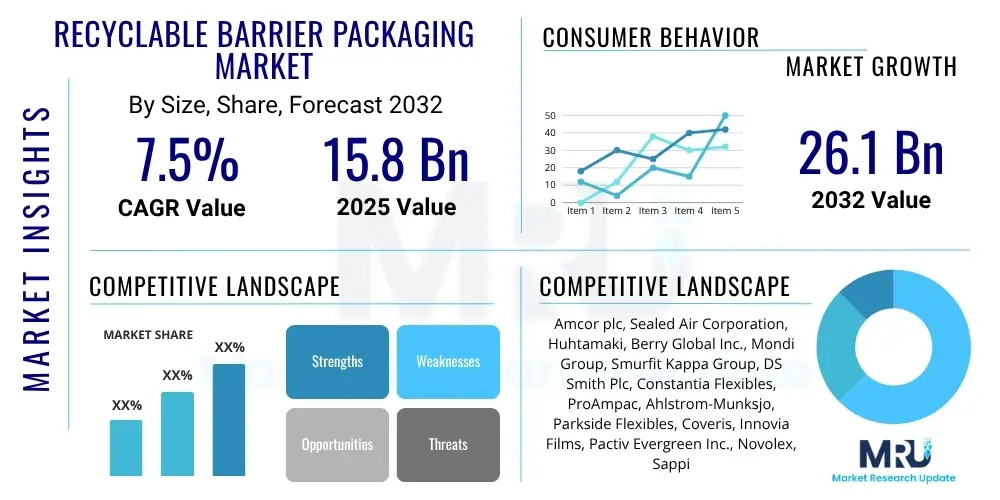

The Recyclable Barrier Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 15.8 Billion in 2025 and is projected to reach USD 26.1 Billion by the end of the forecast period in 2032.

Recyclable Barrier Packaging Market introduction

The Recyclable Barrier Packaging market is undergoing a transformative period of significant expansion, fundamentally driven by an increasingly urgent global imperative towards sustainable consumption and production practices. This specialized market segment encompasses a broad array of packaging solutions meticulously engineered to offer essential barrier properties, such as robust resistance to moisture, oxygen, and light ingress, which are critical for preserving product integrity and extending shelf life. Concurrently, a core design principle for these materials is their ability to be efficiently collected, sorted, and reprocessed into new raw materials or products at their end-of-life, thereby contributing directly to a circular economy model and mitigating environmental impact.

These innovative packaging products find indispensable applications across a multitude of sectors, prominently including the expansive food and beverage industry where maintaining freshness and safety is paramount, the highly regulated pharmaceutical sector demanding sterile and secure containment, the dynamic personal care market seeking enhanced brand perception, and various industrial applications requiring robust protection for sensitive goods. The overarching benefits derived from adopting recyclable barrier packaging include a dramatically reduced environmental footprint through decreased reliance on virgin plastics and lower landfill contributions, strict compliance with escalating global environmental regulations, substantial enhancement of corporate brand reputation through demonstrable sustainability commitments, and increased consumer appeal for eco-conscious products. Key driving forces accelerating the adoption and growth of this market encompass surging consumer demand for environmentally friendly options, increasingly stringent governmental mandates targeting plastic waste reduction, and continuous, groundbreaking advancements in material science and recycling technologies that collectively render high-performance recyclable solutions both feasible and economically viable on a larger scale.

Recyclable Barrier Packaging Market Executive Summary

The Recyclable Barrier Packaging market is currently defined by dynamic business trends heavily centered on pioneering innovation and strategic collaboration across the entire value chain, reflecting a concerted effort by industry players to meet evolving sustainability objectives. Companies are making substantial investments in extensive research and development initiatives aimed at producing next-generation monomaterial and bio-based barrier solutions, which promise to deliver comparable performance to traditional multi-layer structures while simplifying post-consumer recycling processes. Furthermore, there is a pronounced emphasis on establishing robust closed-loop systems, fostering synergistic partnerships with material suppliers, converters, and waste management entities, and integrating advanced manufacturing processes to enhance both the recyclability and overall performance of packaging products.

From a regional perspective, Europe and North America consistently lead in the market's adoption curve, largely propelled by highly developed and stringent regulatory frameworks such as the European Union's comprehensive Plastic Strategy, coupled with elevated levels of consumer environmental awareness that drive demand for sustainable options. These regions are witnessing significant investments in upgrading and expanding recycling infrastructure to accommodate new recyclable barrier formats. The Asia Pacific region is rapidly solidifying its position as a pivotal growth hub, stimulated by burgeoning industrial expansion, a swiftly growing middle class, and increasing governmental and corporate commitments to integrate sustainability into their operational blueprints. Segment-wise, the food and beverage sector continues its dominance as the largest application area, underscored by the critical necessity for extended shelf life and assured product safety, while the pharmaceutical segment is experiencing a notably accelerated growth trajectory as manufacturers increasingly seek sustainable yet highly protective packaging solutions for their sensitive and high-value medical products, demonstrating a broadening commitment to environmental responsibility across diverse industries.

AI Impact Analysis on Recyclable Barrier Packaging Market

Stakeholders and end-users frequently pose crucial questions concerning the potentially transformative influence of artificial intelligence in significantly enhancing both the efficiency and inherent sustainability of the recyclable barrier packaging sector. Common inquiries extensively probe AI's capacity to precisely optimize material selection processes to maximize recyclability, to dramatically improve sorting accuracy and throughput at sophisticated recycling facilities, to enable advanced predictive maintenance protocols for critical packaging machinery thereby minimizing operational downtime and waste, and to furnish sophisticated data analytics capabilities for meticulously tracking and reporting on comprehensive sustainability metrics across the entire packaging lifecycle. The overwhelming consensus and collective sentiment among market participants strongly indicate an anticipation that AI technologies will assume a critically pivotal role in effectively overcoming existing industry challenges, ultimately culminating in the development and widespread adoption of more intelligent, profoundly resource-efficient, and genuinely circular packaging solutions that contribute significantly to environmental preservation.

- AI-driven algorithms for optimizing material formulations, enabling the development of advanced monomaterials with superior barrier properties and inherent recyclability.

- Significant improvement in the accuracy and operational speed of automated waste sorting and recycling processes through the integration of sophisticated computer vision and machine learning models, enhancing the capture rate of valuable materials.

- Implementation of predictive maintenance protocols for critical packaging equipment, which substantially reduces unexpected manufacturing downtime, minimizes material waste during production runs, and optimizes operational efficiency.

- Enhanced supply chain visibility, rigorous traceability of recyclable materials, and improved inventory management facilitated by integrated AI and blockchain technologies, ensuring transparency and accountability.

- Advanced product design and virtual simulation capabilities leveraging AI, allowing for rapid prototyping and optimization of packaging structures for maximal recyclability, material reduction, and performance efficacy before physical production.

- Deployment of sophisticated analytics platforms powered by AI to meticulously assess the environmental impact and track key sustainability performance indicators (KPIs) across the entire packaging lifecycle, from raw material extraction to end-of-life management, enabling data-driven decision making.

- Development of smart packaging solutions embedded with AI-enabled sensors for real-time monitoring of product conditions and shelf life, which can also provide data on packaging integrity and post-consumer recycling information.

DRO & Impact Forces Of Recyclable Barrier Packaging Market

The Recyclable Barrier Packaging market is profoundly shaped by a dynamic and intricate interplay of various drivers, inherent restraints, emerging opportunities, and pervasive impact forces, which collectively dictate its growth trajectory and evolutionary path. Foremost among the primary drivers is the escalating global demand for demonstrably sustainable packaging solutions, largely fueled by an increasingly environmentally conscious consumer base and the relentless imposition of stringent governmental regulations specifically designed to mitigate plastic waste, curtail greenhouse gas emissions, and aggressively promote circularity within the economy. Furthermore, the pervasive desire among brand owners to substantially enhance their corporate social responsibility profile, align with evolving ESG (Environmental, Social, and Governance) investment criteria, and achieve ambitious internal sustainability targets acts as a particularly potent catalyst for market expansion. These multifarious forces converge to compel industries across diverse sectors to proactively embrace and adopt more eco-friendly packaging alternatives, thereby necessitating substantial investment in sophisticated recyclable barrier technologies and related infrastructure.

Conversely, the market confronts several formidable restraints that impede its unchecked growth and widespread adoption. These include the significantly high initial costs frequently associated with intensive research and development efforts required to engineer novel, high-performance recyclable materials that can truly rival the protective capabilities of traditional, difficult-to-recycle laminates. Additionally, there is often a substantial capital expenditure burden associated with upgrading or entirely reconfiguring existing packaging lines and manufacturing processes to accommodate these new material specifications. The inherent technical complexity of achieving truly effective barrier properties using simplified monomaterial structures or designing multi-layer components that are genuinely easy to separate for recycling presents ongoing engineering challenges. Compounding these issues, the often-limited, fragmented, or inadequately developed recycling infrastructure prevalent in numerous regions globally further restricts the widespread efficacy of recyclable barrier solutions. Despite these significant hurdles, the market is rife with substantial opportunities, particularly in the pioneering development of novel bio-based and compostable barrier materials that offer alternatives to conventional plastics, the continuous advancement of innovative chemical recycling technologies capable of breaking down mixed plastic waste into its molecular building blocks, and the strategic expansion into untapped emerging markets where environmental awareness is rapidly accelerating. The overarching impact forces predominantly emanate from continually evolving environmental policies and international agreements, the relentless pace of technological innovation in material science and waste management, and fundamental, dynamic shifts in consumer purchasing preferences which increasingly gravitate towards demonstrably sustainable and ethically produced products.

Segmentation Analysis

The Recyclable Barrier Packaging market is meticulously segmented to offer a granular and comprehensive understanding of its diverse components, a process crucial for facilitating highly targeted strategic planning, precise market analysis, and informed business development. This detailed segmentation typically involves dissecting the market across several critical dimensions, including the specific material types utilized, the various packaging formats employed, the distinct application areas served, and the broad range of end-use industries that procure these solutions. Analyzing each of these differentiated segments individually and in conjunction with others is instrumental in identifying key growth hotspots, deciphering the competitive landscape, and accurately forecasting future trends and demand shifts within the industry. Such an approach enables stakeholders to grasp the nuanced dynamics influencing market evolution.

Each defined segment within the recyclable barrier packaging market presents a unique set of challenges, opportunities, and growth drivers that are significantly influenced by a confluence of factors. These factors include ongoing technological advancements in polymer science and coating formulations, the evolving landscape of regulatory mandates and sustainability targets, and the fluctuating demands and preferences of end-consumers. For instance, the food and beverage segment often prioritizes shelf-life extension and cost-effectiveness, while the pharmaceutical sector places paramount importance on product safety, tamper evidence, and stringent regulatory compliance. Understanding these specific segment characteristics allows manufacturers to tailor their product offerings, adapt their innovation strategies, and target their marketing efforts more effectively, thereby navigating the complexities of the market with greater precision and maximizing their potential for success in an increasingly competitive and sustainability-focused environment.

- By Material Type:

- Polyethylene (PE): Dominant due to its versatility, excellent barrier properties, and increasing recyclability in monomaterial formats.

- Polypropylene (PP): Valued for its stiffness, heat resistance, and growing use in recyclable rigid and flexible barrier applications.

- Paper and Paperboard: Gaining traction with advanced barrier coatings, offering renewable and widely recyclable options.

- Bioplastics (PLA, PHA, PBS): Emerging as sustainable alternatives derived from renewable resources, with varying barrier and compostability profiles.

- EVOH (Ethylene Vinyl Alcohol): A high-performance oxygen barrier often used in co-extruded films, with ongoing efforts to integrate into recyclable structures.

- Aluminum Foil: Offers superior barrier properties but faces recyclability challenges in mixed-material laminates; focus on separability.

- Other Advanced Materials: Includes specialized silicon oxide (SiOx) or aluminum oxide (AlOx) coatings, high-barrier nylons, and innovative multi-layer film delamination technologies designed for improved recyclability.

- By Packaging Type:

- Flexible Packaging: Includes pouches, stand-up bags, flow wraps, and films, widely used for food, beverages, and personal care due to cost-effectiveness and material efficiency.

- Rigid Packaging: Encompasses bottles, jars, trays, and containers, primarily found in dairy, beverages, and pharmaceuticals, offering robust product protection.

- Others: Includes cartons, tubes, and specialty packaging formats that are increasingly adopting recyclable barrier solutions.

- By Application:

- Food & Beverages: The largest segment, covering dairy products, fresh meat, processed foods, snacks, confectionary, and various beverages, where barrier properties are critical for preservation.

- Pharmaceuticals: Essential for protecting sensitive drugs, medical devices, and other healthcare products from moisture, oxygen, and contamination.

- Personal Care & Cosmetics: Used for bottles, tubes, and sachets of creams, lotions, and beauty products, balancing aesthetic appeal with protection and sustainability.

- Industrial: Packaging for chemicals, automotive parts, construction materials, and electronics, requiring robust barrier performance for safety and integrity.

- Others: Includes home care products, agriculture, and various consumer goods where product protection and environmental considerations are important.

- By End-Use Industry:

- Food Industry: Manufacturers of packaged foods, ingredients, and fresh produce.

- Beverage Industry: Producers of soft drinks, juices, water, and alcoholic beverages.

- Pharmaceutical Industry: Drug manufacturers, medical device companies, and healthcare providers.

- Personal Care Industry: Cosmetic brands, personal hygiene product manufacturers.

- Chemical Industry: Manufacturers of industrial and specialty chemicals.

- Other Industries: Companies in agriculture, electronics, and consumer durables seeking sustainable packaging.

Value Chain Analysis For Recyclable Barrier Packaging Market

The value chain for the Recyclable Barrier Packaging market is a complex ecosystem that commences with the upstream activities centered on the meticulous sourcing, innovative research, and industrial-scale production of fundamental raw materials. This initial stage involves a diverse range of suppliers providing various grades of polymers such as polyethylene (PE) and polypropylene (PP), sustainably sourced paper and paperboard, advanced bioplastics including PLA and PHA, and specialized high-performance barrier coatings like EVOH, silicon oxide (SiOx), or aluminum oxide (AlOx). These material suppliers play an absolutely critical role in pioneering innovation, ensuring consistent quality, and developing next-generation recyclable base materials that are specifically engineered to meet the increasingly stringent performance requirements for effective barrier functionality and eventual end-of-life recyclability. Significant research and development efforts at this foundational stage are intensively focused on enhancing intrinsic material properties for both superior barrier performance and improved ease of recycling, frequently exploring novel monomaterial solutions or sophisticated, yet easily separable, laminate structures.

Moving further along the value chain, these refined raw materials are then processed by a specialized segment of converters and packaging manufacturers. These entities possess the advanced technological capabilities and operational expertise to transform the base materials into a vast array of flexible and rigid packaging formats, including films, pouches, bottles, trays, and containers. This critical mid-stream stage involves substantial investment in state-of-the-art machinery and precision manufacturing processes to accurately apply intricate barrier coatings, construct multi-layer structures designed for delamination or monomaterial recycling, and stringently ensure the overall recyclability and compliance of the final packaging product. The downstream segment of the value chain is primarily composed of brand owners and retailers, representing the ultimate procurers and users of these innovative packaging solutions for their diverse product portfolios. These powerful stakeholders exert considerable influence on demand, specification requirements, and sustainability mandates, often dictating the pace of innovation within the upstream and midstream segments. Distribution channels for recyclable barrier packaging are typically segmented; large-scale brand owners often engage in direct procurement relationships with packaging manufacturers, while smaller businesses or specific regional markets are frequently served through a network of specialized distributors and brokers, ensuring broad market access. Seamless collaboration and transparent communication across all stages of this intricate value chain are absolutely vital for the successful widespread adoption, continuous improvement, and long-term triumph of recyclable barrier packaging solutions in a globally competitive and environmentally conscious marketplace.

Recyclable Barrier Packaging Market Potential Customers

The primary potential customers and end-users for sophisticated recyclable barrier packaging solutions encompass an extensive and diverse array of industries, each of which places paramount importance on rigorous product preservation, uncompromising safety standards, and robust environmental stewardship. At the forefront, the expansive food and beverage sector represents an undeniably significant customer base, including manufacturers of high-volume dairy products, fresh and processed meats, a wide assortment of snack foods, delectable confectionaries, and various beverage categories. All these entities critically require packaging that not only reliably extends product shelf life and robustly protects against spoilage and contamination but also consistently meets the escalating consumer and regulatory demands for sustainability. These companies are in constant pursuit of cutting-edge packaging innovations that harmoniously align with burgeoning consumer preferences for eco-friendly options, without ever compromising on essential food safety protocols, sensory quality, or the visual appeal of their products.

Beyond food and beverage, the highly regulated pharmaceutical industry constitutes another profoundly critical segment of potential customers, characterized by an absolute necessity for high-barrier packaging to meticulously protect sensitive drugs, intricate medical devices, and other healthcare products. Such packaging is indispensable for maintaining sterility, ensuring efficacy, and guaranteeing patient safety, particularly amidst increasing global pressure on pharmaceutical manufacturers to integrate sustainable practices into their complex supply chains and product life cycles. Furthermore, manufacturers within the personal care and cosmetics sectors, alongside companies operating in the industrial and chemical goods sectors, represent substantial and growing potential customer segments. These diverse entities are progressively concentrating their strategic efforts on significantly reducing their overall environmental footprint, enhancing their brand image through tangible sustainability initiatives, and rigorously complying with an ever-evolving landscape of global regulations pertaining to packaging waste. Consequently, recyclable barrier packaging has emerged as an indispensable and strategically vital component of their overarching product development and market positioning strategies, underscoring its broad applicability and increasing relevance across the modern industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.8 Billion |

| Market Forecast in 2032 | USD 26.1 Billion |

| Growth Rate | CAGR of 7.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor plc, Sealed Air Corporation, Huhtamaki, Berry Global Inc., Mondi Group, Smurfit Kappa Group, DS Smith Plc, Constantia Flexibles, ProAmpac, Ahlstrom-Munksjo, Parkside Flexibles, Coveris, Innovia Films, Pactiv Evergreen Inc., Novolex, Sappi Limited, AptarGroup Inc., Winpak Ltd., Plastipak Holdings Inc., Taghleef Industries (Ti) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Recyclable Barrier Packaging Market Key Technology Landscape

The technological landscape within the Recyclable Barrier Packaging market is dynamically characterized by an intense and rapid pace of innovation, with a singular overarching objective: to achieve advanced, high-performance barrier properties without compromising the fundamental principle of full recyclability. A paramount focus within this evolving landscape is the pioneering development of sophisticated monomaterial solutions, predominantly leveraging enhanced grades of polyethylene (PE) or polypropylene (PP) that possess intrinsically superior barrier capabilities. This includes the application of cutting-edge co-extrusion techniques and the engineering of specialized film structures that are designed to provide exemplary protection against oxygen and moisture permeation, while simultaneously simplifying the post-consumer recycling stream. This approach represents a significant departure from traditional multi-material laminates, which are notoriously difficult to separate into their constituent components and consequently challenging to recycle efficiently. The continuous evolution and widespread adoption of these single-polymer solutions are critically important for successfully meeting the ambitious objectives of a truly circular economy, as they enable far easier sorting, collection, and reprocessing within existing and developing recycling infrastructures globally.

Another profoundly significant area of technological advancement in this market centers on the development and application of highly sophisticated coating technologies. These innovations encompass advanced barrier coatings based on inorganic compounds such as silicon oxide (SiOx) or aluminum oxide (AlOx), as well as novel organic formulations, which impart high-performance barrier characteristics when meticulously applied to inherently recyclable substrates like paper, paperboard, or monomaterial plastic films. Furthermore, the sustained development of bio-based and compostable polymers endowed with inherent barrier properties, including polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), is rapidly gaining substantial traction, offering promising alternative sustainable solutions that can reduce reliance on fossil-based plastics. The emergence and refinement of advanced chemical recycling processes, which possess the transformative ability to depolymerize or break down complex plastic waste into its foundational molecular components for subsequent reuse in the synthesis of new, high-quality plastics, represent a truly pivotal technology. These processes are uniquely positioned to address many of the inherent limitations of conventional mechanical recycling, thereby enabling the valorization and recovery of complex barrier materials that were historically deemed unrecyclable. Additionally, digital watermarking, RFID tags, and other advanced identification technologies are progressively being integrated into packaging designs to significantly improve post-consumer sorting efficiency and the economic valorization of these increasingly sophisticated packaging types, ensuring higher yields of recyclable materials.

Regional Highlights

- North America: This region consistently demonstrates robust growth in the recyclable barrier packaging market, primarily attributable to an escalating consumer awareness regarding environmental sustainability and a discernible shift in purchasing preferences towards eco-friendly products. Furthermore, significant impetus is provided by increasing pressure from proactive regulatory bodies and the ambitious sustainability initiatives championed by numerous leading corporations. Both the United States and Canada are at the forefront, actively investing in and adopting advanced recycling technologies, fostering innovative material science, and strategically transitioning towards more sustainable packaging materials across various industries.

- Europe: Universally recognized as a global vanguard in the domain of sustainable packaging, Europe's market growth is powerfully propelled by a suite of ambitious and legally binding regulatory frameworks, most notably the European Union's comprehensive Circular Economy Action Plan and the implementation of plastic packaging taxes designed to incentivize recycling. Pioneering countries such as Germany, France, and the United Kingdom are leading extensive research and development efforts, driving innovations in high-performance monomaterial and bio-based barrier solutions, and aggressively pushing for the achievement of significantly higher recycling rates through improved infrastructure and consumer engagement.

- Asia Pacific (APAC): Positioned as the fastest-growing region within the recyclable barrier packaging market, APAC's expansion is dynamically fueled by rapid industrialization, the substantial growth of its burgeoning consumer markets, and a swiftly expanding middle class that is becoming increasingly environmentally conscious. While the development of comprehensive recycling infrastructure remains a work in progress in many parts of the region, economic powerhouses like China, India, and Japan are making profound and strategic investments in cutting-edge sustainable packaging technologies and enacting progressively stricter environmental policies, signifying a strong commitment to future growth in this sector.

- Latin America: This region is concurrently experiencing a significant surge in environmental awareness among its populace and the progressive implementation of novel governmental regulations specifically targeting plastic waste reduction, particularly evident in major economies such as Brazil and Mexico. This growing legislative and public pressure acts as a crucial driver for the increasing demand for recyclable barrier packaging solutions across diverse consumer goods sectors. However, the market's full potential is often tempered by variable economic conditions and the persistent challenges associated with developing robust and widespread recycling infrastructure across the region.

- Middle East and Africa (MEA): Representing an emerging and still relatively nascent market for recyclable barrier packaging, the MEA region is nevertheless showing growing interest in sustainable packaging solutions. While the market size is currently smaller compared to more developed regions, there is an increasing governmental and corporate focus on economic diversification, the modernization of industrial practices, and a concerted effort to improve environmental standards. This concentrated focus is anticipated to significantly boost the adoption of recyclable barrier packaging in the forthcoming years, as awareness grows and infrastructure develops.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Recyclable Barrier Packaging Market.- Amcor plc

- Sealed Air Corporation

- Huhtamaki

- Berry Global Inc.

- Mondi Group

- Smurfit Kappa Group

- DS Smith Plc

- Constantia Flexibles

- ProAmpac

- Ahlstrom-Munksjo

- Parkside Flexibles

- Coveris

- Innovia Films

- Pactiv Evergreen Inc.

- Novolex

- Sappi Limited

- AptarGroup Inc.

- Winpak Ltd.

- Plastipak Holdings Inc.

- Taghleef Industries (Ti)

Frequently Asked Questions

What precisely constitutes recyclable barrier packaging and why is it essential?

Recyclable barrier packaging refers to advanced packaging materials meticulously engineered to provide critical protective properties against external elements like oxygen, moisture, and light, thereby extending product shelf life, while simultaneously ensuring these materials can be effectively collected, sorted, and reprocessed into new products after their initial use. It is essential because it reconciles the dual imperatives of product preservation and environmental sustainability, significantly reducing landfill waste and reliance on virgin resources.

What are the primary drivers fueling the growth of the recyclable barrier packaging market?

The market's growth is predominantly driven by escalating global consumer demand for sustainable products, the implementation of increasingly stringent governmental regulations aimed at reducing plastic waste, robust corporate sustainability initiatives by brand owners, and continuous technological advancements in material science that enable the development of high-performance, recyclable solutions.

What key material types are commonly utilized in recyclable barrier packaging solutions?

Common materials include advanced monomaterials such as enhanced polyethylene (PE) and polypropylene (PP) films, paper and paperboard substrates integrated with specialized barrier coatings, emerging bioplastics like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), and high-performance barrier compounds such as EVOH or silicon oxide (SiOx) applied in a recyclable manner.

Which major industries are the primary consumers of recyclable barrier packaging?

The leading consumers are the Food and Beverages industry, requiring extensive shelf life and freshness preservation; the Pharmaceutical sector, demanding stringent protection for sensitive medical products; and the Personal Care and diverse Industrial sectors, driven by sustainability commitments, regulatory compliance, and enhanced brand image.

What are the principal challenges encountered in the widespread adoption of recyclable barrier packaging?

Key challenges include the substantial research and development costs associated with engineering novel high-barrier, recyclable materials, the technical complexity of achieving effective protection with simplified structures, the often-fragmented or insufficient global recycling infrastructure, and the necessity to ensure consistent consumer acceptance and proper sorting practices for effective circularity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager