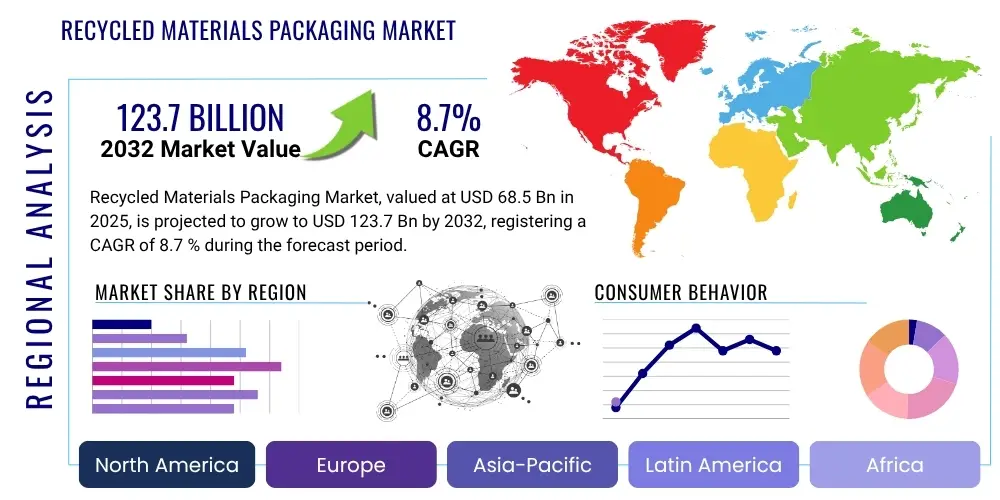

Recycled Materials Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427924 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Recycled Materials Packaging Market Size

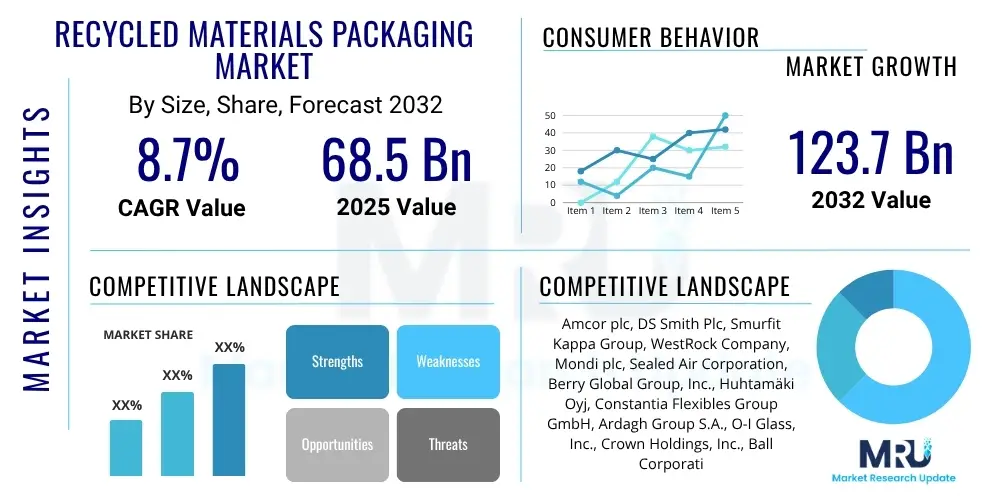

The Recycled Materials Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2025 and 2032. The market is estimated at USD 68.5 billion in 2025 and is projected to reach USD 123.7 billion by the end of the forecast period in 2032.

Recycled Materials Packaging Market introduction

The Recycled Materials Packaging Market encompasses the design, production, and distribution of packaging solutions that utilize materials derived from post-consumer or post-industrial waste streams. This market is a critical component of the circular economy, aiming to reduce reliance on virgin resources, minimize waste generation, and decrease environmental impact. Products range from rigid and flexible packaging made from recycled plastics, glass, and metal, to paper and paperboard products incorporating recycled fibers. The focus is on sustainability, resource efficiency, and meeting evolving consumer and regulatory demands for environmentally responsible products.

Major applications for recycled materials packaging span a broad spectrum of industries, including food and beverages, personal care and cosmetics, pharmaceuticals, consumer goods, and industrial packaging. Within the food and beverage sector, recycled PET (rPET) and recycled glass are extensively used for bottles and containers, while recycled paperboard is prevalent in dry food packaging and cartons. In personal care and cosmetics, brands increasingly adopt rHDPE and rPP for bottles, jars, and tubes. The pharmaceutical sector, driven by stringent safety regulations, is also exploring recycled content for secondary and tertiary packaging.

The benefits of recycled materials packaging are multifaceted, including significant reductions in greenhouse gas emissions, energy consumption, and water usage compared to manufacturing with virgin materials. It also helps divert waste from landfills and oceans, contributing to cleaner environments. Key driving factors for market growth include escalating consumer awareness regarding environmental issues, stringent governmental regulations promoting recycling and recycled content mandates, corporate sustainability commitments, and technological advancements in recycling and packaging design that enhance functionality and aesthetic appeal of recycled materials.

Recycled Materials Packaging Market Executive Summary

The Recycled Materials Packaging Market is experiencing robust growth, primarily propelled by global sustainability initiatives, evolving consumer preferences for eco-friendly products, and increasing regulatory pressure on industries to adopt circular practices. Business trends indicate a significant shift among brand owners towards incorporating higher percentages of recycled content into their packaging portfolios, often driven by public perception and ambitious corporate environmental, social, and governance (ESG) goals. Strategic partnerships between recyclers, packaging manufacturers, and brand owners are becoming more common, aiming to close the loop on material flows and secure stable supplies of high-quality recycled resins and fibers. Investment in advanced recycling technologies, such as chemical recycling, is also gaining momentum to address hard-to-recycle plastics and expand the range of materials suitable for high-value packaging applications. This collaborative ecosystem is fostering innovation in packaging design for recyclability and enhancing the overall efficiency of collection and sorting infrastructure.

Regional trends highlight distinct growth patterns and policy environments. Europe, with its advanced regulatory framework like the European Green Deal and specific targets for recycled content in packaging, leads in adoption rates and technological innovation. North America is also witnessing substantial growth, influenced by consumer demand and state-level legislative actions, alongside significant investments in recycling infrastructure. The Asia Pacific region presents a vast growth opportunity, driven by burgeoning economies, rising environmental consciousness, and increasing commitments from multinational corporations operating within the region. Latin America and the Middle East & Africa are emerging markets, with growing awareness and nascent regulatory frameworks beginning to stimulate demand, particularly in urban centers and for export-oriented industries. Each region faces unique challenges and opportunities related to waste collection systems, recycling capacities, and consumer education.

Segmentation trends reveal diverse dynamics across material types and applications. Recycled plastics, particularly rPET, rHDPE, and rPP, dominate the market due to their versatility and established recycling streams, with continuous innovation focusing on food-grade applications and lightweighting. Recycled paper and paperboard continue to be foundational, especially in e-commerce and dry goods packaging, benefiting from high collection rates. Recycled glass and metal, while having higher energy requirements for recycling, offer infinite recyclability and maintain strong market positions in beverages and preserved foods. The food and beverage sector remains the largest application segment, but personal care, pharmaceuticals, and consumer goods are rapidly increasing their adoption of recycled packaging, driven by brand image and consumer expectations. The market is also seeing a rise in hybrid solutions and multi-material packaging designed for enhanced recyclability.

AI Impact Analysis on Recycled Materials Packaging Market

User questions surrounding AI's impact on the Recycled Materials Packaging Market often revolve around its potential to revolutionize waste sorting, optimize recycling processes, enhance packaging design, and improve supply chain efficiency. Key themes include how AI can address contamination issues in waste streams, whether it can make recycling economically more viable, and its role in accelerating the development of new, more sustainable packaging materials. Concerns are typically linked to the initial investment costs, data privacy, and the need for skilled labor to manage AI-driven systems. Users are also keen to understand if AI can provide a measurable reduction in carbon footprint and genuinely enable a more circular packaging economy. Expectations are high for AI to provide intelligent solutions for complex challenges in material recovery and sustainable packaging development.

Artificial intelligence is poised to fundamentally transform various facets of the recycled materials packaging market, from upstream waste management to downstream packaging design and supply chain optimization. In waste sorting and recycling facilities, AI-powered optical sorters and robotics can accurately identify and separate different types of materials, including various plastic polymers, metals, and glass, with unprecedented speed and precision. This reduces contamination rates significantly, leading to higher quality recycled feedstocks that are more valuable and suitable for high-grade packaging applications, including food-grade materials. Such advancements not only increase recycling yields but also improve the economic viability of recycling operations by decreasing manual labor requirements and enhancing material purity.

Furthermore, AI is instrumental in optimizing the entire lifecycle of packaging. In the design phase, generative AI can assist engineers in creating packaging designs that are inherently more sustainable, using less material, maximizing recycled content, and ensuring ease of recyclability. It can simulate material performance and predict end-of-life characteristics, guiding choices towards mono-materials or easy-to-separate composites. Within the supply chain, AI-driven analytics can forecast demand for recycled content, optimize logistics for waste collection and material transport, and identify bottlenecks in the recycling infrastructure. This leads to more efficient resource allocation, reduced transportation emissions, and a more robust and resilient supply chain for recycled packaging materials, ultimately accelerating the transition towards a truly circular packaging economy.

- Enhanced Waste Sorting Accuracy: AI-powered vision systems and robotics dramatically improve the identification and separation of diverse materials in recycling facilities, reducing contamination and increasing the purity of recycled streams.

- Optimized Material Recovery: Predictive analytics from AI can identify optimal collection routes and processing parameters, maximizing the quantity and quality of materials recovered from waste streams.

- Intelligent Packaging Design: Generative AI assists in developing packaging designs that are lighter, use maximum recycled content, and are inherently designed for recyclability or compostability, based on material properties and end-of-life considerations.

- Supply Chain Efficiency: AI algorithms optimize logistics for sourcing, transport, and inventory management of recycled materials, reducing operational costs and carbon footprint across the supply chain.

- Quality Control and Traceability: AI can monitor the quality of recycled materials throughout the production process, ensuring compliance with standards and enabling better traceability from waste to new packaging.

- Predictive Maintenance for Recycling Equipment: AI-driven sensors and analytics predict equipment failures, allowing for proactive maintenance that minimizes downtime and improves operational continuity in recycling plants.

- Market Demand Forecasting: AI analyzes market trends, consumer preferences, and regulatory changes to accurately forecast demand for various types of recycled packaging, helping manufacturers plan production effectively.

DRO & Impact Forces Of Recycled Materials Packaging Market

The Recycled Materials Packaging Market is significantly shaped by a confluence of drivers, restraints, and opportunities, alongside various impact forces that influence its trajectory. Key drivers include stringent environmental regulations mandating recycled content and extended producer responsibility (EPR) schemes, alongside growing consumer demand for sustainable and eco-friendly products. Corporate sustainability commitments and the pursuit of circular economy models by major brands also strongly propel market expansion. Restraints predominantly involve the variability in quality and supply of recycled feedstocks, which can be inconsistent due to diverse collection and sorting infrastructures globally. High initial capital investments for advanced recycling technologies, the complexity of recycling certain multi-material packaging formats, and the energy intensity of some recycling processes also pose challenges. Opportunities, however, abound in technological advancements like chemical recycling for plastics, innovations in design for recyclability, and the expansion of collection and sorting infrastructure in developing economies. The overarching impact forces include increasing global awareness of plastic pollution, climate change concerns, and resource depletion, all of which push industries towards more sustainable practices, making recycled packaging an imperative.

Drivers like governmental policies, such as the European Union's Plastic Strategy, which sets ambitious targets for recycled content in packaging, act as a significant catalyst. Similarly, various countries are implementing plastic taxes or levies on virgin plastics, thereby making recycled alternatives more economically attractive. Consumer sentiment, increasingly influenced by environmental activism and a desire for brands aligned with their values, is compelling companies to visibly adopt recycled content. Furthermore, the drive for corporate responsibility and the adoption of ESG reporting standards are pushing companies to set and meet ambitious sustainability targets, with packaging often being a primary focus area due to its visibility and environmental footprint. The desire to enhance brand image and comply with international sustainability certifications further strengthens the adoption of recycled packaging solutions.

Conversely, the market faces significant hurdles. The supply chain for recycled materials can be complex and volatile, impacted by fluctuating commodity prices and regional disparities in waste collection efficiency. Achieving consistent food-grade quality for recycled plastics, for instance, requires sophisticated and costly purification processes. The lack of standardized collection and sorting systems across different regions leads to inefficiencies and higher contamination rates, limiting the availability of high-quality recycled feedstock. Additionally, the development and scaling of advanced recycling technologies, while promising, require substantial R&D investment and face technical challenges in processing complex waste streams. The "greenwashing" concern and the need for clear communication to consumers about recycled content also present a challenge in maintaining market credibility. Despite these challenges, the overwhelming societal and environmental pressure to transition away from linear economies ensures continued innovation and investment in the recycled materials packaging sector.

Segmentation Analysis

The Recycled Materials Packaging Market is extensively segmented by various attributes, providing a detailed understanding of its diverse landscape. Key segmentation categories include material type, which differentiates between recycled plastics, paper and paperboard, glass, and metal, each with unique properties, applications, and recycling infrastructures. Further breakdown by packaging type distinguishes between rigid packaging (bottles, trays, jars) and flexible packaging (films, pouches, bags), reflecting different manufacturing processes and end-use requirements. Application-based segmentation highlights the primary industries consuming recycled packaging, such as food & beverage, personal care & cosmetics, pharmaceuticals, consumer goods, and industrial sectors. Each segment exhibits distinct growth drivers, technological advancements, and regulatory considerations, influencing market dynamics and strategic decisions for stakeholders across the value chain. This granular analysis helps identify high-growth areas and specific market needs.

- By Material:

- Recycled Plastics:

- rPET (Recycled Polyethylene Terephthalate)

- rHDPE (Recycled High-Density Polyethylene)

- rPP (Recycled Polypropylene)

- rLDPE (Recycled Low-Density Polyethylene)

- Other Recycled Plastics (e.g., rPS, rPVC, rPLA)

- Recycled Paper & Paperboard:

- Corrugated Board

- Folding Cartons

- Kraft Paper

- Specialty Paperboard

- Recycled Glass:

- Clear Glass (Flint)

- Amber Glass

- Green Glass

- Recycled Metal:

- Aluminum (Cans, Foils)

- Steel (Cans, Drums)

- Other Recycled Materials (e.g., textiles in composite packaging)

- Recycled Plastics:

- By Packaging Type:

- Rigid Packaging:

- Bottles & Jars

- Containers & Tubs

- Trays & Clamshells

- Drums & Barrels

- Flexible Packaging:

- Films & Wraps

- Pouches & Bags

- Sachets & Strips

- Rigid Packaging:

- By Application:

- Food & Beverages:

- Dairy Products

- Meat, Poultry & Seafood

- Baked Goods & Confectionery

- Fruits & Vegetables

- Beverages (Soft Drinks, Water, Alcohol)

- Personal Care & Cosmetics:

- Skincare

- Haircare

- Cosmetics

- Pharmaceuticals & Healthcare:

- Primary Packaging (limited)

- Secondary & Tertiary Packaging

- Consumer Goods:

- Electronics

- Home Care Products

- Apparel & Accessories

- Industrial Packaging:

- Shipping & Logistics

- Construction Materials

- E-commerce Packaging

- Food & Beverages:

- By End-Use Industry:

- FMCG (Fast-Moving Consumer Goods)

- Retail & E-commerce

- Foodservice

- Healthcare

- Industrial Manufacturing

- Automotive

Value Chain Analysis For Recycled Materials Packaging Market

The value chain for the Recycled Materials Packaging Market is a complex and interconnected network, commencing with upstream activities focused on the collection and processing of post-consumer and post-industrial waste. This initial stage involves waste management companies, municipalities, and material recovery facilities (MRFs) that collect, sort, and process discarded materials such as plastics, paper, glass, and metal. The efficiency and sophistication of these upstream operations directly impact the quality and quantity of secondary raw materials available for packaging production. Technological advancements in sorting, cleaning, and chemical recycling are critical at this stage to transform heterogeneous waste streams into valuable, standardized feedstocks, minimizing contamination and maximizing material recovery rates. Investment in collection infrastructure, consumer education on recycling practices, and regulatory support for waste segregation are vital for strengthening the upstream segment.

Moving downstream, the processed recycled materials are supplied to packaging manufacturers. This involves an array of producers, from those specializing in plastic converters (e.g., film extruders, blow molders, injection molders) to paper mills, glass manufacturers, and metal can producers. These manufacturers transform the recycled resins, cullet, fibers, or scrap metal into new packaging formats, such as bottles, trays, cartons, and films. Product development and innovation are key here, focusing on maintaining the performance characteristics of virgin materials while maximizing recycled content, ensuring food-grade safety where necessary, and designing for eventual recyclability or compostability. Packaging design agencies and material science companies also play a crucial role in developing novel solutions that integrate sustainability with functionality and aesthetic appeal, catering to the specific needs of brand owners and end-users.

The distribution channels for recycled materials packaging are diverse, including both direct and indirect routes. Direct sales typically involve large-scale packaging manufacturers supplying directly to major brand owners and consumer goods companies that require customized packaging solutions in high volumes. This allows for closer collaboration, faster feedback loops, and tailored product development. Indirect channels, on the other hand, involve distributors, wholesalers, and packaging brokers who provide a broader range of recycled packaging options to smaller businesses or companies with less specific or lower volume requirements. E-commerce platforms are also emerging as significant indirect channels, offering a wide array of standardized recycled packaging products. The interplay between these channels ensures market accessibility and efficient delivery of recycled packaging solutions to a vast array of end-users across various industries, ultimately supporting the wider adoption of sustainable packaging practices.

Recycled Materials Packaging Market Potential Customers

The potential customers for the Recycled Materials Packaging Market are diverse and span across nearly all sectors that utilize packaging for their products, driven by an increasing imperative for sustainability and adherence to environmental regulations. Fast-Moving Consumer Goods (FMCG) companies represent a colossal customer base, encompassing global giants in food and beverage, personal care, home care, and over-the-counter pharmaceuticals. These companies are under immense pressure from consumers, investors, and regulators to reduce their environmental footprint and enhance brand image through visible sustainability efforts, making recycled content in packaging a strategic priority. Their large production volumes translate into significant demand for consistent, high-quality recycled materials that can perform on par with virgin alternatives, particularly for primary packaging applications requiring direct product contact and extended shelf life.

Beyond FMCG, the retail and e-commerce sectors are rapidly emerging as key consumers of recycled packaging. Retailers are increasingly implementing private label packaging initiatives that feature recycled content, aligning with their corporate sustainability goals and catering to eco-conscious shoppers. E-commerce companies, dealing with massive volumes of shipping and delivery packaging, are actively seeking lightweight, protective, and sustainable solutions made from recycled paperboard, plastics, and compostable materials to minimize waste generated from online purchases. The logistical advantages of lightweight recycled packaging, combined with the positive brand perception it generates, further solidify their position as crucial customers. The need for efficient, protective, and environmentally sound secondary and tertiary packaging solutions is paramount for these sectors.

Furthermore, industries such as pharmaceuticals and healthcare, although slower to adopt due to stringent regulatory requirements regarding material purity and product safety, are gradually expanding their use of recycled materials in secondary and tertiary packaging. Automotive components and industrial goods manufacturers are also integrating recycled plastics and metals for robust, durable, and environmentally responsible transit and protective packaging. Even the building and construction sector is beginning to explore applications for recycled content in packaging for their materials. Essentially, any business that uses packaging in its operations, from small businesses to multinational corporations, represents a potential customer, with the demand being most pronounced in sectors with high consumer visibility and strong sustainability commitments, all seeking to reduce their environmental impact while maintaining product integrity and market appeal.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 68.5 Billion |

| Market Forecast in 2032 | USD 123.7 Billion |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor plc, DS Smith Plc, Smurfit Kappa Group, WestRock Company, Mondi plc, Sealed Air Corporation, Berry Global Group, Inc., Huhtamäki Oyj, Constantia Flexibles Group GmbH, Ardagh Group S.A., O-I Glass, Inc., Crown Holdings, Inc., Ball Corporation, Greif, Inc., International Paper, UPM-Kymmene Corporation, Sonoco Products Company, Graphic Packaging International, BillerudKorsnäs AB, Pactiv Evergreen Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Recycled Materials Packaging Market Key Technology Landscape

The technology landscape for the Recycled Materials Packaging Market is characterized by continuous innovation aimed at improving the efficiency, quality, and versatility of recycled materials. A primary focus is on advanced mechanical recycling technologies, which involve sorting, washing, shredding, and melting plastic waste to reprocess it into pellets suitable for new packaging. Innovations in this area include enhanced optical sorting systems using near-infrared (NIR) and hyperspectral imaging to identify various plastic types and colors with greater accuracy, significantly reducing contamination. Flotation and density separation techniques are also continuously refined to further purify plastic flakes, ensuring a higher quality input for extrusion and molding processes, crucial for achieving food-grade recycled plastics and maintaining material properties comparable to virgin resins.

Beyond mechanical methods, chemical recycling technologies are rapidly gaining prominence as a transformative solution, particularly for hard-to-recycle or mixed plastic waste streams that mechanical recycling struggles with. These processes, such as pyrolysis, gasification, and depolymerization, break down plastic polymers into their molecular building blocks (monomers or oils), which can then be used to produce new, virgin-quality plastics. This allows for infinite recycling loops for certain polymers like PET and polystyrene and addresses the challenge of multi-layer or heavily contaminated plastics. While still in scaling phases, chemical recycling holds immense potential to unlock significant volumes of currently unrecyclable waste, expanding the feedstock pool for high-value packaging applications and contributing to true circularity.

Furthermore, technology advancements extend to packaging design and manufacturing processes. Digital printing technologies enable more efficient production of customized recycled packaging with reduced material waste and faster turnaround times. Innovations in barrier coatings and film technologies are crucial for incorporating recycled content into flexible packaging, ensuring product protection and shelf life without compromising recyclability. Smart packaging solutions, incorporating QR codes or RFID tags, are also improving traceability of materials and enabling better consumer engagement in recycling efforts. The integration of artificial intelligence and machine learning across the value chain, from waste collection optimization to quality control in manufacturing, is further enhancing the overall efficiency and effectiveness of the recycled materials packaging ecosystem, driving the market towards more sustainable and economically viable solutions.

Regional Highlights

- North America: This region is witnessing significant growth driven by increasing consumer awareness, corporate sustainability mandates from major brands, and evolving state-level regulations promoting recycled content. The US and Canada are investing in advanced recycling infrastructure, particularly for plastics, and exploring innovative collection schemes. Demand is strong across food & beverage, personal care, and e-commerce segments.

- Europe: A global leader in recycled materials packaging, Europe benefits from robust regulatory frameworks like the EU Packaging and Packaging Waste Directive and the European Green Deal, setting ambitious targets for recycled content and waste reduction. Countries such as Germany, the UK, France, and the Netherlands boast advanced collection and sorting systems and are at the forefront of chemical recycling research and implementation. High consumer awareness and a strong circular economy focus drive continuous innovation.

- Asia Pacific (APAC): The APAC region represents the largest and fastest-growing market due to rapid industrialization, burgeoning middle-class populations, and increasing environmental concerns. While facing challenges in waste management infrastructure, countries like China, India, Japan, and Australia are making significant strides in adopting recycled packaging. Multinational corporations operating here are importing sustainability practices, and local governments are starting to implement policies to reduce plastic waste and promote recycling.

- Latin America: This region is an emerging market for recycled materials packaging, with Brazil and Mexico leading the adoption. Growth is primarily spurred by rising environmental consciousness among urban consumers, increasing export demands for sustainable products, and initial regulatory efforts to address plastic pollution. Investment in collection and recycling infrastructure is gradually increasing, albeit from a lower base, with a focus on plastics and glass.

- Middle East and Africa (MEA): The MEA market is still nascent but shows promising growth, particularly in the GCC countries and South Africa. Drivers include government initiatives to diversify economies away from fossil fuels, significant investments in sustainable development, and a growing recognition of the economic value of waste. While infrastructure remains a challenge in many parts of Africa, regional collaborations and partnerships are aiming to improve waste collection and recycling capabilities, with a focus on high-volume consumer goods packaging.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Recycled Materials Packaging Market.- Amcor plc

- DS Smith Plc

- Smurfit Kappa Group

- WestRock Company

- Mondi plc

- Sealed Air Corporation

- Berry Global Group, Inc.

- Huhtamäki Oyj

- Constantia Flexibles Group GmbH

- Ardagh Group S.A.

- O-I Glass, Inc.

- Crown Holdings, Inc.

- Ball Corporation

- Greif, Inc.

- International Paper

- UPM-Kymmene Corporation

- Sonoco Products Company

- Graphic Packaging International

- BillerudKorsnäs AB

- Pactiv Evergreen Inc.

Frequently Asked Questions

Analyze common user questions about the Recycled Materials Packaging market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Recycled Materials Packaging?

Recycled materials packaging refers to packaging solutions manufactured using materials recovered from waste streams, such as post-consumer or post-industrial plastics, paper, glass, or metals. This process aims to reduce the consumption of virgin resources, minimize landfill waste, and lower the environmental impact associated with new material production, contributing to a circular economy model. It encompasses a wide range of packaging types, from bottles and containers to cartons and films, across various industries.

What are the primary benefits of using recycled packaging?

The primary benefits include a significant reduction in environmental footprint, such as decreased greenhouse gas emissions, lower energy consumption, and reduced water usage compared to producing packaging from virgin materials. It also diverts waste from landfills and oceans, supports circular economy principles, and enhances a brand's sustainability credentials, appealing to environmentally conscious consumers and meeting regulatory requirements. Additionally, it helps conserve finite natural resources by keeping materials in circulation for longer.

What challenges does the Recycled Materials Packaging Market face?

Key challenges include ensuring consistent quality and sufficient supply of recycled feedstocks, as collection and sorting infrastructure varies widely by region. High initial capital investment is often required for advanced recycling technologies, and the complexity of recycling certain multi-material packaging formats remains a hurdle. Contamination issues in waste streams and fluctuating market prices for recycled materials can also impact economic viability, alongside the need for robust regulatory frameworks and consumer education.

How is AI impacting the Recycled Materials Packaging Market?

AI is profoundly impacting the market by enhancing waste sorting accuracy through intelligent vision systems and robotics, leading to higher quality recycled materials. It optimizes material recovery and logistics in the recycling supply chain, reducing operational costs and environmental impact. Furthermore, AI assists in designing more sustainable packaging, predicting material performance, and enabling better quality control and traceability of recycled content, thereby accelerating the transition to a more circular economy.

Which regions are leading in the adoption of recycled packaging?

Europe is a leader, driven by stringent regulations and advanced recycling infrastructure, notably in Germany and the UK. North America is also showing strong growth due to corporate sustainability commitments and rising consumer demand, with increasing investment in recycling technologies. The Asia Pacific region is the largest and fastest-growing market due to rapid industrialization and growing environmental awareness, with countries like Japan and China making significant strides, while Latin America and MEA are emerging with developing infrastructure and policy support.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager