Refinery Electrification Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428636 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Refinery Electrification Market Size

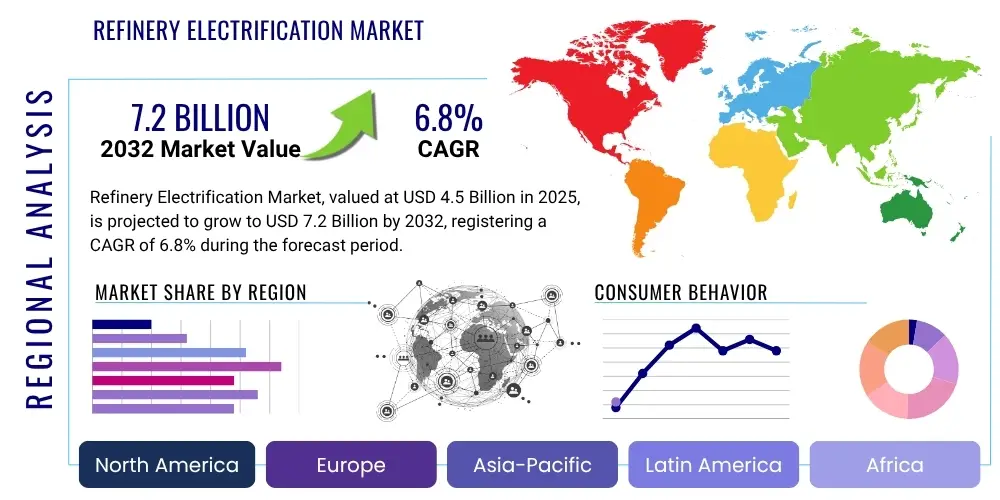

The Refinery Electrification Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 4.5 billion in 2025 and is projected to reach USD 7.2 billion by the end of the forecast period in 2032.

Refinery Electrification Market introduction

The Refinery Electrification Market represents a transformative evolution within the global oil and gas refining sector, characterized by a strategic shift towards leveraging electricity as the primary energy vector, thereby progressively displacing traditional fossil fuel-fired equipment. This fundamental transition involves the comprehensive integration of advanced electrical infrastructure, smart grid technologies, and highly efficient electric process equipment across diverse refinery operations, from crude distillation to hydrocracking. The core product offering in this dynamic market encompasses high-efficiency electric motors and variable frequency drives (VFDs), sophisticated power distribution systems, integrated energy storage solutions, and robust control and automation platforms. These technologies are meticulously engineered to operate reliably and safely within the demanding conditions of modern refineries, ensuring optimal performance while aligning with ambitious global decarbonization agendas and paving the way for a more sustainable and digitally integrated industrial landscape. This monumental shift is pivotal for achieving climate goals and enhancing long-term operational resilience, marking a new era of industrial energy management and environmental stewardship for the entire refining value chain.

Major applications of refinery electrification span critical processes from crude distillation and catalytic cracking to hydrotreating and various utility systems such as pumps, fans, and cooling towers. By replacing traditional steam turbines and gas-fired equipment with electric alternatives, refineries achieve substantial improvements in energy conversion efficiency, minimizing heat losses and enhancing overall system performance. The primary benefits derived from embracing electrification are multifaceted and impactful across operational and environmental dimensions. These include a significant reduction in greenhouse gas emissions, contributing directly to corporate sustainability targets and national climate goals. Furthermore, electrification often leads to considerable operating cost savings through optimized energy consumption, reduced fuel purchasing, and lower maintenance requirements for electric machinery. It also offers enhanced operational flexibility and precise process control, which can improve product quality and yield. This modernization moreover bolsters plant reliability and safety through advanced digital control systems and predictive maintenance capabilities, ensuring a resilient and secure operational footprint for the long term.

Key driving factors propelling the Refinery Electrification Market include the unequivocal global imperative to decarbonize industrial sectors, reinforced by international agreements and national policies that mandate stringent emissions reductions. The escalating volatility and increasing costs associated with fossil fuels render grid electricity, particularly when derived from clean and renewable sources, an increasingly attractive and stable energy alternative for industrial processes. Significant advancements in electric motor technology, power electronics, and sophisticated smart grid solutions have made the technical and economic viability of electrifying even the most complex refinery operations a tangible reality. Moreover, growing corporate commitments to sustainability, coupled with mounting pressure from investors, consumers, and regulatory bodies for environmentally responsible business practices, are compelling refinery operators to invest substantially in electrification technologies. This investment is viewed as crucial for improving their Environmental, Social, and Governance (ESG) performance, securing future operational licenses, and maintaining a competitive edge in a rapidly transforming global energy landscape, thus fostering a proactive approach towards energy transition.

Refinery Electrification Market Executive Summary

The Refinery Electrification Market is experiencing robust and accelerated growth, fundamentally reshaped by global imperatives for decarbonization, continuous technological advancements, and a persistent drive for operational excellence. Current business trends highlight a decisive pivot towards the integration of renewable energy sources directly into refinery operations, fostering greater energy independence and reducing reliance on traditional fossil fuels for internal consumption. This is complemented by significant investments in modernizing and expanding electrical infrastructure to support higher power demands and enhance grid stability, alongside the widespread adoption of digitalization strategies, including advanced energy management systems and smart grid solutions, which are critical for optimizing energy utilization and improving overall operational efficiency. From a regional perspective, mature markets such as Europe and North America currently lead the market in adoption rates, propelled by established regulatory frameworks and ambitious climate targets, fostering substantial investment in both greenfield and brownfield projects. Concurrently, the Asia Pacific region is emerging as a critical growth engine, characterized by the construction of new refining capacities and a burgeoning emphasis on sustainable industrial development. Segment-wise, the market observes substantial demand for high-efficiency electric motors and advanced power distribution components, with an increasing focus on integrated solutions that combine power conversion, energy storage, and intelligent control systems. This strategic alignment across business, regional, and segmental trends underscores a transformative period for the refining industry, steering it towards a more electrified, efficient, and environmentally responsible operational future. The market is further characterized by a strong push for strategic collaborations between traditional industrial players and innovative technology providers, aiming to synergize expertise and accelerate the pace of decarbonization.

AI Impact Analysis on Refinery Electrification Market

Common user inquiries and industry discussions regarding the impact of Artificial Intelligence (AI) on the Refinery Electrification Market predominantly focus on AI's capacity to revolutionize operational efficiency, enhance energy management, and accelerate decarbonization efforts. Stakeholders are particularly interested in how AI algorithms can optimize complex energy consumption patterns, perform predictive maintenance on sophisticated electrical equipment, and facilitate the seamless integration of intermittent renewable energy sources into refinery grids without compromising stability or safety. Key concerns often revolve around the substantial capital investment required for AI implementation, the complexity of integrating advanced AI solutions with legacy refinery infrastructure, and the critical need for robust cybersecurity measures to protect highly interconnected digital systems. Additionally, the development of a specialized workforce with expertise in both refining processes and AI technologies is a frequently raised challenge. However, expectations are high that AI will deliver significant breakthroughs, including substantial reductions in energy costs through intelligent optimization, minimized downtime via proactive anomaly detection, and the enablement of more autonomous, safer, and environmentally compliant refinery operations. These capabilities are anticipated to be pivotal in transforming electrified refineries into highly efficient, resilient, and sustainable industrial assets.

- AI optimizes real-time energy consumption, balancing demand with supply for electrified processes to reduce costs.

- AI enables highly accurate predictive maintenance for electric motors, transformers, and switchgears, minimizing unplanned downtime.

- AI facilitates dynamic load management and grid stabilization for integrating variable renewable energy sources effectively.

- AI enhances process control by analyzing vast datasets to fine-tune electrified unit operations for peak efficiency.

- AI improves safety protocols by predicting potential equipment failures or operational deviations before they occur.

- AI supports asset performance management, extending the lifespan and reliability of critical electrical infrastructure.

- AI assists in optimizing energy procurement strategies from diverse sources, leading to significant cost savings.

- AI contributes to precise carbon emissions monitoring and verification, aiding in regulatory compliance and reporting.

- AI drives the development of digital twin models for simulation, testing, and optimization of electrified refinery systems.

- AI enables automated fault detection and rapid recovery mechanisms in complex refinery electrical networks.

DRO & Impact Forces Of Refinery Electrification Market

The Refinery Electrification Market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively dictate its growth trajectory and strategic landscape. A primary driver is the global consensus on climate action, translating into stringent environmental regulations and carbon reduction mandates from governments and international bodies, compelling refineries to decarbonize their operations. Complementing this is the economic incentive of enhanced operational efficiency and substantial cost reductions achievable through electrification, including lower energy consumption and reduced maintenance requirements. Furthermore, rapid technological advancements in high-efficiency electric motors, power electronics, and sophisticated smart grid systems are making electrification technically viable and economically attractive for complex industrial applications. These drivers are bolstered by increasing corporate social responsibility initiatives and investor pressure for robust Environmental, Social, and Governance (ESG) performance. However, the market faces significant restraints, notably the exceptionally high initial capital investment required for upgrading or retrofitting existing refinery infrastructure, which can involve extensive downtime and complex engineering challenges.

Beyond these immediate factors, other key restraints include concerns over the reliability and stability of existing national grids to support increased industrial electrical loads, alongside the technical complexities of integrating intermittent renewable energy sources on a large scale into critical operations. Regulatory inertia in some regions and the lack of standardized frameworks for integrating new electrified systems into highly regulated refining environments also pose considerable hurdles. The shortage of skilled personnel proficient in both refinery operations and advanced electrical/digital technologies further presents a challenge to widespread adoption. Conversely, numerous opportunities are emerging that promise to accelerate market growth. The development of innovative financing mechanisms and incentive programs designed to offset the high initial investment costs can significantly de-risk electrification projects for refiners. The increasing integration of smart grid technologies and AI-driven energy management systems offers unprecedented levels of optimization, efficiency, and predictive capabilities, transforming how refineries manage their power. Moreover, the burgeoning trend towards green hydrogen production within refineries, which is an inherently electricity-intensive process, presents a substantial growth avenue for electrification solutions. These impact forces collectively propel the market forward while requiring strategic navigation of challenges, encouraging continuous innovation in technology, policy, and business models to realize the full potential of refinery electrification.

Segmentation Analysis

The Refinery Electrification Market is comprehensively segmented to provide a detailed and granular understanding of its diverse components, application areas, and power sources. This structured breakdown is instrumental for market stakeholders, including technology providers, refinery operators, and investors, to identify specific niches, assess growth potential, and formulate targeted strategic initiatives. By analyzing the market through various dimensions, a clearer picture emerges regarding where investment is most concentrated, which technologies are gaining traction, and how different operational scales or regional demands influence adoption patterns. This segmentation analysis not only highlights the intrinsic complexities of modernizing refining infrastructure but also underscores the multifaceted nature of solutions required to achieve comprehensive electrification across the industry. Such an approach facilitates tailored product development and service offerings, ensuring that market participants can effectively address the evolving needs and stringent requirements of the global refining sector as it transitions towards more sustainable and efficient operating models, thereby fostering innovation and competitive differentiation within this critical market landscape.

- By Component: This segment includes the fundamental building blocks of an electrified refinery system, each playing a crucial role in power generation, distribution, and utilization.

- Electric Motors and Drives: High-efficiency motors (e.g., synchronous, induction) and variable frequency drives (VFDs) for process equipment.

- Transformers: Step-up and step-down transformers for voltage regulation and power transmission within the refinery grid.

- Switchgears: Devices for controlling, protecting, and isolating electrical equipment within complex power networks.

- Cables and Wires: Specialized industrial-grade cabling for high-voltage power transmission and critical data communication.

- Control Systems: SCADA, DCS, and PLC systems for monitoring, automating, and optimizing electrical processes.

- Energy Storage Systems: Large-scale batteries (e.g., Li-ion, flow batteries) for grid stability, peak shaving, and backup power.

- Power Converters: Rectifiers and inverters for efficient AC-DC and DC-AC conversion, crucial for renewables integration.

- Sensors and Monitoring Devices: Equipment for real-time data collection on electrical parameters, asset health, and environmental conditions.

- By Application: This segment focuses on the specific refinery processes and auxiliary functions where electrification is implemented for efficiency and emissions reduction.

- Pumps and Compressors: Electrified pumps for fluid transfer and compressors for gas processing across various units.

- Heating and Cooling Systems: Electric heaters (e.g., induction, resistance) and electrically driven chillers for process temperature management.

- Process Units: Electrification of core processing units like distillation columns, reactors, and reformers for direct operational benefits.

- Auxiliary Systems: Electrified lighting, HVAC, and other non-process utility systems supporting overall plant operations.

- Material Handling: Electric conveyors, hoists, and other equipment for raw material and product movement within the refinery.

- By Power Source: This segment categorizes electrification based on where the electricity is generated or procured, highlighting sustainable sourcing.

- Grid Electricity: Utilizing power from the national or regional electrical grid, often with green energy procurement options.

- On-site Renewables: Power generated within the refinery premises from solar, wind, or other renewable sources, promoting energy independence.

- Hybrid Systems: Combinations of grid power, on-site renewables, and sometimes localized fossil fuel generation for enhanced reliability and flexibility.

- By Refinery Type: This segment differentiates between existing facilities undergoing upgrades and entirely new constructions, each presenting unique challenges and opportunities.

- Existing Refineries (Retrofit): Modernization of operational facilities with new electrical infrastructure, often requiring careful planning and execution.

- New Refineries (Greenfield): Integration of comprehensive electrification solutions from the initial design and construction phases, allowing for optimized layouts.

Value Chain Analysis For Refinery Electrification Market

The value chain for the Refinery Electrification Market is a complex and interconnected network spanning multiple stages, from raw material supply to final operational support, ensuring the seamless integration and functioning of electrified refinery systems. Upstream activities are foundational, involving the sourcing of essential raw materials such as high-grade copper for conductive components, specialized steels for robust equipment casings, and advanced semiconductors for power electronics. This segment also includes the crucial supply of specialized software for control systems, digital twin modeling, and advanced analytics platforms, alongside components for renewable energy generation technologies like photovoltaic panels and wind turbines. Key upstream players include raw material extractors, component manufacturers, and specialized technology developers who provide the foundational elements required for high-performance electrical infrastructure tailored for demanding industrial environments. Ensuring quality, reliability, and sustainable sourcing at this initial stage is paramount for the overall integrity and efficiency of the electrification solutions further down the chain, impacting both cost and performance.

Midstream activities primarily encompass the design, manufacturing, and assembly of complex electrical equipment and integrated solutions specifically for refinery applications. This stage is dominated by major industrial conglomerates and specialized technology firms that produce high-efficiency electric motors, variable frequency drives, power transformers, advanced switchgears, energy storage systems, and sophisticated power conversion units. These manufacturers often invest heavily in research and development to innovate solutions that meet stringent industry standards for safety, performance, and environmental compliance, while also offering customization for unique refinery needs. Quality assurance, testing, and certification are integral parts of this stage, ensuring the reliability and longevity of the deployed equipment. Downstream, the value chain extends to engineering, procurement, and construction (EPC) firms that execute projects, handling the intricate design, installation, and commissioning of electrification infrastructure within refinery sites. These firms possess specialized expertise in integrating new electrical systems with existing plant operations, ensuring minimal disruption and adherence to strict safety protocols and timelines.

Distribution channels typically involve a combination of direct sales and project-based contracting, where manufacturers and EPCs engage directly with refinery operators for large-scale, complex projects. For smaller components, standardized equipment, and aftermarket services, indirect channels through authorized distributors, system integrators, and value-added resellers play a significant role, providing wider market access and localized support. Post-installation, the value chain encompasses a critical phase of ongoing maintenance, comprehensive technical support, efficient spare parts supply, and continuous technology upgrades and retrofits. These services are often provided either directly by the original equipment manufacturers (OEMs) or by specialized third-party service providers, leveraging remote monitoring and predictive analytics. This comprehensive approach ensures the sustained operational efficiency, reliability, and continuous improvement of electrified refinery assets throughout their lifecycle, completing the full spectrum of value creation from concept to long-term operation.

Refinery Electrification Market Potential Customers

The primary potential customers and key buyers within the Refinery Electrification Market are predominantly large, integrated oil and gas companies that operate extensive global refining assets, alongside independent refiners striving to modernize their facilities and enhance their operational sustainability. These enterprises are driven by a compelling combination of factors, including the urgent need to comply with increasingly stringent environmental regulations and carbon reduction mandates, the strategic imperative to reduce long-term operational costs through superior energy efficiency, and a commitment to improving their overall environmental, social, and governance (ESG) performance. Their investment decisions are heavily influenced by the potential for significant reductions in greenhouse gas emissions (Scope 1 and Scope 2), which directly impact their public image, investor confidence, and regulatory compliance. The long-term economic benefits, such as reduced fuel consumption, lower maintenance expenditures, and improved process reliability, also serve as powerful motivators for these major industrial players to embrace electrification solutions comprehensively across their operations, ensuring future viability and competitiveness in a low-carbon economy.

Additionally, national oil companies (NOCs) and state-owned enterprises that manage substantial national refining capacities constitute another significant customer segment. Their adoption of refinery electrification is often propelled by national energy policies aimed at diversifying energy sources, promoting sustainable industrial growth, and fulfilling international climate commitments. These entities frequently operate under mandates to lead in national decarbonization efforts, making electrification a strategic priority for modernizing national infrastructure and securing energy independence. Furthermore, co-located petrochemical complexes that are integrated with refineries also represent a notable customer base, as they can leverage shared infrastructure and integrated electrification solutions to achieve similar gains in efficiency and environmental performance across their interconnected operations. The key decision-makers within these organizations typically include C-suite executives responsible for strategic investments, plant managers overseeing day-to-day operations, heads of engineering and technology, and sustainability officers. These individuals meticulously evaluate electrification projects based on factors such as return on investment, regulatory compliance, technological maturity, operational impact, and long-term strategic alignment with corporate and national sustainability objectives.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 Billion |

| Market Forecast in 2032 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, ABB Ltd., Schneider Electric SE, General Electric Company, Eaton Corporation plc, Emerson Electric Co., Rockwell Automation Inc., Mitsubishi Electric Corporation, Danfoss A/S, WEG S.A., Nidec Corporation, Toshiba Corporation, Hitachi Ltd., Fuji Electric Co. Ltd., Yokogawa Electric Corporation, Honeywell International Inc., Baker Hughes Company, Schlumberger Limited, Equinor ASA, TotalEnergies SE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Refinery Electrification Market Key Technology Landscape

The Refinery Electrification Market is profoundly shaped by a dynamic and continuously evolving technological landscape, driven by the imperative to achieve superior energy efficiency, enhance operational reliability, and meet stringent sustainability goals. Core technologies include high-efficiency electric motors, such as permanent magnet synchronous motors (PMSM) and advanced induction motors, coupled with sophisticated variable frequency drives (VFDs). These components are critical for optimizing energy consumption in major refinery equipment like pumps, compressors, and fans, providing precise speed and torque control that significantly reduces energy waste compared to traditional fixed-speed or steam-driven systems. Advanced power electronics, including rectifiers, inverters, and power converters, are equally vital for seamlessly integrating diverse power sources, ranging from grid electricity to intermittent renewable energy (solar, wind), into the refinery's electrical network. These technologies ensure stable power supply, manage voltage fluctuations, and facilitate bidirectional power flow, enabling greater flexibility in energy sourcing and consumption for the electrified processes across the plant.

Furthermore, intelligent smart grid technologies are foundational to modern refinery electrification. These encompass advanced metering infrastructure (AMI), distribution automation, and comprehensive energy management systems (EMS) that enable real-time monitoring, control, and optimization of power flow across the refinery’s entire electrical network. Integrated with robust digital twins and artificial intelligence (AI) platforms, these systems provide advanced predictive maintenance capabilities, optimize process parameters with unparalleled precision, and enhance overall plant safety and operational continuity through proactive anomaly detection. Energy storage solutions, primarily large-scale battery energy storage systems (BESS), play a crucial role in ensuring grid stability, enabling peak shaving, and providing essential backup power to support the continuous operation of electrified processes and maximize renewable energy penetration. Innovations in high-voltage direct current (HVDC) transmission are also gaining traction for long-distance power delivery and connecting remote renewable energy assets, like offshore wind farms, directly to large refinery complexes. The synergistic integration of these advanced technologies creates a resilient, efficient, and sustainable electrical backbone for the modern refinery, facilitating a comprehensive transition towards a low-carbon future and ensuring long-term operational excellence.

Regional Highlights

North America constitutes a pivotal market for refinery electrification, propelled by an interplay of stringent environmental regulations, robust corporate decarbonization commitments, and the presence of advanced technological infrastructure. The region benefits significantly from supportive governmental incentives aimed at enhancing industrial energy efficiency and promoting the widespread adoption of renewable energy. Majo

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager