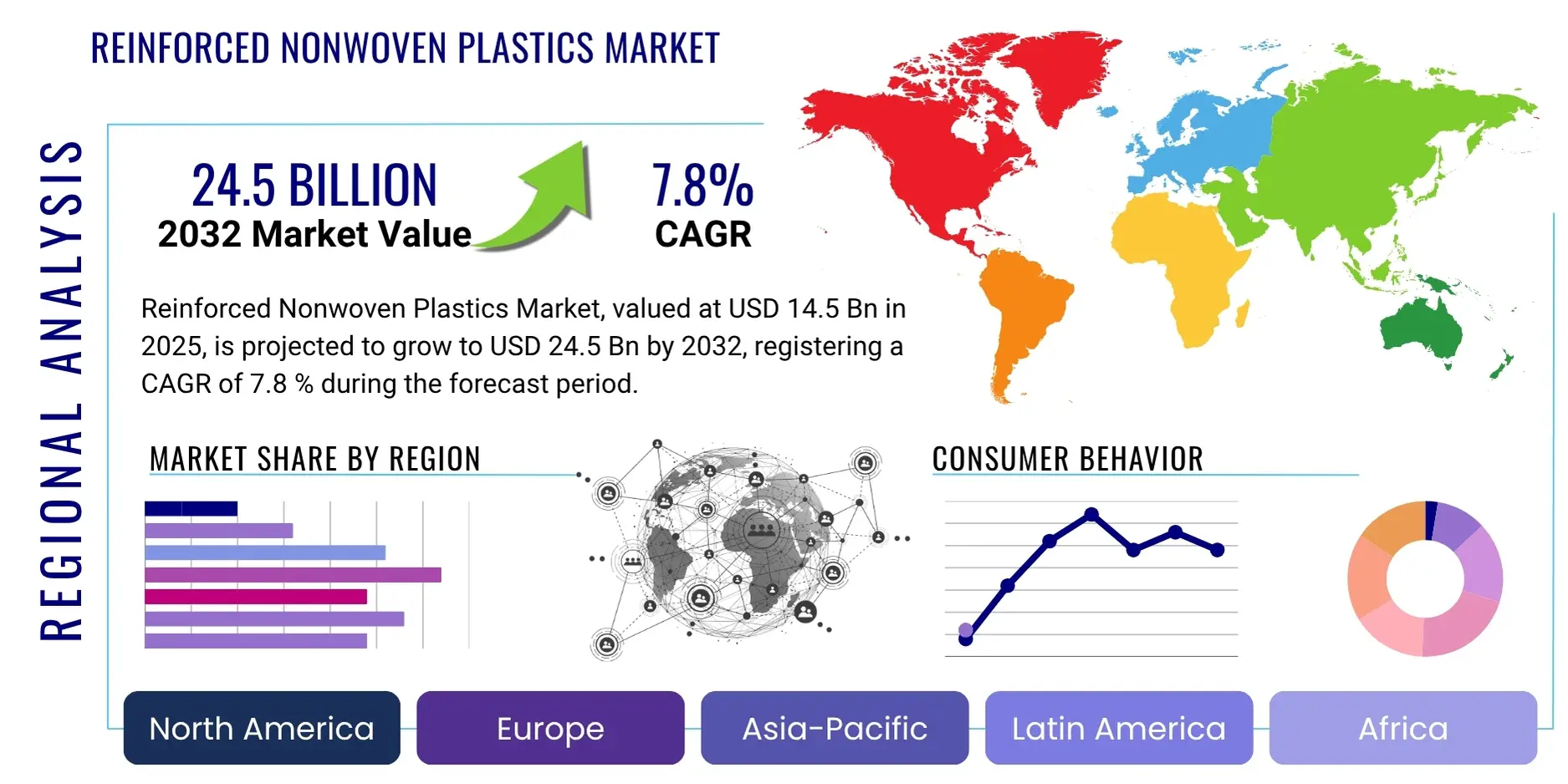

Reinforced Nonwoven Plastics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428312 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Reinforced Nonwoven Plastics Market Size

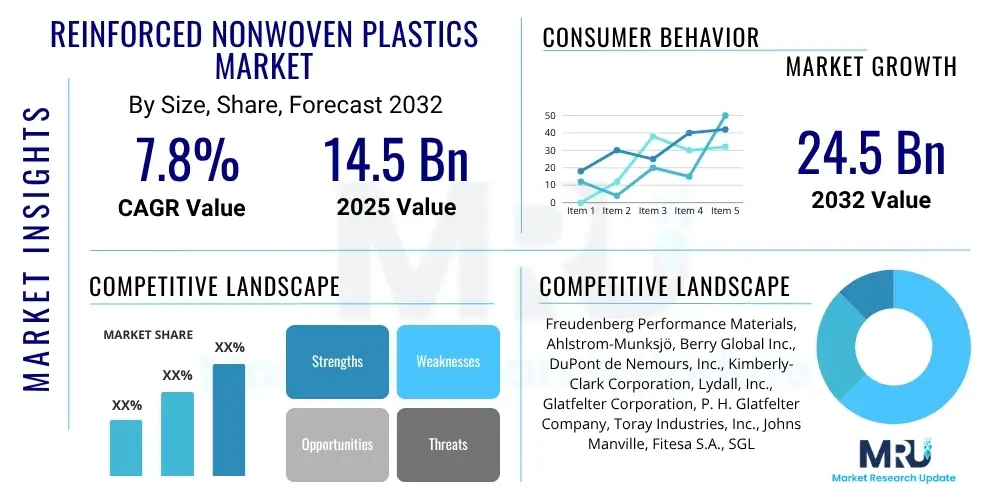

The Reinforced Nonwoven Plastics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 14.5 billion in 2025 and is projected to reach USD 24.5 billion by the end of the forecast period in 2032.

Reinforced Nonwoven Plastics Market introduction

The Reinforced Nonwoven Plastics Market encompasses a diverse range of engineered materials that combine the versatile properties of nonwoven fabrics with the enhanced mechanical strength and stiffness provided by reinforcing elements. These innovative materials are typically constructed by incorporating high-strength fibers, such as glass, carbon, aramid, or even natural fibers, into a nonwoven matrix, which is then often impregnated or bonded with various polymer resins like polypropylene, polyethylene, or polyamide. This unique combination results in materials that offer superior performance characteristics compared to traditional plastics or unreinforced nonwovens, including excellent strength-to-weight ratios, enhanced durability, improved impact resistance, and often better thermal and chemical stability.

Major applications for reinforced nonwoven plastics span across a multitude of industries, driven by the continuous demand for lightweight, high-performance, and cost-effective solutions. Key sectors include automotive, where these materials are vital for interior components, underbody shields, and semi-structural parts, contributing significantly to fuel efficiency and safety. In construction, they are utilized in roofing, insulation, geomembranes, and sound dampening applications. The filtration industry benefits from their controlled pore structures and mechanical integrity for air and liquid filtration systems. Furthermore, their use extends to medical textiles, electrical and electronics, industrial fabrics, and various consumer goods, demonstrating their broad applicability and growing adoption due to their inherent benefits.

The primary benefits of reinforced nonwoven plastics include their remarkable strength and stiffness at reduced weight, which is a critical driving factor in industries striving for energy efficiency and reduced material consumption. They offer design flexibility, allowing for complex shapes and integration of multiple functions. The manufacturing processes for nonwovens can be highly efficient, leading to cost-effective production of large volumes. Furthermore, ongoing advancements in fiber and resin technologies, coupled with the increasing emphasis on sustainable materials and circular economy principles, are propelling the market forward. The quest for lightweighting in transport, infrastructure development in emerging economies, and technological advancements in material science are significant driving forces behind the expansion of this market.

Reinforced Nonwoven Plastics Market Executive Summary

The Reinforced Nonwoven Plastics Market is currently experiencing robust growth, primarily fueled by the accelerating demand for lightweight, durable, and cost-efficient materials across key industrial sectors. Business trends indicate a strong focus on innovation, with manufacturers investing heavily in research and development to enhance material performance, explore new fiber-resin combinations, and develop more sustainable and recyclable product offerings. There is a discernible shift towards advanced manufacturing techniques that optimize production efficiency and enable the creation of tailor-made solutions for specific end-use applications, ensuring that these materials meet stringent industry standards and performance requirements. Strategic collaborations and partnerships between raw material suppliers, nonwoven producers, and end-user industries are also becoming more prevalent, aimed at fostering innovation and accelerating market penetration.

Regional trends highlight the Asia Pacific (APAC) region as a dominant and rapidly expanding market for reinforced nonwoven plastics, driven by extensive industrialization, significant investments in infrastructure development, and the burgeoning automotive and construction sectors in countries like China, India, and Southeast Asian nations. North America and Europe also maintain substantial market shares, characterized by a mature industrial base and a strong emphasis on advanced manufacturing, technological innovation, and stringent environmental regulations that encourage the adoption of high-performance, lightweight, and sustainable materials. The Middle East and Africa (MEA) and Latin America are emerging as promising markets, buoyed by economic diversification, urbanization projects, and increasing foreign investments in manufacturing capabilities, though they currently represent smaller portions of the global market.

Segmentation trends reveal significant growth potential in several key areas. By fiber type, glass fiber reinforced nonwovens continue to hold a substantial share due to their cost-effectiveness and excellent mechanical properties, while carbon fiber reinforced variants are gaining traction in high-performance applications despite their higher cost. Natural fiber reinforced nonwovens are experiencing a surge in demand driven by sustainability initiatives. In terms of application, the automotive industry remains a primary consumer, alongside robust growth in construction and filtration sectors. The medical and electrical & electronics segments are also exhibiting steady expansion, spurred by specific functional requirements for durability, sterility, and lightweight design. These segmental dynamics underscore the versatility and adaptability of reinforced nonwoven plastics across a broad spectrum of industrial needs.

AI Impact Analysis on Reinforced Nonwoven Plastics Market

The integration of Artificial intelligence (AI) is poised to significantly transform the Reinforced Nonwoven Plastics Market, addressing key themes such as optimizing material design, enhancing manufacturing efficiency, improving quality control, and fostering sustainability. Users are commonly questioning how AI can lead to the discovery of novel material compositions with superior properties, reduce development cycles for new products, and enable more precise and adaptive manufacturing processes. There are expectations that AI will play a crucial role in predicting material performance under various conditions, thereby minimizing costly physical testing. Concerns often revolve around the initial investment required for AI integration, the need for specialized data scientists and engineers, and the ethical implications of autonomous decision-making in production. Ultimately, users anticipate that AI will unlock new levels of customization, efficiency, and resource optimization, driving the market towards more advanced and sustainable solutions.

- AI-driven material design and simulation for optimal fiber-resin combinations.

- Predictive analytics for maintenance of nonwoven production machinery, reducing downtime.

- Enhanced real-time quality control through AI-powered vision systems identifying defects.

- Optimization of manufacturing parameters (e.g., fiber distribution, resin impregnation) for superior product consistency.

- Supply chain optimization and demand forecasting for raw materials, improving inventory management.

- Accelerated R&D cycles through AI-assisted data analysis and rapid prototyping.

- Development of smart reinforced nonwovens with integrated sensors for performance monitoring.

- Personalized product development based on specific customer requirements and performance criteria.

- Improved waste reduction and resource efficiency through process optimization and material recycling strategies.

DRO & Impact Forces Of Reinforced Nonwoven Plastics Market

The Reinforced Nonwoven Plastics Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), alongside various impact forces that shape its competitive landscape and future trajectory. Key drivers propelling market expansion include the increasing global demand for lightweight and high-strength materials, particularly from the automotive, aerospace, and construction industries, where these materials contribute to fuel efficiency, structural integrity, and reduced environmental footprint. The growing emphasis on sustainable and eco-friendly manufacturing processes also fuels the adoption of reinforced nonwovens, especially those incorporating natural or recycled fibers. Technological advancements in fiber and resin chemistry, coupled with innovations in nonwoven manufacturing techniques, further enhance material performance and expand their application scope, while the rising economic development in emerging markets creates new avenues for growth as industrialization and urbanization accelerate.

However, the market faces several notable restraints that could temper its growth. High manufacturing costs associated with specialized fibers, resins, and complex production processes, particularly for advanced composites, can make these materials less competitive than traditional alternatives in certain price-sensitive applications. The technical complexity involved in the recycling of multi-material reinforced nonwoven plastics poses a significant environmental challenge and limits their circularity, impacting sustainability credentials. Intense competition from conventional materials, such as metals and unreinforced plastics, which benefit from established infrastructure and lower processing costs, also acts as a restraint. Furthermore, stringent regulatory requirements concerning material composition, environmental impact, and end-of-life disposal can necessitate costly compliance measures for manufacturers, affecting profitability and market entry for smaller players.

Despite these challenges, substantial opportunities exist for market players to capitalize on emerging trends and unmet needs. The development of bio-based and biodegradable reinforced nonwovens presents a major opportunity for sustainable product differentiation and compliance with evolving environmental mandates. Expansion into niche high-performance applications, such as advanced filtration, protective gear, and specialized medical devices, offers lucrative growth prospects. The integration of smart functionalities, such as embedded sensors or conductive elements, within reinforced nonwovens can create entirely new product categories and applications, particularly in the smart textiles and IoT sectors. Additionally, strategic investments in automation, digitalization, and advanced analytics can lead to improved manufacturing efficiency, cost reduction, and enhanced product quality, allowing companies to gain a competitive edge. The impact forces, including the bargaining power of buyers and suppliers, the threat of new entrants and substitutes, and the intensity of competitive rivalry, all necessitate continuous innovation, cost leadership, and strong customer relationships to sustain market position and capitalize on these opportunities.

Segmentation Analysis

The Reinforced Nonwoven Plastics Market is comprehensively segmented based on various critical parameters, including fiber type, resin type, manufacturing process, application, and end-use industry. This segmentation provides a granular view of the market dynamics, enabling a deeper understanding of specific product categories, technological preferences, and demand patterns across diverse industrial landscapes. Each segment reflects unique material properties, performance requirements, and cost structures, thereby influencing market growth and competitive strategies. Analyzing these segments is essential for identifying key growth areas, understanding market concentration, and predicting future trends, which in turn helps market players to tailor their product development and market entry strategies effectively.

- By Fiber Type:

- Glass Fiber

- Carbon Fiber

- Natural Fiber (e.g., Hemp, Flax, Jute)

- Synthetic Fiber (e.g., Polyester, Polypropylene, Aramid)

- Others (e.g., Basalt Fiber, Boron Fiber)

- By Resin Type:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyamide (PA)

- Polyetheretherketone (PEEK)

- Epoxy

- Polyester

- Others (e.g., Vinyl Ester, Polyurethane)

- By Manufacturing Process:

- Spunbond

- Meltblown

- Needle Punch

- Hydroentangled (Spunlace)

- Composites Lamination

- Thermoplastic Consolidation

- Others (e.g., Stitch Bonding, Chemical Bonding)

- By Application:

- Automotive (Interior Trim, Underbody Shields, Headliners, Acoustic Insulation)

- Construction (Roofing Underlayment, Geotextiles, Insulation, Moisture Barriers)

- Filtration (Air Filters, Liquid Filters, Oil Filters)

- Medical & Healthcare (Surgical Drapes, Gowns, Sterilization Wraps, Disposable Medical Devices)

- Geotextiles (Soil Stabilization, Erosion Control, Drainage)

- Electrical & Electronics (Circuit Board Substrates, Insulation, Battery Separators)

- Industrial (Abrasives, Wipes, Protective Clothing)

- Consumer Goods (Furniture, Packaging, Sportswear)

- Others (e.g., Marine, Wind Energy)

- By End-Use Industry:

- Automotive & Transportation

- Building & Construction

- Industrial

- Healthcare

- Consumer Goods

- Filtration

- Electrical & Electronics

- Others

Value Chain Analysis For Reinforced Nonwoven Plastics Market

The value chain for the Reinforced Nonwoven Plastics Market is intricate, involving several distinct stages from raw material sourcing to end-product distribution, each adding value and contributing to the final product's cost and performance. The upstream segment of the value chain is dominated by suppliers of raw materials, which primarily include producers of various reinforcing fibers such as glass fiber, carbon fiber, natural fibers (e.g., flax, hemp, jute), and synthetic fibers (e.g., polyester, polypropylene, aramid). Additionally, this stage involves the suppliers of polymer resins, including polypropylene, polyethylene, polyamide, and various thermoset resins like epoxy and polyester, along with specialized additives, binders, and coatings that enhance material properties. The quality and cost of these fundamental inputs significantly influence the overall competitiveness and characteristics of the reinforced nonwoven plastics.

Moving downstream, the value chain encompasses the core manufacturing processes where these raw materials are transformed into reinforced nonwoven plastic products. This involves nonwoven fabric manufacturers who produce the base nonwoven webs using techniques like spunbond, meltblown, needle punch, or hydroentanglement. Following this, the reinforcement materials are integrated into the nonwoven matrix, often through lamination, impregnation, or consolidation processes with polymer resins. This stage often involves specialized composite material producers or advanced textile manufacturers who combine the nonwoven structure with the reinforcing fibers and polymer matrix to achieve the desired mechanical, thermal, and chemical properties. Innovation in manufacturing techniques, process optimization, and quality control at this stage are crucial for delivering high-performance materials to the market.

The final stages of the value chain focus on the distribution and end-use of reinforced nonwoven plastics. Distribution channels can be both direct and indirect. Direct distribution often involves sales directly to large original equipment manufacturers (OEMs) in sectors such as automotive, construction, and aerospace, who integrate these materials into their final products. Indirect distribution relies on a network of distributors, agents, and specialized fabricators who convert the base reinforced nonwoven materials into specific components or ready-to-use parts for smaller businesses or diverse applications. These fabricators may perform cutting, molding, thermoforming, or other secondary processing steps. Potential customers, or the end-users/buyers of the product, vary widely and include automotive Tier 1 suppliers, construction contractors, filtration system manufacturers, medical device companies, and manufacturers of industrial and consumer goods. The efficiency of these distribution networks and the effectiveness of customer engagement are vital for market penetration and maximizing product reach.

Reinforced Nonwoven Plastics Market Potential Customers

Potential customers for Reinforced Nonwoven Plastics are diverse, spanning a wide array of industries that seek materials offering a superior combination of strength, lightweight properties, durability, and cost-effectiveness. The automotive sector represents a substantial customer base, with vehicle manufacturers and their Tier 1 suppliers consistently looking for advanced materials to achieve lightweighting targets for improved fuel efficiency and reduced emissions, while also enhancing safety and acoustic performance for interior and underbody components. The construction industry is another major end-user, utilizing these materials for geomembranes, roofing underlays, insulation, and various structural and non-structural applications where durability, moisture resistance, and ease of installation are paramount. Their demand is driven by infrastructure development and the need for long-lasting, performance-driven building solutions.

Beyond these large industrial segments, the filtration industry is a critical customer, requiring reinforced nonwovens for air, liquid, and oil filtration systems due to their controlled pore sizes, high surface area, and mechanical integrity, which ensure efficient contaminant removal and extended service life. The medical and healthcare sector also constitutes a significant market for specialized reinforced nonwovens used in surgical drapes, gowns, sterilization wraps, and various disposable medical devices, where material sterility, barrier properties, and comfort are essential. Manufacturers in the electrical and electronics sector utilize these materials for insulation, circuit board substrates, and battery separators, valuing their dielectric properties and thermal stability. Lastly, a broad range of industrial applications, including protective clothing, abrasive backings, and wipes, along with consumer goods like furniture components and sportswear, further expand the potential customer base, each drawn by the unique functional benefits offered by reinforced nonwoven plastics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 14.5 Billion |

| Market Forecast in 2032 | USD 24.5 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Freudenberg Performance Materials, Ahlstrom-Munksjö, Berry Global Inc., DuPont de Nemours, Inc., Kimberly-Clark Corporation, Lydall, Inc., Glatfelter Corporation, P. H. Glatfelter Company, Toray Industries, Inc., Johns Manville, Fitesa S.A., SGL Carbon SE, BASF SE, Cytec Solvay Group, Owens Corning, Trelleborg AB, Asahi Kasei Corporation, Mitsui Chemicals, Inc., The Dow Chemical Company, Teijin Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Reinforced Nonwoven Plastics Market Key Technology Landscape

The Reinforced Nonwoven Plastics Market is characterized by a dynamic and evolving technology landscape, continuously driven by innovations aimed at enhancing material performance, improving manufacturing efficiency, and addressing sustainability concerns. A foundational aspect of this landscape involves advanced fiber manufacturing and modification technologies, including the development of high-performance glass, carbon, and synthetic fibers with optimized mechanical properties and surface chemistries for better adhesion to polymer matrices. Simultaneously, there is significant research into natural fiber processing and treatment to overcome limitations such as moisture sensitivity and lower inherent strength, making them more viable for reinforcement applications. These developments are crucial for providing the building blocks for next-generation reinforced nonwovens that meet increasingly stringent industry requirements.

Another pivotal area is the evolution of nonwoven fabric production processes and reinforcement integration techniques. Technologies such as advanced spunbond, meltblown, needle punch, and hydroentanglement methods are being refined to produce nonwoven webs with highly uniform fiber distribution, controlled porosity, and tailored properties. Furthermore, innovative methods for integrating reinforcing fibers into these nonwoven structures, including in-line lamination, commingling, co-spinning, and advanced thermoplastic consolidation, are crucial for achieving optimal fiber-matrix interaction and overall composite performance. These processes focus on maximizing the load transfer efficiency from the polymer matrix to the reinforcing fibers, thereby unlocking the full potential of the composite material. Digitalization and automation are also playing an increasingly important role, integrating sensors and real-time monitoring systems into production lines to ensure consistent quality and optimize throughput.

Finally, significant technological advancements are occurring in polymer resin development and post-processing techniques. This includes the formulation of specialized thermoplastic and thermoset resins that offer improved adhesion, impact resistance, flame retardancy, and processing characteristics. The focus is also shifting towards bio-based and recyclable resins to align with global sustainability goals. Surface treatment technologies for fibers are continually being developed to enhance wettability and bonding with various resins. Moreover, post-processing techniques such as sophisticated molding, thermoforming, and 3D printing of reinforced nonwoven preforms are expanding design freedom and enabling the production of complex geometries with high precision. Research into end-of-life solutions, including advanced recycling and material recovery technologies for multi-material reinforced nonwovens, is also a key area of focus, aiming to establish a more circular economy for these valuable materials.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to rapid industrialization, burgeoning automotive and construction sectors, significant manufacturing capabilities in China, India, and Southeast Asian countries, and increasing investment in infrastructure projects.

- North America: A mature market characterized by strong demand from the automotive, aerospace, and filtration industries, coupled with a focus on technological innovation, high-performance materials, and strategic investments in R&D.

- Europe: Exhibits robust growth driven by stringent environmental regulations promoting lightweight and sustainable materials, strong automotive manufacturing, and a focus on advanced composite solutions and circular economy initiatives.

- Latin America: An emerging market experiencing growth due to increasing industrial activities, urbanization, and expanding automotive production, though still in developmental stages compared to other regions.

- Middle East and Africa (MEA): Shows promising growth potential, spurred by economic diversification efforts, infrastructure development projects, and increasing demand for industrial and construction materials, particularly in the Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Reinforced Nonwoven Plastics Market.- Freudenberg Performance Materials

- Ahlstrom-Munksjö

- Berry Global Inc.

- DuPont de Nemours, Inc.

- Kimberly-Clark Corporation

- Lydall, Inc.

- Glatfelter Corporation

- P. H. Glatfelter Company

- Toray Industries, Inc.

- Johns Manville

- Fitesa S.A.

- SGL Carbon SE

- BASF SE

- Cytec Solvay Group

- Owens Corning

- Trelleborg AB

- Asahi Kasei Corporation

- Mitsui Chemicals, Inc.

- The Dow Chemical Company

- Teijin Limited

Frequently Asked Questions

What are Reinforced Nonwoven Plastics?

Reinforced Nonwoven Plastics are engineered materials combining nonwoven fabric structures with high-strength reinforcing fibers (e.g., glass, carbon, natural fibers) and a polymer matrix. This fusion results in materials offering enhanced mechanical properties like strength, stiffness, and durability, often with a favorable strength-to-weight ratio, suitable for demanding applications across various industries.

What are the primary applications of Reinforced Nonwoven Plastics?

The primary applications include the automotive industry for lightweight components, the construction sector for roofing and insulation, filtration systems for air and liquids, and medical products requiring barrier properties. They are also used in geotextiles, electrical and electronics, and various industrial and consumer goods due to their versatile performance.

What are the key advantages of using Reinforced Nonwoven Plastics?

Key advantages include superior strength-to-weight ratio, excellent durability, improved impact resistance, design flexibility for complex shapes, and potential for cost-effective manufacturing. These materials contribute to lightweighting efforts, enhance product longevity, and can be tailored to specific performance requirements.

What challenges does the Reinforced Nonwoven Plastics Market face?

Challenges include the relatively high manufacturing costs for advanced variants, the complexity of recycling multi-material composites, and intense competition from conventional materials. Additionally, adherence to evolving environmental regulations and the need for continuous innovation to enhance sustainability pose ongoing challenges for market players.

How is AI impacting the Reinforced Nonwoven Plastics Market?

AI is impacting the market by optimizing material design, enhancing manufacturing efficiency through predictive maintenance and real-time quality control, and improving supply chain management. It enables faster R&D, more precise production, and supports the development of sustainable, customized solutions, ultimately driving innovation and operational excellence within the industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager