Residential Non-Metal Electrical Conduit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429089 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Residential Non-Metal Electrical Conduit Market Size

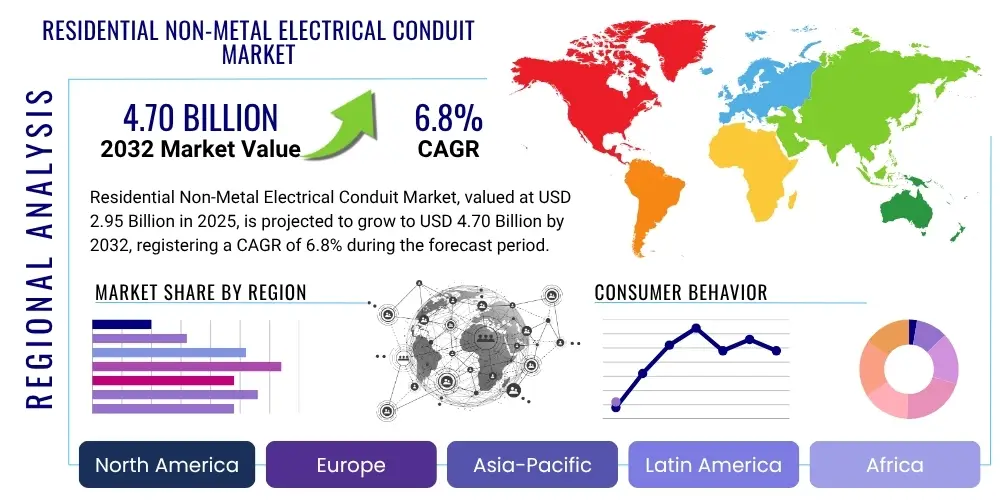

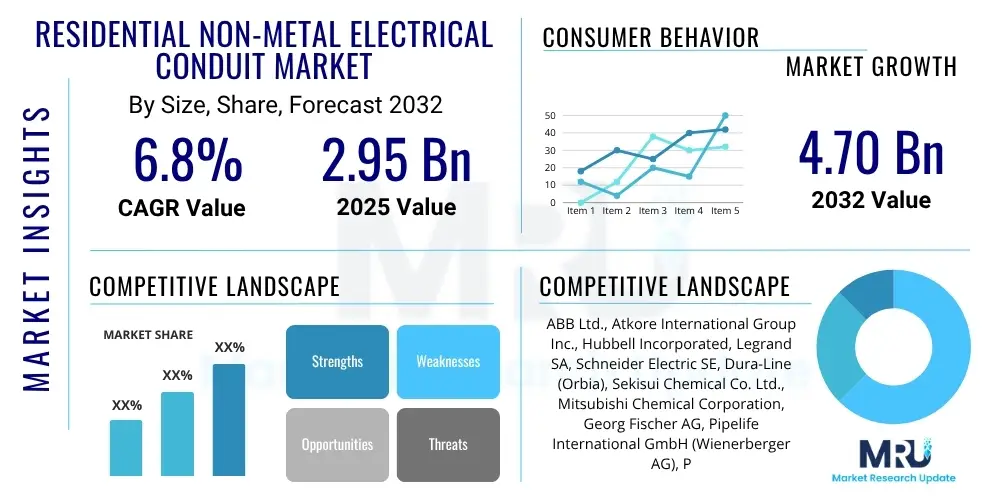

The Residential Non-Metal Electrical Conduit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $2.95 Billion in 2025 and is projected to reach $4.70 Billion by the end of the forecast period in 2032.

Residential Non-Metal Electrical Conduit Market introduction

The Residential Non-Metal Electrical Conduit Market encompasses the production, distribution, and installation of flexible and rigid non-metallic tubing systems designed to protect electrical wiring within residential structures. These conduits, primarily made from materials such as PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), and PP (Polypropylene), serve as vital enclosures, safeguarding electrical conductors from physical damage, moisture, and chemical exposure. Their application is widespread across various residential settings, ranging from single-family homes and multi-unit dwellings to manufactured homes and accessory dwelling units, ensuring the safety and longevity of electrical installations. The inherent characteristics of non-metal conduits, including their lightweight nature, corrosion resistance, and ease of installation, contribute significantly to their growing adoption in modern residential construction practices.

Major applications of non-metal electrical conduits in residential areas include routing power circuits, communication cables, and data lines through walls, ceilings, and floors. They are extensively used in both new construction projects and extensive renovation or remodeling endeavors, providing a secure pathway for wiring in areas susceptible to environmental factors or where wiring needs to be concealed for aesthetic and safety reasons. The benefits derived from using non-metal conduits are substantial, offering superior dielectric strength, reducing the risk of ground faults, and preventing short circuits. Their flexibility allows for easier navigation around structural obstacles, significantly cutting down installation time and labor costs. Furthermore, non-metallic options often exhibit better fire resistance properties and are less prone to rust and degradation compared to their metal counterparts, offering a more durable and safer solution for residential electrical systems.

Driving factors for the expansion of this market include the global surge in residential construction, particularly in developing economies, fueled by urbanization and population growth. Increasing awareness regarding electrical safety standards and stringent building codes mandating the use of protected wiring systems further propel market demand. Technological advancements in material science, leading to the development of more robust, fire-retardant, and environmentally friendly non-metal conduit options, also play a crucial role. The growing trend towards smart homes and integrated communication networks within residences necessitates extensive and organized wiring, for which non-metal conduits offer an ideal, cost-effective, and adaptable solution, ensuring reliable connectivity and power distribution throughout modern living spaces.

Residential Non-Metal Electrical Conduit Market Executive Summary

The Residential Non-Metal Electrical Conduit Market is experiencing robust growth driven by a confluence of favorable business trends, evolving regional dynamics, and strong performance across key segments. Business trends indicate a clear shift towards sustainable and cost-effective construction materials, with non-metal conduits gaining preference due to their durability, ease of installation, and inherent safety features. The global push for enhanced electrical safety standards and the continuous expansion of residential infrastructure, particularly in rapidly urbanizing regions, are fundamental drivers. Additionally, innovations in polymer technology are leading to the development of advanced conduit materials that offer improved fire resistance, greater flexibility, and superior protection against environmental stressors, thereby expanding their application scope and market penetration. Manufacturers are also focusing on optimizing production processes and supply chain efficiencies to meet the escalating demand while maintaining competitive pricing, fostering a dynamic and innovative market environment.

Regionally, the market exhibits diverse growth patterns. Emerging economies in Asia Pacific and Latin America are poised for significant expansion, primarily due to rapid urbanization, substantial investments in affordable housing projects, and a burgeoning middle class demanding modern residential amenities. North America and Europe, while mature, are characterized by steady growth attributed to continuous renovation activities, stringent building codes that favor non-metal solutions, and the increasing adoption of smart home technologies requiring complex and protected wiring networks. The Middle East and Africa also present emerging opportunities, spurred by large-scale residential developments and infrastructure upgrades. These regional trends collectively underscore the market's global resilience and its responsiveness to local economic conditions and regulatory frameworks, indicating a balanced growth trajectory across different geographic landscapes.

Segment-wise, the market sees strong performance across various material types and applications. PVC conduits continue to dominate due to their cost-effectiveness and versatility, while HDPE and PP conduits are gaining traction owing to their enhanced flexibility, impact resistance, and suitability for diverse environmental conditions. The application segment for new residential construction holds the largest share, propelled by global housing demands, but the renovation and remodeling segment is demonstrating accelerated growth as older homes are updated with safer and more efficient electrical systems. Flexible conduits are increasingly favored for complex installations requiring adaptability, whereas rigid conduits remain essential for straight, long runs where robust physical protection is paramount. These segmentation trends highlight the market's ability to cater to a wide spectrum of residential electrical wiring needs, adapting to both traditional and contemporary construction methodologies with tailored product offerings.

AI Impact Analysis on Residential Non-Metal Electrical Conduit Market

User inquiries about AI's impact on the Residential Non-Metal Electrical Conduit Market primarily revolve around how artificial intelligence could optimize manufacturing processes, enhance design and installation efficiency, and integrate with smart home systems. Common themes include expectations for AI-driven material innovation, predictive maintenance capabilities for electrical systems, and the potential for AI to streamline supply chains and project management in residential construction. There is also significant interest in how AI could contribute to improved safety protocols and automated quality control during conduit production and deployment. Users are keen to understand if AI could personalize conduit solutions for specific residential layouts or even enable intelligent routing of conduits through advanced architectural design software, leading to more efficient and less wasteful installations.

- AI in manufacturing optimization: Predictive maintenance for machinery, quality control, material waste reduction.

- AI-enhanced design tools: Automated conduit routing, clash detection in BIM (Building Information Modeling) software.

- Supply chain efficiency: Demand forecasting, inventory management, logistics optimization.

- Installation support: AI-powered robotics for repetitive installation tasks, smart tools for precision.

- Smart home integration: Conduits designed for easy integration with AI-controlled smart electrical grids and IoT devices.

- Predictive analytics for system longevity: Monitoring conduit health and electrical system performance.

- Safety and compliance: AI-driven analysis of installation methods to ensure adherence to safety codes.

- Material innovation: AI accelerating R&D for new conduit materials with enhanced properties.

DRO & Impact Forces Of Residential Non-Metal Electrical Conduit Market

The Residential Non-Metal Electrical Conduit Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and impact forces. A primary driver is the continuous expansion of residential construction globally, fueled by population growth, rapid urbanization, and increased disposable incomes in developing regions, leading to a consistent demand for new housing units and associated electrical infrastructure. Additionally, the growing emphasis on electrical safety and the adoption of more stringent building codes worldwide, which often mandate the use of protected wiring systems, significantly bolster the demand for non-metal conduits. The inherent benefits of these conduits, such as their lightweight nature, corrosion resistance, and superior insulation properties compared to metallic alternatives, further contribute to their market appeal and adoption, driving sustained growth.

Conversely, several restraints impede the market's growth potential. Fluctuations in the prices of raw materials, primarily polymers like PVC, HDPE, and PP, can directly impact manufacturing costs and, consequently, the final product prices, potentially affecting market penetration. Intense competition from traditional metal conduits, particularly in certain regions or for specific applications where metal is historically preferred or mandated, also presents a challenge. The lack of standardized installation practices in some emerging markets can lead to improper usage, compromising system integrity and reputation. Furthermore, economic downturns or recessions can significantly slow down residential construction activities, directly suppressing demand for electrical conduits, as construction projects are often highly sensitive to macroeconomic conditions and consumer confidence levels.

Despite these restraints, significant opportunities exist for market expansion. The increasing trend towards smart homes and integrated building management systems offers a lucrative avenue for non-metal conduits, as they are ideal for housing the complex network of power and data cables required for these advanced systems. Innovations in material science, leading to the development of more fire-retardant, UV-resistant, and sustainable conduit materials, create new market niches and enhance product performance. Furthermore, strategic collaborations between conduit manufacturers, construction companies, and smart home technology providers can accelerate market penetration and foster integrated solutions. The rising focus on renovating and upgrading aging residential infrastructure in mature economies also presents a substantial opportunity for replacing outdated electrical systems with modern, safer non-metal conduit installations, ensuring long-term market vitality and addressing evolving consumer needs and regulatory requirements.

Segmentation Analysis

The Residential Non-Metal Electrical Conduit Market is comprehensively segmented based on material type, application, and structure, each offering unique characteristics and catering to specific market needs. This granular segmentation allows for a detailed understanding of market dynamics, identifying key growth areas and consumer preferences. The dominance of certain materials like PVC reflects their cost-effectiveness and versatility, while the increasing adoption of HDPE and PP highlights a growing demand for specialized properties such as enhanced flexibility and chemical resistance. Application-wise, new construction remains a foundational segment, but the burgeoning renovation and remodeling market demonstrates significant potential for future expansion. Structurally, both flexible and rigid conduits serve distinct purposes, with advancements in manufacturing continually improving their respective functionalities and ease of installation.

- By Material Type

- PVC (Polyvinyl Chloride) Conduit: Widely used due to cost-effectiveness, chemical resistance, and ease of installation.

- HDPE (High-Density Polyethylene) Conduit: Known for flexibility, durability, and superior impact strength, suitable for underground applications.

- PP (Polypropylene) Conduit: Offers good heat resistance and rigidity, often used in specific industrial or high-temperature residential zones.

- Other Polymers (e.g., Nylon, Fiberglass): Niche applications requiring specific properties like extreme temperature tolerance or enhanced tensile strength.

- By Application

- New Residential Construction: Installation in newly built single-family homes, multi-family units, and apartment complexes.

- Renovation and Remodeling: Upgrading existing electrical systems in older homes, adding new circuits, or extending wiring.

- By Structure

- Flexible Conduits: Easier to install in tight spaces and around obstacles, reduces need for fittings.

- Rigid Conduits: Provides maximum physical protection, suitable for straight runs and exposed applications.

Value Chain Analysis For Residential Non-Metal Electrical Conduit Market

The value chain for the Residential Non-Metal Electrical Conduit Market begins with upstream activities involving the procurement of raw materials, primarily various polymer resins such as PVC, HDPE, and PP, from petrochemical industries. These raw materials undergo processing and extrusion to form conduit pipes and fittings. Key suppliers in this stage are chemical companies and polymer producers who provide the essential inputs for manufacturing. The quality and cost of these raw materials significantly influence the final product's performance and market competitiveness. Efficient sourcing and stable supply agreements with reputable raw material providers are critical for manufacturers to ensure consistent production and manage operational costs effectively, forming the foundational layer of the value chain.

Midstream in the value chain, manufacturers convert raw polymers into a diverse range of non-metal electrical conduits, including various sizes, types (flexible, rigid), and specialized fittings. This stage involves complex extrusion processes, quality control, and packaging. Manufacturers invest in research and development to innovate new materials, improve product characteristics such as flame retardancy and UV resistance, and enhance manufacturing efficiency. The distribution channel then plays a crucial role in delivering these products to the residential construction market. Distribution often involves both direct and indirect channels. Direct sales may occur for large-scale construction projects or direct supply to major contractors, fostering strong client relationships and offering customized solutions.

Indirect distribution is more common for the residential market, utilizing a network of wholesalers, distributors, electrical supply houses, and retail hardware stores. These intermediaries store inventory, provide logistical support, and make products readily accessible to electricians, small contractors, and DIY enthusiasts. Downstream activities involve the installation of these conduits by electrical contractors and skilled electricians in residential buildings. The efficiency and quality of installation are critical for ensuring electrical safety and compliance with building codes. End-users, ultimately the homeowners, benefit from the safe and reliable electrical systems facilitated by these conduits. After-sales support, technical assistance, and adherence to product standards throughout this entire chain are essential for market reputation and sustained growth.

Residential Non-Metal Electrical Conduit Market Potential Customers

The primary potential customers and end-users of non-metal electrical conduits in the residential market segment are diverse, encompassing various stakeholders involved in the construction and maintenance of residential properties. Professional electrical contractors form a significant customer base, as they are responsible for designing, installing, and maintaining electrical systems in both new constructions and renovation projects. Their purchasing decisions are often driven by product reliability, compliance with local building codes, ease of installation, and cost-effectiveness. These contractors regularly procure bulk quantities of conduits and associated fittings for their ongoing projects, making them crucial direct and indirect buyers through distributors and wholesalers. Understanding their needs for efficiency and safety is paramount for manufacturers and suppliers.

Beyond specialized contractors, general construction companies and residential developers are also key potential customers. These entities oversee entire residential building projects, from planning to completion, and are increasingly involved in specifying materials that meet performance, budget, and sustainability criteria. They prioritize suppliers who can offer consistent quality, timely delivery, and comprehensive product ranges that simplify procurement processes across multiple sites. The growth in residential development, including single-family homes, multi-family units, and planned communities, directly translates into increased demand for electrical conduits to lay down foundational electrical infrastructure for diverse housing types. Meeting the demands of these large-scale buyers requires robust supply chain capabilities and competitive offerings.

Furthermore, individual homeowners engaged in do-it-yourself (DIY) renovation or home improvement projects, as well as property management companies responsible for maintaining residential complexes, represent an important segment of potential customers. While their individual purchase volumes might be smaller than professional contractors, their collective demand contributes substantially to the market, often channeled through retail hardware stores and home improvement centers. These buyers seek user-friendly products, clear installation guidelines, and readily available options for repair or minor upgrades. Catering to this segment involves effective retail distribution and clear product information, highlighting the safety and ease of use of non-metal conduits for various residential applications, ensuring broad market reach and consumer satisfaction across all levels.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $2.95 Billion |

| Market Forecast in 2032 | $4.70 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Atkore International Group Inc., Hubbell Incorporated, Legrand SA, Schneider Electric SE, Dura-Line (Orbia), Sekisui Chemical Co. Ltd., Mitsubishi Chemical Corporation, Georg Fischer AG, Pipelife International GmbH (Wienerberger AG), Phoenix Contact GmbH & Co. KG, HellermannTyton Group PLC (Delphi Technologies), Thomas & Betts Corporation (ABB Company), Wheatland Tube Company, Cantex Inc., IPEX Inc., Aliaxis Group SA, Electri-Flex Company, AFC Cable Systems Inc. (Atkore International), Southwire Company LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Residential Non-Metal Electrical Conduit Market Key Technology Landscape

The technological landscape of the Residential Non-Metal Electrical Conduit Market is continuously evolving, driven by advancements in material science, manufacturing processes, and installation techniques, all aimed at enhancing product performance, safety, and ease of use. A crucial aspect is the development of advanced polymer compounds that exhibit superior properties such as improved flame retardancy, low smoke emission, enhanced UV resistance, and increased impact strength. These innovations ensure that conduits can withstand more demanding environmental conditions and meet increasingly stringent fire safety regulations, providing greater protection for residential electrical systems. Manufacturers are investing heavily in R&D to create conduit materials that are not only more durable but also more environmentally friendly, incorporating recycled content or bio-based polymers to align with sustainability goals in construction. This focus on material innovation directly impacts the longevity and safety profile of the conduits.

Manufacturing technologies are also undergoing significant advancements, particularly in extrusion processes. Precision extrusion techniques allow for the production of conduits with consistent wall thickness, smoother interior surfaces, and tighter dimensional tolerances, which facilitates easier wire pulling and reduces installation time. Co-extrusion technologies enable the creation of multi-layered conduits that combine different material properties, such as a robust outer layer for protection and a specialized inner layer for improved cable glide. Automation and robotics are increasingly integrated into production lines to enhance efficiency, reduce labor costs, and improve overall product quality and consistency. These manufacturing innovations allow for high-volume production of diverse conduit types while maintaining rigorous quality control standards, ensuring reliability across product batches.

Furthermore, technology related to conduit fittings and installation tools is a significant area of development. Innovations include snap-on connectors, solvent-free joining methods, and advanced bendable conduits that minimize the need for specialized tools and reduce installation complexity. The integration of Building Information Modeling (BIM) software and other digital design tools allows for precise planning and routing of conduit systems within residential projects, optimizing material usage and reducing on-site errors. The future of the technology landscape also points towards conduits designed for smart home integration, incorporating features that facilitate the easy installation and management of IoT devices and data cables alongside power wiring. This includes conduit systems that can accommodate future technological upgrades, ensuring long-term adaptability and readiness for emerging residential electrical and data network demands.

Regional Highlights

- North America: A mature market characterized by stringent building codes, significant renovation activities, and a growing emphasis on electrical safety. The United States and Canada are leading the adoption of non-metal conduits, driven by steady housing starts and robust smart home technology integration.

- Europe: Exhibits steady growth, with Germany, France, and the UK being key contributors. The region benefits from ongoing infrastructure modernization, energy efficiency mandates, and a preference for sustainable construction materials. Regulatory support for non-halogenated and low-smoke, zero-halogen (LSZH) conduits is also a key factor.

- Asia Pacific (APAC): The fastest-growing region due to rapid urbanization, massive investments in residential infrastructure, and an expanding middle class in countries like China, India, and Southeast Asian nations. Increased awareness of electrical safety and rising disposable incomes fuel demand for modern residential electrical systems.

- Latin America: Showing promising growth, particularly in countries like Brazil and Mexico, driven by increasing residential construction, government initiatives for affordable housing, and a rising focus on improving electrical safety standards in new developments and existing homes.

- Middle East and Africa (MEA): An emerging market with significant potential, bolstered by large-scale residential and commercial projects in the GCC countries and increasing foreign investments in housing and urban development across African nations. The adoption is also influenced by extreme climate conditions requiring durable and corrosion-resistant electrical solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Residential Non-Metal Electrical Conduit Market.- ABB Ltd.

- Atkore International Group Inc.

- Hubbell Incorporated

- Legrand SA

- Schneider Electric SE

- Dura-Line (Orbia)

- Sekisui Chemical Co. Ltd.

- Mitsubishi Chemical Corporation

- Georg Fischer AG

- Pipelife International GmbH (Wienerberger AG)

- Phoenix Contact GmbH & Co. KG

- HellermannTyton Group PLC (Delphi Technologies)

- Thomas & Betts Corporation (ABB Company)

- Wheatland Tube Company

- Cantex Inc.

- IPEX Inc.

- Aliaxis Group SA

- Electri-Flex Company

- AFC Cable Systems Inc. (Atkore International)

- Southwire Company LLC

Frequently Asked Questions

What materials are commonly used in residential non-metal electrical conduits?

Residential non-metal electrical conduits are predominantly made from PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), and PP (Polypropylene). These materials are chosen for their insulating properties, flexibility, and resistance to corrosion and chemicals, ensuring safe and durable electrical installations.

Why are non-metal conduits preferred over metal conduits in residential applications?

Non-metal conduits offer several advantages for residential use, including being lightweight, corrosion-resistant, and easier to install. They provide superior dielectric strength, reducing the risk of electrical shock and short circuits, and often exhibit better fire resistance properties, enhancing overall home safety.

What are the primary applications of non-metal electrical conduits in homes?

Non-metal electrical conduits are widely used in residential new construction and renovation projects. They are essential for protecting power circuits, communication cables, and data lines within walls, ceilings, and floors, safeguarding wiring from physical damage, moisture, and pests, especially in concealed installations.

How do building codes influence the adoption of non-metal conduits?

Building codes and electrical safety standards significantly drive the adoption of non-metal conduits by mandating specific protection for electrical wiring in residential settings. These regulations often favor non-metallic options due to their safety features and fire resistance, ensuring compliance and enhancing occupant safety.

What emerging trends are impacting the residential non-metal electrical conduit market?

Key emerging trends include the increasing demand for smart home integration, which requires extensive and protected wiring for IoT devices and data networks. Additionally, advancements in sustainable materials and a growing focus on ease of installation and labor cost reduction are shaping product development and market dynamics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager