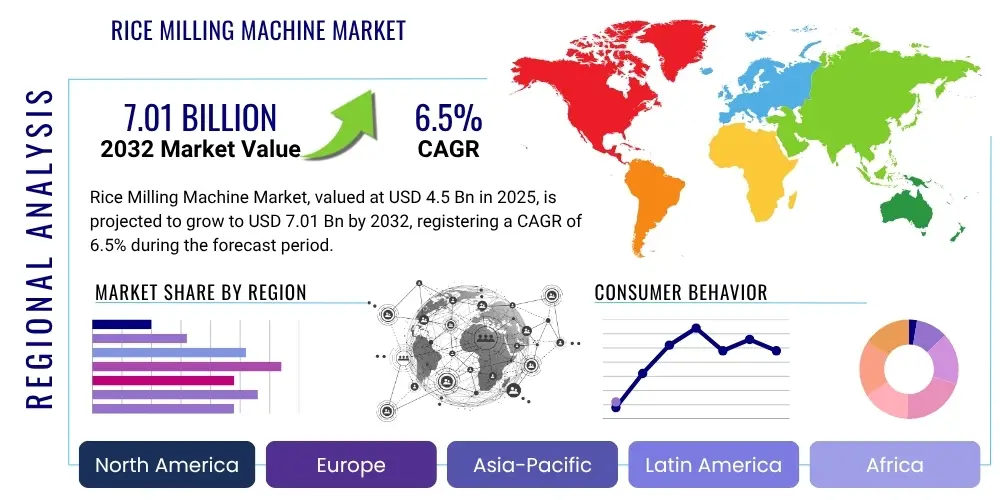

Rice Milling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430396 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Rice Milling Machine Market Size

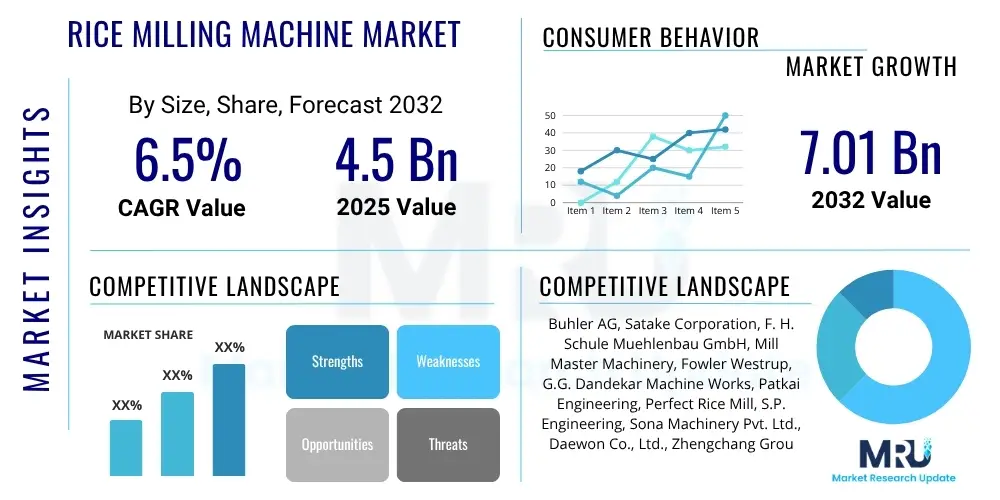

The Rice Milling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 4.5 Billion in 2025 and is projected to reach USD 7.01 Billion by the end of the forecast period in 2032.

Rice Milling Machine Market introduction

The Rice Milling Machine Market plays a pivotal and indispensable role in ensuring global food security, serving as the critical link between paddy cultivation and the final consumption of rice. These sophisticated machines are engineered to meticulously process raw paddy rice, transforming it into various forms of edible rice, predominantly polished white rice, through a series of intricate post-harvest operations. The market landscape is remarkably diverse, encompassing a spectrum of equipment ranging from rudimentary small-scale hullers designed for local farmers and micro-enterprises to highly advanced, fully automated industrial milling complexes capable of processing immense volumes of paddy for large-scale commercial distribution and international export. The foundational drivers sustaining and expanding this market are unequivocally linked to the burgeoning global population, which necessitates consistently increasing rice production, coupled with the unyielding and pervasive demand for rice as a primary staple food across diverse cultures and economies worldwide.

A rice milling machine is essentially a technological system meticulously designed to remove the non-edible husk and various layers of bran from raw paddy grains, ultimately yielding polished rice suitable for human consumption. The comprehensive milling process typically involves multiple distinct stages, commencing with initial cleaning and de-stoning to eliminate impurities, followed by hulling to remove the outer husk, then paddy separation, and subsequently whitening or polishing to remove the bran layers and enhance the grain's appearance. The major applications of these machines are widespread, spanning from direct use by individual farmers for processing their harvest for personal consumption or local sales, to large-scale commercial rice mills that process vast quantities for both domestic distribution and international export markets, and increasingly, industrial food processing units that utilize rice as a fundamental ingredient in their diverse product lines. The tangible benefits derived from adopting modern rice milling machines are extensive, notably encompassing substantial enhancements in milling efficiency, a significant reduction in prevalent post-harvest losses, a marked improvement in the overall quality and aesthetic appeal of the final rice product, and ultimately, an augmented profitability for millers through superior yield recovery and increased market value.

Several key driving factors are propelling the robust expansion of the Rice Milling Machine Market globally. Foremost among these is the escalating global consumption of rice, which is inextricably linked to demographic trends and dietary habits, thereby necessitating more efficient and high-capacity processing solutions. Furthermore, the persistent trend of increasing urbanization and the emergence of a growing middle class, particularly in rapidly developing economies, are contributing to a heightened demand for high-quality, consistently processed, and hygienically packaged rice products. This shift in consumer preference consequently motivates millers to invest strategically in advanced and modern milling machinery. Additionally, supportive government initiatives and policies, including various subsidies for agricultural mechanization, grants for adopting modern farming equipment, and the implementation of more stringent quality control and food safety standards, all contribute significantly to stimulating the market's continued expansion. The continuous stream of technological advancements, particularly those focused on improving energy efficiency, enhancing automation capabilities, and minimizing the overall environmental impact of milling operations, further acts as a powerful catalyst, accelerating the adoption of new and innovative milling technologies across the industry.

Rice Milling Machine Market Executive Summary

The Rice Milling Machine Market is currently experiencing a period of significant expansion, fundamentally driven by the escalating global demand for rice and the critical need for enhanced operational efficiency throughout the post-harvest processing chain. Current business trends within the sector vividly indicate a decisive shift towards the integration of advanced automation, intelligent milling systems, and meticulously engineered energy-efficient designs. These strategic technological adoptions are primarily aimed at optimizing operational costs, minimizing environmental footprints, and consistently elevating the quality of the final rice product. Leading manufacturers are placing a profound emphasis on incorporating sophisticated sensor technologies, artificial intelligence, and robust data analytics platforms to offer integrated smart milling solutions. These innovations provide millers with capabilities such as real-time monitoring of milling parameters, predictive maintenance insights, and comprehensive control over the entire processing workflow. This intensified focus on technological innovation is proving absolutely crucial for meeting the dynamic and evolving demands of the global rice industry, while simultaneously addressing pressing challenges such as persistent labor shortages and the increasing imperative for greater sustainability across the value chain.

From a regional perspective, the Asia Pacific region continues to assert its formidable dominance within the global Rice Milling Machine Market. This leadership is directly attributable to the region's unparalleled rice production volumes and extraordinarily high consumption rates, with agrarian powerhouses such as China, India, Vietnam, and Thailand consistently leading the way in both sheer milling capacity and the rapid adoption of cutting-edge technological advancements. Concurrently, emerging economies across Africa and Latin America are exhibiting considerable growth potential, spurred by proactive government initiatives aimed at modernizing their respective agricultural sectors and bolstering domestic food security. These developing regions are increasingly becoming focal points for increased investment in small and medium-scale milling solutions, a strategy designed to foster local agricultural development and diminish reliance on imported processed rice. The intricate and interconnected nature of global rice trade also profoundly influences regional market dynamics, compelling major rice-exporting nations to invest substantially in sophisticated machinery to rigorously meet and surpass stringent international quality standards, thereby maintaining their competitive edge in global markets.

A meticulous analysis of market segmentation reveals distinct and impactful trends across capacity, machine type, and technological adoption. There is a discernible and accelerating demand for large-scale, fully automatic rice milling machines, particularly within expansive commercial milling operations. These sophisticated systems are crucial for achieving exceptionally high throughput rates and ensuring consistently uniform product quality, a prerequisite for successfully serving demanding domestic markets and lucrative international export channels. Simultaneously, there is a burgeoning interest and corresponding investment in compact, modular, and semi-automatic machines, specifically tailored for the needs of small and medium-sized farms and rural agricultural cooperatives. This trend facilitates decentralized processing capabilities, thereby empowering local communities, enhancing their value addition, and fostering greater economic autonomy. The widespread adoption of advanced cleaning, optical sorting, and precision polishing technologies is rapidly becoming an industry-wide standard across all market segments, unequivocally reflecting a universal and unwavering drive towards producing premium rice products, drastically minimizing waste, and ultimately maximizing overall profitability.

AI Impact Analysis on Rice Milling Machine Market

Common user inquiries regarding the profound influence of Artificial Intelligence (AI) on the Rice Milling Machine Market frequently converge on how this transformative technology can significantly enhance operational efficiency, ensure superior rice grain quality, and substantially contribute to overall cost reduction within milling operations. Users are particularly keen to understand AI's diverse applications, such as its crucial role in implementing predictive maintenance strategies, its ability to deliver unparalleled accuracy in quality control systems, its capacity for real-time optimization of complex milling processes, and the long-term potential for achieving fully autonomous operational capabilities. There is also a pronounced interest in assessing the economic feasibility and practical integration challenges inherently associated with deploying sophisticated AI-driven solutions within both existing and newly constructed milling infrastructures. Generally, users hold high expectations that AI will fundamentally revolutionize rice processing by introducing unprecedented levels of precision, automation, and data-driven insights. However, they also express legitimate concerns regarding the substantial initial investment costs, the critical need for highly specialized technical expertise to manage these advanced systems, and the increasingly important implications surrounding data privacy and security.

- Enhanced precision in quality control through advanced AI-powered optical sorters, capable of accurately identifying and separating defective grains, detecting subtle color variations, and meticulously removing foreign materials with unparalleled efficiency and reliability.

- Predictive maintenance capabilities, where sophisticated AI algorithms meticulously analyze vast quantities of real-time machine performance data to accurately forecast potential equipment failures, thereby minimizing costly unplanned downtime and significantly optimizing scheduled maintenance operations.

- Dynamic optimization of milling parameters in real-time, allowing intelligent machines to autonomously adjust settings such as de-husking pressure, polishing duration, and separation speeds based on the real-time characteristics of the paddy, ultimately maximizing yield and consistently improving rice quality.

- Comprehensive supply chain optimization achieved by leveraging AI for highly accurate demand forecasting, efficient inventory management across multiple locations, and streamlined logistics planning, which collectively reduces waste, improves operational flow, and enhances overall market responsiveness from farm to consumer.

- Facilitation of autonomous or semi-autonomous milling operations, progressively reducing the reliance on manual labor for repetitive and arduous tasks, thereby mitigating human error, enhancing workplace safety, and improving overall processing consistency.

- Significant improvements in energy efficiency throughout the milling process, driven by AI-powered process optimization that intelligently manages and reduces power consumption during various stages of cleaning, hulling, whitening, and polishing, contributing to lower operational costs and environmental sustainability.

DRO & Impact Forces Of Rice Milling Machine Market

The Rice Milling Machine Market is profoundly shaped by a complex and dynamic interplay of driving forces, inherent restraints, emerging opportunities, and broader impact forces that collectively dictate its trajectory. At the forefront of the drivers is the relentless growth of the global human population, which directly translates into an incessantly increasing demand for staple food commodities like rice, thereby creating an urgent necessity for highly efficient and high-capacity milling solutions capable of meeting this burgeoning consumption. Furthermore, the sustained rise in disposable incomes, particularly observed in rapidly developing economies, is precipitating a significant shift in consumer preferences towards higher quality, aesthetically pleasing, and consistently polished rice varieties. This evolving consumer demand compels millers to strategically invest in more advanced and sophisticated machinery capable of consistently meeting these exacting standards. Concurrently, proactive government support, manifest through various subsidies, targeted grants, and forward-thinking policies actively promoting agricultural mechanization, plays an absolutely crucial role in stimulating market expansion, especially within the world's most prominent rice-producing regions. These policy interventions often reduce the financial burden on farmers and millers, accelerating the adoption of modern technology.

Conversely, the market is confronted with several substantial restraints that impede its growth potential. A primary barrier is the considerable initial capital investment typically required for acquiring modern, high-capacity rice milling machines. This significant financial outlay can prove prohibitive for numerous small and medium-sized enterprises (SMEs) and individual farmers, particularly in economies where access to affordable credit and robust financial infrastructure is limited. Additionally, the persistent and widespread shortage of skilled labor proficient in the intricate operation, routine maintenance, and complex repair of advanced milling equipment presents considerable operational challenges. This deficit in expertise often leads to inefficiencies, increased downtime, and higher operational costs. Furthermore, the inherent volatility in global paddy rice prices, coupled with broader macroeconomic uncertainties and geopolitical tensions, can significantly impact investment decisions across the sector, thereby introducing an element of market instability and unpredictability. Environmental considerations, particularly concerning the sustainable disposal and utilization of voluminous rice husk and bran by-products, are also emerging as increasingly relevant restraints, exerting pressure on the industry to develop and adopt more eco-friendly and circular processing solutions.

Despite these aforementioned challenges, numerous lucrative opportunities are dynamically emerging within the Rice Milling Machine Market, promising future growth and innovation. Foremost among these are continuous technological advancements, including the seamless integration of sophisticated automation, Internet of Things (IoT) connectivity, and Artificial Intelligence (AI) into milling machinery. These innovations are opening entirely new avenues for dramatically enhanced efficiency, unparalleled precision in processing, and optimal yield recovery. There is also a substantial and largely untapped potential in rapidly emerging economies, particularly across various regions of Africa and parts of Latin America, where ambitious agricultural modernization initiatives are steadily gaining momentum. These efforts are directly translating into an increased and urgent demand for efficient, reliable milling solutions to support local food security and economic development. The intensified global focus on sustainability and the proactive development of eco-friendly milling processes that not only minimize waste generation but also maximize energy efficiency represent highly lucrative prospects for innovative product development and strategic market differentiation. Moreover, the burgeoning global demand for specialty rice varieties, organic rice, and various value-added rice products offers enticing new market segments for advanced, precision-oriented milling technologies capable of catering to these specific niche requirements.

Segmentation Analysis

The Rice Milling Machine Market is meticulously segmented across various crucial parameters, offering a granular and comprehensive understanding of its intricate structure and underlying dynamics. This strategic segmentation is instrumental in effectively analyzing prevailing market trends, accurately identifying nascent growth opportunities, and discerning the highly varied demands of a diverse array of end-users within the global rice processing industry. The market can be broadly categorized based on several pivotal criteria, including the specific type of milling machine, its operational capacity, the level of technological sophistication employed, and its primary intended application. Each distinct segment reveals unique market characteristics, specific growth trajectories, and varying degrees of sensitivity to market forces, collectively reflecting the broad spectrum of operational needs and investment priorities prevalent within the expansive global rice processing sector.

A rigorous analysis of these segmented categories empowers all relevant stakeholders, including manufacturers, distributors, and investors, to formulate and implement more precise and effective strategies for product development, market penetration, and competitive positioning. For instance, segmenting by capacity clearly differentiates between machines designed for small-scale agricultural operations, typically individual farms or local communities, versus those engineered for vast industrial complexes, thereby highlighting fundamentally distinct buyer personas, technical specifications, and budgetary considerations. Similarly, the segmentation by technology eloquently illustrates the industry's accelerating migration towards greater automation, digital integration, and AI-driven solutions, unequivocally indicating the prevailing and future investment priorities. A deep and nuanced understanding of these critical market differentiations is paramount for any entity seeking to successfully capitalize on specific market niches or leverage broader, overarching trends within the highly competitive and dynamically evolving rice milling sector.

- By Type

- Combined Rice Mill: Integrated units performing multiple milling stages.

- Single Rice Mill: Machines specialized for one particular milling function.

- Huller Rice Mill: Primarily designed for de-husking paddy grains.

- Polisher: Used for refining and enhancing the appearance of milled rice.

- Paddy Cleaner and De-stoner: Essential for removing impurities and stones.

- Paddy Husker: Specifically designed to remove the outer husk from paddy.

- Paddy Separator: Differentiates husked rice from unhusked paddy.

- Rice Grader: Sorts milled rice by size and quality.

- By Capacity

- Small Scale (Under 1 Ton/Hr): Suitable for individual farmers and small businesses.

- Medium Scale (1-5 Ton/Hr): Caters to agricultural cooperatives and regional millers.

- Large Scale (Above 5 Ton/Hr): Designed for high-volume commercial and industrial operations.

- By Technology

- Automatic: Fully automated systems requiring minimal human intervention.

- Semi-Automatic: Combines automated processes with manual controls.

- Manual: Hand-operated or mechanically assisted basic milling units.

- By Application

- Commercial Rice Mills: Large-scale operations for widespread distribution.

- Farm Use: Small-scale processing by individual farmers for personal consumption or local sale.

- Industrial Use: Processing rice as an ingredient for other food products.

- Research & Development: For testing new rice varieties and milling techniques.

Value Chain Analysis For Rice Milling Machine Market

The value chain for the Rice Milling Machine Market meticulously maps out the sequential activities that generate value, spanning from the initial sourcing of raw materials to the ultimate delivery of the product and crucial after-sales support. Upstream activities constitute the foundational segment of this chain, primarily involving the strategic procurement of essential components and diverse raw materials. This includes high-grade steel, robust electric motors, advanced electronic control units, durable conveyor belts, specialized sieves, and precision sensors from a network of vetted suppliers. Component manufacturers play an absolutely pivotal role in this stage, responsible for providing meticulously engineered, high-quality, and resilient parts that strictly adhere to the rigorous specifications required for the continuous and robust operation of sophisticated milling machinery. The operational efficiency and cost-effectiveness achieved during these upstream processes directly and significantly influence the overall quality, performance, and ultimate pricing of the final rice milling product, thereby forming the indispensable foundational layer of the entire value chain.

Midstream activities represent the core manufacturing and assembly phase within the value chain, centrally focusing on the precise manufacturing, intricate assembly, and rigorous quality control protocols applied to the rice milling machines themselves. This critical stage demands complex engineering expertise, precision machining, and exhaustive testing procedures to ensure that each machine not only meets but often exceeds stringent performance, efficiency, and safety standards mandated by the industry and regulatory bodies. Furthermore, dedicated research and development (R&D) initiatives constitute an integral part of this midstream segment, as manufacturers are continuously driven to innovate and introduce progressively more efficient, highly automated, and environmentally sustainable milling technologies. Effective production management, characterized by lean manufacturing principles and strict adherence to industry best practices, is paramount at this stage for consistently delivering highly competitive and market-leading products.

Downstream activities encompass the critical processes of distribution, sales, initial installation, and comprehensive after-sales support for the rice milling machines. The distribution channels utilized are highly diversified, ranging from direct sales engagements with large-scale commercial mills, which often foster closer customer relationships and allow for tailored solutions, to indirect sales strategies executed through an extensive network of authorized dealers and specialized distributors. Increasingly, digitally-enabled online platforms are also emerging as viable channels, particularly for smaller-scale and more modular equipment, offering wider market reach and convenience. Post-sale services, which include expert installation, thorough operational training for end-users, routine maintenance schedules, prompt provision of spare parts, and responsive technical support, are absolutely critical for ensuring sustained customer satisfaction, fostering long-term brand loyalty, and maintaining a formidable market presence. An exceptionally efficient and resilient distribution network, coupled with robust and responsive after-sales support infrastructure, serves as a key differentiator in this highly competitive market, guaranteeing operational continuity and maximizing the lifecycle value for the ultimate end-users.

Rice Milling Machine Market Potential Customers

The potential customer base for rice milling machines is exceptionally broad and spans a wide spectrum, meticulously reflecting the diverse operational scales and specific needs prevalent across the global rice industry. At the foundational and most widespread level, smallholder farmers constitute a profoundly significant customer segment, particularly prominent in agrarian economies within developing countries. For these farmers, the primary demand centers around compact, user-friendly, and economically affordable milling solutions, primarily intended for local consumption and small-scale direct sales within their communities. These crucial end-users invariably prioritize key attributes such as ease of operation, inherent durability to withstand challenging conditions, and overall cost-effectiveness, seeking machines that offer a swift return on investment. The capability to process their own harvested paddy significantly mitigates reliance on external milling services, drastically reduces transportation costs, and substantially increases their direct control over the final product quality, thereby measurably enhancing their potential income and economic autonomy.

Progressing up the organizational scale, agricultural cooperatives and various farmer associations represent another absolutely vital customer group within the market. These collective entities often make strategic investments in medium-capacity milling machines, explicitly designed to efficiently serve the collective processing needs of their numerous members. This collaborative approach facilitates the optimal sharing of valuable resources, enhances processing efficiencies, and significantly improves market access for substantially larger volumes of paddy. Such organized groups are particularly keen to leverage the benefits of economies of scale and invariably seek machines that offer higher throughput capabilities, superior operational efficiency, and advanced features for better rice quality. Their complex purchasing decisions are typically influenced by a rigorous assessment of collective benefit, long-term operational costs, the availability of comprehensive technical support, and the fundamental requirement for exceptionally reliable and robust equipment capable of enduring continuous, demanding operation over extended periods.

The most substantial segment of potential customers encompasses large-scale commercial rice milling companies and sophisticated industrial food processing units. These extensive enterprises demand high-capacity, fully automated, and technologically cutting-edge milling systems engineered to handle massive volumes of paddy. Their operational imperatives include consistently producing exceptionally high-quality rice for expansive domestic distribution networks and highly discerning international export markets, while also seamlessly integrating into broader, often automated, food production lines. For these formidable customers, critical performance metrics such as unparalleled operational efficiency, absolute minimization of post-harvest losses, advanced and precise optical sorting capabilities, sophisticated grading technologies, superior energy efficiency, and strict adherence to rigorous international food safety and quality standards are absolutely paramount. Additionally, governmental food security programs and various non-governmental organizations (NGOs) actively involved in agricultural development initiatives also represent important institutional buyers, particularly when procuring milling machines for community-level food processing projects aimed at enhancing food self-sufficiency and improving livelihoods in vulnerable populations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 Billion |

| Market Forecast in 2032 | USD 7.01 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Buhler AG, Satake Corporation, F. H. Schule Muehlenbau GmbH, Mill Master Machinery, Fowler Westrup, G.G. Dandekar Machine Works, Patkai Engineering, Perfect Rice Mill, S.P. Engineering, Sona Machinery Pvt. Ltd., Daewon Co., Ltd., Zhengchang Group, ABC Machinery, Shandong Sishui Deyi Grain & Oil Machinery, Jiangsu COFCO Engineering & Technology Co. Ltd., Alvan Blanch Development Co. Ltd., Goldin Machinery Co., Ltd., Henan Universal Machinery Manufacturing Co., Ltd., Jinsheng Rice Mill Machine Co., Ltd., VMT S.r.l. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rice Milling Machine Market Key Technology Landscape

The Rice Milling Machine Market is profoundly defined by a rapidly advancing and highly dynamic technological landscape, meticulously driven by an unrelenting pursuit of enhanced operational efficiency, superior rice grain quality, significant waste reduction, and the imperative for increasingly sustainable operational practices. Central to this pervasive evolution is the accelerating adoption of sophisticated automation and Programmable Logic Controller (PLC) systems. These advanced control mechanisms enable exceptionally precise and intricate management over every individual stage of the milling process, encompassing initial cleaning and thorough de-stoning, efficient hulling, meticulous whitening, and precision polishing. Such automated systems drastically minimize the need for manual human intervention, thereby ensuring consistently uniform product quality, optimizing complex processing parameters to maximize valuable yield, and ultimately reducing operational variability. The seamless integration of cutting-edge sensor technologies, prominently featuring highly accurate optical sorters and advanced moisture sensors, further augments this precision. These sensors facilitate real-time monitoring and exact sorting of rice grains based on critical attributes such as color, size, and the detection of minute defect levels, thereby significantly improving the overall purity and enhancing the market value of the final milled product.

Another profoundly significant technological trajectory observed within the industry is the pervasive incorporation of Internet of Things (IoT) capabilities into modern rice milling machinery. IoT connectivity enables extensive remote monitoring and precise control of complex milling operations, providing millers with invaluable, real-time data on machine performance metrics, detailed energy consumption patterns, and comprehensive production output. This wealth of aggregated data can then be rigorously analyzed using advanced analytics to promptly identify operational inefficiencies, accurately predict potential maintenance requirements well in advance, and intelligently optimize complex operational schedules, collectively leading to substantial cost savings, minimized downtime, and enhanced overall productivity. Furthermore, the rapidly burgeoning fields of Artificial Intelligence (AI) and Machine Learning (ML) are strategically beginning to revolutionize critical aspects of milling, such as highly accurate predictive maintenance and exceptionally sophisticated quality control. AI algorithms possess the remarkable capacity to learn from vast datasets, enabling them to identify subtle defects that might evade human observation and to forecast equipment failures proactively before they manifest, fundamentally transforming the reliability and resilience of operational infrastructure.

Beyond the realm of digital and intelligent technologies, continuous advancements in mechanical engineering also play an absolutely crucial and symbiotic role in shaping the modern rice milling landscape. This encompasses the meticulous development of significantly more energy-efficient motors and precision-engineered milling components that demonstrably reduce power consumption, directly aligning with pressing global sustainability objectives and reducing operational overheads. Precision milling techniques, exemplified by multi-stage processing involving carefully calibrated multiple passes through advanced whitening and polishing units, ensure a uniform and controlled removal of bran layers without inflicting damage to the delicate rice kernel, consistently yielding a product of superior quality and integrity. Innovations in primary de-stoning and pre-cleaning equipment, which include highly efficient vibratory separators and advanced aspirators, markedly enhance the purity of the raw paddy prior to its entry into the milling stages. This not only safeguards downstream machinery from potential damage but also dramatically elevates the quality of the final processed product. The overarching technological focus remains firmly on the development and deployment of fully integrated systems that offer comprehensive, end-to-end solutions for the entire rice processing journey, commencing from the raw paddy input all the way to impeccably packaged, high-quality white rice, maximizing value at every step.

Regional Highlights

The global Rice Milling Machine Market demonstrates pronounced regional disparities, with its dynamics significantly shaped by localized rice production volumes, prevalent consumption patterns, varying stages of economic development, and specific governmental agricultural policies. Asia Pacific consistently stands as the undisputed leader in this critical market, a position solidified by its status as the world's foremost rice-producing and consuming region. Countries such as China, India, Thailand, Vietnam, Indonesia, and Bangladesh collectively account for the vast majority of global rice output and possess extensively developed and continually expanding milling infrastructures. The region is witnessing an intense and ongoing drive towards modernizing its agricultural sector, which is directly translating into a substantial increase in the adoption of advanced and fully automated rice milling machines. This strategic investment aims to significantly enhance processing efficiency, drastically reduce pervasive post-harvest losses, and consistently meet the escalating domestic and international demand for high-quality, processed rice. Investment in large-scale, state-of-the-art commercial milling facilities is particularly robust and concentrated across this dynamic region.

Africa, particularly its sub-Saharan regions, represents a rapidly burgeoning market characterized by substantial inherent growth potential. Numerous African nations are actively engaged in ambitious pursuits of food self-sufficiency and are strategically investing in agricultural mechanization to substantially boost their domestic rice production and processing capabilities. Governments and international development organizations are vigorously promoting the widespread adoption of small and medium-scale rice milling machines, recognizing their pivotal role in empowering local farmers, creating rural employment, and significantly reducing reliance on costly imported rice. While the market in Africa is presently dominated by smaller, less automated milling solutions, there is a gradual but discernible transition towards more efficient and semi-automatic systems. This shift is being catalyzed by improving economic conditions, heightened awareness regarding the benefits of advanced technologies, and increasing foreign investment in the agricultural sector. Key countries such as Nigeria, Egypt, and Tanzania are at the forefront of this transformative modernization within the continent's rice milling sector.

Latin America is another pivotal region poised for substantial growth within the Rice Milling Machine Market, a trend largely propelled by expanding rice cultivation areas and a consistently growing demand for diverse processed rice products. Countries like Brazil, Argentina, and Colombia are actively modernizing their agricultural practices and making significant investments in highly efficient milling technologies. These efforts are aimed at not only improving overall productivity but also ensuring superior product quality to meet evolving consumer expectations. The strategic focus in this region is often dual-pronged: achieving consistent product quality for robust domestic consumption and rigorously meeting the exacting standards required for international export markets, which inherently necessitates the deployment of more sophisticated and precision-oriented milling machinery. Conversely, North America and Europe, while not primary global rice producers in terms of volume, maintain a significant niche market for highly specialized, premium, and often organic rice varieties. Demand in these regions is primarily for extremely highly automated, energy-efficient, and precision milling machines that cater to very specific processing requirements, often integrating advanced optical sorting and stringent quality control technologies to serve their discerning, premium consumer segments.

- Asia Pacific (APAC): Dominates the global market due to extensive rice cultivation, the largest consumer base, robust government support for agricultural modernization, and consistently high demand for both domestic consumption and international exports, particularly from powerhouse countries like China, India, Vietnam, and Thailand.

- Africa: An rapidly emerging market characterized by intensifying efforts towards achieving food security, widespread government initiatives promoting agricultural mechanization, and the growing adoption of modern milling technologies, with significant strides being made in key West and East African nations.

- Latin America: Experiencing substantial growth propelled by expanding rice cultivation areas, continuous modernization of farming practices, and increasing consumer demand for processed rice, with Brazil and Argentina serving as leading contributors to this regional expansion.

- North America: A technologically mature market with a pronounced focus on highly automated, energy-efficient, and precision milling machines specifically tailored for specialized rice varieties and smaller-scale, high-quality processing operations that serve niche segments.

- Europe: Similar to North America, characterized by a discerning demand for advanced, highly automated solutions for niche rice production and specialized processing, with a strong overarching emphasis on sustainability, stringent quality output, and compliance with rigorous European standards.

- Middle East: Possesses limited domestic rice production capabilities but exhibits significant and consistent demand for processed rice. This leads to strategic investment in sophisticated milling infrastructure for the processing of imported paddy or re-processing, with a primary focus on maximizing operational efficiency and product quality.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rice Milling Machine Market.- Buhler AG

- Satake Corporation

- F. H. Schule Muehlenbau GmbH

- Mill Master Machinery

- Fowler Westrup

- G.G. Dandekar Machine Works

- Patkai Engineering

- Perfect Rice Mill

- S.P. Engineering

- Sona Machinery Pvt. Ltd.

- Daewon Co., Ltd.

- Zhengchang Group

- ABC Machinery

- Shandong Sishui Deyi Grain & Oil Machinery

- Jiangsu COFCO Engineering & Technology Co. Ltd.

- Alvan Blanch Development Co. Ltd.

- Goldin Machinery Co., Ltd.

- Henan Universal Machinery Manufacturing Co., Ltd.

- Jinsheng Rice Mill Machine Co., Ltd.

- VMT S.r.l.

Frequently Asked Questions

What is a rice milling machine?

A rice milling machine is an essential agricultural processing device meticulously engineered to convert raw paddy rice into edible white rice by systematically removing the non-edible husk, multiple layers of bran, and various impurities. The comprehensive process typically involves cleaning, de-stoning, hulling, paddy separation, whitening, polishing, and precise grading, which collectively significantly enhance both the quality and shelf life of the final rice product for consumption.

What are the main types of rice milling machines?

Rice milling machines are primarily categorized based on their operational capacity (such as small, medium, or large scale) and their level of technological sophistication (ranging from manual and semi-automatic to fully automatic systems). Specific machine configurations include versatile combined rice mills (integrated units performing multiple stages), single-function rice mills (specialized for one particular milling task), robust huller rice mills, and precision polishers, each meticulously designed to serve distinct operational needs and cater to varying production scales within the industry.

How does a rice milling machine improve rice quality?

Rice milling machines significantly enhance rice quality by precisely and uniformly removing the non-edible husk and successive bran layers while meticulously minimizing any physical damage to the delicate rice kernel. Modern machines achieve this through advanced de-stoning, meticulous cleaning, sophisticated optical sorting, and precision polishing technologies. These integrated processes consistently produce clean, uniformly polished grains that are virtually free from impurities, discoloration, and structural defects, thereby substantially improving the rice's aesthetic appearance, optimizing its cooking quality, and ultimately elevating its market value and consumer appeal.

What are the key factors driving the growth of the rice milling machine market?

Key growth drivers propelling the rice milling machine market include the relentless rise in global rice consumption directly attributable to population expansion, a burgeoning consumer demand for high-quality, consistently processed rice products, widespread and increasing trends in agricultural mechanization across diverse regions, and proactive government initiatives that actively support the modernization of farming and food processing infrastructure, particularly in major rice-producing economies around the world. These factors collectively stimulate significant investment and adoption of advanced milling technologies.

What is the role of automation in modern rice milling?

Automation plays an absolutely critical role in modern rice milling by ensuring consistent and precise processing, achieving significantly higher operational efficiency, substantially reducing manual labor costs, and profoundly improving overall product quality. Automated systems meticulously control crucial parameters such as de-husking pressure and polishing duration, and seamlessly integrate advanced features like optical sorting and predictive maintenance. This comprehensive integration leads to optimized yield recovery, minimized waste generation, enhanced workplace safety, and considerably augmented operational reliability and longevity for milling operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager