Rigid Industrial Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430892 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Rigid Industrial Packaging Market Size

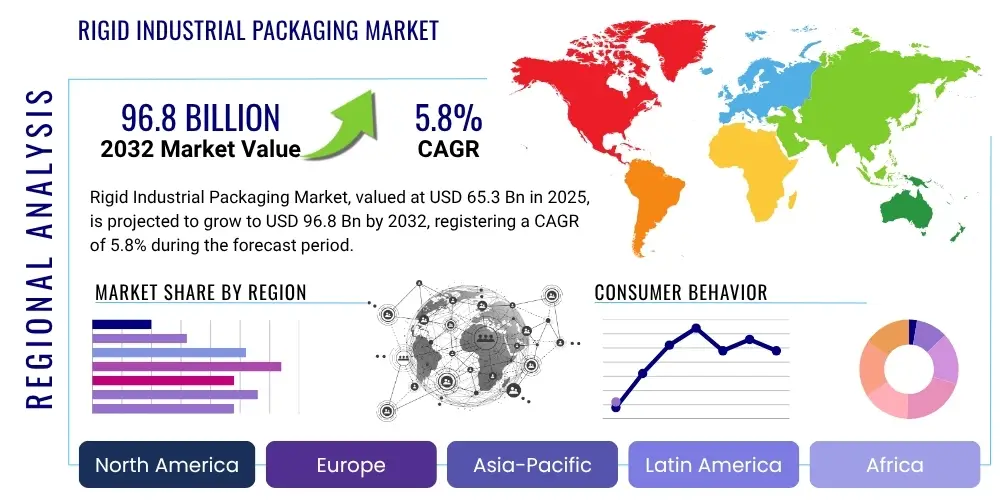

The Rigid Industrial Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 65.3 billion in 2025 and is projected to reach USD 96.8 billion by the end of the forecast period in 2032.

Rigid Industrial Packaging Market introduction

The Rigid Industrial Packaging Market encompasses a diverse range of robust containers designed for the storage, transportation, and handling of bulk industrial goods. These packaging solutions are crucial for protecting contents from physical damage, contamination, and environmental factors, ensuring product integrity throughout the supply chain. Key product types include drums, intermediate bulk containers (IBCs), pails, and bulk boxes, manufactured from materials such as plastic, metal, fiber, and wood, each chosen for specific properties like strength, chemical resistance, and reusability.

Major applications for rigid industrial packaging span across a multitude of sectors, including chemicals, petroleum and lubricants, food and beverages, pharmaceuticals, and building and construction. The primary benefits derived from using rigid industrial packaging include enhanced product protection, superior durability, efficient stackability for optimized storage and transport, and often, the potential for reuse or recycling. These attributes contribute significantly to logistical efficiency and cost-effectiveness for businesses operating in heavy industries.

Driving factors for market growth are profoundly influenced by global industrialization, the continuous expansion of international trade, and the burgeoning demands of various end-user industries. Furthermore, the increasing emphasis on supply chain optimization, coupled with a growing focus on sustainability and compliance with stringent transport regulations for hazardous and non-hazardous materials, are pivotal in shaping the market's trajectory and fostering innovation within the sector.

Rigid Industrial Packaging Market Executive Summary

The Rigid Industrial Packaging Market is characterized by dynamic business trends, including a pronounced shift towards sustainable and recyclable materials, driven by increasing environmental consciousness and regulatory pressures. Manufacturers are heavily investing in advanced production technologies to enhance efficiency, reduce waste, and develop lightweight yet durable packaging solutions. There is a growing demand for customized packaging that meets specific industry standards and product requirements, fostering innovation in design and material science.

Regionally, Asia Pacific continues to emerge as the leading market, propelled by rapid industrialization, expanding manufacturing bases, and robust economic growth in countries like China and India. North America and Europe demonstrate mature market characteristics, with steady growth attributed to stringent safety regulations and an emphasis on sophisticated, high-performance packaging solutions, often focusing on advanced plastics and metal options. Latin America, the Middle East, and Africa are showing significant potential, spurred by infrastructure development and increasing industrial output, particularly in oil and gas, chemicals, and agriculture.

Segment-wise, plastic packaging, particularly intermediate bulk containers (IBCs) and drums, are experiencing substantial growth due to their lightweight properties, versatility, and cost-effectiveness. The metal segment, primarily steel drums, maintains a strong position for transporting hazardous chemicals and petroleum products where maximum protection is paramount. Fiber and wood packaging continue to cater to specific niches, benefiting from their sustainability profiles and suitability for dry goods. The market is also seeing increased adoption of smart packaging solutions that integrate IoT and RFID for enhanced traceability and inventory management across various segments.

AI Impact Analysis on Rigid Industrial Packaging Market

Users are increasingly curious about how Artificial Intelligence will revolutionize the rigid industrial packaging market, specifically focusing on process optimization, supply chain efficiency, and quality control. Key themes include the potential for AI to predict maintenance needs for packaging machinery, automate inspection processes to reduce defects, and optimize inventory management for better material flow. There are also expectations around AI's role in predictive logistics, reducing transit times, and enhancing product safety. However, concerns regarding the initial investment in AI infrastructure, data privacy, and the need for a skilled workforce to manage these advanced systems are frequently raised.

- Predictive maintenance of packaging machinery, reducing downtime and operational costs.

- Automated visual inspection for quality control, minimizing defects and ensuring compliance.

- Optimization of supply chain logistics, including route planning and warehouse management, leading to faster delivery and reduced fuel consumption.

- Enhanced inventory management through demand forecasting and real-time tracking, preventing stockouts and overstocking.

- Intelligent packaging design and prototyping, using AI algorithms to optimize material usage and structural integrity.

- Robotics and automation in packaging lines, improving speed, precision, and worker safety.

- Waste reduction through AI-driven process optimization, identifying inefficiencies in material usage and recycling processes.

DRO & Impact Forces Of Rigid Industrial Packaging Market

The Rigid Industrial Packaging Market is primarily driven by the robust expansion of manufacturing and industrial sectors worldwide, which inherently escalates the demand for reliable bulk packaging solutions. A significant driver is the increasing global trade, necessitating durable and compliant packaging for cross-border transportation of goods. Furthermore, stringent safety and environmental regulations imposed on industries handling hazardous materials compel the adoption of high-integrity rigid packaging. The growing emphasis on the circular economy and corporate sustainability initiatives also boosts demand for reusable and recyclable packaging options.

However, the market faces several restraints, most notably the volatility in raw material prices, particularly for plastics and metals, which can directly impact manufacturing costs and product pricing. Environmental concerns related to plastic waste and the carbon footprint of packaging production present significant challenges, leading to public and regulatory scrutiny. High initial investment required for advanced machinery and sustainable material research can deter smaller players. Additionally, intense market competition and complex international regulations for transporting diverse goods add layers of complexity to market operations.

Opportunities within the market abound with the continuous development of innovative biodegradable and recyclable packaging materials, aligning with global sustainability goals. The integration of smart packaging technologies, such as RFID and IoT sensors, offers new avenues for enhanced traceability, security, and efficiency throughout the supply chain. Expansion into emerging markets, where industrialization is accelerating, provides fertile ground for growth. Moreover, the increasing demand for custom and specialized packaging solutions tailored for niche applications, alongside the exponential growth of e-commerce requiring robust transit packaging, represents promising areas for market players.

Segmentation Analysis

The Rigid Industrial Packaging Market is intricately segmented based on material, product type, and end-use industry, reflecting the diverse requirements and applications across various industrial sectors. This comprehensive segmentation allows for a detailed analysis of market dynamics, growth drivers, and challenges pertinent to specific market niches. Understanding these segments is crucial for stakeholders to identify key growth areas and formulate effective business strategies, ensuring their offerings align with evolving industry demands and regulatory landscapes.

- By Material

- Plastic

- Polyethylene HDPE

- Polypropylene PP

- Polyethylene Terephthalate PET

- Metal

- Steel

- Aluminum

- Fiber

- Corrugated

- Fiberboard

- Wood

- Plastic

- By Product

- Drums

- Plastic Drums

- Steel Drums

- Fiber Drums

- Intermediate Bulk Containers IBCs

- Flexible IBCs

- Rigid IBCs

- Plastic IBCs

- Metal IBCs

- Pails

- Plastic Pails

- Steel Pails

- Bulk Boxes

- Sacks

- Drums

- By End-Use Industry

- Chemicals

- Petroleum and Lubricants

- Food and Beverages

- Pharmaceuticals

- Building and Construction

- Agriculture

- Other Industries

Value Chain Analysis For Rigid Industrial Packaging Market

The value chain for the Rigid Industrial Packaging Market begins with upstream analysis, which involves the sourcing and processing of raw materials. This critical stage includes suppliers of polymers like HDPE and PP for plastic packaging, steel and aluminum for metal containers, wood pulp for fiber drums and boxes, and lumber for wooden pallets and crates. The quality and availability of these raw materials, along with their price fluctuations, significantly impact the cost structure and overall production efficiency of packaging manufacturers.

Midstream activities primarily encompass the manufacturing and conversion processes where raw materials are transformed into various rigid industrial packaging products such as drums, IBCs, and pails. This stage involves complex operations including molding, welding, coating, and assembly, often utilizing advanced machinery and technologies. Packaging manufacturers then engage in branding, quality control, and adherence to industry standards and regulatory compliance, ensuring the final products meet the stringent requirements for industrial applications.

Downstream analysis focuses on the distribution channels and the end-users of rigid industrial packaging. Products are distributed through a mix of direct sales to large industrial clients, specialized packaging distributors, and third-party logistics (3PL) providers who manage warehousing and transportation. Direct channels allow for customized solutions and closer client relationships, while indirect channels provide broader market reach and specialized logistics expertise. The ultimate end-users are diverse industries like chemical, petroleum, food and beverage, and pharmaceutical sectors, who rely on these packaging solutions for safe and efficient storage and transport of their bulk goods.

Rigid Industrial Packaging Market Potential Customers

The primary potential customers and end-users of rigid industrial packaging are diverse industrial sectors that require robust and reliable containers for their bulk products. These include large-scale manufacturing facilities that produce chemicals, petrochemicals, and specialty chemicals, where stringent safety and containment standards are paramount. Companies in the oil and gas sector also represent significant buyers, utilizing these containers for petroleum products, lubricants, and various derivatives, demanding packaging that can withstand harsh environments and transport conditions.

Furthermore, the food and beverage industry, particularly for bulk ingredients, concentrates, and large-volume food items, relies heavily on rigid industrial packaging to ensure hygiene, freshness, and compliance with food safety regulations. Pharmaceutical manufacturers are another key customer segment, using specialized rigid containers for bulk active pharmaceutical ingredients (APIs), excipients, and other raw materials, emphasizing sterility and product integrity. The building and construction industry also utilizes rigid packaging for materials like adhesives, coatings, and certain chemical additives.

Beyond these core sectors, potential customers extend to agriculture for fertilizers and pesticides, waste management for hazardous waste containment, and other general manufacturing industries for raw materials and finished goods. The increasing complexity of global supply chains and the need for efficient logistics mean that virtually any industry dealing with bulk quantities of goods, whether liquid, semi-liquid, or solid, is a potential buyer for rigid industrial packaging solutions that offer durability, safety, and reusability or recyclability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 65.3 billion |

| Market Forecast in 2032 | USD 96.8 billion |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Greif Inc., Mauser Packaging Solutions, RPC Group Plc, Sealed Air Corporation, Amcor plc, Berry Global Group Inc., Sonoco Products Company, Mondi Group, Silgan Holdings Inc., DS Smith Plc, BWAY Corporation, International Paper Company, Remcon Industries, Schoeller Allibert, Myers Industries Inc., Bemis Company Inc., Novio Packaging Group, CCL Industries Inc., Plastipak Holdings Inc., Werit Kunststoffwerke |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rigid Industrial Packaging Market Key Technology Landscape

The Rigid Industrial Packaging Market is continuously evolving with significant advancements in its key technology landscape, primarily driven by demands for increased efficiency, sustainability, and enhanced product protection. Advanced molding techniques, such as blow molding for plastic drums and IBCs, and injection molding for pails, are consistently refined to produce lighter yet stronger containers with improved barrier properties. Automation in production lines, including robotic handling, filling, and sealing systems, is becoming standard, leading to higher throughput, reduced labor costs, and greater consistency in manufacturing quality.

In the realm of material science, there is a strong focus on developing high-performance polymers with enhanced recyclability and increased content of post-consumer recycled (PCR) materials, aligning with circular economy principles. Innovations in metal coatings and treatments improve the corrosion resistance and longevity of steel and aluminum drums, extending their lifecycle and reusability. Furthermore, the development of intelligent packaging solutions is gaining traction, integrating smart sensors, RFID tags, and QR codes directly into industrial packaging. These technologies enable real-time tracking, temperature monitoring, tamper detection, and improved inventory management across complex supply chains.

Predictive analytics and artificial intelligence are also emerging as crucial tools within the technology landscape. AI-driven systems are being utilized for optimizing production schedules, forecasting demand more accurately, and performing predictive maintenance on manufacturing equipment to minimize downtime. These digital technologies contribute significantly to operational excellence, waste reduction, and the overall efficiency of the rigid industrial packaging value chain, marking a transformative shift towards smarter and more sustainable packaging solutions.

Regional Highlights

- North America: A mature market characterized by stringent regulations and a strong focus on sustainable packaging innovations. The region sees steady demand from the chemical, petroleum, and food industries, with increasing adoption of advanced plastics and metal packaging solutions.

- Europe: Driven by robust environmental policies and a circular economy agenda, Europe leads in the adoption of reusable and recyclable industrial packaging. High demand from the pharmaceutical, chemical, and food processing sectors contributes to its stable growth, with a strong emphasis on product safety and efficiency.

- Asia Pacific (APAC): The fastest-growing market globally, fueled by rapid industrialization, expanding manufacturing capabilities, and significant economic development in countries like China, India, and Japan. Increased chemical production, infrastructure projects, and a growing consumer base are major demand drivers.

- Latin America: Experiencing growth due to increasing foreign investments in manufacturing and infrastructure, particularly in countries like Brazil and Mexico. The region's expanding agricultural, chemical, and oil and gas sectors create a steady demand for rigid industrial packaging, albeit with varying levels of technological adoption.

- Middle East and Africa (MEA): This region presents emerging opportunities, primarily driven by the expansion of the oil and gas, chemical, and construction industries. Infrastructure development projects and growing industrial output are boosting the demand for robust packaging solutions, particularly for bulk liquids and hazardous materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rigid Industrial Packaging Market.- Greif Inc.

- Mauser Packaging Solutions

- RPC Group Plc

- Sealed Air Corporation

- Amcor plc

- Berry Global Group Inc.

- Sonoco Products Company

- Mondi Group

- Silgan Holdings Inc.

- DS Smith Plc

- BWAY Corporation

- International Paper Company

- Remcon Industries

- Schoeller Allibert

- Myers Industries Inc.

- Bemis Company Inc.

- Novio Packaging Group

- CCL Industries Inc.

- Plastipak Holdings Inc.

- Werit Kunststoffwerke

Frequently Asked Questions

What is rigid industrial packaging?

Rigid industrial packaging refers to durable, solid containers like drums, IBCs, and pails, designed for the safe storage and transport of bulk industrial goods, often hazardous materials, across various sectors.

What are the main types of rigid industrial packaging materials?

The primary materials used include plastic (HDPE, PP, PET), metal (steel, aluminum), fiber (corrugated, fiberboard), and wood, chosen based on product compatibility, strength, and regulatory requirements.

Which industries primarily use rigid industrial packaging?

Key industries include chemicals, petroleum and lubricants, food and beverages for bulk ingredients, pharmaceuticals, and building and construction, all requiring robust solutions for their bulk products.

How do sustainability trends impact rigid industrial packaging?

Sustainability trends are driving the market towards greater use of recyclable, reusable, and biodegradable materials, and increasing the integration of post-consumer recycled content to minimize environmental footprint.

What technological innovations are shaping this market?

Innovations include advanced molding techniques, automation in production, smart packaging (RFID, IoT sensors for tracking), and AI for optimizing supply chain logistics and predictive maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager