Rigid Metal Electrical Conduit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431145 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Rigid Metal Electrical Conduit Market Size

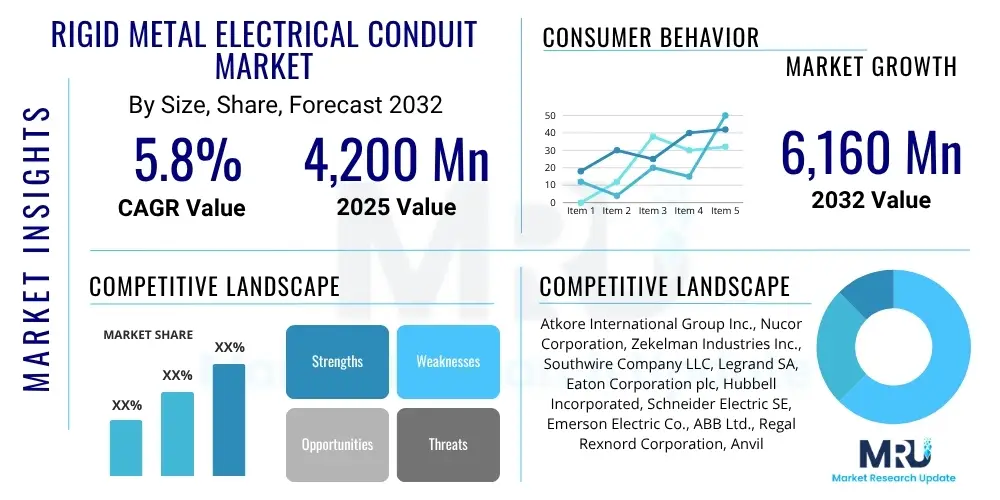

The Rigid Metal Electrical Conduit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $4,200 million in 2025 and is projected to reach $6,160 million by the end of the forecast period in 2032.

Rigid Metal Electrical Conduit Market introduction

The Rigid Metal Electrical Conduit (RMC) market encompasses the robust infrastructure dedicated to manufacturing, distributing, and installing durable metallic raceways essential for safeguarding electrical wiring across diverse applications. RMC, predominantly fabricated from materials such as galvanized steel, aluminum, or stainless steel, serves as a critical protective sheath, offering unparalleled mechanical protection against physical impact, corrosive elements, and electromagnetic interference (EMI). This comprehensive protection ensures the long-term reliability and operational safety of electrical systems, making RMC an indispensable component in modern construction and industrial environments. Its inherent strength and resilience are key attributes that differentiate it from lighter conduit alternatives, positioning it as a preferred choice for demanding installations where circuit integrity cannot be compromised.

The product's versatility allows for a wide array of major applications, spanning from large-scale commercial buildings and complex industrial facilities to critical infrastructure projects such as bridges, tunnels, and public utility networks. Furthermore, RMC is extensively utilized in hazardous locations where strict safety regulations mandate the highest level of wiring protection against potential explosions or environmental hazards. The myriad benefits of RMC include its exceptional mechanical protection, inherent fire resistance, effective electromagnetic shielding, and superior grounding capabilities, all of which contribute to enhanced electrical safety and system longevity. Its ability to withstand harsh conditions ensures electrical continuity and minimizes the risk of system failures, which can be costly and dangerous.

Key driving factors for the Rigid Metal Electrical Conduit market include the continuous global boom in construction activities, particularly in the non-residential and infrastructure sectors, which necessitate robust electrical installations. Significant investments in industrial expansion, especially in manufacturing and processing plants, further fuel demand for RMC due to its reliability in harsh operating environments. Moreover, the unwavering enforcement of stringent electrical safety codes and building regulations across developed and developing nations consistently mandates the use of high-strength conduit solutions, thereby sustaining and accelerating market growth. The increasing complexity of modern electrical systems and the need for resilient power distribution also underscore RMC's ongoing relevance and market expansion.

Rigid Metal Electrical Conduit Market Executive Summary

The Rigid Metal Electrical Conduit market is experiencing a period of significant growth, fueled by global urbanization, industrial development, and an increasing emphasis on electrical safety and infrastructure resilience. Current business trends highlight a robust demand for RMC in large-scale non-residential construction projects, including commercial complexes, institutional buildings, and expansive industrial facilities such as data centers and manufacturing plants. Manufacturers are focusing on optimizing production efficiencies and enhancing product attributes such as corrosion resistance and ease of installation to cater to evolving market requirements. Furthermore, partnerships between RMC producers and major electrical contractors are becoming increasingly prevalent, aiming to streamline supply chains and integrate RMC solutions more effectively into complex project timelines, fostering a collaborative ecosystem focused on reliability and performance.

Regional trends reveal a dynamic landscape, with Asia Pacific emerging as a primary growth engine due to unprecedented infrastructure development, rapid industrialization, and burgeoning urban expansion in countries like China and India. North America and Europe, while being mature markets, demonstrate stable and consistent demand driven by ongoing renovation projects, upgrades to aging electrical infrastructure, and strict adherence to established electrical codes that favor RMC's protective qualities. These regions continue to invest in advanced manufacturing technologies and sustainable practices within the RMC sector, aligning with global environmental objectives. Latin America and the Middle East and Africa regions are also exhibiting accelerated growth, propelled by significant government investments in public utilities, energy sectors, and large-scale commercial developments, creating new avenues for RMC market penetration.

In terms of segment trends, galvanized steel RMC remains the dominant material choice, primarily owing to its exceptional strength, durability, and cost-effectiveness for a broad range of applications. However, there is a noticeable increase in the adoption of aluminum RMC, particularly in projects where lightweight characteristics, enhanced corrosion resistance, and non-magnetic properties are advantageous, such as in marine environments or certain telecommunication installations. Stainless steel RMC, while representing a smaller segment, continues to hold a critical niche in highly corrosive or sterile environments, including chemical processing plants and pharmaceutical facilities, where its superior chemical resistance is indispensable. The market is also seeing innovation in trade sizes and fittings, adapting to accommodate increasingly larger cable bundles and specialized installation requirements, reflecting the evolving demands of modern electrical system design and safety standards.

AI Impact Analysis on Rigid Metal Electrical Conduit Market

User inquiries about Artificial Intelligence's influence on the Rigid Metal Electrical Conduit market predominantly center on how AI can enhance efficiency, optimize operations, and improve safety across the RMC value chain, rather than directly modifying the product itself. Key themes consistently emerging from these questions involve AI's potential to revolutionize manufacturing processes through predictive analytics, streamline complex supply chain logistics, and even contribute to more intelligent design and installation methodologies. Users are keenly interested in understanding how AI algorithms can detect anomalies in production, forecast demand with greater accuracy, and contribute to overall operational excellence, thereby ensuring consistent quality and availability of RMC products in a dynamic market environment. The general expectation is that AI will act as a force multiplier, augmenting human capabilities in decision-making and process optimization.

While AI may not fundamentally alter the physical composition or core function of a rigid metal conduit, its indirect impact promises significant benefits. For instance, AI-driven solutions are increasingly being deployed in RMC manufacturing plants to monitor machinery performance in real-time, anticipate equipment failures through predictive maintenance, and optimize production schedules to reduce downtime and energy consumption. This leads to higher output, lower operational costs, and improved product consistency, which directly translates to a more competitive market offering. Furthermore, AI's analytical prowess is invaluable in managing the intricate global supply chains for raw materials like steel and aluminum, helping manufacturers navigate price volatility and logistical challenges by providing data-driven insights for procurement and inventory management, ensuring a stable and cost-effective supply of RMC to end-users.

Beyond manufacturing and supply chain, AI also holds promise in the design and engineering phases of projects utilizing RMC. Advanced AI algorithms can assist electrical engineers in optimizing conduit layouts, minimizing material waste, and identifying potential installation conflicts during the planning stage, significantly reducing errors and accelerating project timelines. Although direct integration of AI into RMC products is not prevalent, the concept of "smart infrastructure" where AI monitors the performance and integrity of entire electrical systems indirectly benefits from the reliable foundation provided by RMC. This broader application of AI in construction management and smart building technologies enhances the overall value proposition of RMC by enabling more efficient, safer, and ultimately more resilient electrical installations, addressing concerns about long-term operational efficiency and safety in complex environments.

- Enhanced Manufacturing Efficiency: AI-driven systems optimize production lines, predict and prevent equipment failures, and ensure stringent quality control, minimizing defects in RMC manufacturing.

- Supply Chain Optimization: AI algorithms improve raw material procurement, inventory management, and logistics by accurately forecasting demand and identifying potential disruptions, leading to cost savings and improved delivery times.

- Predictive Maintenance for Systems: While not directly on RMC, AI analytics in smart building systems can monitor electrical loads and environmental factors, indicating areas where RMC systems might require inspection or maintenance.

- Automated Design and Installation Planning: AI-powered software tools assist engineers in generating optimized RMC layouts, calculating material requirements, and simulating installation processes, reducing design errors and project delays.

- Improved Worker Safety: AI can analyze real-time data from construction sites to identify safety hazards related to conduit handling and installation, providing proactive alerts and enhancing onsite safety protocols.

DRO & Impact Forces Of Rigid Metal Electrical Conduit Market

The Rigid Metal Electrical Conduit market is significantly influenced by a dynamic interplay of driving forces, inherent restraints, emerging opportunities, and broader impact forces that collectively shape its trajectory. A primary driver for market expansion is the continuous surge in global infrastructure development, particularly in developing economies, where extensive investments in public utilities, transportation networks, and commercial complexes necessitate robust electrical wiring protection. Concurrently, the increasing stringency of electrical safety regulations and building codes across various jurisdictions mandates the use of durable and fire-resistant conduit systems like RMC, thereby reinforcing its demand. The rapid growth of industrialization, the expansion of data centers, and the burgeoning renewable energy sector also act as powerful catalysts, driving the need for secure and resilient electrical conduits capable of withstanding harsh operational environments and high-load demands.

Despite these strong drivers, the RMC market faces several notable restraints. The most significant challenge comes from the volatile pricing of raw materials, predominantly steel and aluminum, which are susceptible to global economic fluctuations, trade policies, and supply chain disruptions. These price instabilities directly impact manufacturing costs, often leading to fluctuating product prices and potentially squeezing profit margins for manufacturers and distributors. Furthermore, the installation of RMC typically requires more specialized skills and labor-intensive processes compared to non-metallic or flexible conduits, contributing to higher installation costs and potential labor shortages. Intense competition from alternative conduit materials, such as PVC, Electrical Metallic Tubing (EMT), and Flexible Metallic Conduit (FMC), which may offer lower upfront costs, easier installation, or specific advantages in less demanding applications, also poses a significant competitive restraint for the RMC market.

However, substantial opportunities exist for market growth, particularly within the context of smart city initiatives, which require robust and future-proof electrical infrastructure capable of supporting advanced technologies. The retrofitting and modernization of aging electrical systems in commercial and industrial buildings also present a vast opportunity, as older installations are upgraded to meet contemporary safety and efficiency standards. Expanding into specialized applications, such as explosion-proof installations in petrochemical facilities, corrosion-resistant solutions for marine environments, and high-impact protection in mining operations, offers niche growth prospects for RMC manufacturers. Moreover, the increasing adoption of advanced construction methodologies like modular construction and Building Information Modeling (BIM) can streamline RMC integration, potentially enhancing efficiency and reducing overall project costs, further opening new avenues for market penetration and innovation.

External impact forces, such as global economic slowdowns or geopolitical tensions, can significantly disrupt the RMC market by affecting construction investments and raw material supply chains. Trade protectionism and tariffs on steel or aluminum can increase input costs, leading to higher product prices and reduced competitiveness. Conversely, advancements in material science, such as the development of lighter, stronger, or more corrosion-resistant alloys, could revolutionize RMC manufacturing, leading to more efficient and durable products. Similarly, technological innovations in coating applications could enhance RMC's protective qualities, extending its lifespan and expanding its applicability in extreme environments. These forces necessitate continuous adaptation and strategic planning from market participants to mitigate risks and capitalize on evolving technological and economic landscapes.

Segmentation Analysis

The Rigid Metal Electrical Conduit market undergoes meticulous segmentation across several key dimensions, including material type, trade size, end-use industry, and application. This granular approach to market analysis is fundamental for understanding the complex dynamics that drive demand and supply within the RMC sector. Each segmentation criterion provides unique insights into consumer preferences, specific performance requirements, and regional variations, enabling market participants to identify lucrative niches and tailor their product offerings more precisely. By disaggregating the market into these distinct categories, stakeholders gain a comprehensive view of where demand is concentrated, what specific product attributes are most valued, and how competitive landscapes differ across various segments, thereby facilitating more informed strategic decision-making and resource allocation for sustained growth and market penetration.

Understanding these segments allows manufacturers to innovate their product lines, developing RMC solutions that are optimized for particular environmental challenges or installation complexities. For instance, the demand for aluminum RMC might be concentrated in coastal regions due to its superior corrosion resistance, while galvanized steel RMC remains a staple in general commercial and industrial construction due to its cost-effectiveness and mechanical strength. Similarly, the choice of trade size is directly correlated with the volume and diameter of electrical cables to be protected, influencing purchasing patterns across different project types, from small branch circuits to heavy-duty feeders. This detailed segmentation not only clarifies current market conditions but also provides a predictive framework for anticipating future trends, such as the growing need for specialized RMC in rapidly expanding sectors like renewable energy and data infrastructure, each with unique conduit requirements.

Moreover, the segmentation by end-use industry and application provides critical context for sales and marketing strategies, allowing companies to target specific customer groups with tailored messages and solutions. Commercial buildings, industrial plants, and infrastructure projects each have distinct priorities regarding cost, compliance, durability, and installation ease, directly impacting their RMC procurement processes. Analyzing these segments helps in forecasting demand shifts, understanding the impact of regulatory changes, and identifying opportunities for value-added services, such as pre-fabrication or customized length cutting. Ultimately, a robust segmentation analysis is indispensable for navigating the multifaceted Rigid Metal Electrical Conduit market, enabling businesses to align their production, distribution, and marketing efforts with the precise needs and evolving demands of a diverse customer base, ensuring sustained competitiveness and market relevance in a technologically advancing electrical landscape.

- By Material Type:

- Galvanized Steel RMC: Offers high strength, durability, and cost-effectiveness, making it the most widely used material for general electrical installations.

- Aluminum RMC: Valued for its lightweight properties, excellent corrosion resistance, and non-magnetic characteristics, preferred in specific applications like marine environments or areas where weight reduction is crucial.

- Stainless Steel RMC: Provides superior chemical resistance and high strength, typically employed in highly corrosive industrial settings, food processing plants, or sterile environments.

- By Trade Size:

- 1/2 inch to 1 inch: Commonly used for smaller branch circuits and individual equipment connections in commercial and light industrial settings.

- 1-1/4 inch to 2 inches: Standard sizes for general power distribution, feeder circuits, and medium-sized equipment wiring in a broad range of applications.

- 2-1/2 inches to 4 inches: Utilized for heavier gauge cables, larger power feeders, and main distribution lines in industrial plants and commercial buildings.

- Above 4 inches: Employed in very large-scale infrastructure projects, utility substations, and major industrial installations requiring extensive cable protection.

- By End-Use Industry:

- Commercial: Includes office buildings, retail centers, hospitals, schools, and other institutional facilities requiring robust and compliant electrical systems.

- Industrial: Covers manufacturing plants, chemical processing facilities, oil and gas refineries, mining operations, and heavy industrial sites demanding high-impact and corrosion-resistant conduit.

- Infrastructure: Encompasses public utilities, transportation systems (airports, railways), data centers, and communication networks where long-term durability and protection are critical.

- Residential: Though less common than in other sectors, RMC is used in specific high-end or demanding residential applications for ultimate durability and protection.

- By Application:

- Power Distribution: Essential for safeguarding main power lines, feeders, and branch circuits from physical damage and environmental factors, ensuring reliable electricity supply.

- Telecommunications: Protects sensitive data and communication cables from physical harm and electromagnetic interference, maintaining signal integrity and network uptime.

- Data Centers: Critical for securing extensive power and network cabling infrastructure, providing mechanical protection and EMI shielding in highly sensitive environments.

- Oil and Gas: Demanding applications requiring explosion-proof and highly corrosion-resistant RMC to ensure safety and operational continuity in hazardous locations.

- Mining: Provides robust protection against extreme physical abuse, abrasion, and harsh environmental conditions common in mining operations.

- Manufacturing: General electrical system protection within industrial settings, ensuring the safe and reliable operation of machinery and production lines.

Value Chain Analysis For Rigid Metal Electrical Conduit Market

The value chain for the Rigid Metal Electrical Conduit market is a meticulously structured process, commencing with upstream activities focused on the procurement and initial processing of fundamental raw materials. This segment is dominated by major steel mills and aluminum smelters, which supply high-quality metallic coils and sheets, along with zinc for galvanization, representing the foundational inputs for RMC manufacturing. The pricing, quality, and availability of these raw materials are critical determinants of the final product cost and market competitiveness, often influenced by global commodity markets and geopolitical factors. Effective supplier relationships, long-term contracts, and diversified sourcing strategies are therefore paramount for manufacturers in mitigating supply chain risks and ensuring a consistent flow of materials, which underpins the stability of the entire value chain.

Midstream in the value chain, specialized manufacturers transform these raw materials into finished RMC products through a series of complex processes. This involves tube formation, precision welding to ensure structural integrity, threading for secure connections, and meticulous galvanization or coating applications for corrosion resistance. Quality control and adherence to international standards such as UL and NEMA are integral at this stage, ensuring that each conduit meets rigorous performance and safety specifications. Innovation in manufacturing technologies, such as advanced welding techniques, automation, and eco-friendly coating solutions, are key to enhancing product quality, reducing production costs, and improving manufacturing efficiency, thereby strengthening a company's position within the competitive RMC market. Research and development also play a significant role here, driving improvements in material properties and installation ease.

Downstream activities focus on the distribution and delivery of RMC products to the end-users. This involves a robust network comprising wholesalers, distributors, electrical supply houses, and direct sales channels that connect manufacturers to electrical contractors, construction companies, and industrial clients. Distribution channels are typically a hybrid of indirect and direct approaches. Indirect distribution, leveraging extensive networks of electrical wholesalers and distributors, provides broad market reach, efficient inventory management, and readily available technical support for a wide array of small to medium-sized projects and contractors. These intermediaries often stock a diverse range of RMC sizes and types, facilitating quick access and local availability, which is crucial for project timelines.

Conversely, direct distribution channels are often employed for large-scale industrial projects, major infrastructure developments, and government contracts. In these scenarios, manufacturers engage directly with large construction firms or project developers, offering bulk purchasing options, customized lengths or specific fabrication services, and direct technical consultation. While direct sales can offer cost efficiencies by bypassing intermediary markups and enable closer relationships with key clients, they require significant logistical capabilities and dedicated sales teams. Both direct and indirect channels play crucial roles, with the optimal mix depending on market segment, customer size, and project complexity. Efficient and well-managed distribution ensures timely product delivery, customer satisfaction, and overall market accessibility, completing the value chain from raw material to final installation.

Rigid Metal Electrical Conduit Market Potential Customers

The Rigid Metal Electrical Conduit market caters to a diverse range of potential customers and end-users, reflecting the ubiquitous need for robust electrical wiring protection across various sectors of the economy. A significant customer segment includes electrical contractors, who are directly responsible for the installation of electrical systems in new constructions, renovations, and maintenance projects. Their purchasing decisions are heavily influenced by project specifications, local building codes, product availability, and the need for reliable, compliant materials that ensure long-term system integrity. Contractors frequently rely on RMC for its superior strength and durability, particularly in demanding environments where other conduit types may not suffice, making them a primary driver of demand in both commercial and industrial applications.

Another crucial segment comprises large-scale construction companies, particularly those engaged in major commercial, industrial, or infrastructure development projects. These entities often procure RMC in significant volumes, either directly from manufacturers or through large distributors, for integration into complex building frameworks. Their focus is typically on cost-effectiveness, compliance with stringent safety standards, project timelines, and the overall lifecycle performance of the electrical infrastructure. Industrial facilities, including manufacturing plants, chemical processing units, oil and gas operations, and mining sites, also represent a substantial customer base. These environments typically present challenges such as mechanical stress, corrosive atmospheres, or high temperatures, where RMC's protective qualities are indispensable for safeguarding critical power and control wiring, thereby ensuring operational continuity and worker safety in hazardous areas.

Furthermore, utility companies and various government agencies are significant end-users of RMC, especially for public infrastructure projects. This includes power generation and distribution facilities, wastewater treatment plants, transportation systems (e.g., airports, subway lines), and municipal communication networks. These sectors prioritize durability, long-term reliability, and adherence to public safety standards, often mandating the use of heavy-duty conduit systems like RMC to ensure the resilience of essential public services. Data centers, which house extensive and sensitive network and power cabling, also rely heavily on RMC for superior physical protection and electromagnetic interference (EMI) shielding, critical for maintaining uninterrupted data flow and operational integrity. The collective demand from these diverse sectors underscores RMC's fundamental role as a foundational component in ensuring the safety, efficiency, and longevity of modern electrical infrastructure across a broad spectrum of applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4,200 million |

| Market Forecast in 2032 | $6,160 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atkore International Group Inc., Nucor Corporation, Zekelman Industries Inc., Southwire Company LLC, Legrand SA, Eaton Corporation plc, Hubbell Incorporated, Schneider Electric SE, Emerson Electric Co., ABB Ltd., Regal Rexnord Corporation, Anvil International, Columbia Conduit, Penn-Union, Bridgeport Fittings Inc., Orbit Industries Inc., Electri-Flex Company, Prime Conduit Inc., AFC Cable Systems, Calbrite |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rigid Metal Electrical Conduit Market Key Technology Landscape

The Rigid Metal Electrical Conduit market relies on a mature yet continuously evolving technology landscape, primarily centered around advanced manufacturing processes and material science innovations designed to enhance product performance, durability, and ease of installation. Core technologies involve the metallurgical expertise required to produce high-strength steel and aluminum tubes, alongside precision welding techniques that ensure consistent seam integrity and structural resilience. A pivotal technology is hot-dip galvanization, which applies a protective zinc coating to steel RMC, offering superior corrosion resistance against environmental factors and extending the conduit's operational lifespan in outdoor and humid conditions. This process is crucial for preventing rust and maintaining the conduit's protective capabilities over decades of service in demanding electrical installations.

Further technological advancements extend to specialized coating applications, where manufacturers are increasingly employing polymer-based or epoxy finishes. These advanced coatings provide enhanced chemical resistance, abrasion protection, and aesthetic appeal, broadening RMC's applicability in highly corrosive industrial environments, sanitary facilities, or architecturally exposed installations where both functionality and appearance are critical. Innovations in threading and bending technologies are also significant, allowing for more precise and uniform threading of RMC ends for secure connections, as well as enabling easier and more accurate on-site bending. This reduces installation time and labor costs, while maintaining the conduit's structural integrity and preventing damage to the enclosed electrical conductors, directly addressing concerns about installation efficiency and long-term reliability in complex projects.

Beyond material and manufacturing processes, the market is also influenced by advancements in digital technologies, particularly in the realm of design and project management. The increasing adoption of Computer-Aided Design (CAD) and Building Information Modeling (BIM) tools allows for the sophisticated integration of RMC specifications into overall electrical system designs. These digital platforms optimize conduit routing, minimize material waste, and facilitate pre-fabrication, leading to more efficient installation sequences and reduced on-site labor. While RMC itself is a passive component, its integration within "smart building" and "smart infrastructure" projects, where digital controls and monitoring systems are prevalent, underscores the importance of its robust and reliable foundation. These technological trends collectively ensure that RMC remains a leading choice for safeguarding electrical systems, adapting to new construction demands, and meeting stringent safety and performance standards in an increasingly complex and interconnected world.

Regional Highlights

- North America: This region represents a mature and stable market for Rigid Metal Electrical Conduit, driven by stringent electrical codes such as the National Electrical Code (NEC) that mandate high-quality wiring protection. Significant investments in commercial construction, industrial modernization, and ongoing infrastructure repair and upgrades consistently fuel demand. The market here emphasizes compliance, reliability, and long-term performance, with a strong focus on established manufacturers and robust supply chains.

- Europe: The European market for RMC is characterized by a steady demand, influenced by sustainable building initiatives, smart city developments, and the continuous need for renovation and upgrading of aging electrical infrastructure. Countries within the European Union adhere to specific safety standards and environmental regulations, pushing for high-efficiency manufacturing processes and durable conduit solutions. The market exhibits a growing inclination towards energy-efficient and environmentally responsible construction practices.

- Asia Pacific (APAC): As the fastest-growing region, APAC is a dynamic hub for the RMC market, propelled by rapid urbanization, extensive industrialization, and massive infrastructure projects across countries like China, India, and Southeast Asian nations. The burgeoning construction sector, coupled with expanding manufacturing capabilities and increasing foreign direct investment, creates immense opportunities for market expansion. Demand is particularly strong in new commercial, industrial, and residential developments requiring robust electrical protection.

- Latin America: This region demonstrates a growing demand for RMC, driven by increasing investments in public infrastructure, industrial expansion, and significant mining operations. Economic development initiatives and governmental support for construction projects in countries such as Brazil, Mexico, and Chile are fostering a need for durable and reliable electrical conduit solutions. The market here is characterized by evolving safety standards and a rising awareness of quality in electrical installations.

- Middle East and Africa (MEA): The MEA region is experiencing substantial growth in the RMC market, largely due to ambitious large-scale construction projects, diversification efforts away from oil economies, and significant infrastructure development, particularly in the Gulf Cooperation Council (GCC) countries. The harsh environmental conditions prevalent in parts of the region necessitate the use of robust and corrosion-resistant RMC solutions, driving demand for high-performance products capable of withstanding extreme temperatures and corrosive elements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rigid Metal Electrical Conduit Market.- Atkore International Group Inc.

- Nucor Corporation

- Zekelman Industries Inc.

- Southwire Company LLC

- Legrand SA

- Eaton Corporation plc

- Hubbell Incorporated

- Schneider Electric SE

- Emerson Electric Co.

- ABB Ltd.

- Regal Rexnord Corporation

- Anvil International

- Columbia Conduit

- Penn-Union

- Bridgeport Fittings Inc.

- Orbit Industries Inc.

- Electri-Flex Company

- Prime Conduit Inc.

- AFC Cable Systems

- Calbrite

Frequently Asked Questions

What is Rigid Metal Electrical Conduit (RMC) and its primary purpose?

Rigid Metal Electrical Conduit (RMC) is a heavy-duty, threaded metallic tubing specifically designed for electrical installations to provide superior protection for wires and cables. Its primary purpose is to shield electrical conductors from physical damage, corrosion, and electromagnetic interference (EMI), thereby ensuring the safety, integrity, and long-term reliability of electrical systems in demanding commercial, industrial, and infrastructure environments. RMC also serves as an effective equipment grounding conductor, vital for electrical safety.

Why is RMC often the preferred choice over other conduit types in certain applications?

RMC is frequently preferred over other conduit types, such as PVC or EMT, in applications demanding the highest levels of mechanical strength, fire resistance, and protection against harsh environmental conditions. Its robust construction makes it ideal for areas exposed to severe physical impact, extreme temperatures, corrosive agents, or hazardous locations where explosion protection is necessary. RMC's ability to offer superior EMI shielding and serve as a reliable grounding path further solidifies its preference in critical industrial and infrastructure projects that require uncompromising durability and safety compliance.

What are the primary materials used in the manufacturing of Rigid Metal Electrical Conduit?

The primary materials used for manufacturing Rigid Metal Electrical Conduit are galvanized steel, aluminum, and stainless steel. Galvanized steel RMC is the most common due to its high strength, durability, and cost-effectiveness, with the zinc coating providing excellent corrosion resistance. Aluminum RMC is favored for applications requiring lightweight properties, superior corrosion resistance in specific environments, and non-magnetic characteristics. Stainless steel RMC is reserved for highly corrosive industrial settings, such as chemical plants or food processing facilities, where its exceptional chemical resistance and hygiene properties are paramount.

Which specific industries constitute the main end-users of Rigid Metal Electrical Conduit?

The main end-users of Rigid Metal Electrical Conduit span several critical industries including commercial construction (e.g., office buildings, hospitals, retail centers), heavy industrial sectors (e.g., manufacturing plants, oil and gas, chemical processing, mining), and large-scale infrastructure projects (e.g., public utilities, data centers, transportation systems). These industries rely on RMC for its unparalleled robust protection, strict compliance with electrical safety codes, and long-term reliability, particularly for safeguarding vital power and control wiring in challenging and high-risk environments where system integrity is non-negotiable.

How does Rigid Metal Electrical Conduit contribute to overall electrical safety and system integrity?

Rigid Metal Electrical Conduit makes significant contributions to overall electrical safety and system integrity by providing an extremely durable physical barrier that protects electrical conductors from mechanical damage, abrasion, moisture ingress, and corrosive substances, thereby preventing insulation breakdowns and potential short circuits. It acts as a primary equipment grounding conductor, ensuring that fault currents are safely directed away from equipment and personnel. Additionally, RMC offers inherent fire resistance, limiting the spread of flames along electrical pathways. This comprehensive protective capacity reduces operational risks, minimizes maintenance requirements, and ensures the continuous, safe, and reliable operation of complex electrical systems, enhancing both personnel safety and asset protection.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager