Risers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430107 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Risers Market Size

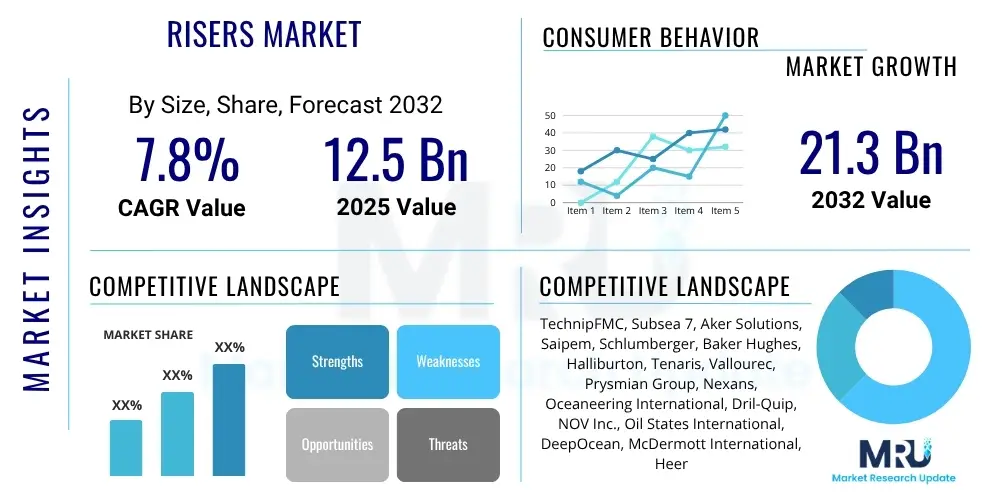

The Risers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 12.5 Billion in 2025 and is projected to reach USD 21.3 Billion by the end of the forecast period in 2032.

Market Value 2025: USD 12.5 Billion

Market Value 2032: USD 21.3 Billion

Risers Market introduction

The Risers market encompasses specialized pipe systems and flexible conduits critical for offshore energy exploration, production, and increasingly, renewable energy infrastructure. These systems are engineered to transport various fluids, including crude oil, natural gas, drilling mud, and injection water, between the seabed and surface facilities or vessels. They serve as a fundamental connection in deepwater and ultra-deepwater operations, enabling the efficient and safe extraction of resources, while also playing a vital role in the structural integrity and operational continuity of offshore installations. The design and material selection for risers are paramount, addressing extreme pressures, temperatures, corrosive environments, and dynamic loads encountered in challenging marine conditions.

Products within this market range from rigid steel risers, often used for production and export, to flexible risers and composite risers that offer enhanced fatigue resistance and suitability for dynamic applications. Major applications span across the entire offshore oil and gas lifecycle, from drilling and well intervention to production and decommissioning. Beyond hydrocarbons, risers are increasingly deployed in offshore wind farms for power transmission and foundation support, and in potential future applications like subsea mining and ocean thermal energy conversion. The robust engineering and material science behind risers ensure operational continuity and safety in high-stakes offshore environments, making them indispensable components of global energy and infrastructure strategies.

The primary benefits derived from advanced riser technologies include enhanced operational safety, improved efficiency in fluid transfer, and the capability to access previously unreachable deepwater reserves. Driving factors for market growth are multifaceted, primarily fueled by the persistent global demand for energy, which necessitates continued deepwater oil and gas exploration, alongside the rapid expansion of offshore renewable energy projects, particularly offshore wind. Technological advancements in material science, subsea engineering, and real-time monitoring systems are further propelling market development, enabling safer and more cost-effective solutions for increasingly complex offshore endeavors. The ongoing evolution of environmental regulations also influences innovation, pushing for more durable and environmentally sound riser solutions.

Risers Market Executive Summary

The Risers market is experiencing dynamic shifts, characterized by evolving business trends, significant regional expansion, and notable segmentation advancements. Business trends indicate a strong emphasis on technological innovation, particularly in the development of lightweight, fatigue-resistant materials such as composites, alongside the integration of smart monitoring systems to enhance asset integrity and operational efficiency. Furthermore, there is a clear trend towards consolidation among key players, aiming to leverage synergistic capabilities and expand service portfolios to offer more comprehensive, integrated solutions to offshore operators. Sustainability and environmental considerations are increasingly shaping business strategies, prompting investments in environmentally friendly designs and improved operational practices to minimize ecological footprints.

Regionally, the market exhibits robust growth in specific geographies. North America, particularly the Gulf of Mexico, remains a crucial hub for deepwater oil and gas activities, driving demand for advanced drilling and production risers. Asia Pacific is emerging as a significant growth engine, fueled by new deepwater discoveries and ambitious offshore wind power projects, especially in countries like China, India, and Vietnam. Europe continues to lead in offshore wind development, creating sustained demand for specialized risers for power transmission and foundation support, while also seeing activity in decommissioning. Latin America, with Brazil's pre-salt fields, continues to be a vital market, and the Middle East and Africa are witnessing renewed investment in offshore gas exploration and production infrastructure maintenance and expansion.

Segmentation trends highlight a growing preference for flexible and hybrid riser systems, which offer superior adaptability to dynamic movements and harsh environments, over traditional rigid steel risers in certain applications. The demand for composite risers is also escalating due due to their inherent advantages in reducing weight, mitigating corrosion, and extending service life, offering compelling lifecycle cost benefits. Moreover, the offshore wind sector is increasingly becoming a dedicated segment for riser demand, necessitating specialized solutions for inter-array and export cables, as well as structural components. Ultra-deepwater applications continue to push the boundaries of riser technology, demanding robust and innovative solutions capable of withstanding extreme hydrostatic pressures and challenging operational dynamics, driving research and development in new materials and design methodologies across the industry.

AI Impact Analysis on Risers Market

Common user questions regarding AI's impact on the Risers Market frequently center on its potential to enhance operational efficiency, safety, and predictive maintenance capabilities. Users are keen to understand how AI can reduce costs associated with inspections and repairs, optimize riser performance under varying environmental conditions, and contribute to more resilient and sustainable offshore operations. Key themes revolve around the automation of data analysis from sensors, the application of machine learning for forecasting equipment integrity issues, and the development of intelligent decision-making support systems. Concerns often include data security, the complexity of AI model deployment in harsh offshore environments, the initial investment required for AI infrastructure, and the potential implications for the workforce, prompting a need for clear communication on benefits versus challenges.

- Advanced predictive maintenance systems utilizing real-time sensor data and machine learning algorithms to forecast potential equipment failures, significantly reducing unscheduled downtime and optimizing maintenance schedules for riser integrity.

- Optimized drilling and production operations through AI-driven analytics, which can process vast amounts of operational data to identify efficiencies, reduce energy consumption, and improve the overall performance of riser systems.

- Enhanced structural health monitoring by employing AI to interpret acoustic, vibration, and visual inspection data, enabling early detection of fatigue cracks, corrosion, and other forms of degradation in risers before they become critical.

- Development of autonomous inspection systems, such as AI-powered ROVs and AUVs, that can conduct detailed and frequent visual or non-destructive testing of risers without constant human intervention, increasing safety and reducing operational costs.

- Improved riser design and engineering through AI-powered simulation tools and generative design algorithms, allowing engineers to explore a wider range of optimized designs that are more resilient, lighter, and cost-effective under extreme conditions.

- Intelligent decision support systems that integrate environmental data, operational parameters, and historical performance to provide real-time recommendations for adjusting riser operations, enhancing safety, and prolonging asset life.

- Streamlined supply chain and logistics for riser components by using AI to forecast demand, optimize inventory levels, and manage complex global logistics, leading to reduced lead times and improved project execution efficiency.

DRO & Impact Forces Of Risers Market

The Risers market is propelled by a confluence of robust drivers, notably the sustained global demand for energy, which continues to necessitate deepwater and ultra-deepwater oil and gas exploration and production, particularly in regions with significant untapped reserves. The burgeoning growth of the offshore renewable energy sector, primarily offshore wind, represents another monumental driver, creating substantial demand for specialized risers for power export and inter-array cable support. Continuous technological advancements in materials science, suchating lightweight composites and high-strength alloys, along with sophisticated subsea engineering solutions, are enabling risers to operate in increasingly harsh and challenging environments, further expanding market opportunities. Conversely, the market faces significant restraints, including the inherent volatility of global oil and gas prices, which can directly impact investment decisions for offshore projects, leading to project delays or cancellations. Stringent and evolving environmental regulations, coupled with increasing public scrutiny, impose higher compliance costs and demand more environmentally sound engineering solutions, which can be capital intensive. High upfront capital expenditure required for deepwater infrastructure and advanced riser systems, alongside complex installation logistics, also acts as a deterrent for some new projects. Opportunities within the Risers market are abundant, especially in the development and deployment of advanced composite risers and hybrid systems that offer superior fatigue performance, corrosion resistance, and weight reduction benefits, leading to lower installation and maintenance costs. The expansion into new offshore frontiers, such as Arctic exploration and potential subsea mining, presents unique challenges that drive innovation in riser technology. The ongoing digitalization of offshore operations, including the integration of AI and IoT for real-time monitoring and predictive maintenance, offers significant avenues for enhancing operational efficiency and safety. The impact forces shaping this market are broad and interconnected, encompassing geopolitical stability and its influence on energy supply chains, global economic growth dictating energy demand and investment appetite, and the accelerating pace of climate change and associated environmental policies, which increasingly favor renewable energy sources and push for lower carbon footprints in traditional energy sectors. Moreover, the continuous evolution of technological capabilities, from advanced manufacturing processes to autonomous inspection systems, fundamentally alters market dynamics, fostering both competition and collaboration among industry players.

Segmentation Analysis

The Risers market is broadly segmented based on several critical parameters including type, material, application, and water depth, reflecting the diverse operational requirements and technological advancements across the offshore industry. Each segment addresses specific needs of various end-users, from the rigorous demands of deepwater oil and gas extraction to the specialized requirements of offshore renewable energy projects. This multi-dimensional segmentation allows for a detailed understanding of market dynamics, growth opportunities, and technological trends, enabling stakeholders to tailor their product offerings and strategic investments effectively across the global market landscape.

- By Type:

- Drilling Risers: Essential conduits for drilling operations, conveying drilling fluid and providing access to the wellbore.

- Production Risers: Used for transporting oil, gas, and water from subsea wells to floating production facilities.

- Export Risers: Large diameter risers for transferring processed hydrocarbons from offshore facilities to onshore terminals or pipelines.

- Utility Risers: Smaller risers for services like chemical injection, hydraulic control, and power supply to subsea equipment.

- Flexible Risers: Multi-layered structures offering flexibility and fatigue resistance, ideal for dynamic movements in harsh environments.

- Hybrid Risers: Combinations of rigid and flexible sections, often integrating buoyancy modules for stability and reduced top tension.

- Composite Risers: Advanced risers manufactured from composite materials, offering significant weight reduction and corrosion resistance.

- By Material:

- Steel: Traditional material, known for strength and durability, commonly used for rigid risers.

- Composites: Carbon fiber or glass fiber reinforced polymers, increasingly used for their lightweight properties, corrosion resistance, and fatigue life.

- Other Alloys: Specialized alloys offering enhanced performance in extreme high-pressure, high-temperature (HPHT) or corrosive environments.

- By Application:

- Oil and Gas: The largest segment, encompassing exploration, drilling, production, and abandonment activities in offshore fields.

- Offshore Wind: Growing segment, for power export cables (dynamic risers) and structural support for floating wind turbines.

- Subsea Mining: Emerging application for conveying excavated materials from the seabed to surface vessels.

- Others: Includes applications in ocean thermal energy conversion, aquaculture, and telecommunication cable protection.

- By Depth:

- Shallow Water: Operations up to 500 meters, requiring robust but less complex riser systems.

- Deepwater: Depths between 500 and 1,500 meters, demanding more advanced riser designs and materials.

- Ultra-Deepwater: Operations beyond 1,500 meters, pushing the boundaries of engineering for extreme pressure and dynamic loads.

Value Chain Analysis For Risers Market

The value chain for the Risers market is complex and integrated, beginning with upstream activities focused on raw material procurement and the manufacturing of specialized components. This initial stage involves suppliers of high-grade steel, advanced composite fibers, polymers, and other critical materials that form the core of riser systems. Component manufacturers then transform these raw materials into specific parts such as connectors, flanges, buoyancy modules, and insulation layers, which are essential for the assembly of complete riser systems. These upstream participants are crucial in ensuring the quality, integrity, and performance characteristics of the final riser products, requiring deep expertise in metallurgy, polymer science, and material engineering. The efficiency and reliability of this segment directly impact the overall cost and safety of offshore projects.

The midstream segment of the value chain is dominated by specialized engineering firms and manufacturers responsible for the design, fabrication, and assembly of the entire riser system. This stage involves sophisticated engineering analysis, including fatigue analysis, hydrodynamic modeling, and structural simulations, to ensure the riser system can withstand the extreme forces and environments of offshore operations. Fabrication includes the precise welding of steel sections or the intricate layering of composite materials, followed by assembly and rigorous testing to meet stringent industry standards and client specifications. Downstream activities involve the transportation, installation, and ongoing maintenance and inspection of riser systems once deployed offshore. Installation is a highly specialized operation, often requiring heavy-lift vessels, ROVs, and experienced marine personnel to safely connect the risers between subsea infrastructure and surface facilities. Post-installation, a continuous cycle of monitoring, inspection, and repair is essential to ensure the long-term integrity and operational reliability of these critical assets.

Distribution channels for Risers are primarily direct, driven by the highly customized and project-specific nature of these systems. Major oil and gas companies, offshore wind developers, and large EPC (Engineering, Procurement, and Construction) contractors typically engage directly with riser system manufacturers and service providers. This direct engagement ensures that technical specifications, project timelines, and performance requirements are meticulously met. Indirect channels might exist through global distributors for standardized components or smaller, specialized parts, but for complete riser systems, the direct sales model predominates. The close collaboration between the client and the supplier throughout the design, fabrication, and installation phases is characteristic of this market, emphasizing long-term relationships and a deep understanding of unique project challenges. This direct approach helps in managing the significant risks associated with high-value, critical offshore infrastructure and ensures bespoke solutions are delivered effectively.

Risers Market Potential Customers

The primary potential customers for the Risers market are diverse and span across critical segments of the global energy and marine industries, all requiring robust and reliable subsea connections for their operations. Leading the demand are major international oil and gas exploration and production (EandP) companies, including national oil companies (NOCs) and independent operators, particularly those engaged in deepwater and ultra-deepwater drilling and production projects. These entities require sophisticated drilling, production, and export riser systems capable of withstanding extreme pressures, temperatures, and dynamic loads to extract hydrocarbons efficiently and safely from challenging offshore fields. Their continuous investment in new field developments, existing asset maintenance, and enhanced oil recovery techniques drives consistent demand for advanced riser technologies. Furthermore, specialized engineering, procurement, and construction (EPC) contractors also represent significant customers, as they are often responsible for delivering integrated offshore projects where riser systems are a fundamental component, acting as intermediaries between the EandP companies and the riser manufacturers. They procure riser solutions as part of larger project packages, ensuring seamless integration with other subsea infrastructure and topside facilities.

Beyond traditional oil and gas, the rapidly expanding offshore renewable energy sector, particularly offshore wind farm developers and operators, constitutes a growing customer base. As offshore wind projects move into deeper waters and utilize floating turbine technologies, there is an increasing need for dynamic risers for power export cables and innovative structural risers to support floating foundations. Companies specializing in offshore wind infrastructure development and marine construction are key buyers of these specialized riser systems, focusing on durability, fatigue life, and environmental resilience. Additionally, a nascent but promising customer segment includes subsea mining companies and research institutions exploring the extraction of minerals from the seabed. These entities will require specialized risers for transporting excavated materials, fluids, and power, demanding highly abrasion-resistant and robust solutions. Government agencies involved in national energy infrastructure and marine defense might also procure specialized risers for strategic projects, although this represents a smaller, more niche segment. Overall, the market is characterized by a demand for high-performance, custom-engineered solutions tailored to meet the exacting standards and unique environmental challenges of each offshore project, making client relationships and technical expertise paramount for suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 12.5 Billion |

| Market Forecast in 2032 | USD 21.3 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TechnipFMC, Subsea 7, Aker Solutions, Saipem, Schlumberger, Baker Hughes, Halliburton, Tenaris, Vallourec, Prysmian Group, Nexans, Oceaneering International, Dril-Quip, NOV Inc., Oil States International, DeepOcean, McDermott International, Heerema Marine Contractors, Boskalis, Fugro |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Risers Market Key Technology Landscape

The Risers market is heavily influenced by a dynamic and evolving technology landscape, with continuous innovation aiming to address the increasing complexities of offshore operations, enhance safety, and reduce operational expenditures. A significant area of focus is on advanced material science, particularly the development and application of composite materials such as carbon fiber and glass fiber reinforced polymers. These composites offer substantial advantages over traditional steel, including significant weight reduction, superior corrosion resistance, and enhanced fatigue life, which are critical for dynamic risers and deepwater applications where weight and durability are paramount. High-strength steel alloys and specialized elastomers are also continually being refined to withstand extreme high-pressure, high-temperature (HPHT) environments and aggressive chemical compositions found in deeper reservoirs. Beyond materials, smart riser technologies are gaining traction, integrating embedded sensors, fiber optics, and acoustic emission detectors directly into the riser structure. These sensors enable real-time monitoring of various parameters such as strain, temperature, pressure, vortex-induced vibrations (VIV), and potential damage, providing critical data for structural health monitoring and predictive maintenance. This data is often fed into advanced analytical platforms utilizing artificial intelligence and machine learning algorithms to detect anomalies, predict failures, and optimize operational strategies, moving from reactive to proactive asset management. Furthermore, advancements in subsea connection systems and installation methodologies are crucial. Technologies like remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) are integral for inspection, maintenance, and repair, reducing human intervention in hazardous environments and improving inspection frequency and data quality. The development of digital twin technology for riser systems allows operators to create virtual models that precisely mirror physical assets, enabling complex simulations, performance optimization, and scenario planning throughout the riser's lifecycle. Moreover, advanced computational fluid dynamics (CFD) and finite element analysis (FEA) software continue to evolve, providing engineers with more accurate tools for designing and optimizing riser configurations for various environmental loads, ensuring structural integrity and minimizing risks. These technological advancements collectively contribute to safer, more efficient, and economically viable deepwater and ultra-deepwater offshore projects, as well as supporting the expansion of the offshore renewable energy sector, by pushing the boundaries of what is technically feasible and operationally reliable.

Regional Highlights

- North America: This region remains a cornerstone of the Risers market, primarily driven by extensive deepwater and ultra-deepwater activities in the Gulf of Mexico. The presence of major oil and gas operators and advanced technological infrastructure fuels demand for high-performance drilling, production, and export risers. Investment in technological innovation and robust regulatory frameworks also characterize this market.

- Europe: A leading region in offshore renewable energy, particularly offshore wind, driving significant demand for dynamic risers and power export cables. The North Sea continues to be an important area for both new developments, particularly gas, and decommissioning projects, requiring specialized riser solutions for extended asset life and safe abandonment operations.

- Asia Pacific (APAC): Emerging as a high-growth market due to increasing energy demand, new deepwater discoveries in countries like Australia, Malaysia, and Indonesia, and ambitious offshore wind power initiatives across China, India, and Vietnam. The region attracts substantial foreign investment in offshore projects, spurring local market development and technological adoption.

- Latin America: Characterized by significant deepwater oil and gas reserves, notably the pre-salt fields off the coast of Brazil. This region consistently requires advanced riser systems capable of operating in challenging, complex geological conditions and at extreme depths. New discoveries and national energy strategies continue to drive substantial market opportunities.

- Middle East and Africa (MEA): This region offers a mix of mature oil and gas fields requiring maintenance and upgrades, alongside new offshore discoveries, particularly gas fields, driving demand for both conventional and specialized riser solutions. Investments in infrastructure expansion and enhanced recovery projects contribute to steady market growth, with a focus on cost-efficiency and durability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Risers Market.- TechnipFMC

- Subsea 7

- Aker Solutions

- Saipem

- Schlumberger

- Baker Hughes

- Halliburton

- Tenaris

- Vallourec

- Prysmian Group

- Nexans

- Oceaneering International

- Dril-Quip

- NOV Inc.

- Oil States International

- DeepOcean

- McDermott International

- Heerema Marine Contractors

- Boskalis

- Fugro

Frequently Asked Questions

What are risers in the context of offshore operations?

Risers are specialized pipe systems used in offshore operations to connect subsea equipment on the seabed to surface facilities or vessels. They are critical for transporting fluids such as oil, gas, drilling mud, and water, and for providing structural support and access to the wellbore during drilling and production activities in deepwater environments.

How is the Risers market expected to grow?

The Risers market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032, increasing from an estimated USD 12.5 Billion in 2025 to USD 21.3 Billion by 2032. This growth is driven by continued deepwater oil and gas exploration and the rapid expansion of the offshore wind energy sector.

What are the main drivers for the Risers market?

Key drivers for the Risers market include the sustained global demand for energy, necessitating continued offshore exploration and production, particularly in deepwater areas. The rapid expansion of the offshore renewable energy sector, especially offshore wind, and ongoing technological advancements in materials and subsea engineering also significantly propel market growth.

What role do composite materials play in riser technology?

Composite materials, such as carbon fiber and glass fiber reinforced polymers, are increasingly crucial in riser technology due to their lightweight properties, superior corrosion resistance, and enhanced fatigue life. These attributes are highly beneficial for dynamic risers, reducing the overall weight and improving the durability and operational efficiency of systems in challenging deepwater environments.

How does AI enhance riser system reliability?

AI enhances riser system reliability through advanced predictive maintenance, utilizing real-time sensor data and machine learning to forecast potential failures and optimize maintenance schedules. It also improves structural health monitoring by analyzing various data types to detect early signs of degradation, and supports autonomous inspection systems, leading to increased safety and reduced downtime.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Subsea Umbilicals, Risers and Flowlines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Subsea Risers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Deep Depth Subsea Umbilicals, Risers and Flowlines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Oil and Gas Subsea Umbilicals, Risers and Flowlines (SURF) Market Size Report By Type (Umbilicals, Risers and Flowlines), By Application (Shallow Water Oil & Gas Fields, Deepwater Oil & Gas Fields, Ultra Deepwater Oil & Gas Fields), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- SURF (Subsea Umbilicals, Risers and Flowlines) Market Statistics 2025 Analysis By Application (Oil, Natural Gas), By Type (Umbilical, Riser), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager