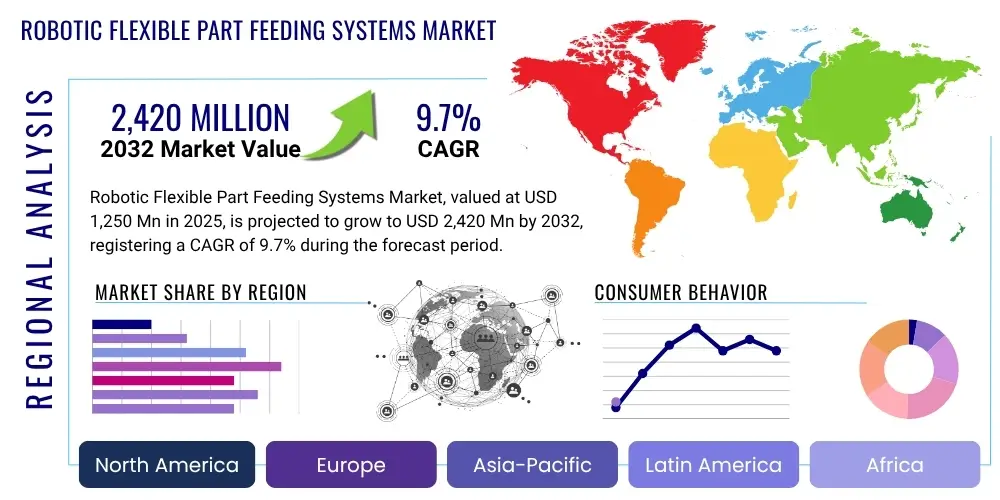

Robotic Flexible Part Feeding Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429980 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Robotic Flexible Part Feeding Systems Market Size

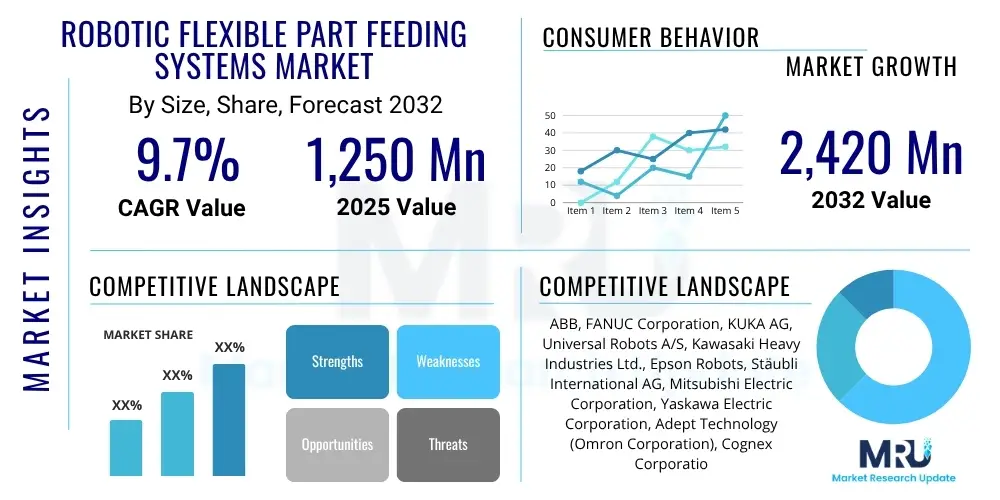

The Robotic Flexible Part Feeding Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.7% between 2025 and 2032. The market is estimated at $1,250 Million in 2025 and is projected to reach $2,420 Million by the end of the forecast period in 2032.

Robotic Flexible Part Feeding Systems Market introduction

The Robotic Flexible Part Feeding Systems market is witnessing substantial expansion driven by the increasing global demand for enhanced manufacturing automation, operational efficiency, and adaptability in production lines. These sophisticated systems integrate advanced robotics with flexible feeding technologies, often leveraging vision systems to handle a diverse range of parts without requiring dedicated tooling or extensive reconfigurations. This product category offers a transformative approach to traditional part presentation, moving away from rigid, dedicated feeders to highly versatile solutions capable of accommodating varying part geometries, sizes, and orientations within a single setup, thereby significantly reducing changeover times and maximizing throughput in high-mix, low-volume manufacturing environments.

Major applications for robotic flexible part feeding systems span across critical industries such as automotive, electronics, medical devices, pharmaceuticals, and general manufacturing, where precision, speed, and the ability to handle a variety of components are paramount. The inherent benefits of these systems include improved uptime, reduced operational costs, enhanced quality control through consistent part presentation, and a notable boost in manufacturing flexibility, enabling manufacturers to respond rapidly to market demands and product variations. Key driving factors propelling market growth include the pervasive trend towards Industry 4.0, the persistent global labor shortage in manufacturing, and the escalating need for efficient automation solutions that can handle complex assembly tasks with greater agility and lower total cost of ownership over their lifecycle.

Robotic Flexible Part Feeding Systems Market Executive Summary

The Robotic Flexible Part Feeding Systems market is characterized by dynamic business trends, marked by increasing integration of advanced AI and machine learning capabilities for enhanced vision processing and adaptive control, alongside a growing emphasis on collaborative robot compatibility to facilitate human-robot interaction in shared workspaces. Manufacturers are increasingly seeking solutions that offer rapid deployment, ease of programming, and seamless integration with existing production infrastructure, driving innovation in user-friendly interfaces and modular system designs. Strategic partnerships between robot manufacturers, vision system providers, and software developers are also becoming more prevalent to deliver comprehensive, turnkey solutions.

Regional trends indicate significant market growth in Asia Pacific, propelled by robust manufacturing sectors in countries like China, Japan, and South Korea, which are rapidly adopting automation to enhance competitiveness and address labor challenges. North America and Europe continue to be strong markets, distinguished by early adoption of advanced manufacturing technologies, substantial investments in research and development, and a focus on high-precision and customized production. Emerging economies in Latin America and the Middle East and Africa are also showing promising growth potential as industrialization accelerates and awareness of automation benefits increases. Segment-wise, vision-guided flexible feeding systems are dominating the market due to their superior adaptability and accuracy, while the electronics and automotive industries remain the largest end-users, consistently driving demand for sophisticated part handling solutions capable of managing smaller, more intricate components with greater efficiency and reliability.

AI Impact Analysis on Robotic Flexible Part Feeding Systems Market

Users frequently inquire about how artificial intelligence fundamentally enhances the capabilities and efficiency of Robotic Flexible Part Feeding Systems, particularly concerning their adaptability to new parts, ability to self-optimize, and role in predictive maintenance. There is a strong interest in understanding AI's contribution to improving vision recognition accuracy, enabling real-time decision-making, and mitigating the complexities associated with handling highly variable part batches. Users also express concerns regarding the integration challenges of AI-driven solutions, the need for specialized technical expertise, and the implications for data security and privacy within intelligent manufacturing environments. The overarching expectation is for AI to unlock unprecedented levels of flexibility, intelligence, and autonomous operation within part feeding processes, minimizing manual intervention and maximizing throughput across diverse manufacturing scenarios.

- Enhanced vision recognition and object detection for a wider array of part geometries and orientations.

- Adaptive sorting algorithms that learn and optimize feeding strategies in real-time based on part characteristics and production demands.

- Predictive maintenance capabilities for feeders and robots, reducing downtime and optimizing operational schedules.

- Improved error recovery and fault detection mechanisms, minimizing human intervention.

- Self-optimization of feeding parameters, such as vibration intensity and vision system settings, to maximize throughput and reliability.

- Facilitation of complex assembly tasks by accurately presenting previously unstructured parts.

- Reduced need for extensive programming for new parts, enabling faster changeovers and greater flexibility.

DRO & Impact Forces Of Robotic Flexible Part Feeding Systems Market

The Robotic Flexible Part Feeding Systems market is significantly influenced by a confluence of driving factors, critical restraints, and substantial opportunities that collectively shape its trajectory and competitive landscape. The primary drivers include the escalating labor costs and persistent skilled labor shortages across developed economies, compelling industries to seek automated solutions for repetitive tasks. Furthermore, the increasing demand for precision and quality in manufacturing, coupled with the global shift towards mass customization and high-mix, low-volume production, necessitates highly adaptable automation. The pervasive adoption of Industry 4.0 principles, emphasizing smart factories and interconnected production systems, further fuels the demand for these intelligent feeding solutions. These forces collectively propel market growth by highlighting the operational and strategic advantages of flexible automation over traditional methods.

Conversely, the market faces notable restraints, including the relatively high initial capital investment required for implementing sophisticated robotic and vision-guided systems, which can be a barrier for smaller and medium-sized enterprises (SMEs). The complexity of integrating these advanced systems into existing legacy infrastructure, often requiring specialized technical expertise for setup, programming, and maintenance, also poses a significant challenge. However, these restraints are offset by emerging opportunities such as the continuous advancements in AI and machine learning, which promise to make these systems more intuitive and easier to deploy. The growing market for collaborative robots (cobots) offers pathways for safer human-robot interaction in flexible feeding applications, expanding their utility. Moreover, the penetration into untapped emerging markets and niche applications, such as pharmaceutical and food processing, presents lucrative growth avenues. The impact forces are predominantly technological advancements, economic shifts influencing investment cycles, and evolving regulatory frameworks pertaining to automation and workplace safety, all of which dynamically interact to shape the market's future.

Segmentation Analysis

The Robotic Flexible Part Feeding Systems market is meticulously segmented to provide a granular understanding of its diverse components, technological applications, and end-user adoption patterns. These segmentations are crucial for identifying specific market niches, understanding competitive dynamics, and forecasting future growth trajectories. The market can be broadly categorized based on the type of technology employed, the specific components that constitute the system, the diverse range of end-user industries that leverage these solutions, and the geographical regions driving their adoption. This comprehensive segmentation allows stakeholders to analyze market performance, strategize product development, and tailor solutions to meet the precise requirements of various industrial applications, ensuring targeted market penetration and sustainable growth.

- By Type

- Vision-Guided Flexible Feeding Systems

- Non-Vision-Guided Flexible Feeding Systems

- By Component

- Robots (e.g., Scara, Delta, Collaborative)

- Vision Systems (2D, 3D, AI-powered)

- Flexible Feeders (Vibratory, Tray, Belt)

- Software and Control Systems

- Grippers and End-Effectors

- By End-User Industry

- Automotive

- Electronics and Semiconductors

- Medical Devices and Pharmaceuticals

- Food and Beverage

- General Manufacturing and Assembly

- Aerospace and Defense

- Consumer Goods

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Robotic Flexible Part Feeding Systems Market

The value chain for Robotic Flexible Part Feeding Systems begins with the upstream suppliers responsible for core components, including robot manufacturers providing robotic arms (SCARA, Delta, collaborative), vision system developers offering 2D and 3D cameras and sophisticated image processing software, and specialized manufacturers producing flexible feeding platforms such as vibratory bowls, tray systems, or belt feeders. Additionally, component suppliers for sensors, controllers, grippers, and other end-effectors form a crucial part of the upstream segment, ensuring the availability of high-quality, precise hardware. Software developers for AI/ML algorithms and human-machine interface (HMI) systems also play a pivotal role here, providing the intelligence and usability layers of these advanced systems.

Moving downstream, the value chain encompasses system integrators who are instrumental in customizing, installing, and commissioning these complex systems for specific end-user applications. These integrators combine various components from different suppliers to create a cohesive and optimized solution, providing training and ongoing support. The end-users or buyers, ranging from large automotive manufacturers to electronics assembly plants and medical device producers, represent the final stage of the value chain, where the flexible part feeding systems are deployed to enhance production efficiency and flexibility. Distribution channels for these systems are typically direct, involving sales teams from robot manufacturers or system integrators engaging directly with industrial clients. However, an indirect approach can also be observed through specialized distributors or value-added resellers who provide regional support and expertise, extending market reach and facilitating adoption across diverse industrial landscapes.

Robotic Flexible Part Feeding Systems Market Potential Customers

Potential customers for Robotic Flexible Part Feeding Systems primarily encompass a broad spectrum of manufacturing industries that require high precision, flexibility, and efficiency in their part handling and assembly processes. These end-users are characterized by the need to handle a variety of parts, often with complex geometries, or to frequently switch between different product types within their production lines. The imperative to reduce labor costs, increase throughput, and improve product quality drives their adoption of these advanced automation solutions. Manufacturers looking to implement Industry 4.0 principles and smart factory concepts are particularly strong candidates for investing in these systems, seeking to enhance their operational agility and maintain a competitive edge in rapidly evolving markets.

Key segments of potential customers include large-scale automotive manufacturers assembling complex vehicle components, electronics and semiconductor companies dealing with miniature and delicate parts, and medical device producers requiring sterile and highly precise handling of small components. Furthermore, industries involved in consumer goods, aerospace, and general manufacturing, particularly those engaged in high-mix, low-volume production or those facing significant labor challenges, represent substantial buyer segments. Small to medium-sized enterprises (SMEs) that are increasingly investing in automation to scale their operations and reduce manual intervention are also emerging as a significant customer base, driven by the increasing affordability and user-friendliness of modern flexible feeding technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1,250 Million |

| Market Forecast in 2032 | $2,420 Million |

| Growth Rate | CAGR 9.7% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, FANUC Corporation, KUKA AG, Universal Robots A/S, Kawasaki Heavy Industries Ltd., Epson Robots, Stäubli International AG, Mitsubishi Electric Corporation, Yaskawa Electric Corporation, Adept Technology (Omron Corporation), Cognex Corporation, Asyril SA, FlexFactory GmbH, RNA Automation Ltd., SCHUNK GmbH & Co. KG, Bosch Rexroth AG, SMC Corporation, Festo AG & Co. KG, Siemens AG, ATS Automation Tooling Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Robotic Flexible Part Feeding Systems Market Key Technology Landscape

The Robotic Flexible Part Feeding Systems market is defined by a rapidly evolving technological landscape, where the convergence of several advanced technologies drives innovation and enhances system capabilities. Core to these systems are sophisticated vision systems, including both 2D and 3D cameras, which are crucial for identifying, locating, and orienting a diverse range of parts presented randomly. These vision systems are increasingly integrated with artificial intelligence (AI) and machine learning (ML) algorithms, enabling more robust object recognition, adaptive sorting, and real-time decision-making, even in complex or poorly lit environments. This AI integration allows the systems to learn from experience, adapt to new part variations without extensive reprogramming, and optimize feeding strategies autonomously.

Another pivotal technology involves the robotic manipulators themselves, with an increasing adoption of collaborative robots (cobots) alongside traditional industrial robots (SCARA, Delta) due to their inherent safety features, ease of programming, and ability to work alongside human operators. Advanced grippers and end-effectors, including vacuum grippers, multi-fingered grippers, and specialized pneumatic or electric grippers, are also critical for handling delicate or irregularly shaped parts with precision. The feeding mechanisms, such as vibratory platforms (e.g., bowl feeders, flexible vibratory plates), tray systems, or belt feeders, are designed for high flexibility and often incorporate smart sensoring to ensure consistent part flow. Furthermore, IoT (Internet of Things) connectivity enables real-time monitoring and data collection, while simulation software and digital twin technologies are utilized for system design, optimization, and predictive maintenance, contributing to the overall intelligence and efficiency of these advanced part feeding solutions.

Regional Highlights

- North America: This region is characterized by early adoption of advanced manufacturing technologies, substantial investments in R&D, and a strong drive towards automation to combat labor shortages and enhance manufacturing competitiveness. The presence of major automotive and aerospace industries fuels demand for high-precision, flexible feeding solutions.

- Europe: With a focus on Industry 4.0 and smart factory initiatives, Europe demonstrates a high propensity for integrating robotic flexible part feeding systems. Countries like Germany, Italy, and France are leading in adopting these technologies, particularly in automotive, electronics, and general manufacturing, driven by a need for efficiency and quality.

- Asia Pacific (APAC): The APAC region is the largest and fastest-growing market, primarily due to the vast manufacturing bases in China, Japan, South Korea, and India. Rapid industrialization, increasing labor costs, government support for automation, and the expansion of electronics and automotive sectors are key drivers.

- Latin America: This region is an emerging market for robotic flexible part feeding systems, driven by increasing foreign direct investment in manufacturing, particularly in countries like Mexico and Brazil. The growing emphasis on modernizing industrial infrastructure and improving production efficiency contributes to market expansion.

- Middle East and Africa (MEA): The MEA region is witnessing gradual adoption, primarily in sectors such as automotive, defense, and oil and gas. Investments in industrial diversification and the establishment of new manufacturing hubs are expected to drive future growth, albeit from a smaller base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Robotic Flexible Part Feeding Systems Market.- ABB

- FANUC Corporation

- KUKA AG

- Universal Robots A/S

- Kawasaki Heavy Industries Ltd.

- Epson Robots

- Stäubli International AG

- Mitsubishi Electric Corporation

- Yaskawa Electric Corporation

- Adept Technology (Omron Corporation)

- Cognex Corporation

- Asyril SA

- FlexFactory GmbH

- RNA Automation Ltd.

- SCHUNK GmbH & Co. KG

- Bosch Rexroth AG

- SMC Corporation

- Festo AG & Co. KG

- Siemens AG

- ATS Automation Tooling Systems Inc.

Frequently Asked Questions

What are Robotic Flexible Part Feeding Systems?

Robotic Flexible Part Feeding Systems are advanced automated solutions that use robots, vision systems, and flexible feeders to present a variety of randomly oriented parts to a robot for assembly or processing, eliminating the need for dedicated tooling for each part type.

What key benefits do these systems offer manufacturers?

They offer significant benefits including increased manufacturing flexibility, reduced changeover times, improved operational efficiency, lower labor costs, enhanced product quality, and the ability to handle high-mix, low-volume production with greater agility.

How does AI impact the performance of Flexible Part Feeding Systems?

AI significantly enhances performance through improved vision recognition, adaptive sorting algorithms that learn and optimize in real-time, predictive maintenance, and self-optimization of feeding parameters, making systems more intelligent, autonomous, and adaptable to new parts.

Which industries are the primary adopters of these systems?

The primary adopting industries include automotive, electronics and semiconductors, medical devices and pharmaceuticals, food and beverage, and general manufacturing, all requiring high precision and adaptability in their assembly processes.

What are the main challenges in adopting Robotic Flexible Part Feeding Systems?

Key challenges include the high initial capital investment, the complexity of integrating these advanced systems into existing manufacturing lines, and the requirement for specialized technical expertise for installation, programming, and ongoing maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager