Robotics Welding Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429023 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Robotics Welding Market Size

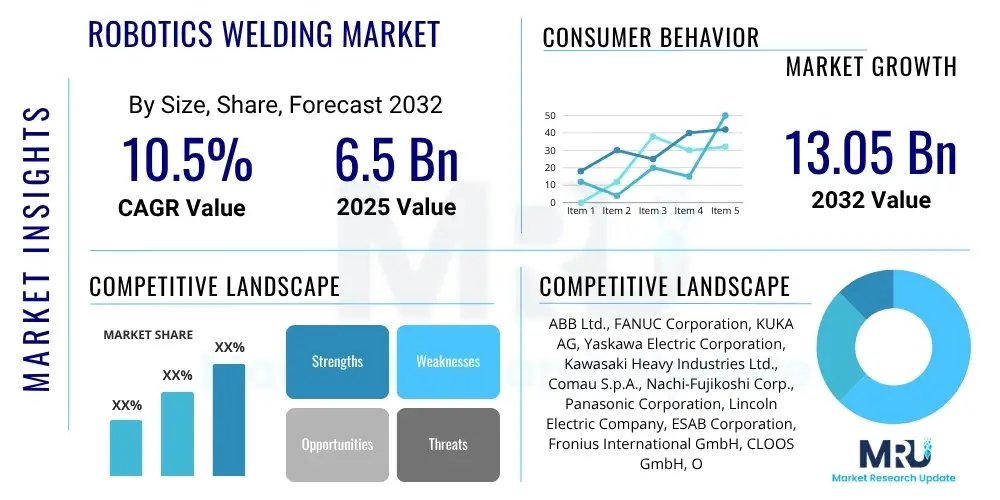

The Robotics Welding Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2025 and 2032. The market is estimated at USD 6.5 Billion in 2025 and is projected to reach USD 13.05 Billion by the end of the forecast period in 2032.

Robotics Welding Market introduction

The Robotics Welding Market encompasses the design, manufacture, and integration of automated systems for welding processes across various industrial applications. This sophisticated technology leverages robotic manipulators to perform welding tasks, significantly enhancing precision, speed, and consistency compared to manual methods. Robotic welding solutions are engineered to handle repetitive, dangerous, or physically demanding welding operations, thereby improving worker safety and overall operational efficiency within manufacturing environments. The core of these systems typically involves an industrial robot arm, a welding power source, a welding torch or gun, a wire feeder, and a sophisticated control system.

Product descriptions within this market range from articulated robots offering high flexibility to collaborative robots (cobots) designed for safe human-robot interaction, as well as specialized gantry or linear robots for large-scale operations. Major applications span critical sectors such as automotive manufacturing, where high-volume, repeatable welds are essential for chassis and body assembly; heavy machinery production for robust structural components; and aerospace and defense for precision welding of complex, high-tolerance parts. Beyond these, general fabrication, electronics, and construction are increasingly adopting robotic welding solutions to address specific production challenges and improve output quality.

The inherent benefits of robotic welding include superior weld quality and consistency, reduced production costs through optimized material usage and lower labor dependency, increased throughput, and enhanced safety by removing human operators from hazardous welding environments. Driving factors for market growth are multifaceted, primarily stemming from a global shortage of skilled manual welders, an escalating demand for high-quality and defect-free welds, and the continuous push towards industrial automation and digital transformation exemplified by Industry 4.0 initiatives. Furthermore, the integration of advanced sensors, vision systems, and artificial intelligence is propelling the capabilities and adaptability of robotic welding systems, making them viable for a broader spectrum of tasks and batch sizes, from mass production to customized fabrication.

Robotics Welding Market Executive Summary

The Robotics Welding Market is experiencing robust expansion, driven by several interconnected business, regional, and segment trends. Business trends are characterized by a pronounced shift towards greater automation, fueled by the persistent challenges of labor shortages in skilled welding professions and the imperative for enhanced manufacturing efficiency and precision. Key industry players are increasingly focusing on developing more user-friendly interfaces, modular robotic systems, and advanced integration capabilities that facilitate seamless deployment into existing production lines. Customization and flexible manufacturing are emerging as critical differentiators, with manufacturers demanding adaptable robotic solutions capable of handling diverse materials and complex geometries, moving beyond traditional high-volume, low-mix production environments. There is a strong emphasis on total cost of ownership (TCO) reduction, prompting innovation in energy-efficient systems and predictive maintenance features.

Regional trends highlight Asia Pacific as the dominant and fastest-growing market, largely due to extensive automotive manufacturing, rapid industrialization, and significant investments in automation infrastructure in countries like China, Japan, and South Korea. North America and Europe also demonstrate substantial growth, driven by advanced manufacturing capabilities, a strong focus on Industry 4.0, and the need to improve competitiveness against lower-cost regions. Governments and industries in these regions are actively promoting automation adoption through various incentives and research funding, underscoring a commitment to bolstering domestic manufacturing capacities and technological leadership. Emerging markets in Latin America, the Middle East, and Africa are showing nascent but accelerating adoption, particularly in sectors such as oil and gas, infrastructure development, and automotive assembly, as they seek to modernize their industrial bases.

Segment trends reveal that arc welding robots continue to hold the largest market share due to their widespread application in various industries, including automotive and heavy machinery. However, spot welding robots are also experiencing significant growth, particularly in automotive body-in-white applications, owing to their speed and precision. Laser welding and other advanced welding process robots are gaining traction for their ability to deliver high-quality, high-speed welds with minimal distortion, expanding their use in electronics and medical device manufacturing. From a component perspective, the demand for robotic arms remains paramount, but there is a growing emphasis on sophisticated software, advanced controllers, and integrated vision systems that enable smarter, more adaptive welding processes. Collaborative robots are a rapidly expanding segment, addressing the need for flexibility and human-robot collaboration in lighter manufacturing tasks, offering a lower entry barrier for small and medium-sized enterprises (SMEs) to adopt automation and enhance productivity.

AI Impact Analysis on Robotics Welding Market

Users are increasingly curious about how artificial intelligence (AI) is transforming the robotics welding market, with common questions revolving around its ability to enhance performance, address operational challenges, and shape future manufacturing practices. Key themes include the potential for AI to optimize welding parameters, improve defect detection, enable truly adaptive welding, and facilitate predictive maintenance, thereby reducing downtime and material waste. Concerns often touch upon the complexity of integrating AI, the initial investment costs, the need for specialized skills to manage AI-driven systems, and the societal implications regarding job displacement. However, there is a strong expectation that AI will unlock new levels of precision and efficiency, allowing robots to perform more complex, variable tasks and bridge the gap in human expertise, leading to a more resilient and intelligent manufacturing ecosystem.

- Enhanced Weld Quality Control: AI-powered vision systems and machine learning algorithms analyze real-time weld data to detect defects and adjust parameters instantaneously, ensuring consistent, high-quality welds.

- Adaptive Welding Processes: AI enables robots to adapt to variations in material thickness, joint gaps, and environmental conditions, optimizing welding paths and parameters on the fly without human intervention.

- Predictive Maintenance: Machine learning models analyze operational data from welding robots to predict potential equipment failures, enabling proactive maintenance and minimizing costly downtime.

- Optimized Path Planning: AI algorithms calculate the most efficient and precise welding paths for complex geometries, reducing cycle times and improving overall productivity.

- Human-Robot Collaboration: AI facilitates more intuitive and safer collaboration between human workers and robots, especially with cobots, by understanding human intent and adapting its movements accordingly.

- Data-Driven Process Improvement: AI analyzes vast datasets from welding operations to identify patterns and insights, leading to continuous process improvements, material savings, and energy efficiency.

- Automated Programming: AI can simplify the programming of complex welding tasks, allowing non-expert operators to set up and manage robotic welding systems more easily, reducing setup times.

- Material Characterization: AI systems can better understand and adapt to different material properties and their behavior during welding, improving the success rate of complex material joints.

DRO & Impact Forces Of Robotics Welding Market

The Robotics Welding Market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces, collectively determining its growth trajectory and adoption rates. Key drivers include the pervasive global shortage of skilled manual welders, which necessitates automated alternatives to maintain production capacities and quality standards. The escalating demand for high-quality, repeatable welds across critical industries such as automotive, aerospace, and heavy machinery further propels market expansion, as robotic systems inherently deliver superior precision and consistency. Additionally, the continuous emphasis on improving manufacturing productivity, enhancing worker safety by removing humans from hazardous environments, and reducing operational costs through optimized material usage and faster cycle times are strong catalysts for robotic welding adoption. The overarching trend of Industry 4.0 and digital transformation, promoting smart factories and interconnected production systems, also serves as a fundamental driving force, as robotic welding solutions are integral to achieving these advanced manufacturing paradigms.

Conversely, several restraints impede the market's full potential. The high initial investment cost associated with purchasing and integrating robotic welding systems can be a significant barrier for small and medium-sized enterprises (SMEs) and businesses with limited capital. Furthermore, the technical complexity involved in programming, operating, and maintaining these advanced systems requires a new set of specialized skills, which can be scarce and expensive to acquire or develop internally. The perception of job displacement due to automation can also lead to resistance from the workforce and labor unions, creating social and economic challenges. Moreover, robotic welding systems might lack the flexibility required for highly customized, small-batch, or highly variable production runs, where manual dexterity and immediate human judgment still offer advantages, although this is rapidly changing with advancements in AI and collaborative robotics.

Despite these restraints, substantial opportunities are emerging that promise to accelerate market growth. The increasing development and adoption of collaborative robots (cobots) are opening new avenues, offering more flexible, safer, and lower-cost automation options that can work alongside humans without extensive safety caging, making automation accessible to a broader range of manufacturers. The deeper integration of artificial intelligence and machine learning is poised to revolutionize robotic welding by enabling adaptive processes, predictive maintenance, and autonomous programming, thereby enhancing system intelligence and versatility. Furthermore, the expansion into new industrial applications beyond traditional manufacturing, such as construction, shipbuilding, and even artistic fabrication, presents untapped market potential. The continuous innovation in sensor technology, vision systems, and advanced welding processes like laser and friction stir welding, when coupled with robotics, promises to address even more complex and niche welding challenges, driving further market penetration.

The impact forces influencing the market are broad and profound. Technological advancements, particularly in robotics, AI, machine vision, and material science, continuously push the boundaries of what robotic welding systems can achieve, leading to more capable, efficient, and cost-effective solutions. Global economic conditions, including manufacturing output, industrial investment cycles, and trade policies, directly affect the demand for automation equipment. Regulatory environments, including safety standards and environmental regulations, influence system design and operational requirements. Lastly, the competitive landscape, characterized by intense innovation and strategic partnerships among key players, drives down costs and expands product offerings, making robotic welding solutions more accessible and appealing to a wider customer base.

Segmentation Analysis

The Robotics Welding Market is comprehensively segmented to provide a detailed understanding of its diverse components, technologies, and end-user applications. This segmentation allows for precise market analysis, highlighting key areas of growth, technological adoption, and industrial demand. The market is primarily broken down by Type of welding process, the various Components that constitute a robotic welding system, and the End-User Industries that leverage these advanced welding solutions. Each segment and subsegment represents a distinct market niche with specific requirements and growth drivers, reflecting the evolving landscape of industrial automation and manufacturing.

- By Type

- Arc Welding:

- MIG/MAG Welding (Gas Metal Arc Welding)

- TIG Welding (Gas Tungsten Arc Welding)

- Plasma Arc Welding

- Submerged Arc Welding

- Spot Welding

- Laser Welding

- Resistance Welding

- Friction Stir Welding

- Brazing and Soldering

- Other Welding Types (e.g., Electron Beam Welding, Ultrasonic Welding)

- Arc Welding:

- By Component

- Robots:

- Articulated Robots

- Collaborative Robots (Cobots)

- Cartesian Robots

- SCARA Robots

- Gantry Robots

- Welding Equipment:

- Welding Power Sources

- Wire Feeders

- Welding Torches/Guns

- Consumables (Welding Wire, Electrodes)

- Controllers and Software:

- Robot Controllers

- Programming Software (Offline/Online)

- Simulation Software

- Vision System Software

- PLC Integration Software

- Peripherals and Accessories:

- Positioners and Manipulators

- Safety Systems (Light Curtains, Fencing)

- Sensors (Vision Sensors, Tactile Sensors, Seam Tracking Sensors)

- Tool Changers

- Fume Extraction Systems

- Services:

- Installation and Integration

- Maintenance and Repair

- Training and Consulting

- Software Upgrades

- Robots:

- By End-User Industry

- Automotive and Transportation

- Heavy Machinery and Construction

- Aerospace and Defense

- Electronics and Semiconductors

- Metal Fabrication and General Manufacturing

- Energy (Oil & Gas, Power Generation)

- Medical Devices

- Shipbuilding

- Other Industries (e.g., Furniture, Agriculture)

Value Chain Analysis For Robotics Welding Market

The value chain for the Robotics Welding Market is a complex ecosystem, starting from the foundational components and extending through various stages of integration, distribution, and end-user adoption. At the upstream end, the chain involves manufacturers of raw materials such as metals for robot construction and electronic components for control systems, along with specialized producers of critical robot components including servo motors, gearboxes, sensors, and vision systems. Beyond core robot parts, the upstream also includes suppliers of welding power sources, wire feeders, and welding consumables, which are integral to the complete robotic welding solution. These foundational suppliers focus on innovation in materials science and component reliability, which directly impacts the performance and longevity of the final robotic welding systems.

Moving downstream, the value chain encompasses robot manufacturers who assemble these components into complete robotic arms and systems, such as articulated, collaborative, or gantry robots. These manufacturers often specialize in developing proprietary control software, human-machine interfaces (HMIs), and specific welding functionalities. A crucial intermediary stage is played by system integrators, who are responsible for designing, customizing, and implementing the robotic welding cells according to the specific needs of end-user facilities. This often involves integrating robots with welding equipment, safety systems, positioners, and programming them for specific applications. System integrators provide invaluable expertise in making these complex systems operational and optimized for diverse manufacturing environments, effectively bridging the gap between hardware manufacturers and end-user requirements.

Distribution channels in the Robotics Welding Market are varied, comprising both direct and indirect approaches. Direct sales are common for large-scale enterprises or sophisticated customers who possess in-house engineering capabilities to integrate systems, often involving direct engagement with robot manufacturers for bulk orders or highly customized solutions. However, indirect channels, primarily through a network of authorized distributors, value-added resellers (VARs), and independent system integrators, are more prevalent, especially for small and medium-sized enterprises (SMEs) seeking comprehensive, turnkey solutions. These indirect partners offer not only the hardware but also installation, programming, training, and ongoing technical support, acting as crucial touchpoints for customer engagement and market reach. The service component, including maintenance, spare parts, and software updates, forms a critical part of the downstream value chain, ensuring the long-term operational efficiency and customer satisfaction.

Robotics Welding Market Potential Customers

The Robotics Welding Market targets a broad spectrum of end-users and buyers across numerous industrial sectors, all seeking to enhance their welding operations through automation, precision, and efficiency. The primary and most significant customer segment continues to be the automotive and transportation industry, including original equipment manufacturers (OEMs) and their extensive network of tier-one and tier-two suppliers. These entities rely on robotic welding for high-volume, repetitive tasks such as chassis assembly, body-in-white fabrication, and component welding, where consistency, speed, and defect reduction are paramount for mass production and safety standards. The stringent quality requirements and continuous pressure for cost efficiency within the automotive sector make robotic welding an indispensable technology.

Another substantial customer base resides within the heavy machinery and construction equipment manufacturing sector. Companies producing agricultural machinery, excavators, cranes, and other large industrial equipment require robust and high-quality welds for structural integrity and durability. Robotic welding offers the capability to handle large, heavy workpieces with consistent quality, reducing the physical strain on human operators and ensuring the longevity of heavy-duty components. The aerospace and defense industry represents a high-value, albeit smaller, segment where extreme precision, material versatility (e.g., titanium, aluminum alloys), and adherence to stringent certifications necessitate advanced robotic welding solutions for critical components and airframe structures. The demand for lightweight, yet incredibly strong, components drives the adoption of sophisticated robotic laser and friction stir welding.

Beyond these large-scale industries, the electronics and semiconductor sectors are increasingly adopting micro-robotic welding and soldering for intricate connections and small components, requiring very high precision and minimal heat input. General metal fabrication shops, which encompass a wide array of manufacturing activities from custom structural steel to sheet metal work, form a growing customer segment as collaborative robots and more affordable solutions become available. These smaller operations seek to overcome labor shortages, improve quality, and expand their capabilities to take on more complex projects. Furthermore, emerging sectors such as shipbuilding, energy infrastructure (including wind turbine components and oil & gas pipelines), and medical device manufacturing are actively exploring or integrating robotic welding solutions to address specific challenges related to scale, safety, material properties, and regulatory compliance. The widespread applicability of robotic welding technology continues to expand its potential customer base across the global manufacturing landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.5 Billion |

| Market Forecast in 2032 | USD 13.05 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., FANUC Corporation, KUKA AG, Yaskawa Electric Corporation, Kawasaki Heavy Industries Ltd., Comau S.p.A., Nachi-Fujikoshi Corp., Panasonic Corporation, Lincoln Electric Company, ESAB Corporation, Fronius International GmbH, CLOOS GmbH, OTC Daihen Corporation, Hyundai Robotics, Universal Robots (Teradyne Inc.), Robotiq Inc., Siasun Robot & Automation Co. Ltd., Reis Robotics GmbH (KUKA AG), Valiant TMS, Valk Welding BV. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Robotics Welding Market Key Technology Landscape

The Robotics Welding Market is characterized by a rapidly evolving technological landscape, driven by continuous innovation aimed at enhancing precision, flexibility, and intelligence in automated welding processes. Central to this evolution are collaborative robots (cobots), which are designed to work safely alongside human operators without extensive safety caging. Cobots are gaining significant traction due to their ease of programming, lower initial investment compared to traditional industrial robots, and inherent flexibility, making them ideal for small to medium batch production and applications requiring human interaction, such as loading and unloading workpieces. This segment is fostering wider adoption, particularly among SMEs, who can integrate automation without completely overhauling their existing production layouts. The development of more intuitive human-robot interfaces and advanced safety features continues to be a key focus in this area, bridging the gap between manual and fully automated operations.

Advanced sensor technologies, particularly vision systems, are fundamentally transforming robotic welding capabilities. High-resolution 2D and 3D vision systems enable robots to accurately locate workpieces, identify joint gaps, and perform real-time seam tracking, even on parts with slight variations or complex geometries. This significantly reduces the need for highly precise fixturing, which can be costly and time-consuming, thereby enhancing the adaptability of robotic systems to real-world manufacturing environments. Beyond vision, tactile and force-torque sensors provide robots with a sense of "touch," allowing them to detect contact, maintain consistent pressure, and adapt to unforeseen changes during the welding process. This sensory feedback loop is crucial for achieving high-quality welds on challenging materials and intricate designs, making the welding process more robust and less prone to errors.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is perhaps the most transformative technological trend, moving robotic welding towards truly intelligent and autonomous operations. AI algorithms are used for optimizing welding parameters, predicting and preventing defects through real-time data analysis, and enabling adaptive welding processes that can adjust to varying material thicknesses, joint configurations, and environmental conditions without human intervention. This leads to superior weld quality, reduced material waste, and enhanced operational efficiency. Furthermore, IoT connectivity and cloud-based platforms are facilitating remote monitoring, predictive maintenance, and data analytics across entire fleets of welding robots, allowing manufacturers to gain deeper insights into their operations, optimize resource allocation, and implement continuous process improvements. Offline programming software with simulation capabilities also plays a crucial role by allowing engineers to design, simulate, and optimize welding programs virtually, reducing setup times and minimizing production downtime before physical implementation on the shop floor.

Regional Highlights

- Asia Pacific: This region is the undisputed leader in the Robotics Welding Market, primarily driven by massive investments in automation across manufacturing sectors in countries like China, Japan, South Korea, and India. China, in particular, dominates due to its vast industrial base, aggressive government support for automation, and the world's largest automotive production. Japan and South Korea are key players, home to major robot manufacturers and advanced automotive and electronics industries, focusing on high-precision and technologically sophisticated solutions. The region benefits from increasing labor costs, a burgeoning middle class demanding manufactured goods, and the widespread adoption of smart factory initiatives.

- North America: The market in North America, encompassing the United States, Canada, and Mexico, is characterized by strong adoption in the automotive, aerospace, and general fabrication industries. The U.S. is a major driver, with a focus on reshoring manufacturing, improving competitiveness through automation, and addressing a persistent shortage of skilled welders. There is a growing emphasis on collaborative robotics and advanced vision systems to enhance flexibility and productivity. Investments in electric vehicle manufacturing and aerospace defense programs are significant growth catalysts.

- Europe: Europe represents a mature yet continually growing market, with Germany, Italy, France, and the UK leading the charge. Germany, with its robust automotive and heavy machinery sectors, is a pioneer in advanced manufacturing and Industry 4.0 adoption. The region focuses on high-quality, efficient, and flexible robotic welding solutions. Strict safety regulations and a strong emphasis on worker well-being further drive the demand for automated systems. Innovation in laser welding and customized robotic cells is a key trend.

- Latin America: The Robotics Welding Market in Latin America is in an emerging growth phase, with significant potential, particularly in countries like Brazil and Mexico. Mexico benefits from its strong automotive manufacturing industry, largely servin

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager