Rotomoulding Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430530 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Rotomoulding Powder Market Size

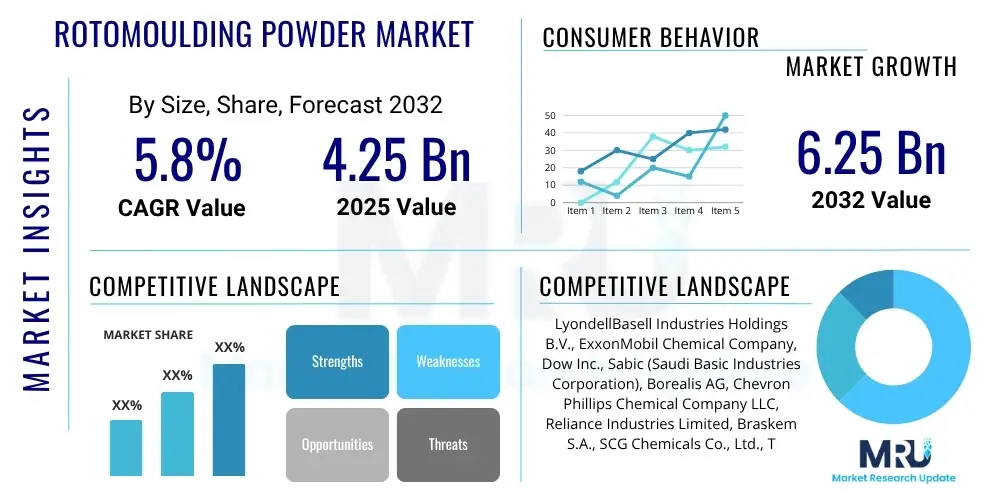

The Rotomoulding Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 4.25 Billion in 2025 and is projected to reach USD 6.25 Billion by the end of the forecast period in 2032.

Rotomoulding Powder Market introduction

The Rotomoulding Powder Market encompasses a diverse range of thermoplastic polymer powders, predominantly polyethylene-based, specifically engineered for the rotational moulding process. This manufacturing technique involves heating a hollow mold filled with the polymer powder while rotating it biaxially, leading to the formation of a uniform, seamless, and stress-free hollow plastic product upon cooling. The process is highly valued for its ability to produce large, complex, and hollow parts with consistent wall thickness, making it an indispensable method in various industrial and consumer applications where design flexibility, durability, and cost-effectiveness for small to medium production runs are paramount. Its inherent advantages over other plastic processing methods, such as low mold costs and the ability to produce multi-layered items, contribute to its steady adoption across a wide array of sectors.

The core product offering includes various grades of Linear Low-Density Polyethylene (LLDPE), High-Density Polyethylene (HDPE), and Low-Density Polyethylene (LDPE), alongside other specialized polymers such as polypropylene, nylon, and polycarbonate. Each polymer type is meticulously formulated and processed to meet specific performance criteria, including tailored melt flow indices, optimal particle size distribution, and enhanced bulk density. These characteristics are critical for achieving high-quality rotomoulded components that exhibit superior attributes such as excellent impact strength, robust chemical resistance, exceptional UV stability, and an appealing aesthetic finish, ensuring long-term durability and functionality in challenging environments ranging from agricultural fields to urban landscapes.

Major applications span across critical sectors such as water management, agriculture, industrial storage, marine industries, and leisure. This includes the production of large water tanks, agricultural spray tanks, septic tanks, industrial containers, marine vessels like kayaks and canoes, playground equipment, and various automotive components. The market's growth is significantly bolstered by increasing global urbanization, substantial investments in infrastructure development particularly for water and sanitation projects, and the expanding demand for durable, lightweight plastic solutions in both developed and emerging economies. Continuous innovation in material science, focusing on enhanced performance characteristics, sustainable options like recycled and bio-based polymers, and the integration of smart technologies, further drives market expansion and diversification.

Rotomoulding Powder Market Executive Summary

The rotomoulding powder market is currently undergoing a dynamic transformation, influenced by an evolving landscape of business, regional, and segment-specific trends that are collectively shaping its growth trajectory. From a business perspective, the industry is witnessing a pronounced shift towards sustainability, with manufacturers increasingly investing in the research and development of recycled, bio-based, and other eco-friendly polymer powders. This trend is driven by heightened environmental awareness, stricter regulatory frameworks, and a growing consumer preference for greener products, compelling companies to innovate in material composition and circular economy practices. Furthermore, there is a strong emphasis on customization and developing specialized formulations that impart enhanced properties, such as advanced anti-microbial capabilities, improved flame retardancy, and highly specific color matching, thereby expanding the utility and value proposition of rotomoulded articles in niche applications and demanding environments.

Geographically, the market exhibits divergent growth patterns, with the Asia Pacific region emerging as a powerhouse for expansion. This robust growth is primarily fueled by rapid industrialization, burgeoning infrastructure spending, and a rapidly expanding middle class that contributes to escalating demand for both industrial and consumer-grade rotomoulded products in countries like China, India, and Southeast Asian nations. The need for efficient water storage, agricultural equipment, and urban utilities in these regions is particularly high. In contrast, mature markets in North America and Europe, while demonstrating slower volumetric growth, remain at the forefront of technological innovation, focusing on developing high-performance materials, advanced process automation, and premium product solutions to maintain competitive edge and meet stringent quality and environmental standards. These regions are pioneers in adopting advanced grades of polymers and integrating smart manufacturing techniques.

Segment-wise, Linear Low-Density Polyethylene (LLDPE) continues to dominate the market due to its exceptional balance of properties including impact strength, stress crack resistance, and cost-effectiveness, making it suitable for a wide array of applications. Its versatility ensures its continued prevalence in large-volume products. However, high-performance engineering polymers such as polypropylene, polycarbonate, and nylon are steadily gaining traction, particularly for specialized applications that demand superior mechanical strength, higher temperature resistance, or enhanced chemical inertness, such as in the automotive or medical sectors where product integrity is critical. The water storage, agricultural, and industrial container segments consistently remain primary drivers of demand, while the leisure and consumer goods sectors, alongside niche automotive and medical applications, present significant opportunities for targeted growth and product diversification, reflecting the market's adaptability to evolving industrial needs and consumer preferences for durable and innovative plastic solutions.

AI Impact Analysis on Rotomoulding Powder Market

Industry discussions concerning the impact of Artificial Intelligence (AI) on the Rotomoulding Powder Market predominantly center on leveraging AI for operational optimization, enhancing product quality, and accelerating innovation across the value chain. There is significant interest in how AI can contribute to streamlining the inherently complex rotational molding process, which involves multiple variables like oven temperature profiles, rotation speed, cooling rates, and material properties. Stakeholders are keen to understand AI's potential in minimizing material waste through precise prediction, optimizing processing parameters for reduced energy consumption, and ensuring consistent product characteristics, thereby addressing critical operational inefficiencies and fostering more sustainable manufacturing practices within the industry.

The key themes that emerge from these inquiries include the potential for AI to introduce a new level of precision and control in manufacturing, moving beyond traditional trial-and-error methods. Manufacturers are exploring how AI-driven analytics can translate vast amounts of sensor data collected during the molding cycle into actionable insights for real-time process adjustments, leading to improved energy efficiency and enhanced material utilization. Furthermore, expectations are high for AI's role in implementing predictive maintenance strategies for machinery and molds, which can significantly minimize costly downtime and extend equipment lifespan. Additionally, AI is anticipated to accelerate research and development through AI-powered material design and formulation, facilitating the creation of novel rotomoulding powders with superior performance characteristics, ultimately driving product innovation and market competitiveness.

- AI-driven optimization of molding cycle times, dynamically adjusting heating and cooling profiles based on real-time data to reduce energy consumption, minimize thermal stress on materials, and increase overall production throughput.

- Enhanced quality control through advanced machine vision systems and sensor data analysis, enabling real-time detection and prediction of defects such as pinholes, bubbles, warpage, or uneven wall thickness, thereby significantly minimizing scrap rates and improving product consistency.

- Predictive maintenance strategies for rotomoulding machinery and molds, utilizing AI algorithms to analyze historical performance data and forecast potential equipment failures, minimizing unscheduled downtime, optimizing maintenance schedules, and extending asset lifespan.

- Accelerated material development and formulation, leveraging AI to simulate and predict the characteristics and performance of new polymer blends and additive packages, optimizing properties like impact strength, UV resistance, melt flow, and chemical resistance for specific application requirements.

- Supply chain optimization and demand forecasting for raw materials, improving inventory management, reducing carrying costs, mitigating risks associated with supply chain disruptions, and enabling more efficient procurement strategies.

- Automated design assistance for mold creation, using generative AI to optimize part geometry for uniform wall thickness, efficient material distribution during rotation, and improved structural integrity, reducing design iteration cycles and accelerating product development.

- Data analytics for comprehensive market trend analysis and competitive intelligence, processing vast datasets to identify emerging product demands, regional growth opportunities, and competitor strategies, informing strategic product development and business expansion decisions.

- Integration of robotics and advanced automation in material handling, mold loading/unloading, and post-molding processes, orchestrated by AI for improved safety, enhanced operational efficiency, and consistent product quality across production batches.

DRO & Impact Forces Of Rotomoulding Powder Market

The Rotomoulding Powder Market is profoundly shaped by a dynamic interplay of drivers, restraints, and opportunities, alongside broader impact forces that continuously redefine its landscape. A significant driver is the escalating global demand for efficient water management and wastewater treatment infrastructure, particularly critical in regions experiencing rapid urbanization and population growth. Rotomoulded tanks and containers offer a cost-effective, durable, and corrosion-resistant solution for these applications, providing long-term reliability for storing potable water, chemicals, and managing waste. Concurrently, the robust expansion of the agriculture sector, requiring resilient storage and transportation solutions for water, fertilizers, and feed, further stimulates market demand for durable plastic components. The burgeoning leisure and consumer goods segments, encompassing items like kayaks, playground equipment, and outdoor furniture, also serve as substantial market accelerators due to the design flexibility, aesthetic appeal, and robust nature of rotomoulded products that withstand outdoor elements.

However, the market also contends with considerable restraints that challenge its growth. The inherent volatility in the pricing of crude oil, which is a primary feedstock for virgin polymer production, directly translates into fluctuating raw material costs. This instability impacts manufacturers' profitability, influences pricing strategies for rotomoulding powders and finished goods, and can deter investment. Furthermore, escalating global concerns regarding plastic waste and the urgent push for a circular economy are leading to more stringent environmental regulations, prompting a fundamental re-evaluation of material choices, waste management practices, and manufacturing processes within the industry. The relatively longer cycle times associated with rotational moulding, when compared to high-speed processes like injection moulding or blow moulding, can limit its competitiveness for high-volume production of smaller, intricate components, posing a constraint on broader market penetration in certain application areas where speed is a primary factor.

Despite these challenges, numerous opportunities are emerging that promise to fuel future growth and innovation within the rotomoulding powder market. The development and commercialization of high-performance and specialized polymer powders, including enhanced grades for automotive, medical, and advanced industrial applications requiring superior mechanical properties, chemical inertness, or temperature resistance, present significant growth avenues for premium products. The increasing adoption of recycled content and the introduction of bio-based polymers represents a pivotal opportunity for sustainable growth, addressing environmental mandates, reducing reliance on virgin fossil fuels, and appealing to eco-conscious consumers and regulatory bodies. Moreover, the integration of smart technologies into rotomoulded products, such as tanks equipped with IoT sensors for real-time monitoring of levels or conditions, offers avenues for product differentiation, value creation, and expansion into smart infrastructure. The market is also heavily influenced by continuous technological advancements in rotomoulding machinery, improved mold design techniques that reduce production complexity, and the development of novel additives that enhance powder flowability, reduce cycle times, and improve the overall performance and aesthetics of finished products. Shifting global regulatory landscapes concerning plastic materials, product safety, and manufacturing standards also act as a potent impact force, dictating compliance requirements and shaping industry best practices and investment priorities.

Segmentation Analysis

The Rotomoulding Powder Market is extensively segmented based on various critical attributes, including the type of polymer used, the specific application areas, and the geographical regions. This multi-faceted segmentation provides a granular understanding of market dynamics, allowing stakeholders to identify key growth pockets, assess competitive landscapes, and formulate strategic investment opportunities. The diversity in polymer types reflects the broad range of performance requirements across different end-use industries, necessitating tailored material solutions, while application segmentation highlights the versatile utility of rotomoulded products in both traditional heavy-duty sectors and emerging specialized markets.

Further analysis of these segments reveals distinct growth patterns, technological advancements, and evolving consumer preferences. For instance, the enduring dominance of polyethylene varieties, particularly LLDPE, signifies their cost-effectiveness, excellent processability, and widespread applicability in high-volume products such as tanks and containers. Conversely, the increasing market share of high-performance engineering plastics like nylon and polycarbonate points towards a growing demand for specialized, higher-value solutions that offer superior mechanical strength, temperature resistance, or chemical inertness for demanding applications. Understanding these segment-specific trends is crucial for market participants to effectively tailor their product offerings, refine marketing strategies, optimize R&D efforts, and ensure strategic alignment with evolving market demands and technological advancements across different regional economies and industrial verticals.

- By Type:

- LLDPE (Linear Low-Density Polyethylene): Dominant segment due to its excellent impact strength, stress crack resistance, and cost-effectiveness, widely used for tanks, bins, and recreational products.

- HDPE (High-Density Polyethylene): Valued for its stiffness, higher heat resistance, and chemical resistance, commonly found in industrial containers, fuel tanks, and agricultural products.

- LDPE (Low-Density Polyethylene): Offers good flexibility and clarity, suitable for specific aesthetic or less rigid applications where softness is desired.

- Polypropylene (PP): Gaining traction for applications requiring higher stiffness, heat resistance, and good chemical resistance, such as automotive parts and some industrial components.

- Polycarbonate (PC): Used in niche applications demanding high transparency, extreme impact resistance, and high-temperature performance, though less common due to higher cost and processing challenges.

- Nylon: Utilized for high-performance engineering applications requiring superior mechanical strength, abrasion resistance, and excellent chemical resistance, particularly in automotive and industrial machinery.

- Others (e.g., Cross-linked Polyethylene, Ethylene Vinyl Acetate EVA): Includes specialty polymers and blends developed for specific properties like enhanced durability, flexibility, or unique aesthetic finishes, catering to niche market demands.

- By Application:

- Tanks (Water Storage Tanks, Septic Tanks, Chemical Storage Tanks, Fuel Tanks): The largest application segment, driven by global demand for efficient fluid storage across residential, agricultural, industrial, and municipal sectors.

- Agricultural Products (Sprayer Tanks, Feeders, Planters, Silos): Crucial for modern agriculture, providing durable, weather-resistant solutions for farming equipment and storage needs.

- Industrial Products (Industrial Containers, Material Handling Bins, Road Barriers, Pallets): Essential for manufacturing, logistics, and construction, offering robust and customizable solutions for material handling and safety.

- Leisure & Consumer Products (Kayaks, Canoes, Playground Equipment, Furniture, Outdoor Seating, Toys): Benefits from design flexibility and durability, catering to growing recreational activities and outdoor living trends.

- Automotive (Air Ducts, Fuel Tanks, Interior Trim Components, Battery Housings): Increasing adoption for lightweighting, complex geometries, and improved functional integration in vehicle manufacturing.

- Medical (Medical Devices, Containers for Sterilization, Lab Equipment): Utilizes specialized grades for biocompatibility, chemical resistance, and ease of sterilization in healthcare applications.

- Others (e.g., Building & Construction components, Marine products like buoys): Covers a range of niche applications leveraging the versatility and performance attributes of rotomoulded plastics.

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Rotomoulding Powder Market

The value chain for the Rotomoulding Powder Market is a multi-stage process beginning with the upstream segment, which primarily encompasses the production of foundational petrochemical feedstocks and their subsequent polymerization into various resin types. This initial phase involves major chemical and petrochemical companies that convert raw materials such as ethylene, propylene, and other monomers, derived from crude oil or natural gas, into essential polymer resins including Linear Low-Density Polyethylene (LLDPE), High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), polypropylene, and specialized engineering plastics like nylon or polycarbonate. The quality, cost, and consistent availability of these virgin polymer resins are absolutely critical, as they directly influence the processing performance, final product characteristics, and overall economic viability of the rotomoulding powders and the end products. Innovation in upstream processes, such as developing new catalysts for more efficient polymerization or exploring sustainable monomer sources, plays a vital role in shaping the market's future and ensuring long-term material supply.

Moving downstream, these bulk polymer resins are meticulously processed into the fine powder form specifically required for rotational moulding. This critical intermediate stage involves specialized compounding and pulverization operations. During compounding, various performance-enhancing additives like UV stabilizers, antioxidants, impact modifiers, colorants, and anti-microbial agents are precisely blended into the polymer melt to impart specific properties tailored to the intended applications, such as enhanced weatherability, improved mechanical strength, or unique aesthetic appeal. Following compounding, the resin is then pulverized into a fine, consistent powder with a specific particle size distribution and bulk density, crucial for achieving uniform melt flow, complete mold coverage, and an excellent surface finish in the subsequent molding process. The distribution channel can vary significantly, ranging from direct sales by major powder manufacturers to large-scale rotomoulders, leveraging long-term contracts and technical support, to indirect channels involving a network of specialized distributors and agents who cater to smaller manufacturers, provide localized stock, or serve niche markets with specific logistical requirements. Finally, rotomoulders, who are at the very end of the value chain, convert these high-quality polymer powders into finished hollow plastic products, which are then supplied to a broad spectrum of end-users across industrial, agricultural, consumer, automotive, and medical sectors, completing the transformation from raw chemical to functional plastic article.

Rotomoulding Powder Market Potential Customers

The Rotomoulding Powder Market serves a highly diverse and extensive customer base, primarily comprising manufacturers across various industries that specialize in producing hollow plastic items that benefit from the unique advantages of rotational molding. These potential customers are typically seeking durable, seamless, and often large-volume plastic components that offer superior impact resistance, excellent chemical compatibility, and robust UV stability, properties uniquely achievable through the rotational molding process. The core demand originates from sectors requiring reliable containment and storage solutions, as well as those focused on outdoor, industrial, and consumer applications where product longevity, safety, and performance under varying environmental conditions are critical considerations for end-users and regulatory bodies alike. The ability of rotomoulding to produce complex shapes without welds or stress points makes it ideal for these demanding applications.

Key end-user segments include manufacturers of essential infrastructure components such as water storage tanks for residential, commercial, and municipal use, alongside septic tanks and chemical storage tanks for industrial and agricultural applications, where material integrity, corrosion resistance, and leak prevention are paramount. Agricultural product manufacturers, producing items like sprayer tanks, feeders, irrigation pipes, and crop storage containers, represent another significant customer group, valuing the durability and chemical resistance required for farm environments. Furthermore, the market extends to producers of leisure and consumer goods, including kayaks, canoes, playground equipment, outdoor furniture, and various recreational items, where design freedom, aesthetic appeal, and robust performance in outdoor settings are highly valued. Emerging demand also comes from the automotive sector for complex air ducts, fuel tanks, and battery housings, and the medical industry for specialized containers, trays, and devices, highlighting the broad applicability and evolving requirements of this versatile market across high-precision and regulated applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4.25 Billion |

| Market Forecast in 2032 | $6.25 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LyondellBasell Industries Holdings B.V., ExxonMobil Chemical Company, Dow Inc., Sabic (Saudi Basic Industries Corporation), Borealis AG, Chevron Phillips Chemical Company LLC, Reliance Industries Limited, Braskem S.A., SCG Chemicals Co., Ltd., TotalEnergies SE, Equistar Chemicals, LP (LyondellBasell), Matrix Polymers, Green Age Industries Private Limited, Amcor Rotomoulding, Polimérica S.A.S., Dalian Jinma Polymer Co., Ltd., A. Schulman, Inc. (now LyondellBasell), Americhem Inc., Polyone (now Avient Corporation), Arkema S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rotomoulding Powder Market Key Technology Landscape

The Rotomoulding Powder Market is continuously influenced and advanced by an evolving landscape of key technologies spanning material science, processing methods, and manufacturing automation, which collectively drive innovation in material performance and production efficiency. Significant technological developments are focused on enhancing the intrinsic properties of polymer powders, aiming to improve their melt flow characteristics for more efficient mold filling and reduced cycle times, increase impact strength for greater product resilience in demanding environments, bolster UV resistance for prolonged outdoor longevity, and ensure chemical inertness for corrosive fluid containment. These advancements are crucial for meeting the increasingly stringent performance requirements across diverse end-use applications and for extending the lifespan and functionality of rotomoulded products, thereby enhancing their value proposition in competitive markets.

Furthermore, the industry is witnessing substantial innovation in advanced compounding techniques, allowing for the precise and uniform incorporation of various functional additives into the polymer matrix. These additives include specialized colorants that offer superior fade resistance and vibrant hues, high-performance flame retardants that meet strict safety standards, and anti-microbial agents that enhance hygiene, particularly in medical and food-contact applications. The development of finer and more consistent pulverization technologies is also pivotal, as optimal powder particle size and distribution directly impact the quality of the final surface finish, significantly reduce cycle times, and minimize common defects such as pinholes or bubbles. Emerging technologies such as smart rotomoulding, which integrates IoT sensors for real-time process monitoring, advanced robotics for automated material handling, and data analytics platforms for predictive maintenance and dynamic process control, are poised to revolutionize manufacturing efficiency, enhance quality assurance, and enable more sustainable production paradigms, thereby driving the industry towards highly automated, precise, and resource-efficient operations.

Regional Highlights

- North America: This region represents a mature and technologically advanced market characterized by high adoption of sophisticated polymer materials and a strong focus on automation and digitalization in manufacturing processes. Significant demand originates from well-established industrial sectors, a robust automotive industry, and a thriving consumer goods market, all of which prioritize stringent quality standards and innovative product solutions. Ongoing infrastructure upgrades and a focus on sustainable manufacturing practices also drive demand for high-performance rotomoulding powders.

- Europe: The European market is strongly driven by a pervasive emphasis on sustainability, circular economy principles, and strict environmental regulations. This has led to an accelerating demand for recycled and bio-based rotomoulding powders, as manufacturers strive to reduce their environmental footprint. Key applications extensively include water management solutions, advanced agricultural components, and specialized industrial parts, with countries like Germany, France, and the UK leading in technological adoption and eco-friendly product development.

- Asia Pacific (APAC): The Asia Pacific region stands out as the fastest-growing market globally, propelled by rapid industrialization, extensive urbanization, and substantial governmental investments in infrastructure development, particularly in economic powerhouses like China, India, and the burgeoning economies of Southeast Asia. This growth fuels exceptionally high demand for essential products such as water tanks, agricultural implements, and a wide array of consumer goods, benefiting from expanding populations and rising disposable incomes. The region also offers competitive manufacturing costs, attracting significant investment.

- Latin America: Exhibiting steady and consistent growth, the Latin American market is primarily driven by ongoing investments in agricultural infrastructure, essential water storage solutions, and a rapidly expanding construction sector across key countries like Brazil and Mexico. The need for durable, cost-effective solutions for fluid storage and material handling in developing agricultural and industrial sectors underpins much of the demand, fostering increasing adoption of rotomoulding technology and materials.

- Middle East & Africa (MEA): This region represents emerging markets with substantial growth potential, particularly in critical sectors like water storage, agricultural irrigation systems, and diverse industrial applications. The growth is fueled by increasing population, significant government-led development projects, and the imperative for robust and reliable infrastructure, especially in water-scarce regions. Investments in manufacturing capabilities are also expanding, supporting localized production of rotomoulded goods.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rotomoulding Powder Market.- LyondellBasell Industries Holdings B.V.

- ExxonMobil Chemical Company

- Dow Inc.

- Sabic (Saudi Basic Industries Corporation)

- Borealis AG

- Chevron Phillips Chemical Company LLC

- Reliance Industries Limited

- Braskem S.A.

- SCG Chemicals Co., Ltd.

- TotalEnergies SE

- Equistar Chemicals, LP (LyondellBasell)

- Matrix Polymers

- Green Age Industries Private Limited

- Amcor Rotomoulding

- Polimérica S.A.S.

- Dalian Jinma Polymer Co., Ltd.

- A. Schulman, Inc. (now LyondellBasell)

- Americhem Inc.

- Polyone (now Avient Corporation)

- Arkema S.A.

Frequently Asked Questions

What is rotomoulding powder and how is it used?

Rotomoulding powder is a finely ground thermoplastic polymer material, predominantly polyethylene, specifically formulated for the rotational moulding process. This manufacturing technique involves heating a hollow mold filled with the powder while rotating it biaxially, melting the polymer and forming a seamless, hollow plastic product upon cooling. It is widely used to produce large, durable, and complex items such as water tanks, industrial containers, and playground equipment due to its design flexibility and cost-effectiveness for medium-volume production.

What are the primary applications and benefits of rotomoulded products?

The primary applications of rotomoulded products include the manufacturing of water storage tanks, septic tanks, agricultural sprayer tanks, industrial containers, marine products like kayaks, and various leisure items such as playground equipment. Benefits include producing large, seamless, stress-free hollow parts with uniform wall thickness, excellent impact strength, high chemical resistance, and UV stability, making them highly durable and suitable for demanding outdoor and industrial environments.

What key factors are driving the growth of the rotomoulding powder market globally?

The global rotomoulding powder market is driven by several key factors, including significant investments in infrastructure development, particularly for water management and wastewater treatment systems, which rely heavily on rotomoulded tanks. Additionally, increasing demand from the agricultural sector for durable storage and irrigation solutions, growth in leisure and consumer goods, and rapid urbanization in emerging economies are major accelerators for market expansion.

What challenges does the rotomoulding powder industry currently face?

The rotomoulding powder industry faces several challenges, including the inherent volatility in raw material prices, which are closely linked to crude oil costs. Increased environmental concerns and stringent regulatory pressures regarding plastic waste and sustainability are also significant hurdles. Furthermore, the relatively longer cycle times of the rotational molding process compared to other plastic manufacturing methods can limit its adoption for high-volume production of smaller components, posing a competitiveness challenge.

How are technological advancements and sustainability efforts impacting the market?

Technological advancements, particularly in polymer science and process automation, are significantly impacting the market by enabling the development of high-performance and specialized rotomoulding powders with enhanced properties. Concurrently, sustainability efforts are driving the adoption of recycled and bio-based polymers, reducing the environmental footprint of products. Emerging technologies like AI and IoT are also being integrated to optimize production, improve quality control, and enable predictive maintenance, fostering greater efficiency and innovation across the industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager