Rubber-Tired Gantry Crane Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428194 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Rubber-Tired Gantry Crane Market Size

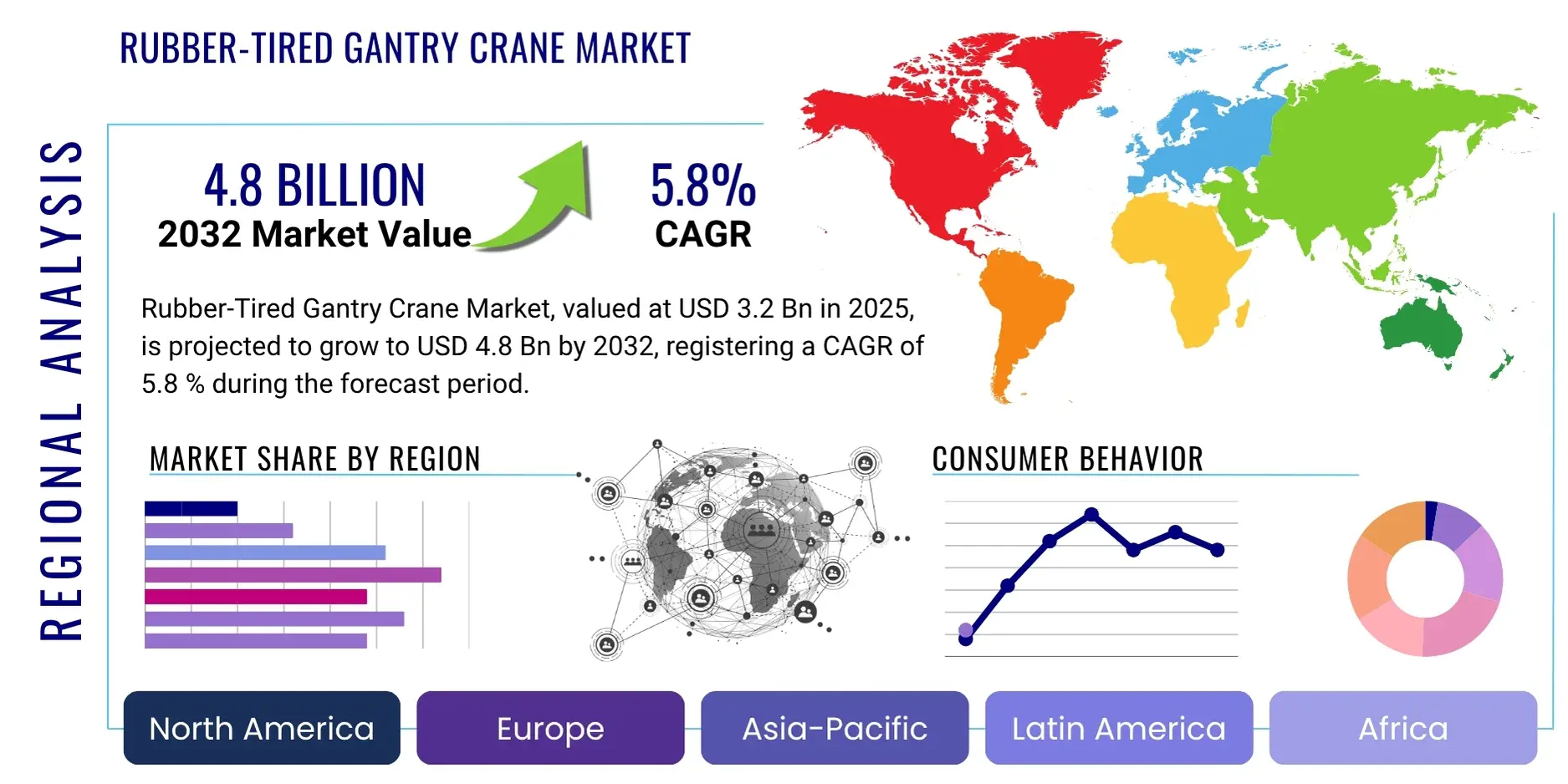

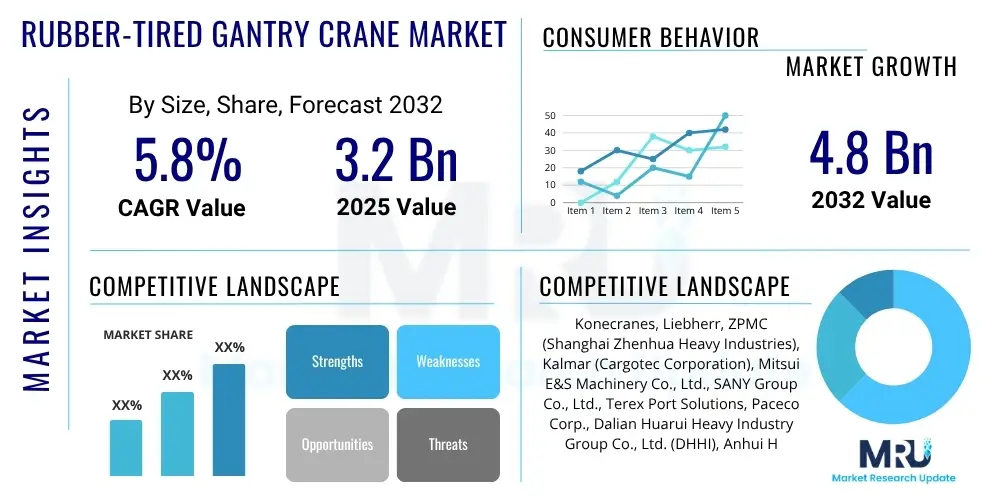

The Rubber-Tired Gantry Crane Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 3.2 Billion in 2025 and is projected to reach USD 4.8 Billion by the end of the forecast period in 2032.

Rubber-Tired Gantry Crane Market introduction

The Rubber-Tired Gantry (RTG) crane market encompasses the global landscape of heavy machinery specifically engineered for the high-volume, efficient, and flexible handling of intermodal containers across various logistical nodes. These robust cranes are indispensable assets, primarily deployed in bustling seaports, strategically located inland terminals, and expansive intermodal freight yards for the precise stacking, movement, and retrieval of shipping containers. Their pivotal role in bolstering global trade infrastructure cannot be overstated, as they ensure the seamless flow of goods through critical points in the supply chain. What distinguishes RTG cranes, and contributes significantly to their widespread adoption, is their unique rubber tire system, which imparts exceptional mobility and operational versatility within the confines of terminal areas. This design feature liberates them from the fixed rail dependency of their rail-mounted counterparts, offering unparalleled flexibility in yard configuration and re-configuration to meet dynamic operational demands. The fundamental objective of RTG cranes revolves around maximizing container storage density and enhancing terminal throughput, thereby directly and substantially contributing to the overall efficiency and responsiveness of global supply chains. Beyond conventional port operations, their key applications extend to large industrial yards and extensive distribution centers, where heavy lifting with stringent precision and meticulous placement of diverse goods are paramount for operational integrity and safety.

The inherent benefits offered by RTG cranes, such as their remarkable mobility, rapid deployment capabilities, and comparatively lower infrastructure requirements when juxtaposed with rail-mounted gantry systems, firmly position them as an attractive and pragmatic solution for a wide spectrum of operational needs. They deliver a potent combination of brute power and refined precision, both of which are absolutely essential for achieving the rapid turnaround of cargo vessels and land-based transport, consequently minimizing vessel and truck dwell times and significantly enhancing overall terminal productivity. Several potent driving factors are currently propelling the RTG crane market forward. These include the relentless and accelerating expansion of global trade volumes, which inevitably leads to a surge in container traffic across all continents. Concomitant investments in port modernization and ambitious expansion projects, particularly concentrated within burgeoning economies, serve as powerful catalysts for market growth. The escalating demand for sophisticated automated and semi-automated container handling solutions further invigorates the market, as terminal operators globally strive to augment safety protocols, curtail operational expenditures, and drastically improve efficiency metrics. Moreover, groundbreaking technological advancements, encompassing the widespread adoption of electrification, sophisticated smart control systems, and predictive analytics, are fundamentally transforming the market by introducing a new generation of RTG models that are not only more environmentally benign but also operationally superior. The escalating focus on intermodal transportation, which seeks to seamlessly integrate diverse modes of transport, is concurrently driving the imperative for flexible, high-capacity container handling equipment like RTG cranes. This continuous and iterative evolution in global logistics and shipping demands unequivocally underscores the indispensable role of RTG cranes in facilitating the smooth, unimpeded, and efficient movement of goods across vast geographical expanses. The inherent ability of RTGs to readily adapt to highly varying yard layouts and diverse operational requirements, often without necessitating extensive and costly civil works, further solidifies their sustained and growing market demand.

Rubber-Tired Gantry Crane Market Executive Summary

The Rubber-Tired Gantry Crane market is currently navigating a period of profound and dynamic transformation, predominantly influenced by a confluence of evolving business trends centered on advanced automation, pervasive digitalization, and an unwavering commitment to sustainability. Terminal operators across the globe are increasingly directing significant capital investments towards RTGs that are comprehensively equipped with cutting-edge automation features. These include sophisticated remote control capabilities, advanced anti-sway systems that ensure precise load handling, and integrated collision avoidance technology, all strategically aimed at meticulously optimizing operational efficiency and concurrently achieving substantial reductions in labor-related costs. The burgeoning imperative for green logistics is acting as a powerful accelerant for the widespread adoption of electric and hybrid RTGs, marking a decisive shift away from conventional diesel-powered models. This transition is motivated by a dual objective: to effectively mitigate carbon emissions and to significantly diminish operational noise levels, thereby contributing to a more environmentally sound and community-friendly operational footprint. These overarching business trends are emblematic of a broader, systemic industry movement towards comprehensive smart port initiatives, where data-driven insights derived from interconnected systems profoundly enhance decision-making processes and optimize resource utilization across the entirety of the complex logistics chain. The strategic and deliberate integration of RTGs into more extensive, fully automated terminal ecosystems is rapidly evolving into a standard industry practice, leading to tangible improvements in safety records, operational reliability, and overall container throughput.

From a regional perspective, the Asia Pacific region continues its formidable dominance within the market, a position solidified by its robust and consistent economic growth, colossal trade volumes, and extensive, rapidly expanding port infrastructure development, particularly evident in economic powerhouses such as China, India, and various Southeast Asian nations. Conversely, Europe and North America are channeling their focus towards the critical modernization of existing port facilities and the strategic upgrading to RTG models that are both more environmentally sound and technologically advanced. This drive is largely compelled by stringent environmental regulations, a growing societal consciousness regarding ecological impact, and the relentless imperative to sustain a competitive edge in the global logistics arena. The Latin America and Middle East & Africa regions are simultaneously experiencing considerable investments in the construction of new ports and the expansion of existing facilities, positioning them as exceptionally high-growth potential markets for RTG cranes in the foreseeable future. These regional trends are intrinsically interwoven with global trade routes, geopolitical considerations, and overarching infrastructure development priorities. On a segment-wise analysis, the market is witnessing a pronounced and discernible shift towards higher capacity RTGs, engineered to proficiently handle the ever-increasing dimensions of mega-vessels and the corresponding surge in container volumes. This reflects an undeniable industry trend towards accommodating larger ships and greater cargo loads. Furthermore, the demand for semi-automated and fully automated RTGs is steadily ascending, paralleling a clear preference for electrified power sources over traditional diesel-only configurations, unequivocally illustrating a profound industry pivot towards sustainable, technologically advanced, and highly efficient operational solutions.

AI Impact Analysis on Rubber-Tired Gantry Crane Market

The profound integration of Artificial Intelligence (AI) within the Rubber-Tired Gantry Crane market is dramatically reshaping fundamental operational paradigms, concurrently driving significant and transformative advancements across critical areas such as efficiency, safety, and predictive maintenance capabilities. Users frequently pose inquiries concerning the tangible ways in which AI can fundamentally enhance crane performance, meticulously streamline intricate container movements, and meaningfully contribute to the realization of more sustainable terminal operations. Common user concerns often revolve around the perceived complexity and substantial investment associated with AI implementation, potential vulnerabilities related to data security, and the anticipated impact of increasing automation on human labor forces within port environments. However, the prevailing and overarching expectation is that AI will unlock unprecedented levels of operational intelligence, empowering RTGs to function with an elevated degree of autonomy, surgical precision, and heightened responsiveness to the inherently dynamic and often unpredictable exigencies of port operations. AI's unparalleled capacity to analyze vast, complex datasets derived from an array of sensors, high-resolution cameras, and extensive operational logs enables real-time, informed decision-making. This capability is instrumental in optimizing critical operational aspects, including container stacking configurations, intricate truck routing paths within the yard, and the precise execution of crane movements. Such optimization not only leads to a substantial reduction in cycle times but also strategically minimizes fuel consumption and mitigates wear and tear on expensive machinery, culminating in significant long-term cost savings and markedly improved environmental performance. Furthermore, sophisticated AI-powered systems possess the ability to continuously learn from evolving operational patterns, accurately predict potential equipment failures before they occur, and even adapt seamlessly to challenging weather conditions or unforeseen operational disruptions, thereby offering robust and resilient solutions for the increasingly complex challenges inherent in modern logistics.

- Enhanced Predictive Maintenance: AI algorithms meticulously analyze real-time sensor data from various crane components to accurately forecast potential equipment failures, significantly reducing unplanned downtime and optimizing scheduled maintenance activities, which ultimately lowers overall maintenance costs.

- Optimized Crane Routing and Stacking: AI-powered intelligent systems dynamically determine the most efficient and optimal paths for crane travel and the most space-effective stacking configurations for containers within the yard, leading to substantial improvements in throughput, yard utilization, and operational flow.

- Autonomous and Semi-Autonomous Operation: AI facilitates incredibly precise, consistent, and inherently safe crane movements, providing foundational support for both fully autonomous and remotely operated RTG systems, thereby minimizing human intervention in hazardous areas.

- Improved Safety Protocols: AI-driven advanced perception systems, integrating technologies like LiDAR and computer vision, coupled with sophisticated collision avoidance technology, significantly enhance safety for both personnel working within the terminal and the valuable equipment itself, preventing accidents and minimizing risks.

- Energy Management and Efficiency: AI intelligently optimizes power consumption patterns in electric and hybrid RTGs by analyzing workload and operational demands, effectively reducing environmental impact through lower emissions and yielding substantial operational cost savings.

- Real-time Data Analytics: AI processes and interprets vast volumes of complex operational data instantly, providing immediately actionable insights for continuous performance improvement, identifying bottlenecks, and informing strategic planning decisions for terminal management.

- Dynamic Demand Forecasting: AI helps to accurately anticipate future container traffic volumes and patterns by analyzing historical data and external factors, enabling proactive resource allocation, optimized shift planning, and adaptive operational adjustments to meet fluctuating demands.

DRO & Impact Forces Of Rubber-Tired Gantry Crane Market

The Rubber-Tired Gantry Crane market is intrinsically shaped by a complex and dynamic interplay of specific Drivers, inherent Restraints, and emerging Opportunities, all of which are collectively influenced and modulated by various external and internal Impact Forces. Key drivers that are powerfully propelling market growth include the unwavering and substantial increase in global containerized trade, an imperative that necessitates ever-greater capacity and enhanced efficiency at ports and terminals across the worldwide logistics network. Significant and strategic investments in port infrastructure development and comprehensive modernization projects, particularly concentrated within rapidly urbanizing regions and burgeoning emerging economies, further act as potent catalysts, fueling a sustained demand for RTG cranes. The industry's pervasive and accelerating thrust towards advanced automation and semi-automation in crucial container handling operations, primarily aimed at substantially reducing operational costs, markedly improving safety standards, and significantly increasing throughput, serves as a compelling and undeniable catalyst for market expansion. Furthermore, groundbreaking technological advancements in foundational crane design, innovative power systems (encompassing electrification and sophisticated hybrid solutions), and intelligent smart control systems are collectively enhancing the intrinsic appeal and augmenting the operational capabilities of modern RTGs. These multifaceted drivers collectively underscore the absolutely essential and increasingly critical role of RTGs in supporting the very backbone of international commerce and intricate global logistics, ensuring that goods move efficiently, reliably, and securely through crucial transshipment points.

However, despite these powerful growth drivers, the market simultaneously confronts considerable and enduring restraints that temper its expansion. Prominent among these is the notably high initial capital investment required for the procurement and meticulous implementation of RTG cranes, which can present a formidable financial barrier for smaller port operators or those managing with constrained budgetary allocations. The pervasive shortage of adequately skilled labor, specifically trained for operating and meticulously maintaining increasingly advanced RTG systems, represents another significant challenge, particularly as automation levels continue their inexorable ascent. Broader economic slowdowns, persistent geopolitical uncertainties, and the proliferation of trade protectionist policies can directly and negatively impact global trade volumes, consequently dampening the demand for new port equipment. Regulatory complexities, coupled with the inherent need for extensive civil engineering works for terminal expansion (though less pronounced than for Rail-Mounted Gantry Cranes), can still pose tangible hurdles to swift market penetration and expansion. Notwithstanding these formidable challenges, a plethora of abundant opportunities exist for sustained market expansion and innovation. The increasing and strategic adoption of holistic smart port technologies, the cost-effective retrofitting of older generation RTGs with cutting-edge advanced features, and the growing, urgent focus on environmental sustainability collectively present promising avenues for innovation and deeper market penetration. The continuous development of more energy-efficient and profoundly eco-friendly models, such as advanced battery-powered and sophisticated hybrid RTGs, directly addresses evolving environmental regulations and increasingly stringent corporate sustainability goals. Moreover, strategically expanding into nascent geographical markets and proactively developing highly customizable solutions tailored for various terminal sizes and operational scales represent significant growth prospects, enabling manufacturers to effectively diversify their client base and augment their revenue streams.

The Rubber-Tired Gantry Crane market is additionally shaped by several critical and overarching impact forces that dynamically influence its trajectory. Unrelenting technological advancements constitute a primary and powerful force, continually pushing the operational boundaries of what RTG cranes can achieve in terms of speed, precision, automation, and overall operational intelligence. Stringent environmental regulations represent another formidable force, compelling manufacturers to innovate relentlessly towards developing greener, lower-emission, and more sustainable solutions. The inherent volatility of global supply chains and the unpredictable fluctuations in raw material prices can significantly affect manufacturing costs and extend crucial lead times, thereby impacting market competitiveness. Broader geopolitical shifts, international trade agreements, and evolving trade relationships directly influence global trade flows, which in turn profoundly impacts the demand dynamics for port equipment. Lastly, the intensely competitive landscape prevalent among manufacturers, characterized by continuous and rapid product innovation, aggressive market strategies, and a relentless pursuit of technological superiority, also acts as a significant and persistent impact force. This intense competition consistently compels companies to sharply differentiate their product offerings and continually enhance their value propositions in order to both retain existing market share and successfully capture new segments. These combined forces necessitate a highly flexible, adaptive, and profoundly responsive market strategy from all stakeholders involved in the RTG crane ecosystem.

Segmentation Analysis

The Rubber-Tired Gantry Crane market undergoes a meticulous and comprehensive segmentation, specifically designed to furnish stakeholders with an in-depth and granular understanding of its inherently diverse operational and technological landscape. This intricate segmentation framework enables a precise and nuanced analysis of prevailing market dynamics across a spectrum of critical dimensions, including distinct product types, varying operational capacities, different modes of operation, and specialized end-user applications. Such a multi-faceted approach accurately reflects the highly varied and often complex requirements prevalent in global logistics and modern port operations. Gaining a profound comprehension of these specific segments is absolutely crucial for manufacturers, as it empowers them to meticulously tailor their product offerings to meet precise market demands. Similarly, it is invaluable for terminal operators, enabling them to make highly informed and strategically sound procurement decisions, ensuring optimal resource allocation. For discerning investors, this segmentation is instrumental in accurately identifying nascent and mature key growth areas within the market, thereby guiding strategic investment choices. The distinct divisions within this segmentation effectively highlight significant shifts in technological preferences, discernible demand patterns originating from various industrial sectors, and the evolving operational strategies conscientiously adopted by terminal operators worldwide. Each individual segment is meticulously characterized by specific features and is engineered to address particular operational challenges, thereby contributing uniquely and substantially to the overall market structure and its projected growth trajectory. This granular, detailed view is indispensable for identifying highly specialized niche markets and uncovering potential areas ripe for groundbreaking innovation, ultimately ensuring that product development initiatives and focused marketing efforts are effectively targeted to precisely meet the unique and specific needs of a broad spectrum of diverse customer groups.

- By Power Source:

- Diesel: Traditional internal combustion engines providing robust power, often paired with generators for electric drives.

- Electric: Embraces various eco-friendly options including Hybrid (diesel-electric), Battery (fully electric with rechargeable batteries), and Cable Reel (grid-powered via cable management systems).

- By Capacity:

- Up to 40 Tons: Typically used for smaller terminals or specific industrial applications with lighter container loads.

- 41-65 Tons: The most common capacity range, suitable for standard container handling in medium to large ports.

- Above 65 Tons: High-capacity cranes designed for handling heavier, specialized cargo or multiple containers simultaneously, catering to mega-ships.

- By Operation Mode:

- Manual: Cranes operated directly by a human operator within the crane cabin, requiring continuous presence.

- Semi-Automated: Features include remote control operation, automated stack profiling, and assisted movements, enhancing precision while retaining human oversight.

- Fully Automated: RTGs capable of entirely autonomous operation, guided by sophisticated software, sensors, and AI, minimizing human intervention.

- By End-User:

- Seaports & Container Terminals: Major global hubs for international trade, demanding high throughput and operational efficiency.

- Inland Terminals & Dry Ports: Critical interfaces for transferring containers between maritime and land-based transport networks.

- Industrial Yards: Facilities for heavy manufacturing, logistics, or project cargo handling within industrial complexes.

- Intermodal Freight Hubs: Central points for consolidating and distributing containers across different modes of transport (road, rail, sea).

Value Chain Analysis For Rubber-Tired Gantry Crane Market

The value chain for the Rubber-Tired Gantry Crane market is characterized by a sequential series of interconnected activities, each meticulously designed to progressively add value from the foundational raw material stage through to the ultimate delivery and post-sales support for the final end-user. The upstream segment of this value chain primarily comprises a diverse ecosystem of suppliers specializing in critical components and fundamental raw materials. This extensive network includes highly specialized manufacturers providing high-grade steel and advanced alloys essential for the structural integrity of the crane components, sophisticated engines (tailored for both diesel and hybrid models), high-performance electric motors, intricate hydraulic systems, precision control systems, robust gearing mechanisms, powerful hoists, durable tires specifically engineered for heavy loads, and an array of cutting-edge electronic sensors and advanced automation technologies. The strategic importance of these upstream suppliers is paramount, as the intrinsic quality, consistent availability, and technological sophistication of their products directly and profoundly impact the overall performance, long-term reliability, and cost-effectiveness of the finalized RTG crane system. Establishing and nurturing strong, enduring relationships with reliable upstream suppliers is absolutely essential for guaranteeing consistent production schedules, consistently meeting stringent quality standards, effectively mitigating inherent supply chain risks, and maintaining a competitive pricing structure within the market. Furthermore, relentless innovation at this foundational stage, particularly in the realm of advanced materials science and the development of energy-efficient components, can significantly enhance the overall product offering and elevate the market appeal of RTG cranes, thereby fostering differentiation and securing a competitive advantage.

Moving further along the value chain, the midstream segment encompasses the core manufacturing and meticulous assembly processes of RTG cranes. This pivotal stage involves a comprehensive array of activities, including intensive research and development (R&D) initiatives aimed at continuous innovation, detailed engineering design and sophisticated simulations, precise fabrication of intricate structural elements, seamless integration of complex electrical and mechanical systems, rigorous software development for advanced control and automation functionalities, and the meticulous final assembly and comprehensive testing procedures. Leading RTG manufacturers dedicate substantial investments to R&D, striving to develop pioneering features, drastically improve energy efficiency across operational cycles, significantly enhance safety protocols, and expertly integrate increasingly sophisticated automation capabilities into their products. This stage is inherently characterized by complex engineering processes that demand highly specialized expertise in heavy machinery manufacturing, precision robotics, and advanced software engineering. Rigorous quality control measures and exhaustive testing protocols are absolutely paramount to ensure that the cranes not only meet but exceed stringent international standards and precise client specifications, thereby guaranteeing operational excellence and unwavering reliability. Efficient production processes, coupled with a robust and agile supply chain management framework at this critical stage, are fundamentally vital for minimizing overall manufacturing costs, optimizing resource utilization, and ensuring the timely, dependable delivery of high-quality equipment to discerning end-users, thus preventing costly delays and maintaining customer satisfaction.

Finally, the downstream segment of the value chain encompasses the multifaceted activities of distribution, direct sales, intricate installation processes, and comprehensive after-sales services. Distribution channels for large-scale RTG cranes are predominantly direct, with manufacturers typically engaging in direct sales relationships with major port authorities, large-scale terminal operators, and prominent global logistics companies. However, for entry into smaller, emerging markets or to penetrate specific regional territories, a meticulously cultivated network of authorized dealers and specialized distributors may be strategically utilized to effectively broaden market reach and engage customers more efficiently. Following the initial sale, a comprehensive and robust suite of after-sales services is critically important. This includes professional installation, precise commissioning of the equipment, in-depth operator training, tailored maintenance contracts, guaranteed spare parts supply, and responsive technical support. These indispensable services are vital for ensuring the long-term operational longevity, optimal performance, and sustained reliability of the cranes, thereby cultivating strong, enduring customer relationships and serving as a significant and recurring revenue stream for manufacturers. The demonstrated effectiveness and widespread reach of both these direct and indirect channels profoundly impact market penetration and overall customer satisfaction, unequivocally emphasizing the indispensable importance of a globally robust and responsive service network. Moreover, invaluable customer feedback systematically collected from the downstream segment often provides crucial insights that directly inform product improvement initiatives and guide future research and development efforts, thus creating a continuous feedback loop that reinforces innovation and ensures the RTG value chain remains adaptive and forward-looking.

Rubber-Tired Gantry Crane Market Potential Customers

The primary potential customers and end-users for Rubber-Tired Gantry Cranes represent a diverse and extensive spectrum of entities operating within the intricate global logistics and vast transportation infrastructure. All these entities share a common, fundamental requirement for highly efficient, supremely reliable, and technologically advanced solutions for high-volume container handling. At the absolute forefront of this customer base are the major Seaports and sprawling Container Terminals located worldwide. These critical logistical hubs continuously require cutting-edge RTGs to expertly manage the immense, ever-increasing volume of containers that arrive on colossal mega-vessels, facilitating rapid, precise loading, efficient unloading, and meticulous stacking within their expansive yards. Their insatiable demand for RTGs is primarily driven by the imperative for achieving exceptionally high throughput, optimizing invaluable yard utilization, and ensuring rapid turnaround times for vessels and trucks, all of which are crucial factors for maintaining acute competitiveness in the relentlessly dynamic global trade landscape. The inherent ability of RTGs to offer supremely flexible, highly mobile solutions that can be deployed across the entire terminal area makes them utterly indispensable for these high-volume operations, where efficient space optimization and operational agility are paramount strategic considerations. As global trade continues its inexorable expansion, so too does the fundamental need for these vital facilities to continuously enhance their operational capacity and improve their overall efficiency, directly fueling the demand for RTGs.

Extending beyond the immediate confines of bustling seaports, Inland Terminals and burgeoning Dry Ports represent another profoundly significant customer segment for RTG cranes. These strategically positioned facilities function as critical interfaces, seamlessly connecting maritime and terrestrial transportation networks, where they expertly handle containers that are transferred from ocean-going vessels to trains or trucks for subsequent onward distribution into various hinterlands. RTGs are exceptionally well-suited for these complex operations due to their unparalleled mobility and their proven capacity to operate with high effectiveness in a myriad of varying yard layouts, thereby facilitating seamless and efficient intermodal transfers. Furthermore, extensive Industrial Yards, particularly those intricately involved in heavy manufacturing processes, large-scale logistics operations, or the specialized handling of voluminous project cargo, also constitute a vital and growing customer base. These particular users necessitate RTGs for the expert management of heavy components, bulk raw materials, or voluminous finished goods within their intricate operational premises, where the inherent flexibility and robust lifting capabilities of RTGs are tremendously valued and often critical for operational success. Lastly, expansive Intermodal Freight Hubs and large-scale Container Depots emerge as crucial end-users within this market. These specialized hubs serve as central consolidation points for the meticulous sorting, storage, and subsequent distribution of containers across a diverse array of different transport modes, including road, rail, and sea. In these complex environments, RTGs provide the essential operational agility and formidable lifting power required to expertly manage intricate and dynamic container flows, ensuring highly efficient storage, rapid retrieval, and seamless transfer processes. The sustained and accelerating growth of global e-commerce, coupled with the ever-increasing complexity of global supply chains, further amplifies the pervasive demand originating from these diverse and critical end-user categories, all of whom are fundamentally reliant on the indispensable capab

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.2 Billion |

| Market Forecast in 2032 | USD 4.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Konecranes, Liebherr, ZPMC (Shanghai Zhenhua Heavy Industries), Kalmar (Cargotec Corporation), Mitsui E&S Machinery Co., Ltd., SANY Group Co., Ltd., Terex Port Solutions, Paceco Corp., Dalian Huarui Heavy Industry Group Co., Ltd. (DHHI), Anhui Heli Co., Ltd., Palfinger AG, Famur S.A., IMPSA S.A., Shanghai Port Machinery Co. (SPMC), Doosan Heavy Industries & Construction Co., Ltd., CVS Ferrari S.p.A., Kocks Kranbau GmbH, Bedeschi S.p.A., MAC Port Macchine Operatrici Portuali S.r.l., Gottwald Port Technology GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rubber-Tired Gantry Crane Market Key Technology Landscape

The Rubber-Tired Gantry Crane market is currently undergoing a profound and rapid technological transformation, primarily impelled by an increasing global demand for significantly enhanced efficiency, a substantial reduction in environmental impact, and a pervasive commitment to augmented safety standards within port and terminal operations. A paramount technological trend dominating this sector is the widespread and accelerating adoption of electrification. This pivotal shift encompasses a diverse range of innovative power solutions, including sophisticated hybrid RTGs that ingeniously combine efficient diesel generators with advanced electric motors and high-capacity battery packs. These hybrid configurations are meticulously engineered for optimized fuel consumption, drastically lower emissions, and improved operational flexibility. Furthermore, the market is witnessing a robust surge in fully electric RTGs, which are either powered by intricate cable reel systems drawing energy from the electrical grid or by cutting-edge, high-density battery packs, offering zero direct emissions during operation. This fundamental transition towards electrification is strategically aligned with increasingly stringent global environmental regulations and ambitious corporate sustainability initiatives, delivering the added benefits of notably quieter operations and substantial reductions in the carbon footprint of terminal activities. The seamless integration of advanced power management systems further optimizes energy usage across various operational cycles, making these electrified cranes not only more economically viable but also unequivocally more environmentally responsible. This evolution towards electric and hybrid solutions marks a fundamental and irreversible change in how RTGs are conceptualized, designed, and operated, consistently pushing the boundaries of sustainable port logistics. Continuous innovation in battery technology, encompassing advancements such as faster charging times, extended operational durations, and improved energy density, is progressively rendering fully electric RTGs an increasingly attractive and commercially viable option for modern, forward-thinking terminals striving for peak environmental performance.

Another critically significant technological development redefining the RTG market landscape is the rapid advancement and sophisticated integration of automation and intelligent control systems. This expansive domain encompasses a broad spectrum of technologies, ranging from highly refined semi-automated functionalities, such as precise remote control operation, intelligent stack profiling, and assisted movements that significantly enhance operational precision while retaining crucial human oversight, to the cutting-edge realm of fully autonomous RTGs. These advanced machines are capable of executing complex container handling tasks with an unprecedented degree of self-sufficiency and without any direct human intervention. Key enabling technologies underpinning this automation drive include an array of advanced sensor systems, such as LiDAR, radar, and high-resolution cameras, which provide comprehensive environmental awareness. Real-time Kinematics (RTK) GPS ensures millimetric precision in positioning, while sophisticated anti-sway systems guarantee exceptionally accurate and safe container placement, even in challenging environmental conditions like high winds. These advanced automation features not only dramatically improve operational consistency and accelerate throughput but also profoundly enhance safety by significantly minimizing human exposure to inherently hazardous operational environments. Furthermore, the pervasive incorporation of Internet of Things (IoT) devices and robust cloud connectivity facilitates comprehensive data collection and real-time remote monitoring of crane performance, thereby enabling highly predictive maintenance strategies, optimized operational planning, and proactive troubleshooting. Advanced data analytics, often powerfully augmented by Artificial Intelligence, processes vast volumes of operational data to provide actionable insights into equipment health, pinpoint operational bottlenecks, and monitor energy consumption patterns, thereby paving the way for smarter, more resilient, and highly adaptive port operations. Integrated collision avoidance systems, which frequently combine multiple sensor types and advanced algorithms, contribute immeasurably to preventing accidents, safeguarding both invaluable personnel and precious cargo. This rapidly evolving technological landscape is characterized by ongoing intensive research into even more sophisticated autonomous capabilities, aiming for seamless integration with broader port logistics systems, ultimately creating a fully interconnected and intelligent terminal ecosystem that promises unprecedented levels of efficiency and safety.

Regional Highlights

- Asia Pacific: This region firmly dominates the global market, primarily owing to its extensive and rapidly developing port infrastructure, consistently high trade volumes driven by robust manufacturing and consumption, and sustained rapid economic growth across key nations like China, India, Japan, and the dynamic economies of Southeast Asia. Substantial ongoing investments in both new port construction and the strategic expansion of existing facilities continue to be the principal drivers of demand for RTG cranes in this region.

- Europe: Characterized by a strong, proactive focus on comprehensive port modernization, advanced automation, and an unwavering commitment to environmental sustainability. Demand here is predominantly fueled by the critical need to upgrade existing, aging infrastructure with state-of-the-art, environmentally friendly, and technologically advanced RTG solutions, adhering rigorously to increasingly stringent emission regulations and sustainability mandates imposed by the European Union.

- North America: Exhibits steady and consistent market growth, largely propelled by escalating intermodal freight traffic, significant ongoing investments in critical port upgrades and capacity enhancements, and a growing, concerted emphasis on drastically improving operational efficiency and safety through the strategic adoption of automation technologies. Major ports across the United States and Canada are actively keen on adopting innovative hybrid and fully electric RTG solutions to meet future demands.

- Latin America: Emerging as a significantly growing market, driven by expanding international trade relationships, substantial national infrastructure development projects aimed at improving connectivity, and the urgent need to enhance overall logistics efficiency across the continent. Key countries such as Brazil, Mexico, Chile, and Colombia are actively investing in modernizing their port facilities and expanding their container handling capabilities.

- Middle East and Africa (MEA): Represents a region with immense untapped potential and considerable future growth prospects. This is primarily driven by its strategic geographic location as a global trade nexus, ongoing and ambitious new port developments (e.g., in UAE, Saudi Arabia, Egypt), and steadily increasing regional trade volumes. Significant investments in large-scale infrastructure projects, often supported by sovereign wealth funds, are creating substantial and lucrative opportunities for the widespread deployment of advanced RTG cranes throughout the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rubber-Tired Gantry Crane Market.- Konecranes

- Liebherr

- ZPMC (Shanghai Zhenhua Heavy Industries)

- Kalmar (Cargotec Corporation)

- Mitsui E&S Machinery Co., Ltd.

- SANY Group Co., Ltd.

- Terex Port Solutions

- Paceco Corp.

- Dalian Huarui Heavy Industry Group Co., Ltd. (DHHI)

- Anhui Heli Co., Ltd.

- Palfinger AG

- Famur S.A.

- IMPSA S.A.

- Shanghai Port Machinery Co. (SPMC)

- Doosan Heavy Industries & Construction Co., Ltd.

- CVS Ferrari S.p.A.

- Kocks Kranbau GmbH

- Bedeschi S.p.A.

- MAC Port Macchine Operatrici Portuali S.r.l.

- Gottwald Port Technology GmbH

Frequently Asked Questions

Analyze common user questions about the Rubber-Tired Gantry Crane market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Rubber-Tired Gantry (RTG) crane, and how is it used in logistics?

An RTG crane is a mobile, rubber-tire-mounted crane primarily utilized in container terminals, seaports, and intermodal yards for the efficient stacking, moving, and retrieval of shipping containers. Its flexibility allows it to operate across various lanes without fixed rails, optimizing valuable yard space and facilitating rapid cargo turnaround in global logistics operations.

What are the primary operational benefits of employing RTG cranes compared to other container handling equipment?

RTG cranes offer superior mobility and unparalleled flexibility in terminal layout configuration, alongside relatively lower initial infrastructure development costs compared to rail-mounted gantry cranes. They also provide exceptionally high stacking density and highly efficient container handling capabilities, which are absolutely crucial for the high-volume demands of modern port and terminal operations, enhancing overall throughput.

How is advanced automation significantly impacting current and future RTG crane operations?

Automation is profoundly transforming RTG operations by enabling advanced remote control, sophisticated semi-autonomous, and even fully autonomous functionalities. This critical shift significantly enhances operational safety, drastically improves precision in container movements, substantially increases throughput capacity, and effectively reduces human error and associated labor costs in complex container handling environments, leading to more resilient terminals.

What key technological advancements are being integrated into modern Rubber-Tired Gantry Cranes to enhance performance?

Modern RTGs are extensively integrating cutting-edge technologies such as comprehensive electrification (including advanced hybrid and powerful battery-powered systems), sophisticated sensor arrays, advanced IoT for real-time data monitoring, powerful AI for predictive maintenance and dynamic route optimization, precise anti-sway systems, and intelligent collision avoidance technology. These innovations collectively boost performance, improve safety, and enhance environmental sustainability.

What are the primary challenges currently faced by the Rubber-Tired Gantry Crane market?

Key challenges confronting the market include the substantial initial capital investment required for procurement and deployment, the pressing need for a highly skilled workforce of operators and maintenance personnel for increasingly advanced systems, the significant impact of global economic fluctuations on international trade volumes, and ever-more stringent environmental regulations driving costly technological upgrades and compliance requirements across the industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager