Safety Limit Switches Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429231 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Safety Limit Switches Market Size

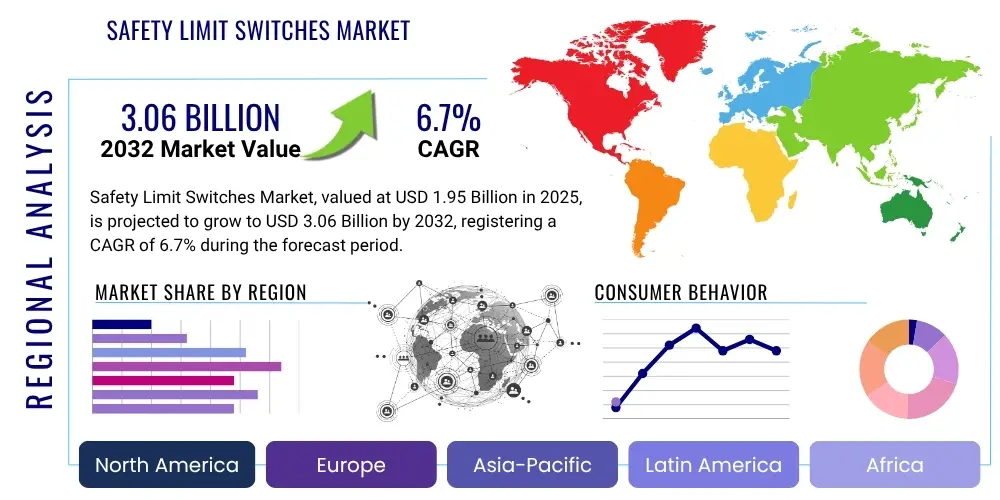

The Safety Limit Switches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 1.95 Billion in 2025 and is projected to reach USD 3.06 Billion by the end of the forecast period in 2032.

Safety Limit Switches Market introduction

Safety limit switches are critical electromechanical devices designed to monitor the position of machine guards, gates, or other moving parts, ensuring that dangerous operations cease when a safety barrier is breached or a component moves beyond its designated safe limit. These devices are integral to industrial safety systems, providing a physical safeguard against hazardous conditions and helping prevent accidents. Their robust design allows them to operate reliably in diverse industrial environments, from clean rooms to heavy manufacturing plants.

The primary function of a safety limit switch is to provide a reliable signal to a control system when a predetermined position is reached or exceeded. This signal then triggers a safety action, such as shutting down machinery, activating an alarm, or preventing startup. Major applications span across industrial automation, robotics, material handling, packaging machinery, and access control systems, where they protect both personnel and equipment. Benefits include enhanced operational safety, compliance with international safety standards, reduced risk of machinery damage, and improved overall industrial productivity through minimized downtime due to incidents. The market's growth is predominantly driven by increasing industrial automation, stringent safety regulations across various sectors, and the growing adoption of smart manufacturing practices that demand reliable safety components.

Safety Limit Switches Market Executive Summary

The Safety Limit Switches Market is currently experiencing robust expansion, propelled by significant global business trends, including the widespread adoption of Industry 4.0 initiatives and the continuous drive for operational efficiency coupled with enhanced worker safety. Businesses are increasingly investing in automated systems, which inherently require sophisticated safety mechanisms, positioning safety limit switches as indispensable components. Key business trends include the miniaturization of switches for compact applications, the integration of advanced diagnostic capabilities, and the development of wireless and non-contact technologies, catering to a broader range of industrial needs and reducing installation complexities. Furthermore, there's a discernible trend towards modular and configurable safety solutions that offer greater flexibility and adaptability to diverse machinery designs and operational requirements.

Regional trends significantly influence market dynamics. Asia Pacific, driven by rapid industrialization, particularly in countries like China and India, and the burgeoning manufacturing sectors, is emerging as a dominant force in market growth. North America and Europe, characterized by mature industrial infrastructures and stringent occupational safety regulations, continue to be significant revenue generators, showing a strong demand for high-performance and compliance-driven safety solutions. These regions are also leading in the adoption of advanced automation technologies, necessitating advanced safety limit switches. Segment-wise, the market is witnessing a shift towards smart safety limit switches that can communicate diagnostic data and integrate seamlessly with programmable logic controllers (PLCs) and other control systems, thereby enabling predictive maintenance and higher levels of machine intelligence. This trend is particularly evident in the automotive, food & beverage, and pharmaceutical industries, where precision and reliability are paramount. Moreover, the demand for hazardous area-certified switches is growing in oil & gas and chemical processing sectors, emphasizing explosion-proof and intrinsically safe designs.

AI Impact Analysis on Safety Limit Switches Market

User inquiries regarding AI's impact on safety limit switches often revolve around whether AI will automate safety functions, enhance existing safety devices, or potentially render traditional switches obsolete. There is considerable interest in how AI can contribute to predictive maintenance, real-time diagnostics, and intelligent fault detection within safety systems, as well as its role in complex robotic and autonomous operations where safety decisions need to be made instantaneously. Users frequently express expectations that AI will not replace the fundamental mechanical safety function but rather augment it, providing layers of intelligence that improve reliability, reduce false positives, and offer deeper insights into system health. The overarching theme is one of augmentation and integration, where AI enhances the robustness and intelligence of safety systems, rather than a disruptive replacement of the physical safety mechanism.

- AI-powered predictive maintenance for switches, anticipating failures before they occur.

- Enhanced diagnostics through AI, providing deeper insights into switch operational status and anomalies.

- Integration with intelligent automation systems for smarter safety decisions and responses.

- Optimization of safety protocols by analyzing data from multiple sensors, including safety limit switches.

- Development of adaptive safety systems that can learn and adjust to changing operational environments.

- Facilitation of remote monitoring and troubleshooting of safety limit switches with AI-driven analytics.

- Improved human-robot collaboration safety through AI-enabled context awareness and responsive safety measures.

DRO & Impact Forces Of Safety Limit Switches Market

The Safety Limit Switches Market is significantly shaped by a confluence of driving factors, critical restraints, and emerging opportunities, all operating under various impact forces. Key drivers include the escalating demand for industrial automation and robotics across diverse manufacturing sectors, which inherently requires robust and reliable safety devices to protect operators and machinery. Furthermore, increasingly stringent global occupational safety regulations and standards, such as ISO 13849 and IEC 62061, compel industries to adopt certified safety components, thus boosting the market for compliant limit switches. The continuous drive towards smart manufacturing and Industry 4.0 also fuels demand for advanced switches that can integrate seamlessly into complex control systems, offering diagnostic capabilities and enhanced reliability. The ongoing modernization of industrial infrastructure and the replacement of older machinery with automated systems further contribute to market expansion.

However, the market faces several restraints. The relatively high initial cost of advanced safety limit switches, particularly those with sophisticated features like diagnostic functions or wireless capabilities, can be a deterrent for small and medium-sized enterprises (SMEs) with limited budgets. The complexity involved in integrating these sophisticated switches into existing legacy systems, requiring significant engineering expertise and potential system overhauls, also poses a challenge. Additionally, a lack of widespread standardization across all industrial applications and regional variances in regulatory interpretations can create market fragmentation and hinder adoption. Economic downturns or slowdowns in industrial production can also temporarily dampen investment in new machinery and associated safety components. The intense competitive landscape, with numerous players offering a wide range of products, can also lead to price pressures affecting profitability.

Despite these restraints, significant opportunities abound for the Safety Limit Switches Market. Emerging economies in Asia Pacific, Latin America, and the Middle East & Africa present untapped growth potential due to ongoing industrialization and increasing awareness of occupational safety. The development of wireless and non-contact safety limit switches, offering easier installation and reduced maintenance, opens new avenues for applications in challenging environments or where wired solutions are impractical. Customization and modular design of switches to meet specific industry requirements, such as those in food & beverage for hygiene or oil & gas for hazardous areas, represent a strong opportunity for product differentiation. Integration with IoT platforms and cloud-based analytics for advanced monitoring and predictive maintenance solutions also offers a lucrative pathway for market participants. The continued expansion of renewable energy projects and electric vehicle manufacturing also presents specialized demand for high-performance safety limit switches.

Segmentation Analysis

The Safety Limit Switches Market is comprehensively segmented based on various critical attributes, providing a granular view of market dynamics and enabling targeted strategic planning. This segmentation allows for a detailed understanding of product types, application areas, end-use industries, and technological advancements that drive market growth. Analyzing these segments helps identify specific demand patterns, emerging niches, and competitive landscapes within different operational contexts. The market is typically categorized by the switch type, the mechanism it employs, its specific application, and the broader industry vertical it serves, ensuring a holistic perspective on its diverse deployment. Each segment demonstrates unique growth trajectories and adoption rates, influenced by technological innovation, regulatory mandates, and industry-specific operational requirements.

- By Type:

- General Purpose Safety Limit Switches

- Hazardous Area Safety Limit Switches

- Miniature Safety Limit Switches

- Heavy Duty Safety Limit Switches

- Non-contact Safety Limit Switches (e.g., Magnetic, RFID, Inductive)

- By Actuator Type:

- Plunger/Piston Type

- Roller Lever Type

- Fork Lever Type

- Rotary Type

- Cable Pull Type

- By Application:

- Machine Guarding

- Conveyor Systems

- Robotics

- Material Handling Equipment

- Process Control Equipment

- Elevators and Lifts

- Presses and Forming Machines

- By Industry Vertical:

- Automotive

- Food & Beverage

- Pharmaceutical & Healthcare

- Packaging

- Metals & Mining

- Oil & Gas

- Chemical

- Aerospace & Defense

- Electronics & Semiconductor

- Energy & Utilities

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Safety Limit Switches Market

The value chain for the Safety Limit Switches Market involves several interconnected stages, beginning with the sourcing of raw materials and extending through manufacturing, distribution, and ultimate deployment by end-users. At the upstream level, the process starts with the procurement of essential raw materials such as various metals (e.g., stainless steel, aluminum), plastics (e.g., engineering plastics for housings), and electronic components (e.g., contact materials, PCB components, semiconductors for smart features). Key suppliers in this segment include specialized material providers and component manufacturers who meet stringent quality and reliability standards required for safety-critical applications. These components are then assembled and integrated by the safety limit switch manufacturers, who often specialize in precision engineering and robust design to ensure product durability and compliance with safety certifications.

Moving downstream, the manufactured safety limit switches are distributed through a combination of direct sales channels, catering to large original equipment manufacturers (OEMs) and major industrial clients, and indirect channels, primarily through a network of distributors, wholesalers, and system integrators. These indirect channels play a crucial role in reaching a broader customer base, including smaller manufacturers, maintenance contractors, and specialized application providers. Distributors often provide value-added services such as technical support, localized inventory, and faster delivery, which are essential for prompt replacements and new installations. System integrators frequently incorporate safety limit switches into larger, custom-built automation systems, providing comprehensive solutions to end-users.

The final stage of the value chain involves the end-users who deploy these safety limit switches in their machinery and industrial processes. This segment includes a wide array of industries such as automotive manufacturing, food & beverage processing, pharmaceuticals, logistics, and heavy industries like metals & mining. The after-sales support, including installation assistance, maintenance services, and replacement parts, also forms a critical part of the downstream activities, ensuring continuous and safe operation of industrial equipment. Both direct sales teams and authorized service partners contribute to providing this ongoing support, thereby enhancing customer satisfaction and ensuring the long-term reliability of safety systems. The efficiency and effectiveness of each stage in this value chain directly impact product quality, market reach, and overall profitability within the safety limit switches industry.

Safety Limit Switches Market Potential Customers

The primary potential customers for safety limit switches are diverse industrial entities that operate machinery or systems requiring position monitoring and safety interlocks to protect personnel and equipment. These end-users span across various manufacturing and processing sectors, where automation is prevalent and occupational safety is a paramount concern. Key buyers include Original Equipment Manufacturers (OEMs) who integrate these switches directly into the machinery they produce, such as robotic arms, packaging lines, conveyor belts, and material handling systems, ensuring built-in safety features for their clients.

Beyond OEMs, large-scale industrial plants and factories in sectors like automotive, food & beverage, pharmaceutical, chemicals, and metals & mining are significant direct purchasers. These facilities regularly update or expand their existing production lines, requiring new safety installations or replacements of worn-out components to maintain compliance with evolving safety standards. Maintenance departments within these industries also constitute a continuous demand segment for replacement parts and upgrades. Furthermore, system integrators and automation solution providers act as intermediaries, procuring safety limit switches as part of comprehensive safety solutions they design and implement for their industrial clients, often customizing configurations to specific operational requirements.

Other substantial customer segments include logistics and warehousing companies utilizing automated storage and retrieval systems (AS/RS), construction companies employing heavy machinery, and the energy sector (including oil & gas and renewable energy installations) for equipment safety and hazardous area applications. The increasing focus on human-robot collaboration in manufacturing further expands the customer base to companies adopting advanced robotics, where precise safety limit switches are vital for defining safe operational zones and ensuring emergency stops. In essence, any industrial operation involving moving parts or processes that pose a risk to human operators or critical equipment represents a potential customer for safety limit switches.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.95 Billion |

| Market Forecast in 2032 | USD 3.06 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Rockwell Automation Inc., Siemens AG, Schneider Electric SE, Honeywell International Inc., Eaton Corporation plc, ABB Ltd., Omron Corporation, SICK AG, Banner Engineering Corp., Pepperl+Fuchs, Schmersal GmbH & Co. KG, Pilz GmbH & Co. KG, Telemecanique Sensors, IFM Electronic GmbH, Keyence Corporation, Conta-Clip Verbindungstechnik GmbH, BERNSTEIN AG, Crouzet S.A., Pizzato Elettrica S.R.L., Euchner GmbH + Co. KG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Safety Limit Switches Market Key Technology Landscape

The technology landscape for the Safety Limit Switches Market is characterized by continuous innovation aimed at enhancing reliability, durability, and integration capabilities. Traditional electromechanical limit switches, while still widely used, are being complemented by more advanced solutions. A significant trend involves the development of non-contact safety limit switches, which utilize technologies such as magnetic, inductive, or RFID sensing. These switches offer advantages such as reduced wear and tear, longer operational lifespan, and improved resistance to harsh industrial environments (e.g., dust, moisture, vibrations), making them ideal for applications requiring high operational uptime and minimal maintenance.

Another crucial technological advancement is the integration of smart features and advanced diagnostics. Many modern safety limit switches now incorporate microcontrollers and communication interfaces, such as IO-Link, enabling them to transmit detailed diagnostic data, operational status, and potential fault conditions directly to programmable logic controllers (PLCs) or other control systems. This capability facilitates predictive maintenance strategies, allowing operators to anticipate failures and schedule proactive interventions, thereby minimizing unplanned downtime and improving overall equipment effectiveness (OEE). The diagnostic information can include switch actuation cycles, temperature, and even environmental conditions, providing a comprehensive health check of the safety system.

Furthermore, the market is seeing increased adoption of wireless safety limit switches, which eliminate the need for complex and costly wiring, simplifying installation and enabling deployment in hard-to-reach or mobile applications. These wireless solutions leverage robust and secure communication protocols to ensure the integrity of safety signals. Miniaturization of components is also a key technological focus, allowing for the development of compact safety limit switches that can fit into constrained spaces without compromising performance or safety standards. The overarching goal of these technological developments is to provide more resilient, intelligent, and easy-to-integrate safety solutions that meet the evolving demands of modern industrial automation and contribute significantly to overall operational safety and efficiency.

Regional Highlights

- North America: This region demonstrates a mature market, driven by stringent safety regulations from bodies like OSHA (Occupational Safety and Health Administration) and high levels of industrial automation across various sectors including automotive, aerospace, and general manufacturing. Continuous investment in advanced manufacturing techniques and a strong focus on worker safety fuel the demand for high-performance and compliant safety limit switches. The United States and Canada are key contributors.

- Europe: Europe is another significant market, largely influenced by robust safety directives and standards such as the Machinery Directive and ISO 13849. Countries like Germany, with its strong industrial base and emphasis on Industry 4.0, along with the UK, France, and Italy, are leading in the adoption of sophisticated safety solutions, including smart and networked safety limit switches. The region's commitment to industrial safety and technological advancement sustains steady market growth.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market due to rapid industrialization, increasing foreign direct investment in manufacturing, and growing awareness of occupational safety in countries like China, India, Japan, and South Korea. The expansion of the automotive, electronics, and food & beverage industries, coupled with government initiatives promoting automation, significantly boosts the demand for safety limit switches. Local manufacturing capabilities are also expanding, catering to regional needs.

- Latin America: This region is characterized by an emerging industrial landscape with increasing investments in manufacturing and infrastructure development, particularly in countries such as Brazil, Mexico, and Argentina. While slower in adoption compared to developed regions, the growing emphasis on industrial safety standards and the modernization of older industrial facilities are gradually propelling the market for safety limit switches.

- Middle East & Africa (MEA): The MEA market is driven by ongoing investments in the oil & gas sector, mining, and infrastructure projects, particularly in Saudi Arabia, UAE, and South Africa. The demand for hazardous area-certified safety limit switches is prominent due to the prevalence of such industries. Increasing awareness of industrial safety and the diversification of economies away from oil also contribute to market growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Safety Limit Switches Market.- Rockwell Automation Inc.

- Siemens AG

- Schneider Electric SE

- Honeywell International Inc.

- Eaton Corporation plc

- ABB Ltd.

- Omron Corporation

- SICK AG

- Banner Engineering Corp.

- Pepperl+Fuchs

- Schmersal GmbH & Co. KG

- Pilz GmbH & Co. KG

- Telemecanique Sensors

- IFM Electronic GmbH

- Keyence Corporation

- Conta-Clip Verbindungstechnik GmbH

- BERNSTEIN AG

- Crouzet S.A.

- Pizzato Elettrica S.R.L.

- Euchner GmbH + Co. KG

Frequently Asked Questions

What is a safety limit switch and its primary function?

A safety limit switch is an electromechanical device used to detect the presence or position of objects, especially machine guards or moving parts, and send a signal to a control system to prevent hazardous operations or initiate a safe stop. Its primary function is to enhance industrial safety by ensuring machinery operates within safe parameters.

How is the Safety Limit Switches Market projected to grow?

The Safety Limit Switches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032, increasing from an estimated USD 1.95 Billion in 2025 to USD 3.06 Billion by 2032, driven by industrial automation and stringent safety regulations.

What impact does AI have on safety limit switches?

AI significantly impacts safety limit switches by enabling predictive maintenance, advanced diagnostics, and seamless integration into intelligent automation systems. It augments traditional safety functions by providing real-time data analysis and enhancing overall system reliability and responsiveness, rather than replacing the physical safety mechanism.

Which industries are the major end-users of safety limit switches?

Major end-users of safety limit switches include the automotive, food & beverage, pharmaceutical, packaging, metals & mining, and oil & gas industries. These sectors heavily rely on automation and robust safety systems to protect personnel and ensure operational compliance.

What are the key technological advancements in safety limit switches?

Key technological advancements include the development of non-contact switches (magnetic, RFID), integration of smart features with advanced diagnostics (IO-Link), wireless communication capabilities, and miniaturization. These innovations aim to improve reliability, reduce maintenance, and enhance integration with modern industrial control systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager