Sand Blasting Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429794 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Sand Blasting Machine Market Size

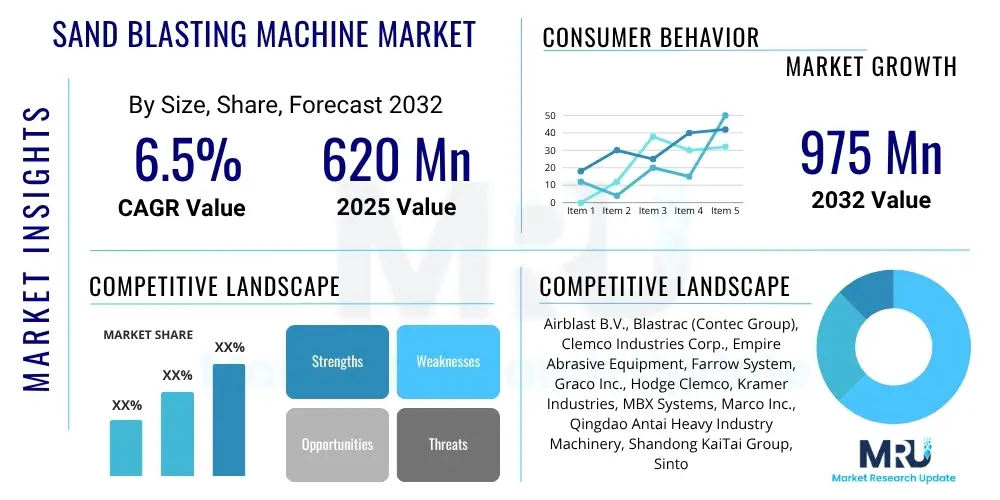

The Sand Blasting Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 620 Million in 2025 and is projected to reach USD 975 Million by the end of the forecast period in 2032.

Sand Blasting Machine Market introduction

The Sand Blasting Machine Market encompasses equipment designed to propel abrasive materials at high velocity to clean, abrade, or prepare surfaces. These machines are crucial for a wide range of industrial applications, providing efficient surface treatment solutions. The product description includes various types such as portable blast pots, abrasive blast cabinets, and complete blast rooms, catering to different operational scales and material processing requirements.

Major applications for sand blasting machines span across industries like automotive for component cleaning, aerospace for surface finishing, marine for hull maintenance, and construction for structural preparation. These machines are also vital in metal fabrication, foundries, and the oil and gas sector for corrosion removal and surface profiling. The primary benefits include superior surface preparation for coating adhesion, removal of rust, paint, and contaminants, and the creation of specific surface textures.

Driving factors for market growth include the escalating demand for high-quality surface finishes in manufacturing, the increasing adoption of automation in industrial processes, and the growing focus on maintenance and refurbishment of existing infrastructure. Additionally, advancements in abrasive media and machine technology, leading to more efficient and environmentally friendly solutions, are propelling market expansion. The global industrialization trend, particularly in emerging economies, further fuels the need for effective surface treatment equipment.

Sand Blasting Machine Market Executive Summary

The Sand Blasting Machine Market is experiencing robust growth, driven by sustained industrial expansion and an increasing emphasis on precision surface engineering across diverse sectors. Business trends indicate a shift towards automated and robotic blasting solutions, enhancing efficiency, consistency, and worker safety. There is also a notable rise in the demand for eco-friendly blasting media and dustless blasting technologies, reflecting growing environmental awareness and stricter regulatory frameworks. Customization of blasting equipment to meet specific application requirements is becoming a key competitive differentiator, pushing manufacturers to innovate modular and versatile systems.

Regionally, the Asia Pacific continues to dominate the market, propelled by its thriving manufacturing base, significant infrastructure development, and burgeoning automotive and construction industries. North America and Europe are characterized by technological advancements and the adoption of high-end automated systems, driven by stringent quality standards and labor cost considerations. Latin America and the Middle East and Africa regions are expected to witness steady growth, fueled by industrialization projects and increased investment in oil and gas, and construction sectors.

Segmentation trends reveal a strong preference for dry blasting methods, though wet blasting is gaining traction in applications requiring dust suppression and fine finish. The increasing sophistication of abrasive types, from traditional sand and steel grit to specialized glass beads and plastic abrasives, is expanding the utility of these machines. Furthermore, the rising demand from end-user industries such as aerospace, medical device manufacturing, and electronics for highly precise and contamination-free surface treatments is driving innovation in smaller, more controlled blasting systems and advanced robotic applications.

AI Impact Analysis on Sand Blasting Machine Market

Common user questions regarding the impact of AI on the Sand Blasting Machine Market frequently revolve around potential improvements in operational efficiency, the degree of automation, the accuracy of blasting processes, and enhanced safety for operators. Users are keenly interested in how AI can optimize abrasive usage, reduce waste, and provide predictive maintenance capabilities for blasting equipment, thereby lowering overall operating costs and extending machine lifespan. Expectations center on AI enabling smarter, more autonomous blasting solutions that can adapt to varying surface conditions and material types, leading to higher quality finishes and fewer manual interventions.

- AI integration into robotic blasting systems for precise path planning and adaptive abrasive delivery.

- Enhanced quality control through AI-powered vision systems that inspect blasted surfaces for defects and uniformity.

- Predictive maintenance analytics using machine learning to forecast equipment failures and optimize maintenance schedules.

- Real-time process optimization by AI algorithms adjusting blasting parameters based on sensor data for consistent results.

- Improved worker safety through autonomous operations, reducing human exposure to hazardous environments.

- Automated abrasive recycling and classification systems driven by AI to maximize media lifespan and reduce waste.

DRO & Impact Forces Of Sand Blasting Machine Market

The Sand Blasting Machine Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, alongside various impact forces that shape its trajectory. Key drivers include the robust growth of the manufacturing sector globally, particularly in automotive, aerospace, and general fabrication industries, which consistently require high-quality surface preparation for product durability and aesthetic appeal. Expanding infrastructure development projects, necessitating extensive surface cleaning and maintenance for structures and components, further fuels demand. The increasing adoption of automation in industrial processes, aimed at improving efficiency and reducing labor costs, also acts as a powerful catalyst for advanced blasting solutions.

However, the market faces several restraints that could impede its growth. High initial capital investment for advanced sand blasting equipment and blast room installations can be a barrier for small and medium-sized enterprises. Environmental concerns related to dust emissions and the safe disposal of spent abrasives necessitate costly dust collection systems and environmentally compliant media, adding to operational expenses. Furthermore, a shortage of skilled labor proficient in operating and maintaining sophisticated blasting machinery poses a challenge for companies. The availability of alternative surface preparation methods, such as chemical stripping or laser cleaning, though often more specialized, also presents a competitive restraint.

Opportunities for market players lie in the development and adoption of eco-friendly blasting technologies, including dustless blasting systems and recyclable, non-toxic abrasives, which align with increasingly strict environmental regulations. The growing demand for robotic and automated blasting solutions, particularly in industries prioritizing precision and safety, offers a lucrative avenue for technological innovation and market penetration. Emerging economies in Asia Pacific and Latin America present significant untapped potential due to their ongoing industrialization and urbanization. Customization of blasting machines to meet specific industrial needs and the integration of IoT for remote monitoring and diagnostics are also key areas for market expansion and competitive advantage.

Segmentation Analysis

The Sand Blasting Machine Market is comprehensively segmented across various parameters, allowing for a detailed analysis of its diverse applications and technological nuances. These segmentations are crucial for understanding market dynamics, identifying key growth areas, and developing targeted strategies. The market is broadly categorized based on machine type, technology employed, the kind of abrasive media used, specific industrial applications, and the end-user profile, each presenting distinct market characteristics and growth opportunities. This granular approach provides insights into evolving customer preferences and technological advancements driving the industry.

- By Type:

- Wet Blasting Machines

- Dry Blasting Machines

- Portable Blasting Machines

- Abrasive Blast Cabinets

- Blast Rooms

- Robotic Blasting Systems

- By Technology:

- Wheel Blasting

- Air Blasting

- Suction Blasting

- Pressure Blasting

- By Abrasive Type:

- Sand (Silica Sand, Garnet Sand)

- Steel Grit and Shot

- Glass Beads

- Aluminum Oxide

- Plastic Abrasives

- Other Abrasives (e.g., Walnut Shells, Ceramic Beads)

- By Application:

- Automotive

- Aerospace and Defense

- Marine

- Construction and Infrastructure

- Heavy Manufacturing and Foundries

- Oil and Gas

- General Industrial Maintenance

- Medical and Electronics

- Other Applications

- By End-User:

- Contract Blasting Service Providers

- In-house Manufacturing and Fabrication Units

- Maintenance and Repair Operations (MRO)

Value Chain Analysis For Sand Blasting Machine Market

The value chain for the Sand Blasting Machine Market begins with upstream activities involving the sourcing and processing of raw materials and components critical for manufacturing the equipment. This includes suppliers of various abrasive media such as steel grit, glass beads, and aluminum oxide, as well as manufacturers of critical machine components like blast nozzles, pressure vessels, dust collectors, and control systems. The quality and availability of these upstream inputs directly influence the production cost and performance of the final blasting machines. Strong relationships with reliable suppliers are crucial for ensuring a consistent supply chain and maintaining product quality standards in a competitive market.

Midstream activities primarily encompass the design, manufacturing, assembly, and testing of sand blasting machines. This stage involves significant research and development investments to innovate new technologies, improve efficiency, and enhance user safety. Manufacturers often specialize in different types of machines, from portable units to large blast rooms, requiring specialized production facilities and skilled labor. Quality control, adherence to safety standards, and efficiency in manufacturing processes are paramount to creating high-value products that meet diverse industrial demands. The integration of advanced manufacturing techniques and automation is key to optimizing this stage.

Downstream activities involve the distribution, sales, installation, and after-sales support for sand blasting machines. Distribution channels are varied, including direct sales from manufacturers to large industrial clients, partnerships with regional distributors and dealers for broader market reach, and increasingly, online platforms for smaller equipment and accessories. Direct channels often provide specialized technical support and customization, while indirect channels offer wider accessibility. After-sales services, including maintenance, spare parts supply, and technical assistance, are critical for customer satisfaction and long-term client relationships. Effective distribution networks and robust customer support significantly impact market penetration and customer loyalty, making them vital components of the value chain.

Sand Blasting Machine Market Potential Customers

The Sand Blasting Machine Market caters to a diverse range of end-users and buyers who require efficient and effective surface preparation solutions across various industrial applications. These potential customers are primarily entities involved in manufacturing, construction, maintenance, and specialized surface treatment services, where the removal of contaminants, creation of surface profiles, or achieving specific finishes are critical operational steps. Their purchasing decisions are often influenced by factors such as the scale of operation, specific material requirements, desired surface quality, environmental regulations, and overall operational costs. Understanding these varied customer profiles is essential for market players to tailor their product offerings and marketing strategies effectively.

Key segments of potential customers include automotive manufacturers who use blasting for engine components, chassis parts, and body panels to improve adhesion of coatings and reduce fatigue. The aerospace and defense industry relies on these machines for precision cleaning and peening of critical aircraft and defense components, ensuring structural integrity and extending lifespan. Shipyards and marine maintenance companies are significant buyers, utilizing large-scale blasting equipment for hull descaling, corrosion removal, and preparation for protective coatings to enhance vessel longevity. Construction companies and infrastructure developers employ sand blasting machines for surface preparation of steel structures, concrete surfaces, and bridges before painting or repair, ensuring robust and durable finishes.

Furthermore, metal fabrication shops and foundries represent a substantial customer base, using blasting for deburring, descaling, and achieving aesthetic finishes on metal parts. The oil and gas sector utilizes these machines extensively for maintaining pipelines, offshore platforms, and refinery components, crucial for preventing corrosion and ensuring operational safety. Contract blasting service providers, who offer specialized surface treatment to various industries without requiring clients to invest in their own equipment, are also major buyers. The medical device manufacturing sector and electronics industry are emerging as high-value customers, demanding highly precise and contamination-free blasting for delicate components, driving innovation in micro-blasting and automated systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 620 Million |

| Market Forecast in 2032 | USD 975 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Airblast B.V., Blastrac (Contec Group), Clemco Industries Corp., Empire Abrasive Equipment, Farrow System, Graco Inc., Hodge Clemco, Kramer Industries, MBX Systems, Marco Inc., Qingdao Antai Heavy Industry Machinery, Shandong KaiTai Group, Sinto Surface Treatment, Sponge-Jet Inc., Trinco, Vixen Surface Treatments, W Abrasives (Winoa Group), Wheelabrator Group, Zirco Products |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sand Blasting Machine Market Key Technology Landscape

The Sand Blasting Machine Market is continuously evolving with significant technological advancements aimed at improving efficiency, precision, and environmental compliance. One of the most prominent technological shifts is the increasing integration of robotics and automation. Robotic blasting systems offer unparalleled consistency and accuracy, especially for complex geometries and repetitive tasks, reducing human error and improving safety. These systems are often equipped with advanced vision systems and programmable logic controllers (PLCs) to ensure optimal abrasive coverage and surface finish, minimizing rework and material waste. The ability to program precise blasting paths allows for highly customized and repeatable processes, which is crucial for industries with strict quality control demands like aerospace and medical device manufacturing.

Another crucial area of innovation is in dustless and environmentally friendly blasting technologies. Traditional dry blasting can generate significant dust, posing health risks and environmental challenges. To address this, technologies like wet blasting, vapor blasting, and the use of specialized dustless media (e.g., Sponge-Jet abrasives) are gaining traction. These systems incorporate water or other liquids to suppress dust, capture contaminants, and provide a cleaner working environment. Furthermore, advancements in abrasive recycling and recovery systems are enhancing sustainability by minimizing media consumption and disposal costs. These systems often utilize sophisticated separation techniques to clean and classify used abrasives, allowing for multiple reuse cycles and reducing the overall environmental footprint of blasting operations.

The rise of Industry 4.0 and the Internet of Things (IoT) is also transforming the sand blasting machine market. Modern blasting equipment is increasingly being fitted with sensors that monitor key operational parameters such as abrasive flow, air pressure, and nozzle wear in real-time. This data can be transmitted to cloud-based platforms for remote monitoring, predictive maintenance, and performance analytics. Such IoT integration enables operators and maintenance teams to identify potential issues before they lead to downtime, optimize machine settings for peak performance, and track consumable usage more accurately. This enhances operational efficiency, reduces maintenance costs, and extends the lifespan of the equipment, providing a significant competitive edge to manufacturers who adopt these smart technologies.

Regional Highlights

- North America: This region is characterized by high adoption of advanced and automated blasting solutions, particularly in the aerospace, automotive, and heavy manufacturing sectors. Stringent environmental regulations and a focus on worker safety drive demand for dustless and robotic blasting systems. The presence of key technological innovators and a strong industrial base contribute to its significant market share.

- Europe: Europe exhibits a mature market with a strong emphasis on environmental compliance and energy efficiency. Countries like Germany and the UK are leaders in adopting automated and precision blasting technologies for their automotive and industrial machinery sectors. The region also sees a strong demand for high-performance abrasives and sustainable blasting solutions.

- Asia Pacific (APAC): The APAC region is the fastest-growing market for sand blasting machines, fueled by rapid industrialization, expanding manufacturing capabilities, and significant infrastructure development in countries like China, India, and Southeast Asian nations. The automotive, construction, and marine industries are key drivers, leading to high demand for both conventional and advanced blasting equipment.

- Latin America: This region presents emerging opportunities, driven by increasing industrialization, mining activities, and investments in infrastructure and manufacturing. Countries like Brazil and Mexico are witnessing a growing demand for cost-effective and robust blasting solutions for maintenance and new production facilities.

- Middle East and Africa (MEA): The MEA market is projected for steady growth, primarily propelled by extensive oil and gas projects, construction booms, and increasing industrial diversification efforts. There is a strong need for surface preparation equipment for pipeline maintenance, refinery infrastructure, and general industrial applications, often with a focus on durability and performance in challenging environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sand Blasting Machine Market.- Airblast B.V.

- Blastrac (Contec Group)

- Clemco Industries Corp.

- Empire Abrasive Equipment

- Farrow System

- Graco Inc.

- Hodge Clemco

- Kramer Industries

- MBX Systems

- Marco Inc.

- Qingdao Antai Heavy Industry Machinery

- Shandong KaiTai Group

- Sinto Surface Treatment

- Sponge-Jet Inc.

- Trinco

- Vixen Surface Treatments

- W Abrasives (Winoa Group)

- Wheelabrator Group

- Zirco Products

Frequently Asked Questions

What is a sand blasting machine used for?

Sand blasting machines are primarily used for surface preparation, cleaning, and finishing various materials. Their applications include removing rust, paint, and contaminants, deburring, creating surface profiles for improved coating adhesion, and aesthetic finishing across industries like automotive, aerospace, marine, and construction.

What are the primary benefits of using sand blasting machines?

The main benefits include highly efficient and thorough surface cleaning, superior preparation for subsequent coatings or treatments, versatility across different materials and applications, and the ability to achieve precise surface finishes and textures quickly compared to manual methods.

What are the different types of sand blasting machines available?

Sand blasting machines are categorized into several types, including portable blasting units for on-site jobs, abrasive blast cabinets for smaller components in a contained environment, and large blast rooms for industrial-scale processing of big parts. They also vary by technology, such as wheel blasting and air blasting (suction or pressure feed).

Is sand blasting considered an environmentally friendly process?

While traditional sand blasting can raise environmental concerns due to dust and abrasive waste, modern advancements include dustless blasting systems, wet blasting, and the use of eco-friendly and recyclable abrasive media. These innovations significantly reduce environmental impact, making the process more sustainable.

How is AI impacting the sand blasting machine market?

AI is transforming the sand blasting market by enabling advanced automation, particularly in robotic blasting for enhanced precision and consistency. AI also contributes to predictive maintenance, optimizing abrasive usage, improving quality control through vision systems, and ensuring greater worker safety by reducing direct human involvement in hazardous operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager