Seed Cracker Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429805 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Seed Cracker Market Size

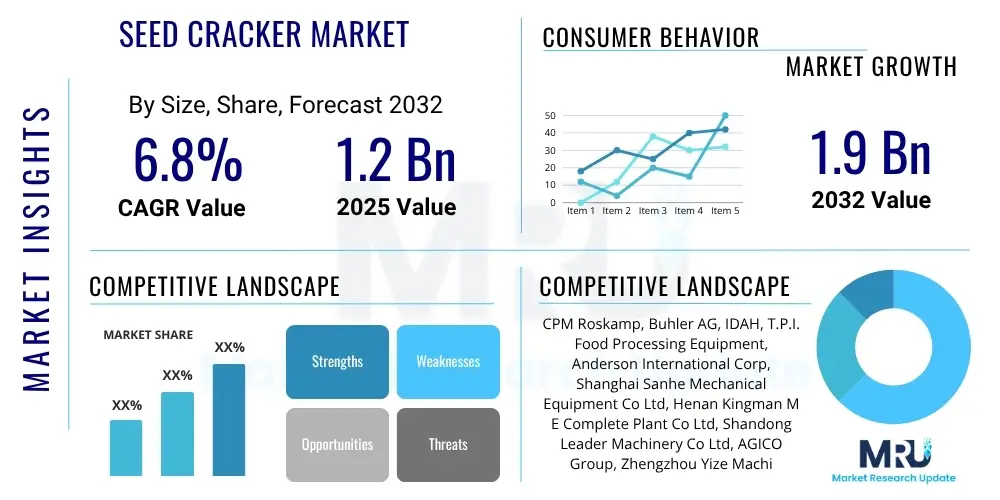

The Seed Cracker Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 1.9 Billion by the end of the forecast period in 2032.

Seed Cracker Market introduction

The Seed Cracker Market, a critical component within the global agricultural and industrial processing landscape, represents the foundational stage in unlocking the intrinsic value of various oilseeds and grains. At its core, a seed cracker is a specialized piece of mechanical equipment designed to precisely fracture or de-hull the outer integument of a seed, thereby exposing its internal kernel or cotyledons. This preparatory step is indispensable across numerous industries, primarily aimed at optimizing the efficiency of subsequent processing stages such as oil extraction, animal feed formulation, or specific industrial applications. The technology involved ranges from robust, high-throughput industrial machines capable of processing tons of seeds per hour, to more compact, specialized units designed for niche applications or smaller-scale operations. The overarching goal of this initial cracking is to enhance the surface area of the kernel, facilitate the penetration of solvents during extraction, improve digestibility in animal feed, and ensure the purity of the final product by separating the hull. The continuous evolution of seed cracking technology reflects a persistent industry drive towards greater precision, higher yields, and reduced energy consumption, addressing critical economic and environmental imperatives. Modern seed crackers are engineered with advanced materials and sophisticated control systems to handle a diverse array of seed types, each with unique physical characteristics requiring tailored approaches to achieve optimal cracking efficiency without damaging the valuable internal components, thus safeguarding the integrity of the primary product.

Major applications for seed cracker technology are deeply embedded within vital global industries, underpinning significant economic activity. The edible oil sector stands as a predominant consumer, where crackers are indispensable for processing a wide array of seeds, including but not limited to soybeans, sunflower, rapeseed, cotton, and palm kernel. In this context, efficient cracking directly correlates with higher oil yields and improved oil quality, as it allows for more complete and effective extraction of lipids. The escalating global demand for edible oils, driven by a growing world population, evolving dietary habits, and increasing awareness of healthier oil options, directly fuels the demand for advanced seed cracking solutions. Parallelly, the animal feed industry relies heavily on cracked seeds to enhance the nutritional value and digestibility of livestock feed. By breaking down seed structures, nutrients become more bioavailable, leading to improved animal growth, health, and feed conversion ratios. This application segment is expanding rapidly, influenced by the burgeoning global livestock population and the intensification of animal farming practices aimed at meeting protein demand. Beyond food and feed, seed crackers are increasingly vital in the burgeoning biofuel industry, where they facilitate the initial processing of oil-rich seeds (e.g., jatropha, pongamia, camelina) to extract oils for conversion into renewable energy sources, supporting global sustainability and energy transition initiatives.

The benefits derived from deploying modern seed cracking technology are substantial and multifaceted, providing compelling incentives for market growth and continuous innovation. Foremost among these is a significant increase in overall processing efficiency, as properly cracked seeds drastically reduce the energy and time required for subsequent oil extraction or grinding processes. This efficiency translates directly into lower operational costs and higher throughput for processors, thereby enhancing their competitive posture. Furthermore, superior cracking precision minimizes damage to the valuable kernel, which is paramount for achieving improved oil yield and a higher quality end product, free from undesirable hull contaminants that can affect taste, color, and shelf life. Energy optimization is another critical advantage, with modern machines designed to operate with greater energy efficiency, contributing to reduced carbon footprints and lower utility expenses in an era of rising energy costs. The adaptability of advanced seed crackers to handle a wide variety of seed types, often with adjustable settings for optimal performance, provides immense operational flexibility for multi-product facilities, enabling processors to diversify their offerings. Driving factors for this market are therefore robust, including the relentless growth in global demand for edible oils and animal feed, continuous advancements in agricultural output, increasing industrialization in developing economies, and the sustained focus on enhancing operational efficiency, sustainability, and product quality across the entire agricultural processing value chain. These combined forces ensure a dynamic and expanding market outlook for seed cracker manufacturers and operators alike, positioning the market for sustained innovation and expansion.

Seed Cracker Market Executive Summary

The Seed Cracker Market is currently experiencing a period of significant expansion, fundamentally driven by the escalating global requirement for processed seeds across a spectrum of industries, predominantly edible oils, animal feed, and emerging biofuel sectors. Key business trends underscore a definitive strategic pivot towards enhanced automation, the development of higher capacity machines capable of handling increased throughput, and the widespread adoption of energy-efficient solutions. These advancements are critical for meeting the strenuous demands of industrial-scale processing operations and for achieving substantial reductions in overall operational expenditures. Manufacturers are channeling considerable investments into research and development, focusing on the integration of advanced materials, such as specialized alloys and composites, and incorporating smart technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) into their equipment designs. The objective is to engineer solutions that offer unparalleled precision, superior durability, and significantly reduced maintenance requirements over the operational lifespan. This technological evolution is not merely incremental but transformative, proving crucial for maintaining a competitive edge in a market where maximizing yield, minimizing environmental impact, and ensuring product quality are paramount. Furthermore, market consolidation, frequently observed through strategic mergers and acquisitions, alongside the formation of collaborative partnerships, represents a prominent overarching trend. These strategic moves enable companies to broaden their product portfolios, extend their geographic footprint, and augment their technological capabilities, positioning them more strongly in a dynamic global environment. The rising global emphasis on stringent food safety and quality standards further compels processors to adopt the most reliable, efficient, and technologically advanced seed cracking technologies available, fostering a culture of continuous improvement and compliance.

Regional dynamics within the Seed Cracker Market distinctly highlight the Asia Pacific region as both the dominant force and the fastest-growing geographical segment. This ascendancy is primarily attributed to the region's vast agricultural expanse, its substantial population base, and the rapid expansion of its edible oil and animal feed industries, particularly in economically vibrant nations such as China, India, and Indonesia. These countries are witnessing monumental investments in the modernization and expansion of their food processing infrastructure, which in turn generates an enormous demand for high-capacity, efficient, and technologically advanced seed cracking equipment. Conversely, North America and Europe, characterized as mature markets, demonstrate a pronounced inclination towards high-efficiency, fully automated, and environmentally compliant machinery. These regions often lead in the early adoption and refinement of cutting-edge technologies, emphasizing sustainability and precision engineering. Latin America is also rapidly emerging as a significant market player, fueled by its expanding agricultural exports and progressively sophisticated domestic processing capabilities, with Brazil and Argentina leading the charge in oilseed production and processing innovation. The Middle East and Africa (MEA) regions, while still nascent, exhibit considerable potential for future growth. This growth is underpinned by increasing urbanization, industrialization, and concerted governmental efforts to enhance local food security and agricultural output, thereby encouraging strategic investments in new processing facilities. Each region presents a unique set of market dynamics, profoundly influenced by local agricultural practices, varying levels of economic development, and distinct regulatory frameworks that shape investment and technological adoption patterns.

Segment-specific trends within the Seed Cracker Market provide granular insights into evolving preferences and technological advancements that are reshaping the industry. In the "By Type" segment, roller crackers continue to command a substantial market share, a testament to their inherent versatility and effective, gentle cracking action suitable for a broad spectrum of oilseeds. Concurrently, impact crackers are gaining notable traction, particularly for processing hard-shelled seeds or when a finer particle size distribution is necessitated. The "By Capacity" segment reveals a clear and accelerating demand for large-scale industrial machines, typically those exceeding 20 Tons Per Hour (TPH), as global processing plants continue to scale up their operations to meet ever-increasing worldwide demand. Alongside this, a stable, albeit smaller, market persists for medium and small-scale crackers, catering to specialized processing needs or localized agricultural operations. Within the "By Application" segment, edible oil production remains the primary and most significant driver of demand, reflecting the fundamental human need for dietary fats. However, the animal feed and biofuel sectors are exhibiting remarkably accelerating growth, diversifying the market's application base and offering new avenues for innovation. Finally, the "By Operational Mode" segment unmistakably indicates a progressive shift towards automatic and semi-automatic machines. This transition is robustly driven by the imperative to substantially reduce labor costs, enhance operational safety protocols, and achieve consistently high processing quality. This trend signifies a broader industry move away from purely manual operations in larger facilities, towards more integrated, controlled, and efficient automated systems that promise greater reliability and precision across the entire cracking process.

AI Impact Analysis on Seed Cracker Market

User inquiries and industry dialogues concerning Artificial Intelligence's influence on the Seed Cracker Market consistently gravitate around core themes of optimizing operational efficiency, ensuring unparalleled product quality, achieving significant reductions in energy consumption, and implementing sophisticated predictive maintenance regimes. Stakeholders are particularly interested in exploring how AI can transcend rudimentary automation, moving towards providing truly intelligent and actionable insights, enabling dynamic adaptation to varying seed characteristics, and proactively managing the health and performance of critical equipment. Key overarching themes emerging from these discussions include the pervasive desire for enhanced yield rates, minimized unscheduled downtime, and the adoption of more environmentally sustainable processing methods. There is a palpable expectation that AI integration will lead to substantial cost reductions across the board, attributable to optimized resource allocation, reduced necessity for constant human intervention, and the minimization of waste. Simultaneously, there is a strong belief that AI will elevate product standards and proactively address pressing environmental concerns by optimizing energy use and reducing processing inefficiencies. Users actively seek tangible, real-world examples of AI's practical application, ranging from real-time data analysis for precise process control to advanced automated defect detection in processed seeds. This collective interest points towards an envisioned future where seed cracking operations are not merely automated but are intelligently adaptive, self-optimizing, and capable of consistently delivering superior performance with minimal human oversight.

- Predictive Maintenance: AI algorithms analyze vast streams of real-time sensor data from critical components of seed crackers, such as rollers, bearings, and motors, to accurately anticipate equipment failures. This enables the scheduling of maintenance proactively during planned downtimes, thereby minimizing unscheduled operational disruptions, extending the overall lifespan of machinery, and significantly reducing emergency repair costs.

- Process Optimization: Machine learning models are deployed to dynamically analyze diverse parameters including seed moisture content, inherent hardness, size uniformity, and current machine settings. Based on this analysis, AI can intelligently adjust cracking pressure, roller speed, and gap settings in real-time, optimizing the cracking process for maximum yield, minimal kernel damage, and reduced energy consumption for each batch of seeds.

- Enhanced Quality Control: AI-powered computer vision systems, integrated with high-speed cameras, can meticulously inspect cracked seeds for damage, incomplete cracking, hull residue contamination, or the presence of foreign materials. These systems operate at speeds far beyond human capability, ensuring a consistently high output quality, reducing manual sorting requirements, and improving overall product purity.

- Automated Fault Detection: AI integrates seamlessly with the internal diagnostics and control systems of seed crackers to immediately identify subtle anomalies or malfunctions in cracking mechanisms or peripheral components. This instantaneous detection enables rapid troubleshooting and precise localization of the problem, preventing minor issues from escalating into major breakdowns and thereby safeguarding operational continuity.

- Supply Chain Optimization: Leveraging AI, processors can analyze historical data and real-time inputs to optimize the utilization of incoming raw materials. AI algorithms can predict optimal processing routes based on the specific characteristics of different seed batches, leading to more efficient raw material allocation, optimized inventory management, and reduced material waste across the entire supply chain.

- Energy Consumption Optimization: AI algorithms continuously monitor and meticulously control the energy consumption patterns of various components within seed cracking systems. By identifying opportunities for efficiency improvements through dynamic load adjustments and operational scheduling, AI actively reduces the overall electricity usage, thereby lowering operational costs and contributing significantly to a smaller carbon footprint for the processing operations.

DRO & Impact Forces Of Seed Cracker Market

The Seed Cracker Market is intricately shaped by a complex and dynamic interplay of driving forces, inherent restraints, promising opportunities, and prevailing impact forces that collectively define its competitive landscape and influence its trajectory of growth. A fundamental and overarching driver is the escalating global demand for both edible oils and high-quality animal feed, a demand relentlessly propelled by an ever-growing world population, steadily rising disposable incomes, and significant shifts in dietary habits, particularly within rapidly developing economies. This sustained and intensifying demand necessitates increasingly higher levels of efficiency and capacity in oilseed processing operations, directly fueling the adoption and investment in advanced seed cracking machinery. Furthermore, continuous and rapid technological advancements in machine design, robust automation solutions, and specialized materials science are consistently enhancing the performance, durability, and energy efficiency of modern seed crackers. These innovations make contemporary machines more attractive and compelling investments for discerning processors. The increasing global focus on maximizing yield from agricultural produce and simultaneously minimizing waste across the food chain also acts as a profound driver, as highly efficient cracking is absolutely fundamental to achieving these critical sustainability and economic objectives. The significant expansion of the global biofuel industry, driven by a quest for sustainable alternatives to traditional fossil fuels, further contributes to the market's growth by increasing the demand for efficient initial processing of oil-rich seeds, thereby diversifying the market's application base.

Despite the robust underlying growth drivers, the Seed Cracker Market is concurrently confronted by several formidable restraints that can impede its expansion. Foremost among these is the inherently high initial capital investment required for acquiring and installing modern, large-scale industrial seed cracking equipment. This substantial financial outlay can pose a significant barrier, particularly for smaller enterprises or those operating in developing regions with limited access to capital. Coupled with this, the ongoing operational costs associated with regular maintenance, the procurement of specialized spare parts, and the consumption of energy can significantly impact the long-term profitability and viability of processing operations. Volatility in the global prices of raw materials, specifically oilseeds, can introduce considerable market uncertainty for processors, directly influencing their investment decisions in new machinery or upgrades. Additionally, the market is increasingly subject to stringent environmental regulations, particularly those pertaining to noise pollution, dust emissions, and energy efficiency standards. These regulations necessitate costly compliance measures, involving investment in pollution control technologies and environmentally friendly designs, which can slow down market expansion and increase operational complexity in some regions. The limited lifespan of certain highly abrasive machine components, due to the nature of processing hard seeds, also contributes to persistent maintenance challenges, requiring frequent replacements and thereby increasing the total cost of ownership. These cumulative factors collectively represent hurdles that market participants must strategically navigate to sustain growth and maintain a competitive advantage.

Opportunities within the Seed Cracker Market are predominantly found in the accelerating adoption of smart manufacturing technologies and digital integration. This includes the widespread deployment of the Internet of Things (IoT), Artificial Intelligence (AI), and advanced data analytics platforms to create more intelligent, adaptive, and predictive cracking solutions. Such integration allows for revolutionary capabilities like predictive maintenance, real-time process optimization, and enhanced quality control, thereby opening entirely new avenues for improved efficiency, reduced waste, and increased profitability. Expanding into the processing of niche or specialty seeds, beyond traditional oilseeds, offers significant diversification potential and access to untapped market segments with unique value propositions. The development and commercialization of more sustainable and eco-friendly cracking methods, with a resolute focus on demonstrably reduced energy consumption and minimal waste generation, align seamlessly with global environmental goals and are highly attractive to environmentally conscious processors and consumers alike. Furthermore, aggressive market penetration into untapped or currently under-penetrated emerging economies, where agricultural processing infrastructure is still undergoing development and modernization, represents a substantial, long-term growth opportunity for manufacturers. The impact forces acting upon the market, derived from Porter's Five Forces analysis, include the moderate bargaining power of buyers (owing to a competitive, albeit specialized, supplier base) and suppliers (due to the specialized nature of components). The threat of new entrants is relatively low, primarily due to the high capital investment requirements, significant R&D costs, and the technical expertise necessary to compete effectively. The threat of substitute products or alternative processing methods for initial cracking remains moderate, as no method currently offers the same efficiency for de-hulling. Finally, competitive rivalry within the market is robust, driven by established players constantly innovating to gain market share, collectively shaping the industry's competitive intensity and its overall attractiveness for investment.

Segmentation Analysis

The Seed Cracker Market is comprehensively segmented to provide a granular and intricate understanding of its diverse components and the underlying dynamics that drive its evolution. This meticulous segmentation is instrumental in effectively identifying specific market niches, discerning nuanced consumer preferences, and accurately evaluating the competitive landscapes across various critical dimensions, including product types, operational capacities, application areas, and distinct operational modes. Analyzing these segments rigorously reveals varying growth rates and demand patterns, which are inherently influenced by the relentless pace of technological advancements, the specific agricultural practices prevalent in different regions, and the precise industrial requirements of end-users. The market's intricate structure inherently reflects the highly specialized nature of seed processing, where the optimal choice of cracking equipment is profoundly dependent on the specific type of seed to be processed, the desired characteristics of the final output, and the sheer scale of the operation. This ranges from compact machines for small-scale agricultural cooperatives or artisan producers to vast, integrated systems for multi-national industrial processing plants, each requiring tailored solutions that maximize efficiency and product integrity.

- By Type:

- Roller Cracker: These machines remain dominant in the market due to their exceptional versatility and ability to perform a gentle yet effective cracking of a wide variety of oilseeds, including soybeans, sunflower seeds, and rapeseeds, minimizing kernel damage.

- Hammer Mill: Primarily utilized for seeds requiring a more aggressive breaking action or for the initial preparation of raw materials intended for comprehensive animal feed formulations, where a coarser grind is acceptable or desired.

- Impact Cracker: Ideal for processing hard-shelled seeds or when a very fine, uniform particle size is specifically required. These crackers employ high-speed impact forces for efficient disintegration, often used for specialized applications.

- Disk Cracker: Employed for specific seed types where a controlled shearing action is preferred over crushing or impact. This method is often chosen to minimize oil loss and the generation of undesirable fines, preserving material integrity.

- By Capacity:

- Small Scale (up to 5 TPH): These units are typically suitable for small and medium-sized enterprises (SMEs), local agricultural cooperatives, or highly specialized processing operations that do not require high throughput.

- Medium Scale (5-20 TPH): Caters to mid-sized processing plants with moderate production volumes, offering a balance between capital investment and operational output, commonly found in regional processing centers.

- Large Scale (above 20 TPH): Designed for high-volume industrial oil mills, major animal feed production facilities, and large-scale biofuel plants that demand maximum throughput and continuous operation to meet global supply chains.

- By Application:

- Edible Oil Production: Constitutes the largest and most critical application segment, directly preparing various oilseeds for the subsequent extraction of oils consumed globally for food and culinary purposes.

- Animal Feed Production: Seeds are cracked and processed to significantly improve their digestibility and enhance nutrient absorption rates for various types of livestock, contributing to animal health and productivity.

- Biofuel Production: Represents an essential initial step in the processing chain for oilseeds, converting biomass into renewable energy sources like biodiesel, aligning with global efforts for sustainable energy.

- Other Industrial Applications: Includes specialized processing for diverse uses such as industrial lubricants, cosmetic formulations, pharmaceutical ingredients, and the production of highly specialized food ingredients.

- By Operational Mode:

- Manual: Predominantly limited to very small-scale operations, specific laboratory research, or artisan production. Its industrial application is significantly declining due to efficiency and labor cost considerations.

- Semi-automatic: Offers a strategic balance of automation and human control, commonly found in medium-sized processing plants where some degree of human oversight and intervention is still desired or necessary.

- Automatic: Predominant in large industrial facilities, offering unparalleled high throughput, minimal human intervention, precise control, and highly consistent processing quality, leading to optimal operational efficiency and safety.

Value Chain Analysis For Seed Cracker Market

The value chain for the Seed Cracker Market is a sophisticated and highly interconnected network of activities, each strategically designed to progressively add value to the product from its initial conceptualization and design phase through to its final deployment, ongoing operation, and comprehensive after-sales support. Upstream analysis, the foundational segment of this chain, meticulously examines the sourcing of essential raw materials. These primarily include a diverse range of metals, such as high-grade steel, specialized alloys crucial for rollers and wear-resistant components, and various electronic components integral for sophisticated control systems and automation. Auxiliary materials, including polymers and industrial coatings, also play a significant role. Key suppliers operating within this upstream stage frequently possess considerable bargaining power, particularly for highly specialized components that demand exceptional precision, durability, and compliance with stringent industrial standards. Furthermore, intensive research and development (R&D) activities, synergistically coupled with innovative design engineering, form the intellectual bedrock of this segment. These activities are paramount in dictating the ultimate efficiency, maximum operational capacity, and overall technological sophistication of the final seed cracking machinery. Manufacturers often strategically engage in vertical integration or forge robust, long-term partnerships with critical material suppliers. This approach is designed to ensure the consistent quality of incoming materials, achieve optimal cost-effectiveness, and critically mitigate risks associated with potential supply chain disruptions and the inherent volatility of commodity prices, thereby safeguarding production continuity and market stability.

The manufacturing stage constitutes the pivotal core of the entire value chain, where all these meticulously sourced raw materials and intricate components are expertly assembled and integrated into finished, fully functional seed cracking machines. This stage encompasses highly complex fabrication processes, ultra-precision machining, and an array of rigorous quality control checks implemented at every step to ensure that the resultant machines not only meet but often exceed demanding performance standards, comply with stringent international safety regulations, and precisely align with specific customer specifications. Manufacturers typically invest substantial capital into developing and maintaining advanced production facilities, employing a highly skilled labor force, and integrating cutting-edge automation technologies. These investments are crucial for achieving economies of scale, maintaining competitive pricing strategies, and ensuring consistent product quality across various production batches. Following the completion of the manufacturing process, the strategic focus seamlessly transitions to downstream activities. These encompass a broad spectrum of critical functions, including efficient distribution logistics, effective sales and marketing initiatives, professional machine installation, and comprehensive, ongoing after-sales services. The efficacy and reach of the distribution channels are of paramount importance for broad market penetration, ensuring that seed cracking machines are delivered efficiently and reliably to a diverse array of end-users spread across varied geographical locations and operational environments. Sales strategies are often dual-faceted, involving direct engagement and negotiation with large industrial clients for bespoke solutions, or collaborating extensively with a robust network of authorized distributors and specialized agents to cater effectively to the needs of smaller and medium-sized enterprises (SMEs).

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.2 Billion |

| Market Forecast in 2032 | USD 1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CPM Roskamp, Buhler AG, IDAH, T.P.I. Food Processing Equipment, Anderson International Corp, Shanghai Sanhe Mechanical Equipment Co Ltd, Henan Kingman M E Complete Plant Co Ltd, Shandong Leader Machinery Co Ltd, AGICO Group, Zhengzhou Yize Machinery Co Ltd, Myande Group, F. H. SCHULE Muehlenbau GmbH, Zhengzhou Amisy Trading Co Ltd, Jiangsu Muyang Group Co Ltd, Jiangsu Fuyang Machinery Co Ltd, Mianyang Huahui Machinery Co Ltd, Rajkumar Agro Machinex Pvt Ltd, Kiron Food Processing Technologies, Seedburo Equipment Company, Alvan Blanch Development Co Ltd |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Seed Cracker Market Key Technology Landscape

The pervasive deployment of cutting-edge sensor technologies and the strategic integration of the Internet of Things (IoT) are increasingly transforming seed cracking operations by enabling the systematic collection of vital operational data. Integrated sensors meticulously monitor a comprehensive range of parameters, including critical factors such as vibration levels, internal temperatures, material flow rates, and precise roller gap measurements. This rich stream of data provides operators with instantaneous, real-time insights into every aspect of machine performance, moving beyond mere observation to proactive management. This data, when subjected to advanced analytical techniques, can be leveraged to meticulously optimize throughput, accurately identify potential bottlenecks in the processing line, and inform the creation of highly efficient, predictive maintenance schedules. This foresight is invaluable in preventing costly, unscheduled breakdowns and extending the effective operational life of the machinery. Furthermore, the incorporation of advanced, energy-efficient motor technologies, frequently utilizing Variable Frequency Drives (VFDs), facilitates incredibly precise control of motor speed and power consumption. This innovation demonstrably reduces electricity usage, leading to significant reductions in operational costs and contributing positively to the overall environmental footprint of the processing facility. Addressing growing environmental and occupational health concerns, state-of-the-art noise and dust reduction technologies are also becoming standard features in modern seed crackers. These systems are designed to minimize airborne particulate matter and significantly reduce sound levels within processing facilities, improving working conditions and ensuring compliance with increasingly stringent regulatory standards.

The future technological landscape for the Seed Cracker Market is poised for an even deeper and more transformative integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms for advanced process optimization. AI is expected to move beyond current capabilities, developing algorithms that can accurately predict optimal cracking parameters based on a sophisticated analysis of vast historical data combined with real-time sensor inputs. This will allow for dynamic adaptation to subtle changes in seed characteristics or fluctuating environmental conditions, ensuring peak performance at all times. This includes highly advanced predictive maintenance capabilities that will not only flag potential equipment failures far in advance but also intelligently suggest optimal, data-driven maintenance schedules, thereby further minimizing downtime and dramatically extending the operational life of the machinery. Furthermore, augmented reality (AR) and virtual reality (VR) technologies are anticipated to be increasingly utilized for immersive training programs, precise maintenance guidance, and efficient remote diagnostics, providing technicians with interactive, real-time assistance and troubleshooting capabilities. The unwavering emphasis will continue to be on developing highly intelligent, self-optimizing, and fundamentally sustainable seed cracking solutions. These future machines will offer unparalleled levels of efficiency, generate minimal waste, and deliver robust, consistent performance, thereby profoundly supporting the evolving and increasingly complex demands of the global agricultural and industrial processing sectors. This visionary technological trajectory promises a future of greater productivity, enhanced sustainability, and superior product quality across the entire value chain.

Regional Highlights

- Asia Pacific: The Asia Pacific region unequivocally stands as the largest and most rapidly expanding market for seed crackers globally. This remarkable growth is predominantly fueled by the region's vast agricultural sectors in economically dynamic countries such as China, India, Indonesia, and Malaysia, which are significant global producers of key oilseeds like soybeans, palm kernels, and rapeseeds. The converging forces of a continuously increasing population, rising disposable incomes, and accelerated urbanization within these nations have collectively propelled a substantial surge in the demand for both edible oils and protein-rich animal feed. Consequently, monumental investments are being channeled into the modernization and strategic expansion of existing food processing infrastructure throughout the region, thereby driving the widespread adoption of high-capacity, energy-efficient, and technologically advanced seed cracking machinery. An emerging trend is the strong presence and growth of local manufacturers, who contribute significantly to competitive pricing and foster technological innovation precisely tailored to meet specific regional requirements and operational contexts. Concurrently, major international players are actively seeking strategic partnerships and collaborations to effectively penetrate and capitalize on the immense potential of this lucrative market, underscoring its pivotal global importance.

- North America: North America represents a mature yet highly dynamic and profoundly innovative market for seed crackers. It is distinctively characterized by an unwavering emphasis on advanced automation, achieving exceptional efficiency, and integrating cutting-edge processing technologies. The United States and Canada, being formidable global leaders in agricultural production, particularly for soybeans and corn, serve as the primary drivers of demand for sophisticated and high-performance equipment. Processors within this technologically advanced region consistently prioritize machinery that offers consistently high throughput, demonstrably minimal operational costs, and scrupulous compliance with stringent environmental protection and occupational safety regulations. The market dynamics here are also significantly influenced by a strong regional focus on developing and implementing sustainable processing methods and the accelerating integration of smart technologies, including IoT and AI, for advanced predictive maintenance and real-time process optimization. Investments are typically directed towards strategically upgrading existing facilities with state-of-the-art equipment to maintain and further solidify a competitive edge in a highly competitive global market, reflecting a continuous drive towards technological superiority.

- Europe: Europe stands as another critically important market for seed crackers, renowned for its exceptionally stringent quality standards, robust environmental regulations, and a distinct regional preference for technologically advanced and highly energy-efficient processing solutions. Key countries like Germany, France, and the Netherlands are consistently at the forefront of adopting and pioneering innovative seed cracking technologies, largely driven by a profound and pervasive regional focus on sustainable agriculture, stringent food safety protocols, and circular economy principles. The sustained demand for high-quality edible oils, coupled with a growing market for specialized animal feed, and an increasing strategic interest in biofuel production, collectively underpins and supports the robust market growth. European manufacturers are globally recognized for their unparalleled precision engineering and the production of exceptionally durable machinery, often leading international efforts in the development of sophisticated automated systems that meticulously optimize resource utilization and significantly reduce environmental emissions. The market also significantly benefits from supportive governmental policies and substantial funding initiatives aimed at promoting green technologies and fostering innovation within the agricultural processing sector.

- Latin America: The Latin American market for seed crackers is currently experiencing a period of significant and accelerated growth, fundamentally attributed to the region's rapidly expanding agricultural sector and its progressively sophisticated processing capabilities. Countries such as Brazil and Argentina are formidable global leaders in the production of key oilseeds like soybeans and sunflower, leading to a substantial and burgeoning domestic demand for efficient and high-capacity seed processing equipment. The ongoing regional industrialization efforts and strategic initiatives to add greater value to agricultural exports are powerfully driving investments in modern, large-scale oilseed crushing plants and advanced animal feed production facilities. While the imperative of cost-effectiveness remains a crucial purchasing factor for many regional players, there is a clear and accelerating trend towards adopting semi-automatic and fully automatic machines. This transition is driven by the desire to substantially improve operational efficiency, enhance processing scale, and achieve greater consistency in output. The region offers considerable and largely untapped potential for further market expansion as its agricultural output and processing capabilities continue to grow and diversify, positioning it as a key area for future investment and development.

- Middle East and Africa (MEA): The MEA region is emerging as a dynamic and increasingly important market for seed crackers, primarily characterized by growing strategic investments in comprehensive agricultural development and the rapid build-out of modern food processing infrastructure. These initiatives are designed to critically enhance local food security and reduce the region's historical reliance on external food imports. Key countries like Saudi Arabia, the UAE, South Africa, and Egypt are actively witnessing concerted efforts to establish or significantly expand robust domestic oilseed crushing and animal feed industries. While the market within the MEA region is still in its relatively nascent stages compared to more mature global counterparts, increasing governmental initiatives aimed at boosting local agricultural production and fostering industrialization are demonstrably creating substantial new opportunities for market players. Challenges, however, persist, including varying technological disparities across countries, the need for cost-effective and highly adaptable solutions meticulously tailored to specific regional climatic and operational conditions, and the development of local technical expertise. Despite these hurdles, the long-term growth potential for the MEA market remains significantly robust, as the region actively strives for greater self-sufficiency and resilience in its food production and processing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Seed Cracker Market.- CPM Roskamp

- Buhler AG

- IDAH

- T.P.I. Food Processing Equipment

- Anderson International Corp

- Shanghai Sanhe Mechanical Equipment Co Ltd

- Henan Kingman M E Complete Plant Co Ltd

- Shandong Leader Machinery Co Ltd

- AGICO Group

- Zhengzhou Yize Machinery Co Ltd

- Myande Group

- F. H. SCHULE Muehlenbau GmbH

- Zhengzhou Amisy Trading Co Ltd

- Jiangsu Muyang Group Co Ltd

- Jiangsu Fuyang Machinery Co Ltd

- Mianyang Huahui Machinery Co Ltd

- Rajkumar Agro Machinex Pvt Ltd

- Kiron Food Processing Technologies

- Seedburo Equipment Company

- Alvan Blanch Development Co Ltd

Frequently Asked Questions

What is the projected growth rate for the Seed Cracker Market?

The Seed Cracker Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. This steady expansion is primarily driven by escalating global demand for processed seeds across key industries like edible oils and animal feed, coupled with continuous technological advancements aimed at optimizing processing efficiency and yield.

What are the primary applications of seed cracker machines?

The primary applications of seed cracker machines are diverse and critical to several industries. They are predominantly utilized in large-scale edible oil production, processing a wide variety of oilseeds for extraction. Additionally, they are essential for the preparation of animal feed, where cracking seeds enhances nutrient digestibility for livestock. A growing application also includes the initial processing steps for biofuel manufacturing from various oil-rich crops, supporting renewable energy initiatives.

How do technological advancements influence the Seed Cracker Market?

Technological advancements profoundly influence the Seed Cracker Market by integrating automation, introducing precision roller designs, and deploying IoT and AI for real-time data analysis. These innovations significantly enhance operational efficiency, increase overall yield, reduce energy consumption and operational costs, and improve the consistency and quality of cracked seeds, thereby driving market growth and fostering intense competitiveness among manufacturers.

What are the main challenges faced by manufacturers in this market?

Manufacturers in the Seed Cracker Market confront several significant challenges. These include the high initial capital investment required for acquiring and installing advanced machinery, the recurring and substantial maintenance and operational costs, the inherent volatility and unpredictable fluctuations in raw material prices, and the imperative to comply with increasingly stringent global environmental and occupational safety regulations, which often necessitate costly upgrades and compliance measures.

Which geographical region leads the Seed Cracker Market?

The Asia Pacific region currently holds the largest market share in the Seed Cracker Market and is simultaneously anticipated to exhibit the fastest growth over the forecast period. This dominance is primarily attributable to the region's extensive agricultural base, its vast population, and substantial, ongoing investments in modernizing and expanding its food and animal feed processing infrastructure, particularly in countries like China, India, and Indonesia.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager