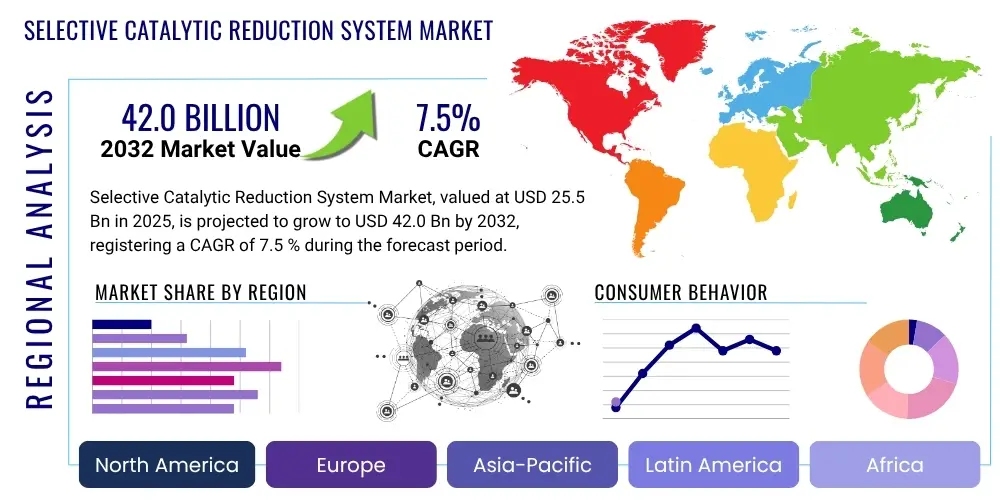

Selective Catalytic Reduction System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427942 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Selective Catalytic Reduction System Market Size

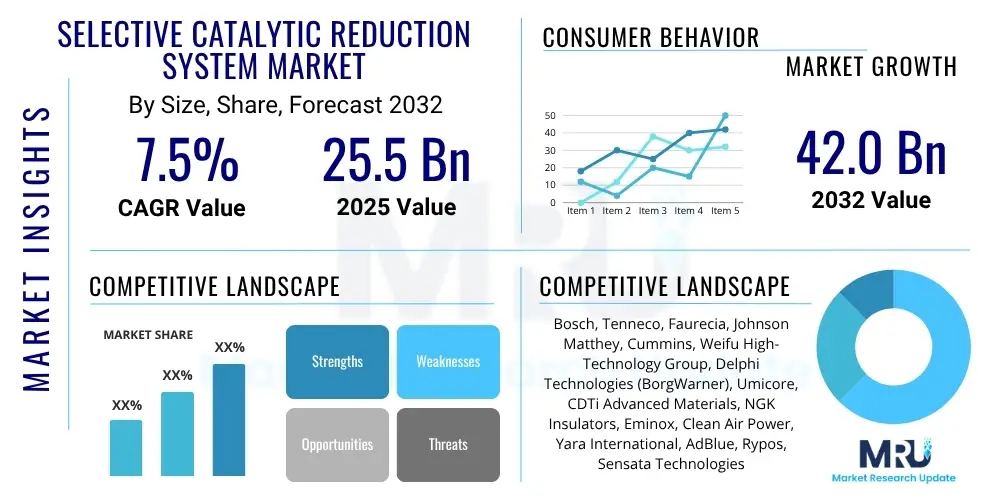

The Selective Catalytic Reduction System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 25.5 Billion in 2025 and is projected to reach USD 42.0 Billion by the end of the forecast period in 2032. This growth is underpinned by increasing global environmental consciousness, stringent regulatory frameworks targeting vehicular and industrial emissions, and technological advancements enhancing system efficiency and cost-effectiveness. The expansion of automotive manufacturing, particularly in developing economies, further contributes significantly to this upward trajectory, creating a robust demand for effective emission control solutions.

Selective Catalytic Reduction System Market introduction

The Selective Catalytic Reduction (SCR) system market plays a pivotal role in mitigating harmful nitrogen oxide (NOx) emissions from diesel engines and various industrial applications. These systems chemically convert NOx into benign nitrogen and water vapor, employing a reducing agent, typically Diesel Exhaust Fluid (DEF) which is a urea-water solution. The core components include a DEF tank, a dosing unit, an injector, a dedicated SCR catalyst, and a sophisticated control unit, all working in concert to optimize the reduction process based on engine operating conditions and exhaust gas temperatures.

Major applications for SCR technology span across a wide spectrum of industries and vehicle types. In the automotive sector, SCR systems are predominantly found in heavy-duty commercial vehicles, passenger cars, light commercial vehicles, and buses, enabling compliance with Euro VI, EPA, and other regional emission standards. Beyond road transport, SCR is critical in off-road machinery such as construction and agricultural equipment, marine vessels, and stationary industrial engines like power generators and cement kilns. The versatility and proven effectiveness of SCR technology make it an indispensable solution for modern emission control.

The primary benefits of SCR systems include a significant reduction in NOx emissions, often achieving efficiency rates of over 90%, thereby improving air quality and reducing the environmental footprint of diesel engines. Furthermore, SCR allows for engine optimization for fuel efficiency, as designers are less constrained by internal engine NOx reduction measures that can compromise performance. Driving factors for market growth include escalating global emission regulations, the robust expansion of the commercial vehicle fleet, increasing industrialization in emerging markets, and continuous technological advancements aimed at improving system reliability and reducing operating costs for end-users, alongside a growing awareness regarding the adverse health impacts of air pollution.

Selective Catalytic Reduction System Market Executive Summary

The Selective Catalytic Reduction System Market is characterized by dynamic business trends driven by global regulatory pressures and technological innovation. Manufacturers are increasingly focusing on integrated solutions that combine SCR with other exhaust after-treatment technologies, such as Diesel Particulate Filters (DPF), to meet ultra-low emission targets. There is a notable trend towards lightweight and compact SCR designs, crucial for passenger car applications where space is at a premium, alongside the development of advanced control algorithms that enhance dosing precision and system efficiency under diverse operating conditions. Furthermore, strategic collaborations and mergers among component suppliers and system integrators are shaping the competitive landscape, aiming to offer comprehensive, turn-key solutions to original equipment manufacturers (OEMs) and aftermarket clients.

Regionally, Europe and North America have historically led the adoption of SCR technology due to early and stringent emission mandates. However, the Asia Pacific region, particularly China and India, is emerging as the fastest-growing market, propelled by escalating air pollution concerns, rapidly implementing emission standards, and substantial growth in their respective automotive and industrial sectors. Latin America, the Middle East, and Africa are also expected to demonstrate steady growth as regulatory frameworks mature and infrastructure for DEF supply becomes more widespread. Each region presents unique challenges and opportunities, influencing market strategies for global players.

Segmentation trends indicate robust growth across various application areas. While on-road commercial vehicles remain the largest segment, significant expansion is anticipated in off-road machinery and marine applications, driven by sector-specific emission regulations. The passenger car segment is also gaining traction, particularly with advanced diesel vehicles, although electrification trends pose a long-term challenge. By component, the SCR catalyst and DEF dosing systems are critical revenue generators, continuously undergoing innovation for improved performance and durability. The market is also seeing diversification by fuel type, with SCR systems being adapted for applications beyond traditional diesel engines, though diesel remains dominant.

AI Impact Analysis on Selective Catalytic Reduction System Market

Common user questions regarding AI's impact on the Selective Catalytic Reduction System Market often revolve around how artificial intelligence can enhance efficiency, reduce operational costs, and improve the predictive capabilities of these complex systems. Users are keen to understand if AI can optimize DEF consumption, predict component failures before they occur, or adapt SCR performance to real-time environmental conditions and fuel quality variations. There is also significant interest in AI's role in making SCR systems more autonomous, reducing the need for constant manual intervention, and providing more precise diagnostics for maintenance, thereby extending the lifespan and reliability of emission control technologies.

Another area of user inquiry focuses on how AI might integrate with existing vehicle or industrial control systems to create a more holistic approach to emission management, moving beyond just NOx reduction to overall exhaust gas optimization. Concerns also include the data privacy implications of collecting vast amounts of operational data for AI analysis, the cybersecurity risks associated with connected SCR systems, and the potential for job displacement in maintenance and operational roles due to increased automation. Users expect AI to deliver smarter, more responsive, and environmentally superior emission control while maintaining economic viability for operators and fleet managers. The expectation is for AI to transform SCR from a reactive system to a proactive and self-optimizing one, capable of learning and adapting.

- AI-driven Predictive Maintenance: Enables forecasting of SCR component wear and failure, optimizing maintenance schedules and reducing downtime.

- Optimized DEF Dosing Strategies: Utilizes machine learning to fine-time DEF injection based on real-time engine load, exhaust gas temperature, and ambient conditions, minimizing consumption and improving NOx conversion efficiency.

- Enhanced System Diagnostics: AI algorithms can analyze sensor data for anomalies, providing more accurate and faster fault detection and troubleshooting.

- Adaptive Emission Control: Allows SCR systems to dynamically adjust performance to varying fuel qualities, driving patterns, and environmental regulations in different geographical areas.

- Improved Fuel Efficiency: By optimizing NOx reduction externally, AI can allow engines to operate at more fuel-efficient settings internally without compromising emission compliance.

- Autonomous Operation: Contributes to the development of self-regulating SCR systems that learn and adapt without constant human oversight.

- Data Integration and Analytics: Facilitates the integration of SCR performance data with broader fleet management or industrial process control systems for holistic operational insights.

DRO & Impact Forces Of Selective Catalytic Reduction System Market

The Selective Catalytic Reduction System Market is primarily driven by increasingly stringent global emission regulations, such as Euro VII, EPA Tier 4, and China VI, which mandate significant reductions in nitrogen oxide (NOx) emissions from on-road, off-road, and marine applications. This regulatory push compels original equipment manufacturers (OEMs) across the automotive, construction, agriculture, and power generation sectors to integrate advanced SCR systems into their products. The growing global demand for commercial vehicles, particularly in emerging economies undergoing rapid industrialization and urbanization, further fuels market expansion as these vehicles are major adopters of SCR technology. Additionally, heightened public awareness regarding air quality and the health impacts of pollution creates consumer and policy pressure for cleaner technologies, reinforcing the market's growth trajectory. Advancements in SCR technology, leading to improved efficiency, durability, and reduced operating costs, also act as a significant driver, making these systems more attractive to end-users.

However, several restraints pose challenges to market growth. The high initial cost of SCR systems, including the complex hardware and associated installation expenses, can be a barrier for some buyers, especially in cost-sensitive markets or for smaller fleets. The continuous requirement for Diesel Exhaust Fluid (DEF) and the necessary infrastructure for its distribution and storage add to the operational complexity and cost, which can deter adoption. Fluctuations in raw material prices, particularly for platinum group metals (PGMs) used in catalysts, introduce cost volatility for manufacturers. Furthermore, issues such as DEF quality variations, DEF freezing in cold climates, and potential tampering with emission control systems to avoid DEF consumption can undermine system effectiveness and market confidence. The emergence of alternative powertrain technologies, such as electric vehicles and hydrogen fuel cell vehicles, presents a long-term restraint, potentially reducing the demand for internal combustion engine after-treatment systems over time, though this impact is more gradual for heavy-duty applications.

Despite the restraints, significant opportunities exist for market participants. The expanding application of SCR technology into new segments, such as marine engines, stationary power generation, and small off-road equipment, opens new revenue streams beyond traditional automotive uses. Continued innovation in catalyst materials, dosing strategies, and DEF solutions promises to enhance system efficiency, reduce PGM loading, and lower overall cost of ownership, making SCR more competitive and widely adoptable. The development of compact and integrated SCR-DPF systems offers opportunities for improved packaging and performance, especially for space-constrained applications. Furthermore, the growth of the aftermarket for SCR components and DEF refills, driven by the expanding installed base of SCR-equipped vehicles, presents a lucrative segment. Strategic partnerships between technology providers, vehicle manufacturers, and DEF suppliers can streamline the supply chain and expand market reach, capitalizing on the increasing global emphasis on sustainable environmental practices and strict emission compliance.

Segmentation Analysis

The Selective Catalytic Reduction System Market is extensively segmented to reflect the diverse applications and technological nuances inherent in emission control. This segmentation allows for a granular understanding of market dynamics, growth drivers, and competitive landscapes across different product categories and end-use industries. Key segmentations include analysis by component, application, vehicle type, and fuel type, each revealing distinct market behaviors and opportunities. Understanding these segments is crucial for stakeholders to develop targeted strategies, optimize product offerings, and capitalize on specific market trends. The primary aim of this comprehensive segmentation is to dissect the market into manageable parts, providing a clearer picture of its structure and potential.

- By Component:

- Urea Tank: Stores Diesel Exhaust Fluid (DEF).

- Urea Pump: Doses DEF from the tank to the injector.

- SCR Catalyst: Facilitates the chemical reaction to convert NOx.

- Diesel Exhaust Fluid (DEF) Injector: Sprays DEF into the exhaust stream.

- Sensors: Monitor exhaust gas temperature, NOx levels, and DEF levels.

- Control Units: Manage system operation, dosing, and diagnostics.

- By Application:

- On-Road Vehicles: Passenger Cars, Commercial Vehicles (Light and Heavy-Duty).

- Off-Road Vehicles: Construction Equipment, Agricultural Machinery, Mining Equipment.

- Marine: Commercial Ships, Ferries, Yachts.

- Industrial: Power Plants, Stationary Engines, Cement Kilns, Glass Furnaces.

- By Vehicle Type:

- Passenger Cars: Diesel sedans, SUVs, hatchbacks.

- Light Commercial Vehicles (LCV): Vans, pick-up trucks.

- Heavy Commercial Vehicles (HCV): Trucks, lorries.

- Buses: City buses, coaches.

- By Fuel Type:

- Diesel: Predominant fuel type utilizing SCR.

- Other Fuels: Emerging applications with natural gas engines or hybrid powertrains adapted with SCR.

Value Chain Analysis For Selective Catalytic Reduction System Market

The value chain for the Selective Catalytic Reduction System Market begins with the upstream activities involving the sourcing and processing of raw materials. This includes the extraction and refining of base metals like vanadium, titanium, and tungsten for catalyst production, as well as the specialized production of urea for Diesel Exhaust Fluid (DEF). Manufacturers of electronic components, sensors, and pumps also form a crucial part of the upstream segment, supplying highly specialized parts. Research and development activities, focusing on new catalyst formulations, advanced dosing technologies, and more robust system architectures, are integral to this stage, driving innovation and cost efficiencies within the supply chain. These raw material and component suppliers form the foundational layer, providing the necessary inputs for system fabrication.

Moving downstream, the value chain encompasses the manufacturing and assembly of complete SCR systems. This stage involves sophisticated engineering and precision manufacturing to integrate various components like the urea tank, dosing module, injector, and catalyst housing. System integrators and Tier 1 suppliers play a critical role in assembling these complex modules and ensuring their compatibility and optimal performance with different engine types and vehicle platforms. Direct distribution channels predominantly involve sales and supply agreements with Original Equipment Manufacturers (OEMs) in the automotive, construction, agriculture, and marine sectors. These OEMs then integrate the SCR systems into their final products, which are subsequently sold to end-users such through their established dealer networks.

Indirect distribution channels are also vital, particularly for the aftermarket segment, which includes replacement parts and DEF refills. This involves a network of independent distributors, wholesalers, and retailers who supply SCR components and DEF to repair shops, service centers, and directly to fleet operators for maintenance and operational needs. The growth of the installed base of SCR-equipped vehicles and machinery directly supports the aftermarket's expansion, creating opportunities for a broader range of participants in the value chain. After-sales services, including diagnostics, repairs, and technical support, are also critical, delivered by both OEMs and specialized service providers, enhancing customer satisfaction and system longevity throughout the product lifecycle.

Selective Catalytic Reduction System Market Potential Customers

Potential customers for Selective Catalytic Reduction (SCR) systems are diverse and span across multiple industries, primarily driven by the imperative to comply with stringent emission regulations and a growing commitment to environmental stewardship. The largest segment of end-users are vehicle manufacturers, encompassing producers of heavy-duty commercial vehicles, light commercial vehicles, passenger cars, and buses. These OEMs integrate SCR systems as standard equipment into their diesel-powered offerings to meet current and future emission standards, making them primary direct customers of SCR system suppliers. As global automotive production continues to grow, especially in emerging markets with escalating environmental concerns, this customer base expands proportionally, creating sustained demand for advanced emission control technologies.

Beyond the automotive sector, a significant customer base exists within the off-road equipment industry. This includes manufacturers of construction machinery such as excavators, loaders, and bulldozers, as well as agricultural machinery like tractors and combine harvesters. Marine vessel builders, ranging from large commercial ships and cargo vessels to smaller ferries and pleasure crafts, also constitute a vital customer segment, driven by international maritime emission regulations. In the industrial sector, operators of stationary diesel engines for power generation, combined heat and power (CHP) plants, cement kilns, glass furnaces, and other industrial processes that emit significant NOx are increasingly adopting SCR technology to comply with air quality permits and contribute to cleaner industrial operations.

Furthermore, fleet operators and logistics companies represent a substantial indirect customer segment, as they are the ultimate end-users and buyers of SCR-equipped vehicles. Their decisions are influenced by operating costs, fuel efficiency, and compliance with fleet-specific environmental mandates. The aftermarket segment caters to these operators and individual vehicle owners who require replacement parts, maintenance services, and continuous supply of Diesel Exhaust Fluid (DEF). This diverse array of end-users and buyers, from large global corporations to individual vehicle owners, underscores the broad applicability and enduring demand for SCR systems across a global landscape striving for reduced environmental impact.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 25.5 Billion |

| Market Forecast in 2032 | USD 42.0 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch, Tenneco, Faurecia, Johnson Matthey, Cummins, Weifu High-Technology Group, Delphi Technologies (BorgWarner), Umicore, CDTi Advanced Materials, NGK Insulators, Eminox, Clean Air Power, Yara International, AdBlue, Rypos, Sensata Technologies, Grundfos, Hitachi Astemo, Katcon, Corning Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Selective Catalytic Reduction System Market Key Technology Landscape

The Selective Catalytic Reduction System market is characterized by a dynamic and continuously evolving technology landscape, with ongoing advancements focused on improving efficiency, durability, and integration. A core technological area involves the development of novel catalyst materials. While vanadium-based catalysts have been traditionally used, there's a growing trend towards copper-zeolite and iron-zeolite catalysts, especially for mobile applications, due to their superior low-temperature NOx conversion efficiency and enhanced hydrothermal stability. Research is also being conducted on non-PGM (platinum group metal) catalysts to reduce cost and dependence on precious metals, while maintaining robust performance. These catalyst innovations are crucial for meeting increasingly stringent emission standards that demand higher performance under various operating conditions, including cold starts and urban driving cycles.

Another significant technological advancement lies in the precision and integration of Diesel Exhaust Fluid (DEF) dosing systems. Modern SCR systems employ highly sophisticated dosing modules that precisely control the amount of urea injected into the exhaust stream, optimizing NOx conversion while minimizing DEF consumption. This involves advanced electronic control units (ECUs) with complex algorithms that analyze multiple engine and exhaust parameters in real-time, such as exhaust gas temperature, NOx sensor readings, and engine load. Innovations in injector design, including airless dosing systems and improved atomization techniques, are also enhancing DEF distribution and reducing the risk of deposits in the exhaust system. These developments contribute to overall system reliability and reduce the total cost of ownership for end-users.

Furthermore, the integration of SCR with other exhaust after-treatment technologies, such as Diesel Particulate Filters (DPF) and Diesel Oxidation Catalysts (DOC), represents a key technological frontier. Hybrid systems, like SCR-on-Filter (SCRoF) or close-coupled SCR units, aim to achieve higher overall emission reduction in a more compact package, which is particularly beneficial for space-constrained applications like passenger cars and light commercial vehicles. Advancements in sensor technology, including more accurate and durable NOx sensors and ammonia slip sensors, are vital for closed-loop control and monitoring system performance. The development of intelligent diagnostic systems, often leveraging AI and machine learning, is also becoming prevalent, allowing for predictive maintenance and real-time performance optimization, thus ensuring long-term compliance and operational efficiency of SCR systems.

Regional Highlights

- North America: This region is a mature market driven by stringent EPA (Environmental Protection Agency) regulations for on-road and off-road diesel engines. The focus is on heavy-duty commercial vehicles and the expanding off-road machinery sector. Innovations in DEF supply infrastructure and advancements in cold-weather performance are key areas of development. The market benefits from a strong manufacturing base and a high adoption rate of advanced emission control technologies.

- Europe: Europe stands as a pioneering market for SCR technology, propelled by the successive implementation of Euro emission standards (currently Euro VI and moving towards Euro VII). The region showcases high penetration in both commercial vehicles and diesel passenger cars. Emphasis is placed on compact system designs, PGM reduction in catalysts, and the integration of SCR with DPF to meet stringent urban air quality targets. Robust environmental policies and a mature automotive industry continue to drive innovation.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven primarily by China and India, which are rapidly adopting and enforcing stringent emission standards (e.g., China VI, Bharat Stage VI). Rapid industrialization, increasing vehicle production, and escalating air pollution concerns are key growth factors. The market here is characterized by a high volume demand, with a focus on cost-effective solutions and localized manufacturing capabilities to serve the vast automotive and industrial base.

- Latin America: This region is experiencing steady growth, with countries like Brazil and Mexico progressively implementing stricter emission regulations, aligning with global standards. The market is primarily influenced by the commercial vehicle sector and gradually expanding to off-road applications. Infrastructure development for DEF supply and local production capabilities are important considerations for market expansion.

- Middle East and Africa (MEA): Growth in MEA is more nascent but picking up pace, particularly in economies with significant industrial development and increasing automotive fleet sizes. The adoption of SCR systems is often tied to imported vehicle standards and evolving local regulatory frameworks. Opportunities exist in heavy commercial vehicles and industrial applications, though challenges include varying fuel quality and the need for robust, durable systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Selective Catalytic Reduction System Market.- Bosch

- Tenneco

- Faurecia

- Johnson Matthey

- Cummins

- Weifu High-Technology Group

- Delphi Technologies (BorgWarner)

- Umicore

- CDTi Advanced Materials

- NGK Insulators

- Eminox

- Clean Air Power

- Yara International

- AdBlue

- Rypos

- Sensata Technologies

- Grundfos

- Hitachi Astemo

- Katcon

- Corning Inc.

Frequently Asked Questions

What is Selective Catalytic Reduction (SCR) and how does it work?

Selective Catalytic Reduction (SCR) is an advanced active emissions control technology that injects a liquid-reductant agent, typically Diesel Exhaust Fluid (DEF), through a special catalyst into the exhaust stream of a diesel engine. The DEF initiates a chemical reaction that converts harmful nitrogen oxides (NOx) into harmless diatomic nitrogen (N2) and water (H2O), significantly reducing atmospheric pollution. This process occurs in the exhaust system after the engine, allowing the engine to be optimized for fuel efficiency.

Why are SCR systems becoming increasingly important for commercial vehicles and off-road machinery?

SCR systems are increasingly crucial for commercial vehicles and off-road machinery due to stringent global emission regulations, such as Euro VI and EPA Tier 4 standards, which mandate significant reductions in nitrogen oxide (NOx) emissions. These systems enable compliance while allowing engines to be tuned for optimal fuel efficiency and power output, offering a cost-effective and environmentally responsible solution for heavy-duty applications that operate for extended periods and are major contributors to air pollution.

What are the primary components of an SCR system?

The primary components of an SCR system include a Diesel Exhaust Fluid (DEF) tank for storing the reductant, a DEF dosing unit (pump) to deliver the fluid, an injector to spray DEF into the exhaust stream, an SCR catalyst where the chemical conversion takes place, and various sensors (NOx, temperature, ammonia slip) and a control unit (ECU) to monitor and manage the entire process, ensuring optimal performance and emission compliance.

How does the availability and cost of Diesel Exhaust Fluid (DEF) impact the SCR market?

The availability and cost of Diesel Exhaust Fluid (DEF) are critical factors impacting the SCR market. Widespread and accessible DEF distribution networks are essential for vehicle operators to ensure continuous system operation and regulatory compliance. High DEF costs can increase operational expenses for end-users, potentially hindering adoption, while stable pricing and readily available supply can significantly boost market confidence and growth. Innovations in DEF production and supply chain optimization are crucial for the market's sustained expansion.

What is the long-term outlook for the SCR market considering the rise of electric vehicles (EVs)?

While the rise of electric vehicles (EVs) is a long-term trend, the Selective Catalytic Reduction (SCR) market is expected to maintain robust growth, particularly for heavy-duty commercial vehicles, off-road machinery, marine, and industrial applications. These sectors are harder to electrify due to power, range, and operational demands. SCR will remain critical for new diesel engine production in these segments, driven by persistent emission regulations and the need for fuel-efficient, compliant internal combustion engines for decades to come, ensuring a sustained market presence.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager