Semi-Rigid Spray Polyurethane Foam Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431129 | Date : Nov, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Semi-Rigid Spray Polyurethane Foam Market Size

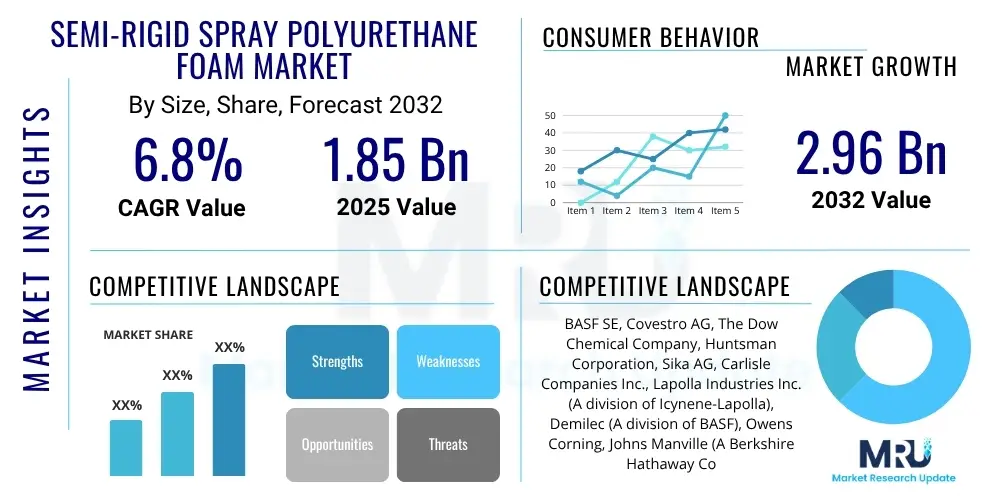

The Semi-Rigid Spray Polyurethane Foam Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.85 Billion in 2025 and is projected to reach USD 2.96 Billion by the end of the forecast period in 2032.

Semi-Rigid Spray Polyurethane Foam Market introduction

The Semi-Rigid Spray Polyurethane Foam Market encompasses the production, distribution, and application of specific polyurethane foam systems designed for spray application, offering a unique balance between flexibility and structural integrity. Unlike rigid foams that are very dense and hard, or flexible foams used in upholstery, semi-rigid foams provide good energy absorption, sound dampening, and moderate structural support, making them versatile for a range of demanding applications. These foams are typically formed by combining two liquid components, an isocyanate and a polyol blend, at the point of application using specialized spray equipment, leading to a rapid exothermic reaction that forms the foam directly on the substrate.

The product is characterized by its ability to conform to irregular surfaces, providing seamless coverage, and offering excellent adhesion to various materials, including metals, wood, and concrete. Major applications span across the construction, automotive, and industrial sectors. In construction, it is widely used for air sealing, gap filling, and insulation in areas requiring a degree of movement or where traditional rigid insulation might crack. For automotive manufacturing, it serves critical functions in noise, vibration, and harshness (NVH) reduction, as well as for structural reinforcements in cavities and pillars, enhancing vehicle safety and passenger comfort.

The primary benefits of semi-rigid spray polyurethane foam include superior thermal insulation properties, effective air barrier capabilities, sound attenuation, and lightweight characteristics. These advantages contribute significantly to energy efficiency in buildings and improved fuel economy in vehicles. Key driving factors for market growth include stringent building codes mandating energy performance, the increasing demand for advanced materials in electric vehicles for battery protection and NVH management, and growing industrial applications for protective coatings and void filling. The versatility and performance attributes of semi-rigid SPF position it as a critical material in modern engineering and construction practices.

Semi-Rigid Spray Polyurethane Foam Market Executive Summary

The Semi-Rigid Spray Polyurethane Foam Market is currently experiencing robust growth, primarily driven by escalating demand in the construction sector for enhanced energy efficiency and stringent building regulations. Business trends indicate a strong focus on sustainable product development, with manufacturers investing in bio-based polyols and low-VOC formulations to address environmental concerns and meet green building standards. The market is also witnessing increasing automation in spray application technologies, improving efficiency and consistency, which helps overcome skilled labor shortages. Furthermore, strategic partnerships and mergers and acquisitions are common as companies seek to expand their product portfolios, geographic reach, and technological capabilities.

Regionally, North America and Europe are mature markets, characterized by advanced building codes and a strong emphasis on insulation upgrades in existing structures, alongside innovation in automotive applications. The Asia Pacific region, particularly countries like China and India, represents the fastest-growing market due to rapid urbanization, significant infrastructure development, and burgeoning automotive manufacturing hubs. Latin America and the Middle East and Africa are also showing promising growth, fueled by construction boom projects and increasing adoption of modern building techniques, albeit starting from a lower base. Each region presents unique opportunities and challenges related to regulatory landscapes, raw material availability, and economic development.

Segmentation trends highlight the dominance of the building and construction sector, especially for residential and commercial insulation and air sealing applications. The automotive segment is poised for substantial growth, driven by the electric vehicle revolution and the need for advanced NVH and lightweighting solutions. Innovation in product types, such as those optimized for specific temperature ranges or fire resistance, continues to expand their applicability. Furthermore, the market is seeing a shift towards higher-performance and specialized foams, indicating a maturation in customer requirements and a move away from commoditized offerings, pushing manufacturers to differentiate through superior product characteristics and application support.

AI Impact Analysis on Semi-Rigid Spray Polyurethane Foam Market

User inquiries regarding the impact of Artificial Intelligence on the Semi-Rigid Spray Polyurethane Foam Market frequently revolve around optimizing application processes, enhancing quality control, and predicting material performance. Common questions explore how AI could automate or assist in precise mixing ratios, improve spray pattern consistency, and identify potential defects in real-time, thereby reducing material waste and ensuring application quality. There is also significant interest in AI's role in supply chain management for raw materials, predicting market demand, and potentially developing novel foam formulations through data-driven insights. Users anticipate AI fostering greater efficiency, sustainability, and consistency in production and application within this niche market.

- AI driven sensor systems can monitor and optimize spray application parameters such as temperature, pressure, and flow rates in real time, ensuring consistent foam density and coverage.

- Predictive analytics powered by AI can forecast equipment maintenance needs for spray foam rigs, minimizing downtime and extending the lifespan of machinery, thereby improving operational efficiency.

- Machine learning algorithms can analyze data from material properties and environmental conditions to predict long-term performance and durability of semi-rigid foams in various applications, enhancing product reliability.

- AI could assist in optimizing raw material procurement and inventory management, predicting demand fluctuations and reducing waste across the supply chain.

- Advanced AI models might contribute to the development of new, high-performance foam formulations by simulating molecular interactions and predicting material characteristics, accelerating R&D cycles.

- Quality control can be significantly enhanced through AI-powered visual inspection systems, capable of identifying surface imperfections, inconsistencies, or voids in applied foam much faster and more accurately than human inspection.

DRO & Impact Forces Of Semi-Rigid Spray Polyurethane Foam Market

The Semi-Rigid Spray Polyurethane Foam Market is significantly influenced by a confluence of drivers, restraints, and opportunities that collectively shape its growth trajectory and competitive landscape. Key drivers include the global push for energy efficiency in buildings, catalyzed by stringent governmental regulations and increasing consumer awareness regarding sustainable construction practices. The superior insulation and air-sealing capabilities of semi-rigid SPF directly address these demands, making it a preferred choice for builders and homeowners. Furthermore, the burgeoning automotive industry, particularly the rapid growth of electric vehicles, provides a strong impetus due to the need for advanced lightweight materials for NVH reduction and battery thermal management, where semi-rigid foams excel in performance and application flexibility. The versatility of spray application also allows for seamless coverage in complex geometries, expanding its utility across diverse industrial applications, thus maintaining consistent demand.

Despite the strong growth drivers, the market faces several notable restraints that could impede its expansion. The volatility and fluctuating prices of key raw materials, particularly isocyanates (MDI, TDI) and polyols, which are petrochemical derivatives, introduce cost uncertainties for manufacturers and can impact profit margins. Environmental concerns surrounding the use of certain blowing agents and the potential for off-gassing of volatile organic compounds (VOCs) during and after application pose regulatory challenges and public perception issues, driving the need for more eco-friendly formulations. Additionally, the installation of spray polyurethane foam requires specialized equipment and skilled applicators, which can be a barrier to entry for smaller contractors and can lead to inconsistent application if not performed correctly, potentially leading to performance issues.

Opportunities within the Semi-Rigid Spray Polyurethane Foam Market are primarily driven by innovation and expanding application scope. The development and commercialization of bio-based and recycled content polyols present a significant opportunity to address sustainability concerns, reduce reliance on petrochemicals, and enhance the market's environmental profile, appealing to eco-conscious consumers and regulatory bodies. Moreover, advancements in application technology, such as robotic spray systems and improved safety equipment, can mitigate installation challenges and expand market reach. Niche applications in sectors like marine, aerospace, and specialized industrial equipment, where precise insulation, sound dampening, and lightweighting are crucial, also offer untapped growth potential. The continuous evolution of building codes and automotive design specifications demanding higher performance materials will further open avenues for customized semi-rigid SPF solutions, ensuring ongoing market relevance and innovation.

Segmentation Analysis

The Semi-Rigid Spray Polyurethane Foam Market is comprehensively segmented based on various critical attributes including raw material, application, end-use industry, and region. This segmentation provides a granular view of market dynamics, enabling stakeholders to identify specific growth areas, competitive landscapes, and consumer preferences. The intricate interplay of these segments reveals varying growth rates and adoption patterns, influenced by technological advancements, regulatory environments, and regional economic conditions. Understanding these segments is crucial for strategic planning, product development, and market entry decisions, allowing companies to tailor their offerings to specific market needs and optimize their value proposition.

- By Raw Material:

- Isocyanates:

- MDI (Methylene Diphenyl Diisocyanate)

- TDI (Toluene Diisocyanate)

- Polyols:

- Polyether Polyols

- Polyester Polyols

- Bio-based Polyols

- Blowing Agents:

- Hydrofluorocarbons (HFCs)

- Hydrofluoroolefins (HFOs)

- Water-blown

- Additives and Catalysts

- Isocyanates:

- By Application:

- Insulation (Thermal and Acoustic)

- Air Barrier/Sealing

- Void Filling

- Sound Dampening and NVH (Noise, Vibration, Harshness)

- Structural Reinforcement

- Protective Coatings

- By End-Use Industry:

- Building & Construction:

- Residential

- Commercial

- Industrial

- Automotive:

- Passenger Vehicles

- Commercial Vehicles

- Electric Vehicles (EVs)

- Industrial & Manufacturing:

- Pipes and Tanks

- Appliances

- Marine

- Aerospace

- Furniture and Bedding

- Packaging

- Building & Construction:

Value Chain Analysis For Semi-Rigid Spray Polyurethane Foam Market

The value chain for the Semi-Rigid Spray Polyurethane Foam Market begins with the upstream suppliers of crucial raw materials, primarily petrochemical companies that produce isocyanates (MDI, TDI) and polyols (polyether, polyester). These core components are then combined with various additives such as catalysts, blowing agents, flame retardants, and surfactants, which are supplied by specialized chemical manufacturers. The quality and consistent availability of these upstream materials are paramount as they directly influence the final properties and performance of the spray foam. Innovations in this segment, particularly the development of bio-based polyols and more environmentally friendly blowing agents, are driven by sustainability goals and regulatory pressures. Relationships with these suppliers are often long-term and strategic due to the specialized nature of the chemicals involved and the need for rigorous quality control to ensure product consistency.

Moving downstream, the raw materials and additives are processed by specialized chemical companies, who formulate them into A-side (isocyanate) and B-side (polyol blend) components of the spray foam system. These formulators often conduct extensive research and development to create specific formulations tailored for various applications, such as formulations optimized for low-temperature application, enhanced fire resistance, or specific densities. The formulated semi-rigid SPF systems are then distributed through a network of distributors, including specialized chemical distributors, construction material suppliers, and directly to large-scale contractors or OEMs. These distributors play a crucial role in inventory management, technical support, and logistical efficiency, bridging the gap between manufacturers and end-users. Direct sales channels are also common for large industrial customers or sophisticated projects requiring direct technical engagement from the manufacturer.

The final stage of the value chain involves the application of the semi-rigid spray polyurethane foam by certified applicators or professional contractors. These end-users utilize specialized high-pressure spray equipment to mix and apply the two components, ensuring proper reaction and adhesion to the substrate. The effectiveness and performance of the installed foam heavily rely on the skill and training of these applicators, as well as adherence to manufacturer specifications. After installation, the product's performance impacts a wide range of end-users in the building & construction, automotive, and industrial sectors, who benefit from improved energy efficiency, enhanced sound dampening, and structural integrity. Both direct and indirect distribution channels are utilized, with direct sales often involving large-scale industrial clients and indirect channels serving a broader base of construction contractors and smaller projects through distributors and retailers. The entire chain is underpinned by regulatory compliance, technical service, and a strong emphasis on safety protocols, from chemical handling to on-site application.

Semi-Rigid Spray Polyurethane Foam Market Potential Customers

The primary potential customers and end-users for Semi-Rigid Spray Polyurethane Foam are diverse, spanning multiple high-growth industries that seek advanced material solutions for insulation, sealing, structural enhancement, and sound management. In the building and construction sector, residential and commercial builders, renovation contractors, and large-scale industrial facility developers represent a significant customer base. These entities frequently specify semi-rigid SPF for applications such as attic and wall insulation, crawlspace encapsulation, air barrier systems, and void filling in both new constructions and retrofitting projects. The demand stems from the need to meet stringent energy codes, improve building envelope performance, and enhance occupant comfort and indoor air quality.

Another crucial segment of potential customers is the automotive industry, particularly vehicle manufacturers (OEMs) and their Tier 1 suppliers. With the increasing focus on lightweighting, fuel efficiency, and electric vehicle battery protection, semi-rigid foams are sought after for their ability to reduce noise, vibration, and harshness (NVH) in vehicle cabins, provide thermal management for sensitive components, and offer structural reinforcement in various body cavities. As the shift towards electric vehicles accelerates, the demand for high-performance insulating and dampening materials that also contribute to occupant safety and battery longevity is expected to grow substantially, positioning automotive manufacturers as a key demographic for this product category.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.85 Billion |

| Market Forecast in 2032 | USD 2.96 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Covestro AG, The Dow Chemical Company, Huntsman Corporation, Sika AG, Carlisle Companies Inc., Lapolla Industries Inc. (A division of Icynene-Lapolla), Demilec (A division of BASF), Owens Corning, Johns Manville (A Berkshire Hathaway Company), Gaco Western (A Holcim Company), Accella Polyurethane Systems (A Carlisle Company), Rhino Linings Corporation, SWD Urethane, BaySeal, General Coatings Manufacturing Corp., Era Polymers, Kumho Mitsui Chemicals Inc., Wanhua Chemical Group Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Semi-Rigid Spray Polyurethane Foam Market Key Technology Landscape

The technology landscape for the Semi-Rigid Spray Polyurethane Foam Market is characterized by continuous innovation aimed at improving product performance, enhancing application efficiency, and addressing environmental concerns. A significant area of technological advancement lies in the formulation of the foam components themselves. This includes the development of advanced polyol blends, such as those incorporating bio-based or recycled content, to reduce reliance on petrochemicals and improve sustainability. Manufacturers are also investing in novel blowing agents, moving away from high-global warming potential (GWP) hydrofluorocarbons (HFCs) to more eco-friendly hydrofluoroolefins (HFOs) and water-blown systems, aligning with stricter environmental regulations and green building initiatives. Furthermore, advancements in catalyst technology are enabling faster cure times and better cell structure control, leading to improved insulation properties and reduced on-site application durations, enhancing project turnaround times for contractors.

Beyond material formulations, critical technological developments are occurring in the application equipment and process control systems used for semi-rigid spray polyurethane foam. High-pressure proportioning machines are becoming more sophisticated, offering precise control over temperature and pressure settings for both A-side and B-side components, ensuring optimal mixing ratios and consistent foam quality. Innovations in spray gun design are focusing on minimizing overspray, improving atomization, and providing better ergonomic features for applicators, which reduces material waste and enhances worker safety and comfort. Robotic spray application systems are also emerging, particularly for large industrial projects or complex automotive assembly lines, offering unparalleled precision, repeatability, and speed, thereby mitigating issues related to skilled labor shortages and inconsistent human application.

Digitalization and smart technologies are increasingly influencing the semi-rigid SPF market, leading to the integration of sensors and data analytics in application equipment. These technologies enable real-time monitoring of spray parameters, environmental conditions, and material consumption, providing valuable data for quality assurance and process optimization. The ability to collect and analyze this data can help in predictive maintenance of equipment, troubleshooting application issues, and ensuring compliance with project specifications. Furthermore, advanced modeling and simulation tools are being utilized in the research and development phase to predict foam characteristics and performance under various conditions, accelerating the development of new products and customized solutions. These technological strides collectively aim to make semi-rigid SPF a more efficient, sustainable, and reliable material for its diverse applications.

Regional Highlights

- North America: This region represents a mature and significant market for semi-rigid spray polyurethane foam, driven by stringent building codes emphasizing energy efficiency and a robust construction sector. The demand is particularly high in residential and commercial retrofitting projects, as well as new green building initiatives. Canada and the United States are key contributors, benefiting from high consumer awareness regarding energy savings and strong government incentives for sustainable construction. The automotive sector in North America also significantly contributes, leveraging these foams for NVH reduction and lightweighting in vehicles, including the rapidly expanding electric vehicle segment.

- Europe: Europe is another dominant region, characterized by its advanced regulatory framework for thermal insulation and a strong focus on reducing carbon footprints in buildings. Countries like Germany, France, and the UK are leading in the adoption of semi-rigid SPF for both new construction and extensive renovation programs to meet ambitious energy performance targets. The European automotive industry, known for its innovation and premium segment, also extensively uses these foams to enhance vehicle comfort and structural integrity. Strict environmental norms encourage the development and use of low-VOC and sustainable foam formulations.

- Asia Pacific (APAC): The Asia Pacific region is projected to be the fastest-growing market due to rapid urbanization, increasing infrastructure development, and a burgeoning manufacturing sector, especially in construction and automotive. China and India are at the forefront of this growth, driven by massive investments in residential and commercial buildings, alongside the expansion of their domestic automotive production, including a significant push into electric vehicles. The rising middle class and improving living standards further fuel the demand for high-quality insulation and construction materials, making APAC a critical growth engine.

- Latin America: This region presents emerging opportunities, with countries like Brazil and Mexico showing considerable growth in their construction and automotive industries. While starting from a lower base compared to North America and Europe, increasing foreign investment, government support for infrastructure projects, and a growing awareness of energy efficiency are driving the adoption of modern building materials like semi-rigid SPF. Economic stability and industrial expansion are key factors influencing market penetration in this region.

- Middle East and Africa (MEA): The MEA region is witnessing a steady uptake of semi-rigid spray polyurethane foam, primarily driven by large-scale construction projects in the Gulf Cooperation Council (GCC) countries and increasing demand for energy-efficient solutions in hot climates. Countries like Saudi Arabia and the UAE are investing heavily in new cities and commercial developments, where advanced insulation materials are crucial for mitigating extreme temperatures. Additionally, the growing industrial sector and infrastructure development in parts of Africa are contributing to the market's expansion, albeit at a nascent stage.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Semi-Rigid Spray Polyurethane Foam Market.- BASF SE

- Covestro AG

- The Dow Chemical Company

- Huntsman Corporation

- Sika AG

- Carlisle Companies Inc.

- Lapolla Industries Inc. (A division of Icynene-Lapolla)

- Demilec (A division of BASF)

- Owens Corning

- Johns Manville (A Berkshire Hathaway Company)

- Gaco Western (A Holcim Company)

- Accella Polyurethane Systems (A Carlisle Company)

- Rhino Linings Corporation

- SWD Urethane

- BaySeal

- General Coatings Manufacturing Corp.

- Era Polymers

- Kumho Mitsui Chemicals Inc.

- Wanhua Chemical Group Co. Ltd.

- Hexion Inc.

Frequently Asked Questions

What are the primary benefits of using semi-rigid spray polyurethane foam in construction?

Semi-rigid spray polyurethane foam offers superior thermal insulation, acts as an effective air barrier to prevent drafts, provides sound attenuation for quieter interiors, and offers lightweight structural reinforcement. These benefits contribute significantly to energy efficiency, enhanced building durability, and improved occupant comfort.

How does semi-rigid SPF contribute to energy efficiency in buildings?

By creating a continuous thermal envelope and an effective air barrier, semi-rigid SPF significantly reduces heat transfer and air leakage in buildings. This minimizes energy consumption for heating and cooling, leading to lower utility bills and a reduced carbon footprint, making buildings more sustainable.

What role does semi-rigid spray polyurethane foam play in the automotive industry?

In automotive applications, semi-rigid SPF is primarily used for noise, vibration, and harshness (NVH) reduction, enhancing passenger comfort. It also provides lightweight structural reinforcement in vehicle cavities and pillars, contributing to improved safety and fuel efficiency, especially critical for electric vehicles for battery protection and thermal management.

Are there environmental concerns associated with semi-rigid spray polyurethane foam, and how are they being addressed?

Concerns primarily relate to the use of petrochemical-based raw materials and certain blowing agents with high global warming potential (GWP). The industry is addressing these by developing bio-based polyols, utilizing recycled content, and transitioning to eco-friendly blowing agents like hydrofluoroolefins (HFOs) and water-blown systems to reduce environmental impact.

What key factors are driving the growth of the semi-rigid spray polyurethane foam market?

The market's growth is largely driven by stringent energy efficiency regulations in the building sector, increasing demand for advanced materials in the rapidly expanding automotive industry (particularly electric vehicles), and the inherent advantages of spray foam in terms of insulation, air sealing, and versatility in application.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager