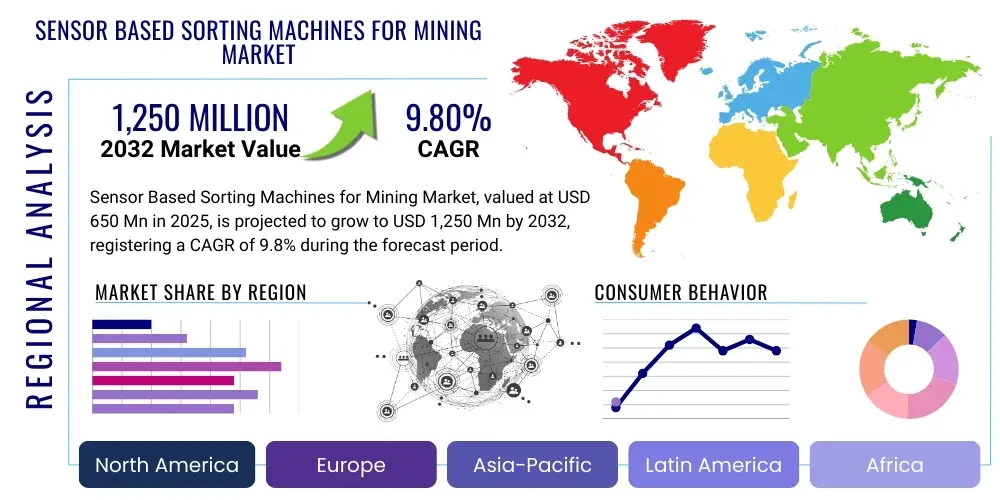

Sensor Based Sorting Machines for Mining Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427659 | Date : Oct, 2025 | Pages : 254 | Region : Global | Publisher : MRU

Sensor Based Sorting Machines for Mining Market Size

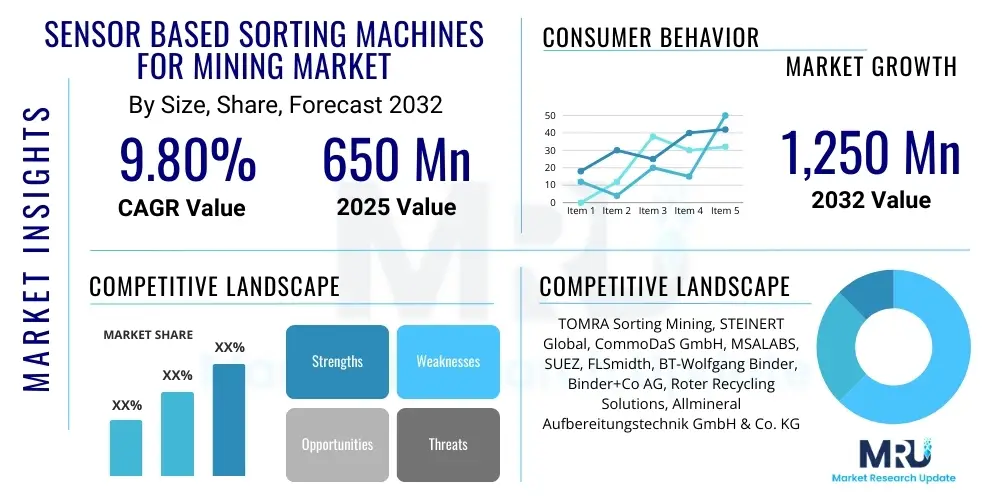

The Sensor Based Sorting Machines for Mining Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2025 and 2032. The market is estimated at USD 650 Million in 2025 and is projected to reach USD 1,250 Million by the end of the forecast period in 2032.

Sensor Based Sorting Machines for Mining Market introduction

The Sensor Based Sorting Machines for Mining Market encompasses advanced technological solutions designed to enhance the efficiency and sustainability of mineral processing. These machines utilize various sensor technologies to differentiate between valuable minerals and waste rock, enabling pre-concentration or refinement before further processing. The primary objective is to reduce energy consumption, minimize water usage, lower operational costs, and increase overall resource recovery rates within mining operations. The rising demand for critical minerals, coupled with decreasing ore grades and increasing environmental regulations, significantly drives the adoption of these sophisticated sorting systems across the global mining industry.

Sensor-based sorting machines employ a range of detection methods, including X-ray transmission (XRT), X-ray fluorescence (XRF), near-infrared (NIR), visible spectroscopy, laser, electromagnetic, and color sorting. These technologies analyze material properties such as density, atomic composition, reflectivity, and color, allowing for rapid, high-throughput separation of particles. The sorted materials can include anything from precious metals and diamonds to base metals like copper and nickel, industrial minerals, and even aggregates. Their application spans various stages of the mining value chain, from run-of-mine (ROM) pre-concentration to waste stream recovery, making them versatile tools for optimizing resource utilization.

The major applications of sensor-based sorting machines in mining extend across primary processing of various ore types, including gold, platinum group metals, copper, zinc, iron, diamonds, and industrial minerals such as limestone, phosphate, and potash. These systems are instrumental in improving the economic viability of mining operations, especially for low-grade deposits, by significantly reducing the volume of material that needs to be crushed, ground, and chemically processed. The core benefits include enhanced recovery of valuable minerals, reduced operational expenditures due to lower energy and water consumption, decreased environmental footprint, and extended mine life. These advantages collectively contribute to the markets robust growth, driven by an industry-wide push for smarter, more sustainable, and cost-effective mining practices.

Sensor Based Sorting Machines for Mining Market Executive Summary

The Sensor Based Sorting Machines for Mining Market is experiencing substantial growth, propelled by a confluence of business and technological trends focusing on efficiency, sustainability, and digitalization. Business trends highlight a strong industry shift towards automation and intelligent processing solutions to combat declining ore grades and rising operational costs. Mining companies are increasingly investing in these technologies to optimize resource recovery, minimize environmental impact, and enhance profitability in a highly competitive and regulated global landscape. The emphasis is on integrating advanced data analytics and artificial intelligence to further refine sorting accuracy and predictive maintenance capabilities, thereby ensuring higher system uptime and overall operational performance.

Regionally, the market exhibits dynamic growth patterns, with Asia-Pacific emerging as a dominant force, driven by extensive mining activities in countries like Australia, China, and India, coupled with increasing investments in modernizing existing infrastructure. North America and Europe are also significant markets, characterized by stringent environmental regulations and a strong inclination towards advanced technological adoption to enhance sustainability. Latin America, particularly countries with rich mineral resources such as Chile and Peru, represents a high-growth potential segment as mining operations in these regions seek to improve efficiency and reduce their environmental footprint. These regional trends are underpinned by varying levels of regulatory support, technological infrastructure, and local investment climates.

Segment-wise, the market is primarily driven by the expanding adoption of X-ray transmission (XRT) and near-infrared (NIR) sorting technologies, known for their high precision and versatility across a broad spectrum of mineral types. Applications in precious metals and industrial minerals continue to be significant, alongside a growing emphasis on sorting base metals and diamonds. The mobility segment, encompassing both static and mobile sorters, reflects the diverse operational needs of the mining sector, with mobile units gaining traction for their flexibility in various mine site conditions. The overarching trend across all segments is the continuous innovation in sensor technology, software algorithms, and machine integration, aimed at delivering more precise, reliable, and cost-effective sorting solutions tailored to specific ore characteristics and operational requirements.

AI Impact Analysis on Sensor Based Sorting Machines for Mining Market

The integration of Artificial Intelligence (AI) into Sensor Based Sorting Machines for Mining is revolutionizing the industry by addressing critical challenges related to efficiency, accuracy, and operational optimization. Users frequently inquire about how AI enhances sorting precision, the potential for real-time decision-making, and its role in predictive maintenance, alongside concerns about data management and the complexity of adoption. The prevailing sentiment is an expectation that AI will usher in a new era of intelligent mineral processing, making operations more adaptive, cost-effective, and environmentally responsible. Key themes revolve around improving the identification of complex mineralogical characteristics, optimizing throughput based on dynamic conditions, and developing self-learning systems that continuously refine sorting parameters. This transformative impact positions AI as a pivotal technology for unlocking higher value from increasingly challenging ore bodies.

- Enhanced sorting accuracy through advanced pattern recognition and machine learning algorithms, enabling the differentiation of subtle material variations.

- Real-time optimization of sorting parameters by analyzing continuous data streams, adapting to changes in ore characteristics and operational conditions.

- Predictive maintenance capabilities, where AI analyzes sensor data to anticipate equipment failures, reducing downtime and extending machine lifespan.

- Data-driven decision-making, providing valuable insights into ore body characteristics, recovery rates, and operational bottlenecks.

- Integration with broader digital mining ecosystems, facilitating seamless data exchange and collaborative optimization across the entire value chain.

- Improved energy efficiency by reducing the amount of waste material processed, directly contributing to lower power consumption and carbon footprint.

- Autonomous operation potential, reducing the need for continuous human intervention and increasing safety in hazardous environments.

- Ability to process complex and low-grade ores more economically, unlocking previously unviable resources.

DRO & Impact Forces Of Sensor Based Sorting Machines for Mining Market

The Sensor Based Sorting Machines for Mining Market is shaped by a powerful interplay of drivers, restraints, opportunities, and underlying impact forces. Key drivers include the global imperative for sustainable mining practices, compelling operators to minimize waste and maximize resource utilization. Declining ore grades globally necessitate more efficient pre-concentration methods, making sensor-based sorting indispensable. Additionally, the drive for operational efficiency and cost reduction across the mining value chain, combined with increasingly stringent environmental regulations, further accelerates market adoption. These factors collectively push mining companies towards innovative technologies that offer significant advantages in resource recovery and environmental stewardship, thereby fueling the demand for advanced sorting solutions.

However, the market also faces notable restraints. The high initial capital investment required for these sophisticated machines presents a significant barrier to entry, particularly for smaller mining operations or those with limited access to financing. The technological complexity of integrating these systems into existing mine infrastructure, along with the need for highly skilled personnel to operate and maintain them, poses additional challenges. Furthermore, the variability in ore characteristics across different deposits can sometimes limit the universal applicability of certain sensor technologies, requiring customized solutions that may increase implementation costs and time. These impediments necessitate careful strategic planning and investment justification for potential adopters.

Opportunities for market growth are abundant, especially in the increasing adoption of these technologies in small-scale and artisanal mining operations, where the benefits of efficiency and resource recovery can be transformative. The development of customized and modular sorting solutions tailored to specific mine conditions and ore types presents a strong growth avenue. Furthermore, the continuous integration of advanced technologies such as Artificial Intelligence, Machine Learning, and the Internet of Things (IoT) for enhanced data analytics, remote monitoring, and autonomous operations offers significant avenues for innovation and market expansion. The long-term impact forces, including the bargaining power of buyers driven by the need for cost-effective solutions and the competitive rivalry among technology providers, ensure continuous innovation and value creation within the market. Suppliers, while having some power due to specialized technology, are balanced by the growing sophistication of buyers. The threat of substitutes is low given the unique benefits, while new entrants face high barriers due to capital and technological expertise requirements, reinforcing the existing market structure.

Segmentation Analysis

The Sensor Based Sorting Machines for Mining Market is segmented based on several key criteria, including technology type, application, and mobility, providing a detailed view of its diverse landscape. This segmentation allows for a comprehensive understanding of market dynamics, highlighting areas of high growth and specific technological preferences within the mining industry. Each segment addresses distinct operational requirements and material characteristics, enabling technology providers to offer tailored solutions that maximize efficiency and profitability for various mining operations.

- By Technology Type:

- X-ray Transmission (XRT) Sorting

- X-ray Fluorescence (XRF) Sorting

- Near-Infrared (NIR) Sorting

- Laser Sorting

- Visible/Color Sorting

- Electromagnetic (EM) Sorting

- Other Sensor Technologies (e.g., Hyperspectral, Atomic Emission)

- By Application:

- Precious Metals (e.g., Gold, Platinum Group Metals)

- Base Metals (e.g., Copper, Zinc, Nickel)

- Industrial Minerals (e.g., Limestone, Phosphate, Potash, Salt)

- Diamonds

- Coal

- Recycling & Aggregates

- Waste Rock Pre-Concentration

- By Mobility:

- Static/Fixed Sorting Systems

- Mobile Sorting Systems

- By End-Use Industry:

- Large-Scale Mining Operations

- Small and Medium-Scale Mining Operations

Sensor Based Sorting Machines for Mining Market Value Chain Analysis

The value chain for Sensor Based Sorting Machines for Mining involves several critical stages, beginning with upstream raw material and component suppliers, extending through manufacturing and assembly, to downstream distribution and end-user adoption. Upstream, the value chain is characterized by specialized providers of high-precision sensors (e.g., X-ray tubes, NIR spectrometers, laser modules), advanced electronic components, mechanical parts, and sophisticated software and control systems. These suppliers often operate in highly niche markets, providing the foundational technologies that enable the sorting machines to function effectively. Strong relationships with these specialized vendors are crucial for ensuring the quality, reliability, and continuous innovation of the sorting technology.

Midstream activities involve the design, manufacturing, assembly, and testing of the sensor-based sorting machines. This stage includes research and development efforts focused on improving sorting algorithms, integrating new sensor technologies, and enhancing machine throughput and robustness. Manufacturers like TOMRA, STEINERT, and CommoDaS leverage their engineering expertise to build complete systems that can withstand harsh mining environments while delivering precise separation. Quality control, software development for user interfaces, and system integration are paramount at this stage, ensuring that the final product meets the high performance and reliability standards expected by mining operators globally.

Downstream, the value chain focuses on the distribution, installation, commissioning, and ongoing after-sales support for the end-users, primarily mining companies and mineral processing plants. Distribution channels often involve a mix of direct sales forces, especially for large, complex projects requiring extensive customization, and a network of authorized distributors or system integrators who can provide local support and service. Both direct and indirect channels play a vital role in market penetration. Post-installation services, including maintenance, spare parts supply, training, and performance optimization, are critical for customer satisfaction and ensuring the long-term operational efficiency of the sorting machines. The robustness of this downstream support directly influences customer loyalty and market reputation, completing the value cycle by ensuring sustained operational excellence for the mining industry.

Sensor Based Sorting Machines for Mining Market Potential Customers

Potential customers for Sensor Based Sorting Machines for Mining primarily consist of entities involved in the extraction, processing, and recycling of mineral resources, all seeking to enhance efficiency and profitability. Large-scale mining corporations, operating vast open-pit or underground mines, represent a significant segment due to their substantial processing volumes and continuous pursuit of operational excellence. These companies are driven by the need to extend mine life, reduce energy and water consumption, and meet stringent environmental regulations, making advanced sorting technologies highly attractive for their core operations. Their investment capabilities often allow for the adoption of high-capital, high-throughput systems that can be integrated into complex existing infrastructures.

Beyond large corporations, the market also targets small and medium-scale mining operations and junior mining companies, particularly those exploring or developing new deposits with variable ore characteristics. For these entities, sensor-based sorting offers a cost-effective solution for pre-concentrating ore, reducing initial processing costs, and improving the economic viability of deposits that might otherwise be considered marginal. The flexibility of mobile sorting solutions also appeals to this segment, enabling deployment in remote locations or for temporary mining ventures. Furthermore, companies involved in aggregates production for construction and infrastructure development, as well as those in the recycling of industrial waste and demolition materials for mineral recovery, are emerging as increasingly important customers, seeking to recover valuable materials from mixed streams and reduce landfill waste.

Mineral processing contractors and engineering, procurement, and construction (EPC) firms that design and build processing plants also represent indirect but crucial potential customers. They integrate sensor-based sorting solutions into their project designs for their clients, acting as key influencers and implementers of these technologies. Ultimately, any entity aiming to improve the selectivity of material separation, reduce energy and water intensity, and enhance the overall sustainability and profitability of their resource extraction or recovery processes stands as a potential buyer in this evolving market. This broad customer base underscores the versatility and growing indispensability of sensor-based sorting in the modern resource sector.

Sensor Based Sorting Machines for Mining Market Key Technology Landscape

The key technology landscape of the Sensor Based Sorting Machines for Mining Market is characterized by continuous innovation across multiple domains, from advanced sensor development to sophisticated data processing and automation. At its core are the diverse sensor technologies themselves, each offering unique capabilities for material characterization. X-ray Transmission (XRT) remains prominent for density-based sorting, effective for applications like diamond and industrial mineral recovery. X-ray Fluorescence (XRF) excels in elemental analysis, crucial for base metals and complex ores. Near-Infrared (NIR) and visible spectroscopy are vital for identifying mineral compositions based on spectral signatures, particularly useful for distinguishing different rock types and for various industrial minerals.

Beyond the primary sensor types, the technological landscape is increasingly defined by the integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms. These advanced computational techniques enable machines to learn from vast datasets, recognize complex patterns, and make highly accurate sorting decisions in real-time, even for challenging ore bodies with fine-grained dissemination or highly variable characteristics. AI enhances the precision of material differentiation, optimizes machine performance, and facilitates predictive maintenance, moving towards more autonomous and self-optimizing sorting operations. This evolution from basic sensor output interpretation to intelligent, adaptive decision-making represents a significant leap forward in processing capabilities and efficiency.

Further technological advancements include the robust integration of the Internet of Things (IoT) for remote monitoring, data collection, and analytics, allowing for real-time performance tracking and proactive adjustments from any location. Cloud computing platforms provide the infrastructure for processing and storing large volumes of data generated by these machines, supporting advanced analytics and machine learning models. Automation and robotics are also playing a crucial role in enhancing the reliability and safety of sorting operations, particularly in hazardous or remote environments. The trend is towards interconnected, intelligent sorting systems that are not just machines, but integral components of a wider digital mining ecosystem, contributing to smarter, more efficient, and sustainable resource management across the entire value chain.

Regional Highlights

- Asia Pacific: This region dominates the market due to extensive mining activities in countries like Australia, China, and India, coupled with significant investments in modernizing processing plants to enhance efficiency and comply with environmental standards. Australia, in particular, is a leader in adopting advanced sorting technologies across iron ore, gold, and other mineral sectors.

- North America: Characterized by stringent environmental regulations and a strong emphasis on technological innovation, North America exhibits high adoption rates, especially in the US and Canada. The region focuses on optimizing operations for critical minerals and improving the profitability of existing mines through advanced sorting.

- Europe: Driven by a push for sustainable mining practices and a robust manufacturing base for sorting equipment, European countries like Germany and the UK are key players. The focus here is often on high-value minerals, recycling applications, and developing highly specialized sorting solutions.

- Latin America: This region, rich in mineral resources such as copper, gold, and iron ore (e.g., Chile, Peru, Brazil), represents a high-growth potential market. Increasing investments in mining infrastructure and the need to process lower-grade ores more efficiently are driving the adoption of sensor-based sorting.

- Africa: With vast mineral wealth, particularly in diamonds, gold, and various industrial minerals (e.g., South Africa, Botswana), Africa is experiencing growing interest in sensor-based sorting to improve recovery rates and combat illegal mining activities. The market is developing, with potential for significant future growth as investment in modern mining practices increases.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sensor Based Sorting Machines for Mining Market.- TOMRA Sorting Mining

- STEINERT Global

- CommoDaS GmbH

- MSALABS

- SUEZ

- FLSmidth

- BT-Wolfgang Binder

- Binder+Co AG

- Roter Recycling Solutions

- Allmineral Aufbereitungstechnik GmbH & Co. KG

Frequently Asked Questions

What is sensor-based sorting in mining?

Sensor-based sorting is an advanced mineral processing technique that uses various sensors (e.g., X-ray, laser, optical) to identify and separate valuable minerals from waste rock or other undesirable materials based on their physical and chemical properties, prior to or during comminution and beneficiation. This process significantly improves efficiency and reduces processing costs.

How do sensor-based sorting machines improve mining efficiency?

These machines enhance efficiency by pre-concentrating ore, reducing the volume of material sent for energy-intensive crushing, grinding, and chemical processing. This leads to lower energy and water consumption, decreased operational costs, increased throughput, higher recovery rates of valuable minerals, and a smaller environmental footprint, ultimately boosting overall mine profitability and sustainability.

What are the primary types of sensor technologies used in mining sorting?

The main sensor technologies include X-ray Transmission (XRT) for density differentiation, X-ray Fluorescence (XRF) for elemental analysis, Near-Infrared (NIR) for mineral composition, visible/color sensors for visual characteristics, and laser sensors for surface properties. Each technology is selected based on the specific ore characteristics and the desired separation criteria.

What are the environmental benefits of adopting sensor-based sorting?

Environmental benefits are substantial, including reduced energy consumption from less material needing comminution, lower water usage in downstream processes, decreased generation of tailings and waste, and a smaller carbon footprint. By minimizing the amount of waste processed, these technologies contribute significantly to sustainable mining practices and resource conservation.

What role does AI play in the future of sensor-based sorting in mining?

AI is pivotal for the future, enabling enhanced sorting accuracy through advanced pattern recognition, real-time optimization of sorting parameters, and predictive maintenance to minimize downtime. AI-driven systems can adapt to varying ore conditions, process complex data for better decision-making, and pave the way for more autonomous and efficient mineral processing operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager