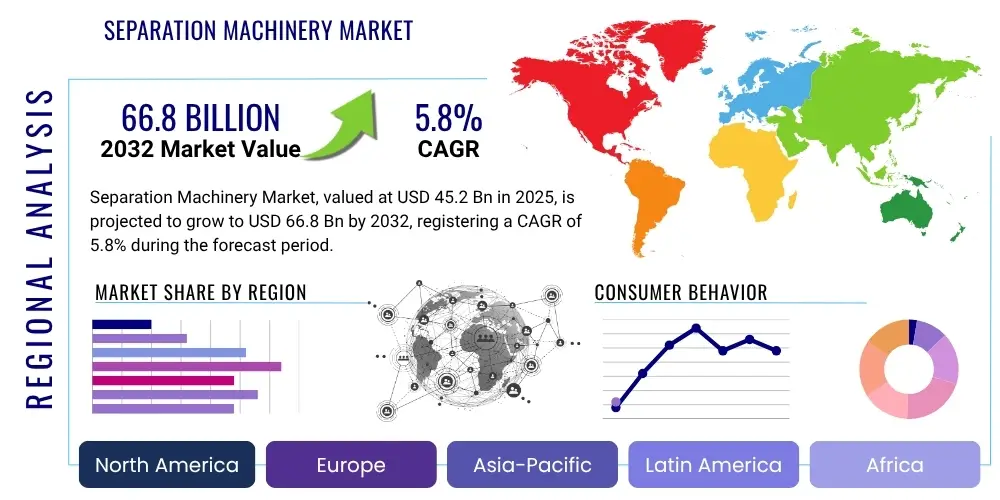

Separation Machinery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431263 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Separation Machinery Market Size

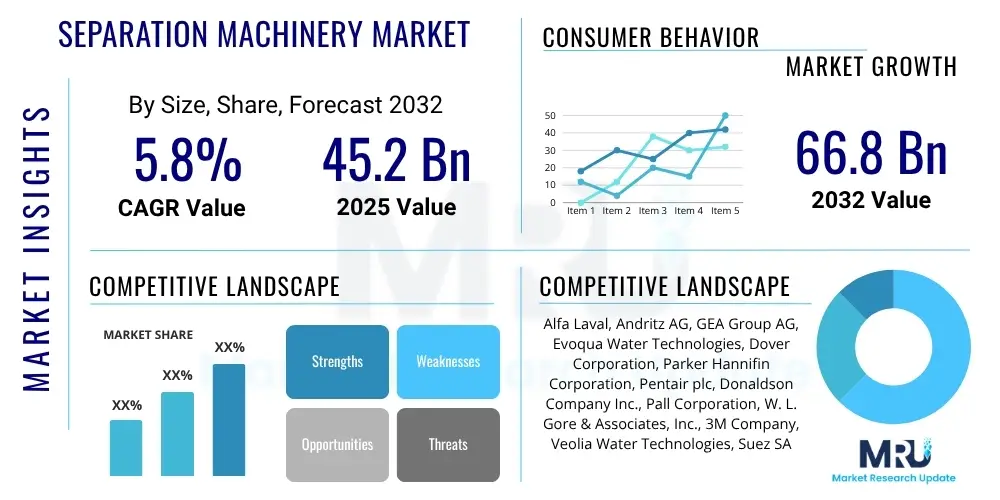

The Separation Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $45.2 billion in 2025 and is projected to reach $66.8 billion by the end of the forecast period in 2032.

Separation Machinery Market introduction

The Separation Machinery Market encompasses a diverse range of industrial equipment designed to segregate components of a mixture based on their physical or chemical properties. This critical sector provides essential solutions across numerous industries, enabling the purification of liquids, solids, and gases, as well as the recovery of valuable resources and the treatment of waste streams. These machines perform vital functions such as filtration, centrifugation, membrane separation, decantation, and magnetic separation, each tailored to specific application requirements and material characteristics. The fundamental objective is to achieve a desired level of purity, concentrate specific substances, or remove unwanted contaminants, thereby enhancing product quality, optimizing processes, and ensuring environmental compliance.

Products within this market range from conventional filters and centrifuges to advanced membrane bioreactors and smart separation systems. Major applications span industrial wastewater treatment, pharmaceutical manufacturing, food and beverage processing, petrochemical refining, mining, and air purification. The core benefits derived from these technologies include increased operational efficiency, significant improvements in product purity, reduced waste generation, and the sustainable recovery of valuable materials, leading to cost savings and adherence to stringent regulatory standards. The market's expansion is primarily driven by escalating global industrialization, growing demand for purified products, increasing stringency of environmental regulations concerning wastewater and emissions, and continuous technological advancements aimed at improving separation efficacy and energy efficiency.

Separation Machinery Market Executive Summary

The Separation Machinery Market is poised for substantial growth, driven by an accelerating industrial landscape and tightening environmental compliance requirements worldwide. Key business trends indicate a strong focus on automation, integration of smart technologies, and the development of energy-efficient and sustainable separation solutions. Manufacturers are increasingly investing in research and development to produce machinery that offers higher throughput, reduced operational costs, and enhanced selectivity, catering to complex industrial challenges. The emphasis on circular economy principles and resource recovery is also spurring innovation, particularly in waste treatment and material recycling applications, leading to a shift towards more advanced and customized separation systems.

Regionally, the Asia Pacific market is expected to exhibit the most rapid growth, fueled by rapid industrialization, burgeoning populations, and increasing investments in infrastructure and manufacturing sectors, particularly in countries like China and India. North America and Europe, while mature markets, continue to drive innovation, adopting advanced separation technologies for high-value applications in pharmaceuticals, biotechnology, and advanced materials, alongside strict environmental protection mandates. Segment-wise, membrane separation technologies are witnessing significant expansion due to their versatility and efficiency in diverse applications, including water desalination and industrial fluid purification. Concurrently, traditional segments such as centrifuges and filters maintain robust demand, benefiting from upgrades that incorporate automation and predictive maintenance features to improve performance and reliability across various end-use industries.

AI Impact Analysis on Separation Machinery Market

User inquiries regarding AI's influence on the Separation Machinery Market frequently revolve around how artificial intelligence can enhance operational efficiency, reduce maintenance costs, improve product quality, and contribute to more sustainable processes. There is a strong interest in understanding AI's role in predictive analytics for equipment failure, real-time process optimization, and the potential for autonomous system operation. Users are keen to explore how AI-driven insights can translate into tangible benefits such as minimized downtime, reduced energy consumption, and superior separation outcomes. Concerns often include the initial investment required for AI integration, data security, and the need for specialized skills to manage these advanced systems.

- Predictive Maintenance: AI algorithms analyze sensor data to predict equipment failures, enabling proactive maintenance and reducing unscheduled downtime.

- Process Optimization: Machine learning models optimize operational parameters in real-time, enhancing separation efficiency, yield, and energy consumption.

- Quality Control and Monitoring: AI-powered vision systems and analytics ensure consistent product quality by detecting anomalies and maintaining precise process conditions.

- Energy Efficiency: AI identifies patterns for optimal energy usage in pumps, motors, and heating elements, leading to significant power savings.

- Autonomous Operation: Advanced AI systems can enable self-regulating separation processes, minimizing human intervention and improving operational stability.

- Resource Recovery: AI optimizes the extraction and recovery of valuable materials from waste streams, supporting circular economy initiatives.

DRO & Impact Forces Of Separation Machinery Market

The Separation Machinery Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, shaped by broader economic and environmental forces. Key drivers include accelerating industrialization across developing economies, stringent environmental regulations mandating effective wastewater treatment and emission control, and a rising global demand for high-purity products in industries such as pharmaceuticals, food and beverage, and electronics. Technological advancements, particularly in smart materials, automation, and IoT integration, are continually enhancing the performance, efficiency, and versatility of separation equipment. Furthermore, the increasing global emphasis on resource recovery and sustainability initiatives is creating significant demand for advanced separation solutions that can extract valuable components from waste streams and facilitate recycling.

However, the market also faces notable restraints. The high initial capital investment required for advanced separation machinery can be a barrier for smaller enterprises or regions with limited financial resources. The complexity of operating and maintaining sophisticated equipment often necessitates skilled labor, which can be scarce, adding to operational costs. Additionally, the energy-intensive nature of some separation processes, such as distillation and certain membrane applications, presents an ongoing challenge, though continuous innovation is addressing this. Regulatory hurdles and diverse certification requirements across different regions can also complicate market entry and expansion for manufacturers. The impact forces affecting this market include global economic growth patterns influencing industrial output, evolving environmental policies dictating treatment standards, rapid technological innovation that redefines separation capabilities, and shifts in global supply chain dynamics affecting raw material availability and manufacturing costs.

Segmentation Analysis

The Separation Machinery Market is broadly segmented based on various criteria to provide a comprehensive understanding of its intricate structure and diverse applications. These segmentations allow for detailed analysis of market dynamics, competitive landscapes, and growth opportunities across different product types, end-use industries, and geographical regions. Understanding these distinct segments is crucial for stakeholders to identify specific market niches, develop targeted strategies, and align their offerings with prevailing industry demands and emerging trends. The market's complexity necessitates a granular view to capture the nuances of technological adoption, regulatory impacts, and customer preferences across its varied components.

- By Type

- Centrifuges: Decanter Centrifuges, Disc Stack Centrifuges, Tubular Centrifuges, Basket Centrifuges

- Filters: Cartridge Filters, Bag Filters, Media Filters, Self-Cleaning Filters, Pressure Filters, Vacuum Filters

- Membrane Separators: Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis, Electrodialysis

- Decanters: Solid-Bowl Decanters, Screen-Bowl Decanters

- Screens: Vibrating Screens, Rotary Screens, Static Screens

- Magnetic Separators: Permanent Magnetic Separators, Electromagnetic Separators

- Others: Cyclones, Settlers, Flotation Units

- By Application

- Solid-Liquid Separation

- Liquid-Liquid Separation

- Gas Separation

- Solid-Gas Separation

- By End-Use Industry

- Water and Wastewater Treatment

- Food and Beverage

- Chemical and Petrochemical

- Pharmaceutical and Biotechnology

- Oil and Gas

- Mining and Metallurgy

- Pulp and Paper

- Power Generation

- Others (e.g., Electronics, Textile)

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Separation Machinery Market

The value chain for the Separation Machinery Market involves a complex network of activities, commencing from the sourcing of raw materials and extending through manufacturing, distribution, and post-sales support, ultimately reaching the end-users. The upstream segment of the value chain is critical, encompassing the supply of specialized raw materials such as high-grade stainless steel, advanced polymers, ceramics, and composite materials, along with the provision of precision components like motors, pumps, valves, sensors, and control systems. Strong relationships with reliable raw material suppliers and component manufacturers are essential for ensuring product quality, cost efficiency, and timely delivery. Innovation in material science directly impacts the performance and durability of separation equipment, making R&D in this upstream segment a key differentiator.

Moving downstream, the value chain focuses on the manufacturing, assembly, and testing of diverse separation machinery. This stage involves significant engineering expertise to design and produce custom solutions tailored to specific industry needs, whether it is for large-scale industrial processing or specialized laboratory applications. Distribution channels play a pivotal role in market reach; these include direct sales teams for large industrial clients, a network of specialized distributors and agents for broader market penetration, and partnerships with Original Equipment Manufacturers (OEMs) who integrate separation components into larger systems. After-sales services, including installation, maintenance, spare parts supply, and technical support, are integral to customer satisfaction and long-term market presence. Both direct sales and indirect channels via distributors are crucial, with direct engagement often preferred for complex, high-value systems, while indirect channels provide wider geographical coverage and access to smaller clients. The effectiveness of the entire value chain, from raw material sourcing to end-user support, directly influences market competitiveness and customer loyalty.

Separation Machinery Market Potential Customers

The potential customers for Separation Machinery are incredibly diverse, spanning nearly every industrial sector that requires purification, concentration, or waste management processes. These end-users are primarily driven by the need to achieve specific product quality standards, comply with environmental regulations, optimize their operational efficiency, or recover valuable resources from waste streams. Industries such as water and wastewater treatment plants, municipal and industrial facilities, chemical manufacturers, and pharmaceutical companies represent a significant portion of the market, relying heavily on separation technologies for their core operations.

Beyond these major sectors, the customer base extends to the food and beverage industry, which utilizes separation machinery for product clarification, ingredient extraction, and quality control. Oil and gas companies depend on these machines for crude oil processing, water separation from oil, and gas purification. Mining and metallurgy operations employ separation equipment for ore beneficiation and mineral processing. Pulp and paper mills use separation technologies for fiber recovery and effluent treatment. The breadth of applications underscores the universal utility and essential nature of separation machinery across a wide array of industrial and commercial buyers seeking to enhance process performance, ensure product integrity, and maintain environmental stewardship.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $45.2 billion |

| Market Forecast in 2032 | $66.8 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alfa Laval, Andritz AG, GEA Group AG, Evoqua Water Technologies, Dover Corporation, Parker Hannifin Corporation, Pentair plc, Donaldson Company Inc., Pall Corporation, W. L. Gore & Associates, Inc., 3M Company, Veolia Water Technologies, Suez SA, Sulzer Ltd., FLSmidth & Co. A/S, SPX Flow, Inc., Dürr AG, Russell Finex Ltd., Baker Hughes, Flowserve Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Separation Machinery Market Key Technology Landscape

The technological landscape of the Separation Machinery Market is rapidly evolving, driven by the persistent demand for higher efficiency, reduced energy consumption, and greater sustainability across various industrial applications. Innovations in material science are leading to the development of advanced membranes with enhanced selectivity, flux, and fouling resistance, particularly in microfiltration, ultrafiltration, and reverse osmosis processes. The integration of smart sensors, IoT (Internet of Things) devices, and advanced control systems is transforming traditional machinery into intelligent, connected systems capable of real-time monitoring, predictive maintenance, and autonomous operation, thereby optimizing performance and minimizing downtime.

Furthermore, the application of artificial intelligence and machine learning algorithms is enabling more precise process control, facilitating adaptive separation parameters, and improving overall system efficiency by learning from operational data. Energy-efficient designs, such as advanced pump technologies and optimized hydraulic systems, are becoming standard to address the high energy consumption traditionally associated with separation processes. Modular and compact designs are gaining traction, offering greater flexibility, easier installation, and reduced footprint, particularly beneficial for industries with limited space or those requiring scalable solutions. Emerging technologies like centrifugal chromatography, electrophoresis, and advanced oxidation processes are also expanding the scope and capabilities of separation, enabling ultra-fine separation and the treatment of complex mixtures previously deemed challenging.

Regional Highlights

- North America: A mature market characterized by early adoption of advanced separation technologies, strong regulatory frameworks for environmental protection, and significant investments in research and development, particularly in biotechnology, pharmaceuticals, and industrial water treatment. The region benefits from a robust industrial base and a high demand for energy-efficient and automated systems.

- Europe: Driven by stringent environmental regulations, a strong focus on sustainability, and a well-established industrial sector, particularly in Germany, France, and the UK. The market emphasizes high-performance, energy-efficient solutions and circular economy principles, with considerable innovation in membrane technologies and waste-to-value applications.

- Asia Pacific (APAC): Expected to be the fastest-growing market due to rapid industrialization, burgeoning populations, and increasing investments in infrastructure development, particularly in China, India, and Southeast Asian countries. Growing awareness of water scarcity and pollution, coupled with supportive government policies, is fueling demand across all end-use industries.

- Latin America: An emerging market experiencing increasing industrialization and urbanization. Growth is primarily driven by investments in water and wastewater treatment infrastructure, mining, and food and beverage processing sectors. Adoption of advanced technologies is gradually increasing, albeit with challenges related to economic stability and infrastructure development.

- Middle East and Africa (MEA): Marked by significant demand stemming from water scarcity issues, leading to substantial investments in desalination and wastewater treatment plants. The region's vast oil and gas industry also constitutes a major end-user for separation machinery, with ongoing projects driving market expansion, particularly in GCC countries and North Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Separation Machinery Market.- Alfa Laval

- Andritz AG

- GEA Group AG

- Evoqua Water Technologies

- Dover Corporation

- Parker Hannifin Corporation

- Pentair plc

- Donaldson Company Inc.

- Pall Corporation

- W. L. Gore & Associates, Inc.

- 3M Company

- Veolia Water Technologies

- Suez SA

- Sulzer Ltd.

- FLSmidth & Co. A/S

- SPX Flow, Inc.

- Dürr AG

- Russell Finex Ltd.

- Baker Hughes

- Flowserve Corporation

Frequently Asked Questions

What are the primary drivers of growth in the Separation Machinery Market?

The market's growth is primarily driven by global industrial expansion, increasingly stringent environmental regulations for waste treatment and emissions, the rising demand for high-purity products across industries, and continuous technological advancements enhancing efficiency and capabilities. The focus on resource recovery and sustainability also plays a crucial role.

How is AI impacting the operational efficiency of separation machinery?

AI significantly impacts operational efficiency through predictive maintenance, which reduces unscheduled downtime by forecasting equipment failures. It also optimizes process parameters in real-time for improved yield and reduced energy consumption, enhances quality control, and facilitates the development of more autonomous separation systems.

Which types of separation technologies are experiencing the fastest growth?

Membrane separation technologies, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis, are experiencing rapid growth due to their versatility, efficiency in fine separation, and increasing application in water treatment and specialized industrial processes. Advanced filtration and smart centrifuges are also seeing significant innovation and adoption.

What are the key challenges faced by manufacturers in the Separation Machinery Market?

Key challenges include high initial capital investment requirements for advanced machinery, the complexity of system integration and maintenance, high energy consumption in some processes, the scarcity of skilled labor for operation and servicing, and navigating diverse and evolving regulatory landscapes across different regions.

What role do environmental regulations play in shaping the Separation Machinery Market?

Environmental regulations are a fundamental driver, compelling industries to adopt more effective separation technologies for wastewater treatment, air pollution control, and resource recovery. Stricter standards regarding effluent discharge, emissions, and waste management directly stimulate demand for advanced and compliant separation solutions, fostering innovation and market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager