Single Phase Fixed Shunt Reactor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427171 | Date : Oct, 2025 | Pages : 239 | Region : Global | Publisher : MRU

Single Phase Fixed Shunt Reactor Market Size

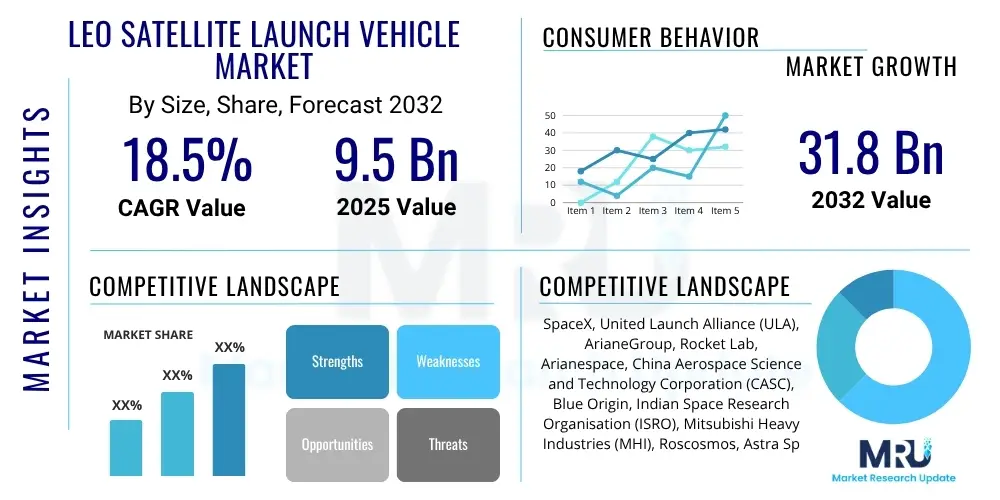

The Single Phase Fixed Shunt Reactor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.8 Billion in 2025 and is projected to reach USD 2.9 Billion by the end of the forecast period in 2032.

Single Phase Fixed Shunt Reactor Market introduction

The Single Phase Fixed Shunt Reactor Market encompasses devices crucial for maintaining voltage stability and improving power quality within electrical transmission and distribution networks. These reactors, typically connected in parallel to the power line, absorb reactive power, thereby compensating for capacitance generated by long transmission lines and high-voltage underground cables. This compensation prevents overvoltage conditions, reduces transmission losses, and ensures a stable power supply, which is critical for the reliable operation of modern grids.

A Single Phase Fixed Shunt Reactor is a passive electrical device designed to draw lagging reactive power from the system. Unlike variable reactors, fixed shunt reactors have a constant inductive reactance and are permanently connected to the grid or can be switched in and out as required, but their inductance value itself is not adjustable. The product primarily comprises an iron core or air core, windings, and an insulation system, all housed within a robust tank, often filled with oil for cooling and insulation. Their design allows for efficient operation in single-phase applications, commonly found in high-voltage alternating current (AC) systems.

Major applications for these reactors include integration with renewable energy sources like wind and solar farms, which can introduce voltage fluctuations, and in extensive urban power grids where cable capacitance is significant. The fundamental benefits include enhanced grid stability, reduced system losses, and prevention of equipment damage due to overvoltages. Key driving factors for market growth involve the increasing global demand for electricity, ongoing grid modernization initiatives, the rapid expansion of renewable energy capacity, and the necessity to enhance power transmission efficiency and reliability across diverse geographical regions.

Single Phase Fixed Shunt Reactor Market Executive Summary

The Single Phase Fixed Shunt Reactor Market is experiencing robust growth, driven primarily by evolving business trends centered on global energy transition and infrastructure development. Utilities worldwide are investing heavily in grid modernization, aiming to integrate a higher penetration of renewable energy sources and manage the inherent intermittency and voltage regulation challenges they present. This trend necessitates advanced reactive power compensation solutions, with fixed shunt reactors playing a vital role in stabilizing grid voltages and minimizing power losses. Furthermore, the expansion of high-voltage direct current (HVDC) and extra-high-voltage alternating current (EHVAC) transmission lines across continents further fuels demand for these critical components, as longer transmission distances inherently increase reactive power requirements.

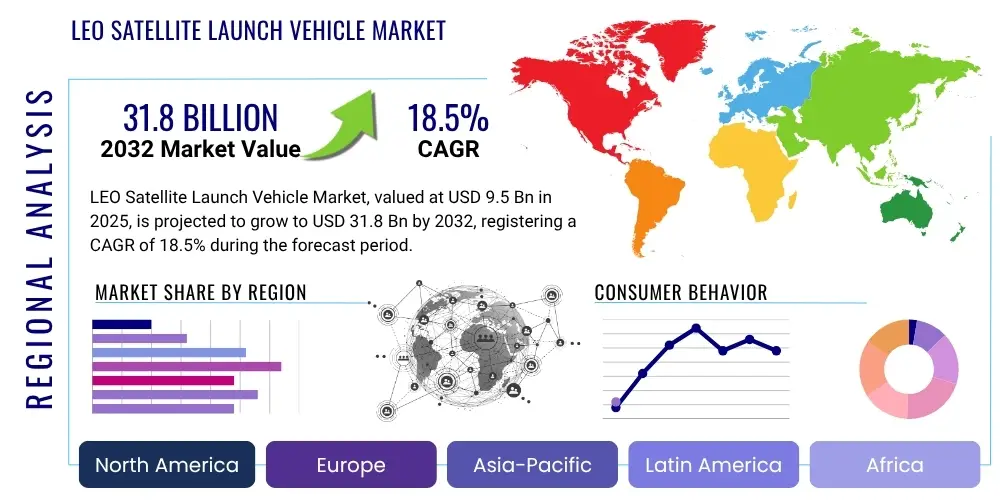

Regionally, the market exhibits diverse growth patterns. Asia-Pacific stands out as a dominant force, propelled by rapid industrialization, urbanization, and extensive government investments in power infrastructure expansion, particularly in countries like China and India. North America and Europe are also significant markets, driven by stringent grid reliability standards, aging infrastructure replacement cycles, and aggressive targets for renewable energy deployment. These regions are focusing on upgrading existing transmission networks and implementing smart grid technologies, where single phase fixed shunt reactors are integral to ensuring system stability and optimizing power flow. Emerging economies in Latin America and Africa are gradually increasing their adoption as they expand their nascent power grids and strive for energy security.

Segmentation trends highlight a growing preference for oil-immersed reactors due to their superior cooling capabilities and established reliability, although dry-type (air-core) reactors are gaining traction in specific applications requiring reduced fire risk or lower maintenance. The utility sector remains the largest end-user, accounting for a substantial share of the market, driven by large-scale transmission projects. However, industrial applications, including heavy manufacturing plants and data centers, are increasingly recognizing the benefits of shunt reactors for improving power quality and protecting sensitive equipment. Voltage ratings are continuously evolving, with a noticeable shift towards higher voltage applications to support EHV and UHV transmission, indicating a future market leaning towards advanced, high-capacity solutions to meet escalating energy demands.

AI Impact Analysis on Single Phase Fixed Shunt Reactor Market

Common user questions regarding AIs impact on the Single Phase Fixed Shunt Reactor Market often revolve around how artificial intelligence can enhance the operational efficiency, predictive maintenance, and strategic deployment of these critical grid components. Users frequently inquire about AIs role in optimizing reactive power compensation, predicting potential failures, and integrating shunt reactors more seamlessly into smart grid ecosystems. Key themes include the shift from traditional, static operation to dynamic, AI-driven control, and the potential for AI to extend reactor lifespan and reduce operational expenditures by minimizing unscheduled downtime and improving overall grid reliability. Expectations are high for AI to transform reactive power management from a reactive process into a proactive, predictive function.

While Single Phase Fixed Shunt Reactors themselves are static devices, AI significantly impacts their strategic deployment and operational context within the broader power grid. AI-powered analytics can process vast amounts of real-time grid data, including voltage levels, load patterns, and fault occurrences, to recommend optimal switching schedules for fixed reactors where applicable. This enables utilities to dynamically manage reactive power flow more effectively, ensuring that reactors are engaged precisely when and where needed to prevent overvoltage conditions or minimize transmission losses, leading to more efficient and resilient grid operation compared to manual or time-based switching protocols. The ability of AI to identify subtle patterns in grid behavior allows for more intelligent use of fixed assets.

Furthermore, AI is instrumental in the predictive maintenance of single phase fixed shunt reactors. By continuously monitoring operational parameters such as temperature, vibration, and oil quality, AI algorithms can detect anomalies and predict potential equipment failures long before they occur. This predictive capability allows utilities to schedule maintenance proactively, minimizing costly outages and extending the operational lifespan of these high-value assets. AI also aids in asset management by optimizing inventory, spare parts, and maintenance crew deployment, thereby reducing overall operational costs. The long-term impact of AI will likely involve the development of highly autonomous grids where the management of reactive power devices, including fixed shunt reactors, is largely automated and optimized in real-time by intelligent systems, paving the way for more resilient and self-healing electricity networks.

- AI optimizes switching schedules for fixed reactors based on real-time grid conditions.

- Predictive maintenance driven by AI reduces downtime and extends reactor lifespan.

- AI-powered analytics enhance grid stability and reduce transmission losses.

- Smart grid integration allows AI to manage reactive power more dynamically.

- Improved asset management through AI optimizes resource allocation for maintenance.

DRO & Impact Forces Of Single Phase Fixed Shunt Reactor Market

The Single Phase Fixed Shunt Reactor Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, all shaping its trajectory. A primary driver is the accelerating integration of renewable energy sources, such as wind and solar, into national grids. These intermittent sources introduce substantial voltage fluctuations and reactive power imbalances, making shunt reactors indispensable for maintaining grid stability and power quality. Alongside this, the global push for grid modernization and infrastructure upgrades, particularly in developing economies, further fuels demand for reliable reactive power compensation. The expansion of long-distance transmission lines to deliver power from remote generation sites to consumption centers inherently necessitates shunt reactors to mitigate capacitive effects and prevent overvoltages, solidifying their role as critical grid components. Increased industrialization and urbanization globally also contribute, as robust and stable power supplies are essential for burgeoning industrial complexes and expanding urban centers.

Despite these strong drivers, the market faces notable restraints. The high upfront capital cost associated with the manufacturing and installation of single phase fixed shunt reactors can be a significant barrier for some utilities and smaller grid operators, particularly in regions with limited financial resources. The complex installation process, often requiring specialized expertise and extensive planning for integration into existing grid infrastructure, can also deter rapid adoption. Furthermore, the fixed nature of these reactors means they offer less flexibility in reactive power compensation compared to more advanced, variable solutions like STATCOMs or switched capacitor banks, which might be preferred in highly dynamic grid environments. Regulatory hurdles and lengthy approval processes for new power projects can also delay procurement and deployment, impacting market growth momentum.

Opportunities within the Single Phase Fixed Shunt Reactor Market are abundant and largely tied to technological advancements and evolving energy landscapes. The increasing focus on smart grid development presents a substantial opportunity for integrating these reactors with advanced monitoring and control systems, enhancing their operational efficiency and adaptability within intelligent networks. Emerging markets in Asia-Pacific, Latin America, and Africa, characterized by rapid economic growth and underdeveloped power infrastructure, offer significant untapped potential for new installations and grid expansion projects. Moreover, the growing emphasis on energy efficiency and reduction of transmission losses globally creates a persistent demand for optimized reactive power management. Innovation in materials and design, leading to more compact, efficient, and cost-effective reactors, also represents a key opportunity to overcome current restraints and broaden market adoption across diverse applications and geographies.

Segmentation Analysis

The Single Phase Fixed Shunt Reactor Market is comprehensively segmented by various parameters, providing a detailed understanding of its dynamics across different product types, voltage levels, and end-use applications. This segmentation helps identify key growth areas, market preferences, and strategic opportunities for manufacturers and stakeholders. The market is primarily categorized based on core type, distinguishing between oil-immersed and dry-type reactors, each offering distinct advantages in terms of cooling, size, and environmental considerations. Further segmentation occurs by voltage class, reflecting the diverse requirements of transmission and distribution networks from medium to ultra-high voltages, alongside a crucial breakdown by the primary end-user sectors, including utilities, industrial facilities, and commercial enterprises. Each segment demonstrates unique demand drivers and adoption patterns, contributing to the markets overall growth trajectory and competitive landscape.

- By Core Type: Oil-Immersed Shunt Reactors, Dry-Type (Air-Core) Shunt Reactors

- By Voltage Level: Medium Voltage (up to 36 kV), High Voltage (36 kV to 245 kV), Extra High Voltage (245 kV to 800 kV), Ultra High Voltage (above 800 kV)

- By Application: Utilities (Transmission & Distribution), Industrial (e.g., Heavy Manufacturing, Chemical, Metals & Mining), Commercial (e.g., Data Centers, Large Infrastructures)

- By Rating: Small (up to 50 MVAR), Medium (50 MVAR to 200 MVAR), Large (above 200 MVAR)

Single Phase Fixed Shunt Reactor Market Value Chain Analysis

The value chain for the Single Phase Fixed Shunt Reactor Market begins with the upstream segment, which primarily involves the sourcing and processing of essential raw materials. Key components include high-grade electrical steel for the core, copper for windings, specialized insulation materials (such as cellulose paper, pressboard, and insulating oils), and structural materials like steel for tanks and cooling systems. Suppliers in this phase are critical for providing high-quality, reliable, and cost-effective inputs, as the performance and longevity of the reactor are heavily dependent on the quality of these raw materials. Robust supply chain management is vital to ensure consistent material availability, manage price volatility, and maintain manufacturing standards across the industry.

Moving downstream, the value chain encompasses the manufacturing, assembly, and testing phases, where raw materials are transformed into finished shunt reactors. This stage involves complex engineering, precision winding, core assembly, insulation system integration, and final testing to ensure compliance with stringent industry standards and customer specifications. Manufacturers leverage advanced design tools, automated production lines, and rigorous quality control processes to produce reliable and efficient reactors. Following manufacturing, the distribution channel plays a crucial role in bringing these products to end-users. This involves both direct sales, where manufacturers engage directly with large utilities or engineering, procurement, and construction (EPC) contractors, and indirect channels, which may include distributors, system integrators, or local representatives, especially for smaller projects or specific regional markets. The choice of distribution channel often depends on the projects scale, geographical reach, and the manufacturers established market presence.

The final stages of the value chain involve installation, commissioning, and aftermarket services. EPC contractors and specialized installation companies typically handle the complex on-site integration of shunt reactors into the power grid, often requiring civil works, electrical connections, and extensive testing to ensure seamless operation. Post-installation, the value chain extends to comprehensive aftermarket services, including maintenance, repair, spare parts supply, and technical support. These services are critical for ensuring the long-term reliability and performance of the reactors, as well as for maximizing their operational lifespan. Strong direct relationships between manufacturers and their end-users (utilities and industrial clients) are often fostered at this stage, building trust and facilitating continuous improvement based on operational feedback and evolving grid requirements.

Single Phase Fixed Shunt Reactor Market Potential Customers

The primary end-users and potential buyers in the Single Phase Fixed Shunt Reactor Market are predominantly entities involved in the generation, transmission, and distribution of electrical power, along with large industrial and commercial enterprises that require stable and high-quality power for their operations. National and regional power grid operators, often referred to as Transmission System Operators (TSOs) and Distribution System Operators (DSOs), constitute the largest customer segment. These entities are responsible for the reliable and efficient operation of the electricity grid, frequently investing in shunt reactors to manage voltage profiles, reduce reactive power losses, and ensure system stability, especially with the integration of remote generation sources and extensive cabling infrastructure. Their procurement decisions are driven by grid modernization initiatives, asset replacement cycles, and the need to accommodate growing electricity demand while enhancing grid resilience against various operational challenges and fluctuations.

Beyond traditional utilities, the market also targets Engineering, Procurement, and Construction (EPC) companies that undertake large-scale power projects. These contractors often procure shunt reactors as part of broader substation development, transmission line expansion, or new power plant integration projects. They act as intermediaries, sourcing equipment on behalf of the ultimate end-users, and their purchasing decisions are influenced by project specifications, supplier reliability, and cost-effectiveness. The increasing number of renewable energy projects, such as large-scale wind farms and solar power plants, also represents a significant customer base. Developers and operators of these facilities require shunt reactors to compensate for the capacitive effects of collector cables and ensure stable voltage output when connecting to the main grid, thereby improving the overall power quality and efficiency of renewable energy integration into the existing infrastructure.

Furthermore, various industrial and commercial sectors emerge as crucial potential customers, particularly those with substantial power consumption and a high dependence on stable electricity supply. Heavy manufacturing industries, including metals, chemicals, and mining, often install shunt reactors to mitigate power quality issues, such as harmonic distortions and voltage sags, that can disrupt sensitive equipment and processes. Data centers, which require an exceptionally stable and uninterrupted power supply, also represent a growing segment, utilizing shunt reactors to maintain optimal voltage levels and protect their critical IT infrastructure. Other commercial entities with extensive electrical infrastructure, such as large hospital complexes, airports, and major commercial hubs, also form part of the potential customer base seeking to enhance their power system reliability and operational efficiency through effective reactive power management solutions.

Single Phase Fixed Shunt Reactor Market Key Technology Landscape

The Single Phase Fixed Shunt Reactor Market is characterized by a mature yet continuously evolving technology landscape, driven by the persistent demand for enhanced efficiency, reliability, and grid integration capabilities. Core technological advancements primarily focus on improving core materials, winding designs, insulation systems, and thermal management. The use of advanced electrical steel with optimized grain orientation and lower core losses directly contributes to higher efficiency and reduced operational costs for the reactors. Innovations in core construction, such as gapless cores or multi-gapped core designs, aim to minimize magnetizing current and optimize impedance characteristics, further enhancing performance. For air-core reactors, developments in composite materials for structural support and improved winding techniques are crucial for maintaining mechanical stability and reducing footprint while ensuring effective inductive reactance.

Beyond the fundamental design, significant technological developments are observed in the insulation and cooling systems, which are critical for the longevity and reliable operation of high-voltage reactors. Research into more environmentally friendly insulating liquids, such as ester-based fluids, offers safer and more sustainable alternatives to traditional mineral oils, providing higher flash points and biodegradability. Advances in solid insulation materials also contribute to more compact and robust designs, capable of withstanding higher dielectric stresses. Thermal management technologies, including optimized cooling duct designs and enhanced heat dissipation systems, are essential for managing temperature rises, especially in high-power applications, thereby improving the overall lifespan and reliability of the reactor under demanding operational conditions. These innovations are vital for allowing reactors to operate efficiently in diverse climatic conditions and under increasing load demands.

Another area of technological evolution involves the integration of smart monitoring and diagnostic systems. While fixed shunt reactors are inherently passive, their operational status and surrounding grid conditions can be significantly enhanced through intelligent sensors and data analytics. Digital monitoring devices track parameters such as winding temperature, oil temperature, pressure, and partial discharges, providing real-time data for predictive maintenance and operational optimization. These systems often incorporate communication interfaces to transmit data to a central control system, enabling remote diagnostics and supporting smart grid functionalities. The drive towards digital substations and grid automation further propels the demand for reactors that can seamlessly integrate with these advanced control architectures, ensuring that fixed shunt reactors, while simple in principle, remain a vital and adaptable component within the increasingly complex and intelligent electrical power infrastructure.

Regional Highlights

- Asia-Pacific: Dominant market due to rapid industrialization, extensive grid expansion projects in China and India, and increasing renewable energy integration, requiring significant reactive power compensation.

- North America: Strong market driven by aging infrastructure replacement, smart grid initiatives, and the integration of large-scale renewable energy projects, particularly in the US and Canada.

- Europe: Mature market characterized by stringent grid reliability standards, high penetration of offshore wind power, and ongoing efforts to modernize transmission networks and reduce carbon emissions.

- Latin America: Emerging market with increasing investments in new power generation capacity and transmission infrastructure, driven by economic growth and rising electricity demand in countries like Brazil and Mexico.

- Middle East & Africa: Growing market supported by robust investments in power infrastructure development, especially in the GCC countries for oil and gas operations, and initiatives to improve energy access in Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Single Phase Fixed Shunt Reactor Market.- Hitachi Energy Ltd.

- Siemens Energy AG

- General Electric Company

- ABB Ltd.

- Toshiba Energy Systems & Solutions Corporation

- Bharat Heavy Electricals Limited (BHEL)

- Hyosung Heavy Industries Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Single Phase Fixed Shunt Reactor market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Single Phase Fixed Shunt Reactor?

A Single Phase Fixed Shunt Reactor is an inductive electrical device permanently connected in parallel to a power line to absorb reactive power, primarily used to compensate for capacitive effects in long transmission lines or cables, thereby stabilizing grid voltage and improving power quality.

Why are shunt reactors essential for modern power grids?

Shunt reactors are essential for modern power grids to prevent overvoltage conditions, reduce transmission losses, and maintain voltage stability, especially with the increased integration of renewable energy sources and the expansion of high-voltage transmission lines that generate excess reactive power.

How does a fixed shunt reactor differ from a variable shunt reactor?

A fixed shunt reactor has a constant inductive reactance and is typically switched on or off as needed, whereas a variable shunt reactor can dynamically adjust its inductive reactance in real-time to provide precise and continuous reactive power compensation, offering greater flexibility for dynamic grid conditions.

What are the main applications of Single Phase Fixed Shunt Reactors?

Primary applications include high-voltage transmission lines, underground cable systems, renewable energy generation plants (wind, solar), and industrial facilities to manage reactive power, stabilize voltage, and enhance overall power system reliability and efficiency.

What factors are driving the growth of the Single Phase Fixed Shunt Reactor Market?

Key drivers include global grid modernization initiatives, the accelerating integration of renewable energy sources, the expansion of high-voltage transmission infrastructure, and increasing industrialization and urbanization, all demanding stable and efficient power delivery.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager