Slideway Oil Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428114 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Slideway Oil Market Size

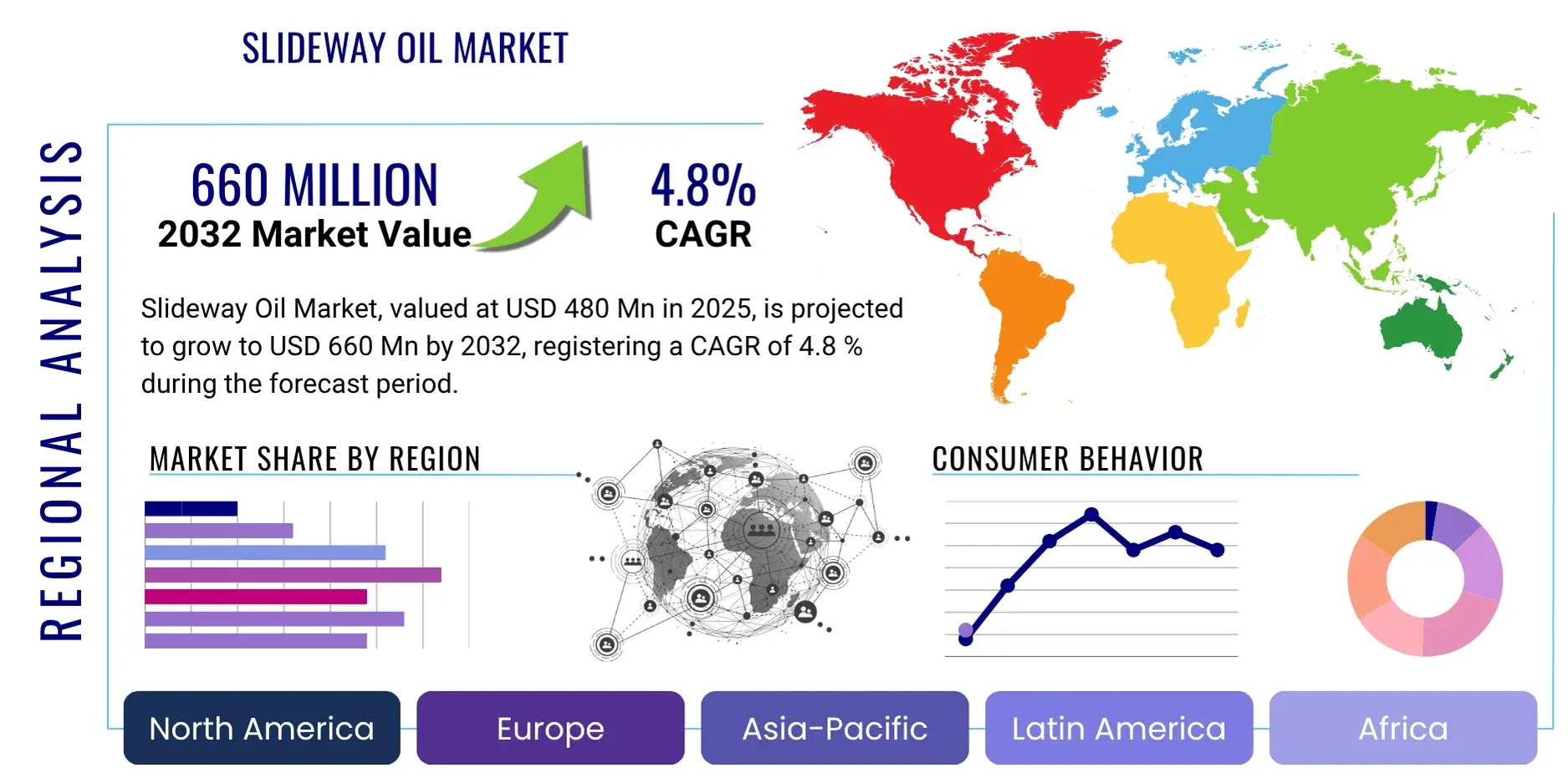

The Slideway Oil Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 480 million in 2025 and is projected to reach USD 660 million by the end of the forecast period in 2032.

Slideway Oil Market introduction

The Slideway Oil Market encompasses a specialized segment of industrial lubricants designed to facilitate the smooth, precise, and chatter-free movement of machine tool slideways, guides, and tables. These oils are formulated to offer excellent lubricity, strong adhesion to metal surfaces, and superior demulsibility, ensuring optimal performance and protection of critical machinery components under varying operational conditions. The unique characteristics of slideway oils prevent stick-slip phenomena, reduce friction, and minimize wear, which are essential for maintaining the accuracy and lifespan of sophisticated manufacturing equipment.

Product descriptions typically highlight their unique blend of high-quality base oils, often refined mineral oils or advanced synthetics, combined with specific additive packages. These additives impart properties such as extreme pressure (EP) resistance, anti-wear capabilities, corrosion inhibition, and strong adhesion to prevent runoff, especially on vertical slides. The primary applications for slideway oils are found in a wide array of industrial sectors, predominantly in metalworking, where they are indispensable for CNC machining centers, grinding machines, milling machines, lathes, and other precision manufacturing equipment. Their role extends to general industrial machinery requiring stable and accurate linear motion.

The benefits derived from using specialized slideway oils are substantial, including enhanced machine precision, extended tool life, reduced energy consumption due to lower friction, and significant prevention of wear on expensive guide ways. These lubricants also contribute to a cleaner work environment by separating quickly from water-based coolants, thereby extending coolant life and reducing downtime associated with maintenance. Key driving factors for the market include the continuous growth of the manufacturing sector, particularly in precision engineering and automation, increasing demand for high-performance lubricants that meet stringent industrial standards, and the imperative for businesses to maximize operational efficiency and equipment longevity. Technological advancements in machine tool design, which require even more specialized and robust lubrication solutions, further propel market expansion.

Slideway Oil Market Executive Summary

The Slideway Oil Market is experiencing steady expansion, driven by the persistent global growth in manufacturing, particularly in sectors reliant on precision machinery like automotive, aerospace, and general metalworking. Business trends indicate a shift towards high-performance synthetic and semi-synthetic slideway oils, favored for their enhanced longevity, superior thermal stability, and improved additive packages that deliver better protection and efficiency. Manufacturers are increasingly focused on developing environmentally friendly formulations with lower volatile organic compound (VOC) emissions and extended drain intervals, aligning with sustainability goals and operational cost reduction. Consolidations and strategic partnerships among lubricant suppliers are also becoming prevalent, aimed at broadening product portfolios and enhancing distribution networks to cater to a diverse global customer base.

Regional trends reveal Asia Pacific as a dominant and rapidly growing market, fueled by robust industrialization in countries like China, India, and Southeast Asian nations, alongside significant foreign investments in manufacturing capabilities. Europe and North America, while more mature, maintain strong demand for premium slideway oils due to their advanced manufacturing infrastructure and stringent quality control standards, driving innovation in specialized lubricant solutions. Latin America, the Middle East, and Africa are showing nascent growth, as industrial development and infrastructure projects stimulate the need for reliable machinery lubrication. Each region presents unique market dynamics influenced by local industrial policies, environmental regulations, and the level of technological adoption in manufacturing processes.

Segment trends underscore the increasing preference for higher viscosity grades in heavy-duty applications and synthetic formulations for critical, high-precision operations. The application segment for metalworking machines, including CNC machinery, continues to hold the largest share, reflecting its critical dependence on stable and accurate linear motion. The demand for slideway oils with excellent demulsibility properties is particularly high, driven by the widespread use of water-miscible coolants in modern machining operations, which necessitates lubricants that can rapidly separate from contaminants. Furthermore, the trend towards smart manufacturing and Industry 4.0 is influencing product development, with a growing emphasis on lubricants that can perform optimally under conditions monitored by predictive maintenance systems, ensuring peak machine performance and reducing unplanned downtime across all segments.

AI Impact Analysis on Slideway Oil Market

Common user questions regarding AI's impact on the Slideway Oil Market frequently revolve around how artificial intelligence can optimize lubricant performance, predict maintenance needs, and revolutionize supply chain management within industrial settings. Users are keen to understand if AI can lead to smarter lubrication schedules, enhance the development of next-generation lubricants, or even create adaptive systems that adjust oil properties in real-time based on machine conditions. Concerns often include the initial investment costs for AI integration, data security, and the necessity for specialized expertise to implement and manage such advanced systems. There is also an underlying expectation that AI will ultimately drive greater efficiency, reduce operational expenditures, and extend the lifespan of high-value industrial machinery, fundamentally altering how slideway oils are selected, utilized, and managed.

- AI-driven predictive maintenance systems can monitor machine slideway conditions in real-time, optimizing oil change intervals and preventing premature wear.

- Generative AI can accelerate the research and development of novel slideway oil formulations by simulating performance under various conditions, identifying optimal additive combinations.

- AI-powered sensor networks can detect early signs of lubricant degradation or contamination, allowing for proactive intervention and extending equipment life.

- Supply chain optimization using AI can forecast demand for specific slideway oil types, streamline inventory management, and enhance logistics efficiency for manufacturers and distributors.

- AI analytics can analyze operational data to recommend the most suitable slideway oil for specific machine types and operating environments, improving lubrication precision.

- Automated quality control systems integrated with AI can monitor slideway oil production, ensuring consistent product quality and adherence to specifications.

DRO & Impact Forces Of Slideway Oil Market

The Slideway Oil Market is propelled by several significant drivers, including the expanding global manufacturing sector, particularly in emerging economies, which necessitates a growing fleet of machine tools requiring specialized lubrication. The increasing demand for precision engineering components in industries like automotive, aerospace, and medical devices directly fuels the need for high-performance slideway oils that ensure machine accuracy and reduce wear. Furthermore, the imperative for industries to enhance operational efficiency, minimize downtime, and extend the service life of expensive machinery drives the adoption of premium, long-lasting slideway lubricants. Stringent regulatory standards for environmental protection and worker safety also push for the development and use of more sustainable and eco-friendly oil formulations, stimulating innovation.

However, the market faces notable restraints. The maturity of some industrial markets in developed regions can lead to slower growth rates compared to nascent markets. The fluctuating prices of crude oil, a primary raw material for conventional base oils, can introduce cost volatility for manufacturers, affecting product pricing and profit margins. Additionally, the increasing trend towards maintenance-free machinery or equipment designed with alternative guide systems (e.g., linear guides, roller guides) that may not require traditional slideway oils could potentially limit market expansion. The high upfront cost associated with premium synthetic slideway oils, despite their long-term benefits, can also be a deterrent for small and medium-sized enterprises (SMEs) operating on tight budgets.

Opportunities within the Slideway Oil Market are abundant, especially in the development of bio-based and biodegradable slideway oils that cater to growing environmental consciousness and regulatory pressures, opening new market niches. The integration of advanced sensor technologies and the rise of Industry 4.0 present significant opportunities for smart lubrication solutions, where oils can be monitored and optimized in real-time, offering value-added services. Expansion into untapped industrial sectors or geographic regions undergoing rapid industrialization also provides avenues for growth. Moreover, the continuous innovation in additive technology to enhance specific properties like extreme pressure resistance, demulsibility, and anti-chatter characteristics offers a competitive edge and allows for differentiation in a crowded market. The need for specialized lubricants for new generations of high-speed and high-precision machine tools creates a continuous demand for advanced formulations.

Segmentation Analysis

The Slideway Oil Market is typically segmented based on several critical factors, including the type of base oil used, the specific application of the lubricant, its viscosity grade, and the end-use industry. These segmentations provide a granular view of the market dynamics, helping manufacturers tailor their products to specific customer needs and market demands. The diverse requirements across different industrial processes and machinery types necessitate a wide range of slideway oil formulations, each designed to optimize performance, protect equipment, and ensure operational continuity. Understanding these segments is crucial for strategic market positioning and product development.

- By Base Oil Type:

- Mineral Oil Based Slideway Oils

- Synthetic Oil Based Slideway Oils (e.g., PAO, Ester-based)

- Semi-Synthetic Slideway Oils

- Bio-based Slideway Oils

- By Viscosity Grade (ISO VG):

- ISO VG 32

- ISO VG 46

- ISO VG 68

- ISO VG 100

- ISO VG 150

- ISO VG 220 and above

- By Application:

- Metalworking Machines (e.g., CNC machines, Lathes, Grinders, Milling machines)

- Textile Machinery

- Paper & Pulp Machinery

- Heavy Industrial Equipment

- Other Industrial Applications

- By End-Use Industry:

- Automotive

- Aerospace & Defense

- Heavy Machinery & Equipment

- Metal Fabrication

- Textile

- General Manufacturing

- Others (e.g., Marine, Energy)

Value Chain Analysis For Slideway Oil Market

The value chain for the Slideway Oil Market begins with upstream activities involving the sourcing and refining of base oils and the manufacturing of performance-enhancing additives. Key raw materials include crude oil for mineral oil-based lubricants, or specific chemicals for synthetic base oils like polyalphaolefins (PAO) and esters. Additive suppliers play a crucial role, providing a range of chemicals such as anti-wear agents, extreme pressure additives, rust inhibitors, demulsifiers, and adhesion promoters, which are essential for imparting the specialized properties of slideway oils. These suppliers often engage in extensive research and development to create innovative additive packages that meet evolving industrial demands and environmental regulations.

Midstream activities primarily involve the blending and formulation processes undertaken by lubricant manufacturers. Here, base oils are carefully combined with various additives in precise ratios to produce slideway oils of different viscosity grades and performance characteristics. This stage also includes quality control, packaging, and branding. Downstream activities focus on the distribution and sales of the finished products. Slideway oils reach end-users through a combination of direct and indirect distribution channels. Direct channels involve manufacturers selling directly to large industrial clients, often through dedicated sales teams or technical support engineers, providing customized solutions and bulk supplies. This approach allows for closer relationships and tailored technical assistance.

Indirect distribution channels are more diverse and include a network of industrial distributors, wholesalers, and retailers. These intermediaries play a vital role in reaching a broader customer base, including smaller manufacturing units and workshops. They often stock a wide range of lubricant products and provide localized support, warehousing, and logistics. E-commerce platforms are also emerging as a significant indirect channel, especially for standardized products or for reaching geographically dispersed customers. Both direct and indirect channels are critical for market penetration and ensuring product availability, with the choice often depending on the scale of the customer, the volume of purchase, and the complexity of technical requirements. Strong distribution networks are essential for maintaining market share and responsiveness to customer needs in the competitive slideway oil market.

Slideway Oil Market Potential Customers

Potential customers for slideway oil are predominantly found within the manufacturing and industrial sectors that operate precision machinery requiring stable and accurate linear motion. The primary end-users are companies engaged in metalworking, including those operating CNC machining centers, lathes, milling machines, grinding machines, and boring machines. These industries rely heavily on slideway oils to prevent stick-slip, reduce friction, and protect guide ways from wear, thereby ensuring the accuracy, repeatability, and surface finish of machined parts. The automotive manufacturing sector is a significant consumer, using slideway oils in the production lines for engine components, chassis parts, and other precision-engineered elements.

Beyond metalworking, other key buyers include companies in the aerospace and defense industries, which demand exceptionally high precision and reliability from their machinery, making specialized slideway oils indispensable. Heavy machinery and equipment manufacturers, as well as firms in the general manufacturing, textile, and paper & pulp industries, also represent substantial customer segments. Any industrial setting with machinery featuring slides, guides, or linear motion systems, such as packaging machinery, woodworking equipment, and even certain types of robotics, will be a potential purchaser of slideway oils. The decision-makers typically include maintenance managers, procurement officers, and production engineers who prioritize equipment longevity, operational efficiency, and product quality in their selection criteria.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 480 Million |

| Market Forecast in 2032 | USD 660 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Shell plc, ExxonMobil Corporation, Castrol (BP plc), TotalEnergies SE, Chevron Corporation, FUCHS Petrolub SE, Valvoline Inc., Idemitsu Kosan Co., Ltd., ENEOS Corporation, Phillips 66 Company, Quaker Houghton, Kluber Lubrication (Freudenberg Chemical Specialties), Petro-Canada Lubricants Inc. (HollyFrontier Corporation), Sinopec Group, LUKOIL, Indian Oil Corporation Ltd., Pertamina (Persero), SK Lubricants, GS Caltex, Motul S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Slideway Oil Market Key Technology Landscape

The Slideway Oil Market's technological landscape is continuously evolving, driven by the need for enhanced machine performance, longer lubricant life, and greater environmental compliance. A core technological aspect involves the development of advanced additive packages. These packages incorporate anti-wear agents, extreme pressure (EP) additives, friction modifiers, and tackifiers that improve adhesion to vertical and inclined surfaces, significantly reducing stick-slip phenomena and ensuring smooth, precise machine movement. The ongoing research focuses on synergistic combinations of these additives to achieve multi-functional benefits, such as improved demulsibility for rapid separation from water-based coolants, and superior corrosion protection for various metal types.

Another significant technological advancement is in the formulation of base oils, moving beyond traditional mineral oils to more sophisticated synthetic and semi-synthetic alternatives. Synthetic base oils, such as Group IV (PAO) and Group V (esters), offer superior thermal stability, oxidation resistance, and extended service life, which translates into longer drain intervals and reduced maintenance costs for end-users. Bio-based and biodegradable base oils are also gaining traction, driven by environmental regulations and corporate sustainability initiatives, requiring specialized formulation techniques to match the performance characteristics of conventional oils while meeting ecological standards. These advanced formulations allow for operation under more extreme temperatures and loads, which is crucial for modern high-speed and high-precision machine tools.

Furthermore, the integration of smart lubrication technologies represents a burgeoning area within the market. This includes the use of sensors for real-time monitoring of lubricant condition, temperature, viscosity, and contamination levels. These sensors, often connected to a centralized monitoring system or an Industrial Internet of Things (IIoT) platform, can provide data for predictive maintenance algorithms. This technology allows for proactive intervention, preventing equipment failure and optimizing lubricant usage. Nano-lubricants and self-healing lubricants, though still in early stages of commercialization, also represent future technological frontiers, promising to deliver unprecedented levels of wear protection and extended operational periods by integrating microscopic particles or self-repairing polymers into the oil matrix. These innovations collectively aim to maximize efficiency, reduce environmental impact, and enhance the overall reliability and performance of industrial machinery.

Regional Highlights

- Asia Pacific: Dominant market due to rapid industrialization, expansion of automotive, metalworking, and general manufacturing sectors in China, India, Japan, South Korea, and Southeast Asian countries. Significant investments in new production facilities and rising demand for precision machinery are key drivers.

- Europe: Mature market with strong demand for high-performance and specialty slideway oils, particularly in Germany, Italy, and France, driven by advanced manufacturing, automotive, and aerospace industries. Strict environmental regulations promote the adoption of eco-friendly and synthetic lubricants.

- North America: Stable market driven by robust manufacturing, aerospace, and defense industries in the United States and Canada. Emphasis on operational efficiency, machinery longevity, and the adoption of premium, high-quality slideway oils is prominent.

- Latin America: Emerging market with growth potential, particularly in industrializing economies like Brazil and Mexico. Expansion in automotive and general manufacturing sectors contributes to increasing demand for industrial lubricants, including slideway oils.

- Middle East and Africa (MEA): Nascent but growing market, influenced by infrastructure development, diversification of economies away from oil, and growing manufacturing capabilities in countries like Saudi Arabia, UAE, and South Africa. Demand is gradually increasing with industrial expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Slideway Oil Market.- Shell plc

- ExxonMobil Corporation

- Castrol (BP plc)

- TotalEnergies SE

- Chevron Corporation

- FUCHS Petrolub SE

- Valvoline Inc.

- Idemitsu Kosan Co., Ltd.

- ENEOS Corporation

- Phillips 66 Company

- Quaker Houghton

- Kluber Lubrication (Freudenberg Chemical Specialties)

- Petro-Canada Lubricants Inc. (HollyFrontier Corporation)

- Sinopec Group

- LUKOIL

- Indian Oil Corporation Ltd.

- Pertamina (Persero)

- SK Lubricants

- GS Caltex

- Motul S.A.

Frequently Asked Questions

What is slideway oil and why is it important for machine tools?

Slideway oil is a specialized industrial lubricant formulated to ensure smooth, precise, and stick-slip-free movement of machine tool slideways, guides, and tables. It is crucial because it reduces friction and wear, protects valuable machinery components, and maintains the accuracy and longevity of precision manufacturing equipment, directly impacting product quality and operational efficiency.

What are the primary differences between mineral oil-based and synthetic slideway oils?

Mineral oil-based slideway oils are derived from crude oil and offer good general performance, while synthetic slideway oils (e.g., PAO, esters) are chemically engineered to provide superior performance characteristics. Synthetics typically offer enhanced thermal stability, extended service life, better oxidation resistance, and superior performance in extreme conditions, but usually come at a higher cost.

How often should slideway oil be changed?

The frequency of slideway oil changes depends on several factors, including machine operating conditions, oil type, contamination levels, and manufacturer recommendations. Modern industrial practices, often aided by oil analysis and predictive maintenance systems, aim to optimize change intervals, extending them where possible without compromising machine protection, leveraging the longer life of high-performance and synthetic oils.

What is demulsibility and why is it important in slideway oils?

Demulsibility refers to a lubricant's ability to separate quickly and completely from water or water-based fluids, such as coolants. It is crucial for slideway oils because water and coolants often contaminate the lubrication system in metalworking operations. Good demulsibility prevents the formation of stable emulsions, which can degrade lubricant performance, promote corrosion, and reduce the lifespan of both the oil and the machine.

Which industries are the largest consumers of slideway oil?

The largest consumers of slideway oil are industries heavily reliant on precision machine tools. This primarily includes the metalworking sector, encompassing automotive manufacturing, aerospace and defense, and general metal fabrication. Other significant consumers include the heavy machinery and equipment, textile, and paper & pulp industries, all requiring precise linear motion in their production processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager