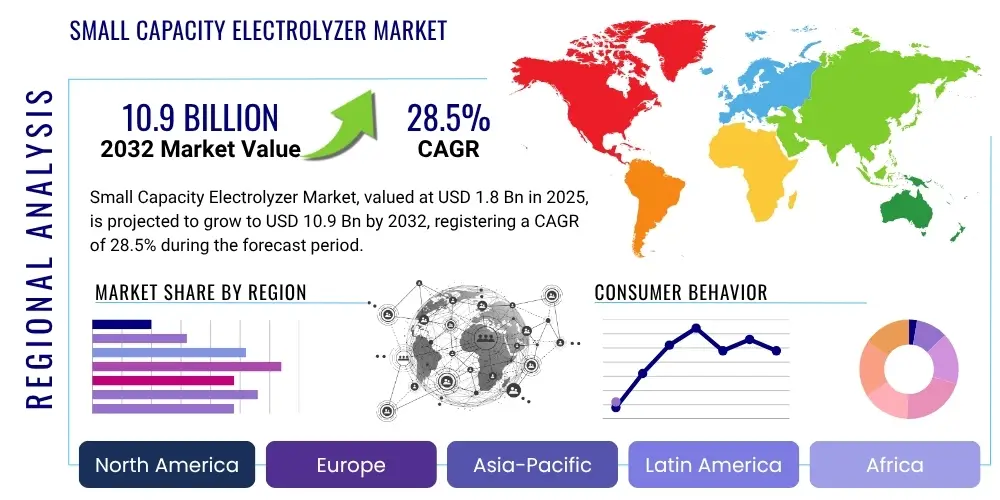

Small Capacity Electrolyzer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430774 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Small Capacity Electrolyzer Market Size

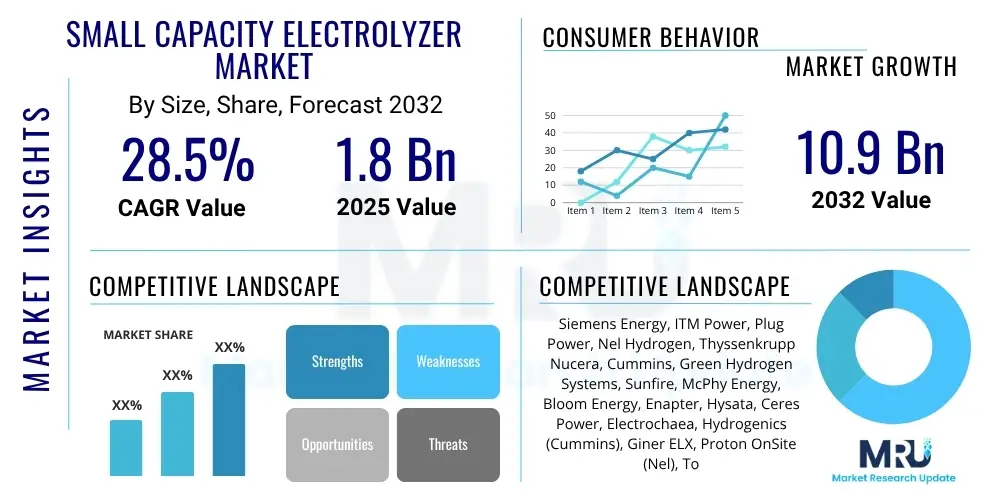

The Small Capacity Electrolyzer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 28.5% between 2025 and 2032. The market is estimated at USD 1.8 Billion in 2025 and is projected to reach USD 10.9 Billion by the end of the forecast period in 2032.

Small Capacity Electrolyzer Market introduction

The Small Capacity Electrolyzer Market encompasses devices designed for efficient hydrogen production on a relatively compact scale, typically ranging from a few kilowatts up to 1 megawatt. These electrolyzers convert water into hydrogen and oxygen through electrolysis, serving as a critical component in the nascent green hydrogen economy. Their smaller footprint and modular nature enable decentralized hydrogen generation, catering to a diverse range of applications where large-scale, centralized hydrogen production is impractical or uneconomical.

Product descriptions for small capacity electrolyzers highlight their versatility, ease of integration, and suitability for on-site hydrogen production. Major applications span industrial feedstock, energy storage for renewable power, refueling stations for fuel cell vehicles, and even residential or commercial energy systems. The inherent benefits include reduced transportation costs for hydrogen, improved energy independence, lower capital expenditure for smaller deployments, and the ability to integrate seamlessly with intermittent renewable energy sources such as solar and wind power. These systems are crucial for fostering a distributed hydrogen infrastructure.

Driving factors propelling this market's growth include the global impetus for decarbonization, stringent environmental regulations, and the increasing adoption of renewable energy technologies. Falling costs of renewable electricity make green hydrogen production more economically viable. Furthermore, government incentives, subsidies for hydrogen projects, and rising awareness of hydrogen's role in achieving net-zero emissions are significantly stimulating demand. The market is also benefiting from continuous technological advancements that enhance the efficiency, durability, and cost-effectiveness of these compact systems, making them increasingly attractive to a broader customer base.

Small Capacity Electrolyzer Market Executive Summary

The Small Capacity Electrolyzer Market is experiencing robust growth, driven by an escalating global demand for green hydrogen and supportive regulatory frameworks aimed at decarbonization. Business trends indicate a strong focus on modularity, scalability, and enhanced efficiency, with manufacturers investing heavily in research and development to reduce costs and improve performance. Key players are forming strategic partnerships and collaborations across the hydrogen value chain to offer integrated solutions, encompassing everything from renewable energy sourcing to hydrogen storage and distribution. There is also a notable shift towards automation and digital integration in electrolyzer operation and maintenance, optimizing system longevity and output.

Regionally, Europe and North America are at the forefront of market adoption, largely due to ambitious hydrogen strategies, significant public and private investments, and a mature renewable energy infrastructure. Countries such as Germany, the UK, and the Netherlands in Europe, and the United States and Canada in North America, are implementing policies to accelerate green hydrogen production. Asia Pacific, particularly China, Japan, and South Korea, is rapidly emerging as a significant market, propelled by industrial decarbonization goals, a growing interest in fuel cell electric vehicles, and strategic national hydrogen roadmaps. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, driven by abundant renewable resources and the potential for green hydrogen exports.

In terms of segmentation, the Proton Exchange Membrane (PEM) and Alkaline Electrolyzer types currently dominate the market due to their technological maturity and proven performance. However, Anion Exchange Membrane (AEM) electrolyzers are gaining traction as a cost-effective alternative that combines some benefits of both PEM and alkaline technologies. Solid Oxide Electrolyzer Cells (SOEC) are also under intense development for high-temperature applications. By capacity, units up to 100 kW are seeing strong demand for niche and decentralized applications, while the 100 kW to 1 MW range is critical for small-to-medium industrial and energy storage projects. Applications in industrial feedstock and energy storage are the primary revenue generators, though the mobility sector and power-to-gas initiatives are anticipated to exhibit the fastest growth rates over the forecast period.

AI Impact Analysis on Small Capacity Electrolyzer Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the efficiency and operational economics of small capacity electrolyzers. Key themes revolve around optimizing hydrogen production rates, predicting maintenance needs to prevent downtime, and enhancing the overall system lifespan. There is a strong expectation that AI will unlock new levels of performance and cost reduction, making green hydrogen more competitive. Users also express interest in AI's role in integrating electrolyzers seamlessly with intermittent renewable energy sources, ensuring stable and efficient operation despite fluctuating power inputs. The core concern often centers on whether AI can truly deliver tangible improvements in reliability and cost-effectiveness for these compact systems, and how readily it can be implemented without significant infrastructure overhauls.

- Predictive maintenance through AI algorithms minimizes downtime and reduces operational costs by identifying potential failures before they occur.

- Real-time process optimization enables electrolyzers to adjust parameters dynamically, maximizing hydrogen output and energy efficiency based on power input, water quality, and demand.

- Enhanced energy management allows AI to intelligently integrate electrolyzers with renewable energy grids, optimizing energy consumption and production schedules to minimize electricity costs and grid impact.

- Accelerated research and development by AI-driven simulations and data analysis helps engineers design more efficient electrode materials, membranes, and system architectures, speeding up innovation cycles.

- Improved quality control and diagnostics utilize AI to monitor system health, detect anomalies, and ensure consistent hydrogen purity and performance over the electrolyzer's operational lifetime.

DRO & Impact Forces Of Small Capacity Electrolyzer Market

The Small Capacity Electrolyzer Market is propelled by a confluence of powerful drivers, primarily the urgent global imperative for decarbonization and the transition to cleaner energy sources. Robust government policies, incentives, and subsidies for green hydrogen production and adoption are creating a favorable investment landscape. The declining cost of renewable energy, particularly solar and wind power, directly reduces the operational expense of green hydrogen, making small capacity electrolyzers more economically viable for diverse applications. Furthermore, the increasing demand from industries seeking to reduce their carbon footprint, coupled with advancements in hydrogen storage and distribution technologies, further strengthens market growth. The modular and scalable nature of small electrolyzers is particularly appealing for decentralized production and integration into existing infrastructure.

Despite significant growth prospects, several restraints challenge the market. The relatively high upfront capital expenditure for electrolyzer systems, although decreasing, can still be a barrier for widespread adoption, particularly for smaller enterprises or remote applications. A lack of comprehensive hydrogen infrastructure, including robust storage, transportation, and refueling networks, limits large-scale deployment, especially for mobility applications. Technical challenges such as the degradation of electrode materials, limited efficiency at very low capacities, and the need for high-purity water can impact performance and operational costs. Furthermore, the nascent stage of the green hydrogen economy means that regulatory frameworks and standardization are still evolving in many regions, creating uncertainty for investors and developers.

Opportunities for the Small Capacity Electrolyzer Market are abundant and diverse. The burgeoning power-to-X sector, where surplus renewable electricity is converted into hydrogen and then into other synthetic fuels or chemicals, presents a significant growth avenue. The market can also capitalize on remote power generation applications, off-grid communities, and niche industrial uses where on-site hydrogen production offers substantial advantages. Continuous innovation in materials science, catalysts, and system design promises to enhance efficiency and reduce costs further. The growing global investment in hydrogen valleys and hubs, aimed at creating integrated hydrogen ecosystems, will significantly boost demand for small and medium-scale electrolyzers. As economies transition away from fossil fuels, the role of green hydrogen produced by small capacity electrolyzers in a distributed energy landscape is set to expand dramatically.

Segmentation Analysis

The Small Capacity Electrolyzer Market is comprehensively segmented to provide granular insights into its diverse components, technologies, applications, and end-users. This segmentation allows for a detailed understanding of market dynamics, growth drivers, and competitive landscapes across various sub-sectors. Key segmentation criteria include the type of electrolyzer technology employed, the production capacity of the unit, the specific applications for which hydrogen is generated, and the ultimate end-user industries utilizing the green hydrogen. Each segment presents unique opportunities and challenges, reflecting the evolving technological maturity and varying demand profiles across different market verticals.

- Electrolyzer Type

- Alkaline Electrolyzers

- Proton Exchange Membrane (PEM) Electrolyzers

- Anion Exchange Membrane (AEM) Electrolyzers

- Solid Oxide Electrolyzer Cells (SOEC)

- Capacity

- Up to 100 kW

- 100 kW to 500 kW

- 500 kW to 1 MW

- Application

- Industrial Feedstock (e.g., Ammonia, Methanol, Steel)

- Energy Storage and Grid Balancing

- Fueling Stations (Mobility)

- Residential and Commercial Energy Systems

- Power-to-Gas (P2G)

- Research and Development

- End-Use

- Chemical Industry

- Electronics Industry

- Metals and Mining

- Transportation and Logistics

- Power Generation and Utilities

- Oil and Gas (for green hydrogen blending)

- Food and Beverages

Value Chain Analysis For Small Capacity Electrolyzer Market

The value chain for the Small Capacity Electrolyzer Market begins with upstream activities involving the sourcing and processing of critical raw materials and components. This includes specialized materials for electrodes, such as platinum group metals (PGMs) for PEM electrolyzers or nickel-based alloys for alkaline systems, as well as membranes, catalysts, power electronics, and balance of plant components like purification systems and gas separators. Suppliers in this segment play a crucial role in ensuring the quality, availability, and cost-effectiveness of these foundational elements. Research and development institutions are also critical upstream, driving innovation in material science and system design to enhance efficiency and durability.

Moving downstream, the value chain encompasses the manufacturing, assembly, and testing of the electrolyzer systems, followed by their integration into larger hydrogen production units or energy systems. This stage often involves collaboration between electrolyzer manufacturers and system integrators who specialize in designing and deploying complete hydrogen solutions tailored to specific customer needs. Post-installation, the downstream activities extend to operational support, maintenance services, and the management of hydrogen storage and distribution. This involves specialized companies dealing with high-pressure storage tanks, pipelines, and logistics for hydrogen delivery to end-users, ensuring safe and efficient supply. The availability of a robust service network is paramount for the long-term success and widespread adoption of small capacity electrolyzers.

Distribution channels for small capacity electrolyzers are multifaceted, adapting to the diverse customer base. Direct sales are common for larger industrial clients or major energy projects, where manufacturers engage directly with end-users or engineering, procurement, and construction (EPC) firms. For smaller, more standardized units, distribution often occurs through specialized industrial equipment distributors, energy solution providers, or even online platforms catering to niche applications or research institutions. Indirect channels involve partnerships with renewable energy developers, utility companies, and automotive manufacturers who integrate electrolyzers into their broader offerings. The choice of channel is often dictated by the capacity of the electrolyzer, the complexity of the installation, and the geographic reach required, with a trend towards integrated solution providers offering turnkey hydrogen systems.

Small Capacity Electrolyzer Market Potential Customers

Potential customers for small capacity electrolyzers are broadly diversified across various industries and applications, reflecting the versatility of green hydrogen. The chemical industry represents a significant segment, using hydrogen as a feedstock for producing ammonia, methanol, and in refining processes, seeking to replace fossil fuel-derived hydrogen with cleaner alternatives. Similarly, the electronics and metals industries require high-purity hydrogen for manufacturing semiconductors, annealing, and reducing agents, offering a robust market for on-site, small-scale green hydrogen production. Companies focused on sustainable manufacturing and those with ambitious decarbonization targets are prime candidates for adopting these technologies.

The energy sector, encompassing power generation utilities, renewable energy developers, and energy storage solution providers, forms another critical customer base. Small capacity electrolyzers are vital for grid balancing, storing excess renewable electricity as hydrogen, and enabling power-to-gas applications. The burgeoning mobility sector is a key end-user, with hydrogen fueling stations for fuel cell electric vehicles (FCEVs) and heavy-duty transport vehicles requiring reliable, decentralized hydrogen supply. Public transport authorities and logistics companies are increasingly exploring hydrogen solutions for their fleets, driving demand for compact electrolyzer units that can be deployed at depots or key transport hubs.

Furthermore, research institutions, universities, and technology developers are important customers, utilizing small electrolyzers for experimental purposes, pilot projects, and advanced material testing. Remote communities and off-grid locations seeking energy independence and sustainable power solutions also represent a niche yet growing market segment. Small industrial users, commercial enterprises with specific hydrogen needs, and even residential users looking into micro-grid solutions or hydrogen appliances are emerging as potential buyers, especially as costs decrease and integrated systems become more accessible. The market is thus characterized by a wide array of buyers, all united by a common interest in sustainable and decentralized hydrogen production.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.8 Billion |

| Market Forecast in 2032 | USD 10.9 Billion |

| Growth Rate | CAGR 28.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens Energy, ITM Power, Plug Power, Nel Hydrogen, Thyssenkrupp Nucera, Cummins, Green Hydrogen Systems, Sunfire, McPhy Energy, Bloom Energy, Enapter, Hysata, Ceres Power, Electrochaea, Hydrogenics (Cummins), Giner ELX, Proton OnSite (Nel), Toshiba Energy Systems & Solutions, IHI Corporation, Asahi Kasei. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Small Capacity Electrolyzer Market Key Technology Landscape

The Small Capacity Electrolyzer Market is characterized by a dynamic and evolving technology landscape, with several core technologies competing and innovating to offer more efficient, durable, and cost-effective solutions. Alkaline electrolyzers, a mature technology, remain prominent due to their robustness and lower capital costs, particularly for smaller scales. They utilize a liquid electrolyte and non-precious metal catalysts. However, their lower efficiency at partial loads and bulkier design present limitations. Proton Exchange Membrane (PEM) electrolyzers offer higher efficiency, faster response times, and a compact footprint, making them ideal for integration with intermittent renewable energy sources, but they typically involve higher material costs due to the use of platinum group metals and specialized membranes.

Emerging technologies like Anion Exchange Membrane (AEM) electrolyzers aim to combine the benefits of both alkaline and PEM systems by using an anion exchange membrane and non-precious metal catalysts, thereby reducing costs while maintaining decent performance. Solid Oxide Electrolyzer Cells (SOEC) operate at very high temperatures, offering high electrical efficiency and the potential for co-electrolysis of steam and CO2 to produce syngas; however, their high operating temperature demands specialized materials and presents challenges for rapid startup and shutdown, making them more suitable for steady-state applications or waste heat integration. The ongoing research focuses on improving catalyst activity, membrane durability, and reducing the need for expensive materials across all electrolyzer types.

Beyond the core electrochemical cells, the key technology landscape also encompasses advancements in balance of plant components and smart control systems. This includes highly efficient power electronics for converting and supplying electricity, advanced gas separation and purification units to ensure high-purity hydrogen, and sophisticated system integration software. The integration of artificial intelligence and machine learning for predictive maintenance, operational optimization, and real-time performance monitoring is becoming increasingly crucial for enhancing the reliability and economic viability of small capacity electrolyzers. Modular design principles are also key, enabling easier scaling, installation, and maintenance, thereby reducing overall project timelines and costs and accelerating market adoption for distributed hydrogen solutions.

Regional Highlights

- North America: This region is a significant market, driven by robust government support for clean energy, the push for industrial decarbonization, and significant investments in hydrogen infrastructure, particularly in the United States and Canada. The region benefits from a strong innovation ecosystem and a growing demand for hydrogen in mobility and industrial applications.

- Europe: Europe stands as a global leader in green hydrogen development, backed by ambitious decarbonization targets, the European Green Deal, and national hydrogen strategies across key economies like Germany, the Netherlands, and the UK. The region sees extensive research and development, pilot projects, and a strong focus on renewable energy integration for hydrogen production.

- Asia Pacific (APAC): The APAC region is rapidly expanding its footprint in the small capacity electrolyzer market, spearheaded by countries such as China, Japan, South Korea, and Australia. Driven by industrial demand for hydrogen, energy security concerns, and proactive government policies, the region is investing heavily in green hydrogen production and related technologies.

- Latin America: Latin America offers immense potential due to its abundant renewable energy resources, particularly wind and solar. Countries like Chile and Brazil are positioning themselves as future exporters of green hydrogen, leading to increased investment in electrolyzer technologies to capitalize on this export opportunity and support local industrial decarbonization.

- Middle East and Africa (MEA): The MEA region is emerging as a key player in the green hydrogen economy, leveraging vast solar resources to produce cost-effective green hydrogen. Countries like Saudi Arabia and the UAE are making substantial investments in large-scale hydrogen projects, which will also create demand for small capacity electrolyzers for localized industrial use and energy applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Small Capacity Electrolyzer Market.- Siemens Energy

- ITM Power

- Plug Power

- Nel Hydrogen

- Thyssenkrupp Nucera

- Cummins

- Green Hydrogen Systems

- Sunfire

- McPhy Energy

- Bloom Energy

- Enapter

- Hysata

- Ceres Power

- Electrochaea

- Hydrogenics (Cummins)

- Giner ELX

- Proton OnSite (Nel)

- Toshiba Energy Systems & Solutions

- IHI Corporation

- Asahi Kasei

Frequently Asked Questions

What is a small capacity electrolyzer?

A small capacity electrolyzer is a device that produces hydrogen from water through electrolysis on a compact scale, typically with a power input ranging from a few kilowatts up to 1 megawatt. These units are designed for decentralized or on-site hydrogen generation, offering flexibility and efficiency for various applications without requiring large-scale infrastructure.

What are the primary applications of small capacity electrolyzers?

The primary applications include industrial feedstock for chemical processes, energy storage and grid balancing for renewable energy systems, fueling stations for fuel cell vehicles, and distributed power-to-gas solutions. Their compact nature makes them suitable for niche markets and localized hydrogen production.

Which electrolyzer technologies are most prevalent in the small capacity segment?

Proton Exchange Membrane (PEM) and Alkaline Electrolyzers are currently the most prevalent technologies due to their maturity and performance characteristics suitable for smaller scales. Anion Exchange Membrane (AEM) electrolyzers are an emerging technology gaining traction for their cost-effectiveness and efficiency.

What are the key drivers for the growth of the Small Capacity Electrolyzer Market?

Key drivers include the global push for decarbonization, decreasing costs of renewable energy, supportive government policies and incentives for green hydrogen, and the increasing demand for decentralized and on-site hydrogen production across various industries and energy sectors.

How does AI impact the efficiency and operation of small capacity electrolyzers?

AI significantly impacts efficiency and operation by enabling predictive maintenance, optimizing real-time production based on energy input and demand, enhancing energy management for seamless renewable integration, and accelerating R&D for material and design improvements, leading to lower operational costs and increased reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager