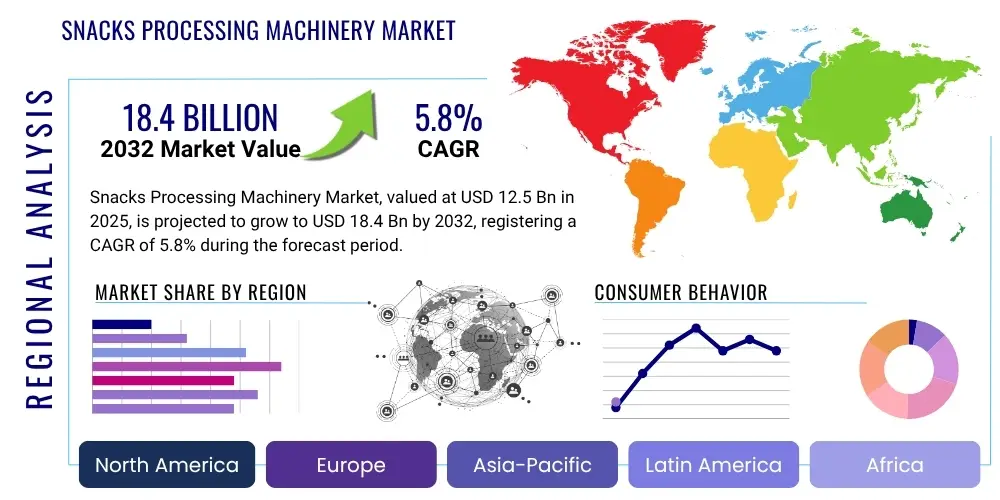

Snacks Processing Machinery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429738 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Snacks Processing Machinery Market Size

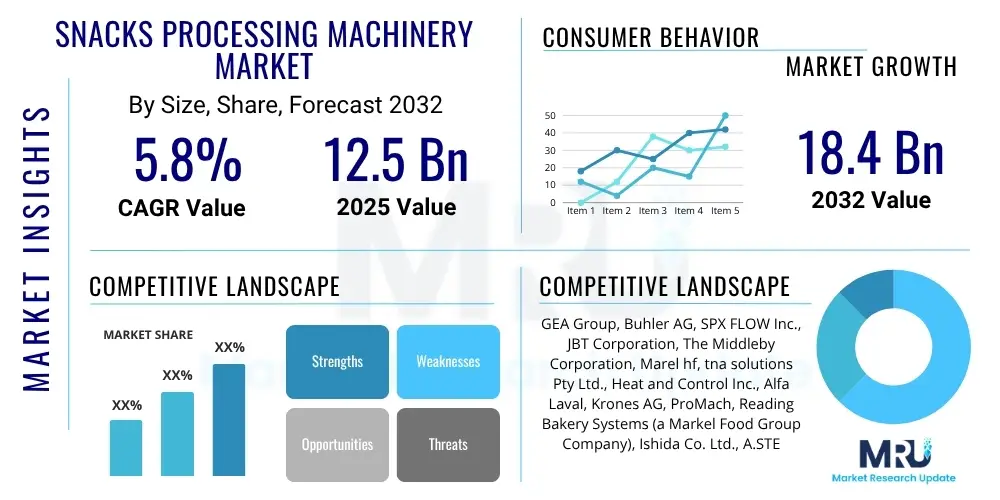

The Snacks Processing Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $12.5 Billion in 2025 and is projected to reach $18.4 Billion by the end of the forecast period in 2032.

Snacks Processing Machinery Market introduction

The Snacks Processing Machinery Market encompasses a wide range of equipment and systems used for manufacturing various types of snack products, from raw ingredient preparation to packaging. This includes machinery for washing, peeling, slicing, mixing, extruding, frying, baking, seasoning, and packaging snacks such as potato chips, extruded snacks, nuts, and confectionery items. The increasing global demand for convenience foods, coupled with evolving consumer preferences for diverse and innovative snack options, continues to drive advancements and investment in this sector. Modern machinery focuses on enhancing operational efficiency, ensuring product quality and safety, and accommodating varied production scales.

The product description for snacks processing machinery highlights its versatility and technological sophistication. It covers everything from high-capacity industrial lines capable of continuous production to more flexible, modular systems suitable for specialized or smaller-batch snack manufacturing. These machines are designed to handle different raw materials, including potatoes, corn, grains, legumes, and nuts, transforming them into final snack products with precise control over texture, flavor, and appearance. Key benefits for manufacturers include significant improvements in production speed, consistency, hygiene standards, and cost efficiency through automation and reduced manual labor.

Major applications for snacks processing machinery span across various segments of the food industry, supporting the production of a broad spectrum of snack types. The primary driving factors for market growth include rising disposable incomes, rapid urbanization leading to busier lifestyles and increased demand for ready-to-eat foods, and the continuous innovation in snack product development. Additionally, stringent food safety regulations necessitate the use of advanced, hygienic processing equipment, further propelling market expansion. The ongoing trend towards automation and integrated solutions also plays a crucial role in shaping the market landscape.

Snacks Processing Machinery Market Executive Summary

The Snacks Processing Machinery Market is experiencing robust growth, primarily fueled by shifting consumer preferences towards convenience foods and the global expansion of the snack industry. Business trends indicate a strong move towards automation, digitalization, and the integration of smart technologies to enhance efficiency, reduce operational costs, and improve product consistency. Manufacturers are increasingly seeking machinery that offers flexibility for product diversification, energy efficiency to lower environmental impact and operating expenses, and advanced food safety features to comply with evolving global regulations. The competitive landscape is characterized by continuous innovation in equipment design and the provision of end-to-end processing solutions.

Regional trends reveal Asia Pacific as a significant growth engine, driven by its large population, rising disposable incomes, and the rapid adoption of Western snacking habits. North America and Europe, while mature markets, continue to innovate, focusing on high-tech, sustainable, and specialized machinery catering to health-conscious and gourmet snack segments. Latin America and the Middle East and Africa regions are showing promising growth, attributed to increasing urbanization and the development of local snack industries, leading to higher investments in modern processing infrastructure. Each region presents unique opportunities and challenges, influenced by local consumer tastes, economic conditions, and regulatory environments.

Segment trends within the market highlight the dominance of frying and extrusion machinery due to the popularity of chips and extruded snacks. However, there is a growing demand for baking and roasting equipment as consumers increasingly opt for healthier snack alternatives. Packaging machinery, particularly advanced form-fill-seal machines with enhanced automation and material efficiency, remains a critical segment, driven by the need for longer shelf life and appealing product presentation. The market is also seeing an uptick in demand for integrated processing lines that offer comprehensive solutions from raw material handling to final packaging, streamlining the entire production process for snack manufacturers.

AI Impact Analysis on Snacks Processing Machinery Market

Common user questions regarding AI's impact on the Snacks Processing Machinery Market often revolve around how artificial intelligence can enhance operational efficiency, improve product quality, and contribute to cost savings. Users are keen to understand the practical applications of AI in real-time monitoring, predictive maintenance, and optimized resource utilization within snack production lines. There is a strong interest in how AI can facilitate greater automation, reduce waste, and enable more precise control over complex processing parameters, thereby leading to consistent product output and compliance with stringent food safety standards. The expectation is that AI will usher in a new era of smart factories, capable of self-optimization and rapid adaptation to market demands.

The key themes emerging from user inquiries include the potential for AI-driven analytics to identify process bottlenecks and recommend adjustments, the ability of machine learning algorithms to fine-tune recipes and cooking parameters for optimal taste and texture, and the role of computer vision in quality control and sorting. Concerns are sometimes raised about the initial investment costs, the complexity of integration with existing legacy systems, and the need for a skilled workforce capable of managing AI-powered machinery. However, the overarching sentiment is one of optimism regarding AI's transformative potential to revolutionize traditional snack manufacturing processes, making them more agile, responsive, and data-driven.

Users anticipate that AI will not only automate repetitive tasks but also provide valuable insights into consumer preferences and supply chain dynamics, enabling manufacturers to make more informed decisions. The integration of AI with IoT sensors across the production line is seen as crucial for achieving true predictive capabilities and minimizing downtime. This holistic approach, from ingredient handling to final packaging, is expected to lead to significant operational improvements, enhanced product innovation capabilities, and a stronger competitive edge in the fast-evolving snack market.

- AI-driven predictive maintenance reduces downtime and extends machinery lifespan.

- Optimized process control through machine learning enhances product consistency and quality.

- Real-time quality inspection and sorting via AI-powered vision systems minimize defects.

- Enhanced supply chain management and inventory optimization with AI forecasting.

- Automated recipe adjustment and parameter fine-tuning for improved flavor and texture.

- Energy efficiency optimization through AI monitoring and control of machinery.

- Increased flexibility and customization capabilities for diverse snack products.

- Improved food safety and hygiene monitoring with intelligent sensor networks.

DRO & Impact Forces Of Snacks Processing Machinery Market

The Snacks Processing Machinery Market is significantly influenced by a confluence of drivers, restraints, and opportunities, all shaped by various impact forces. Key drivers include the ever-growing global demand for convenience foods, particularly in developing economies where urbanization and changing lifestyles are prevalent. The increasing emphasis on food safety and hygiene standards worldwide mandates the adoption of advanced, automated processing equipment that ensures consistent product quality and minimizes contamination risks. Additionally, manufacturers' persistent need for higher production efficiency, reduced labor costs, and greater output capacity pushes the market towards sophisticated and integrated machinery solutions. The continuous innovation in snack products, ranging from healthier options to exotic flavors, also necessitates flexible and versatile processing equipment.

However, several restraints impede the market's growth. The substantial capital investment required for acquiring and installing high-tech snacks processing machinery can be a significant barrier, especially for small and medium-sized enterprises (SMEs). The operational complexities associated with maintaining and troubleshooting advanced automated systems often necessitate a highly skilled workforce, which can be difficult to find and retain. Furthermore, fluctuating raw material prices, global supply chain disruptions, and the rising costs of energy can impact manufacturers' profitability and their willingness to invest in new equipment. Economic uncertainties and geopolitical tensions can also dampen market expansion by affecting consumer spending power and investment confidence.

Despite these challenges, numerous opportunities exist to fuel future growth. Emerging markets, particularly in Asia Pacific, Latin America, and Africa, present untapped potential due to their expanding middle classes and increasing adoption of processed snack consumption. The rising consumer demand for healthier and sustainable snack options, such as baked, air-fried, or plant-based snacks, creates opportunities for machinery manufacturers to innovate and offer specialized equipment. The ongoing trend towards smart factories and Industry 4.0, integrating IoT, AI, and robotics into production lines, promises enhanced automation, predictive maintenance, and optimized resource utilization, offering significant long-term growth prospects. Customized and niche snack trends also open doors for flexible, small-batch processing solutions, catering to diverse market demands.

Segmentation Analysis

The Snacks Processing Machinery Market is comprehensively segmented based on various attributes, including the type of machinery, its mode of operation, the specific application of the snack produced, and the form of the raw materials or finished product. This segmentation allows for a detailed analysis of market dynamics, identifying key growth areas and niche opportunities within the broader snack manufacturing landscape. Understanding these segments is crucial for both machinery manufacturers to tailor their offerings and for snack producers to select the most appropriate equipment for their specific production needs and market demands, ensuring optimal efficiency and product quality.

The segmentation highlights the diverse range of equipment required to produce the vast array of snack products available globally. From the initial stages of ingredient preparation to the final packaging, each segment addresses a critical part of the production value chain. The distinctions between automatic and semi-automatic operations reflect varying levels of capital investment and production scale capabilities among manufacturers, while application-based segmentation underscores the specialized requirements for different snack categories. Analyzing these segments provides strategic insights into technological advancements, competitive pressures, and evolving consumer preferences, guiding market participants in their product development and investment decisions.

- By Type:

- Extruders

- Fryers

- Mixers

- Ovens

- Form Fill Seal Machines

- Slicers and Dicers

- Seasoning and Coating Machines

- Others (e.g., Coolers, Dryers, Blanchers)

- By Operation:

- Automatic

- Semi-Automatic

- By Application:

- Potato Chips

- Extruded Snacks

- Baked Snacks

- Nuts and Seeds

- Meat Snacks

- Confectionery Snacks

- Fruits and Vegetables Snacks

- Others (e.g., Puffed Snacks, Granola Bars)

- By Form:

- Solids (e.g., Chips, Biscuits)

- Powders (e.g., Seasoning mixes, Dough mixes)

- Liquids (e.g., Coatings, Flavorings)

Value Chain Analysis For Snacks Processing Machinery Market

The value chain for the Snacks Processing Machinery Market begins with upstream activities involving the sourcing and manufacturing of essential components and raw materials. This includes suppliers of specialized metals, electrical components, automation systems, sensors, and various precision parts necessary for constructing robust and efficient processing machines. Key players in this stage focus on providing high-quality, durable, and technologically advanced components that meet stringent industry standards and contribute to the overall reliability and performance of the final machinery. Strong relationships with these upstream suppliers are critical for machinery manufacturers to ensure consistent quality, control costs, and drive innovation in their product offerings.

Moving downstream, the value chain extends to the direct sales, distribution, and after-sales support networks that connect machinery manufacturers with their end-user customers – the snack producers. Direct distribution involves manufacturers selling directly to large-scale snack companies, often involving custom-built solutions and comprehensive service contracts. Indirect channels leverage a network of distributors, agents, and system integrators who facilitate sales, provide local support, and sometimes offer complementary services such as installation and training, particularly for smaller and medium-sized snack manufacturers. Effective distribution ensures market penetration and accessibility, while robust after-sales support, including maintenance, spare parts, and technical assistance, is paramount for customer satisfaction and long-term relationships.

The distribution channels for snacks processing machinery are diverse, reflecting the varied needs and scales of snack manufacturers globally. Direct sales offer close collaboration and customization, which is often preferred by large multinational food corporations. Indirect channels, through specialized distributors, are vital for reaching regional markets and providing localized technical expertise, especially in emerging economies. Both direct and indirect channels are critical in educating potential customers about new technologies, ensuring efficient delivery, and providing essential post-purchase services, which collectively enhance the overall value proposition and support the sustained operation of the machinery throughout its lifecycle.

Snacks Processing Machinery Market Potential Customers

The primary potential customers and end-users of snacks processing machinery are diverse, ranging from large-scale multinational food and beverage corporations to small and medium-sized enterprises (SMEs) specializing in artisanal or niche snack production. These customers include established snack brands seeking to upgrade their existing production lines for higher efficiency, capacity expansion, or product diversification, as well as new entrants to the snack market looking to set up state-of-the-art facilities. The demand for machinery is influenced by factors such as market share goals, consumer trends, regulatory compliance, and the need to optimize operational costs. Each customer segment has unique requirements concerning machinery scale, automation level, and technological sophistication.

Beyond traditional snack manufacturers, the customer base also extends to contract manufacturing organizations (CMOs) that produce snacks for other brands, private label manufacturers, and even institutional food service providers looking to produce snacks in-house. These various types of buyers prioritize different aspects when investing in machinery. Large corporations might focus on integrated, high-throughput, fully automated lines with advanced data analytics capabilities. In contrast, SMEs and niche producers might prioritize modular, flexible, and more cost-effective semi-automatic solutions that allow for easier recipe changes and smaller batch production, catering to specific local or specialized markets. The evolving preferences for healthier snacks also drive investment from companies focusing on baked, air-fried, or plant-based snack categories.

Ultimately, all end-users share a common goal: to produce safe, high-quality, and appealing snack products efficiently and cost-effectively. Machinery suppliers must therefore understand these varied needs and offer tailored solutions, whether it is through customizable equipment, scalable systems, or comprehensive after-sales support. The growth in the global snack market, coupled with increasing consumer demand for variety and innovation, ensures a continuous stream of potential customers seeking advanced and reliable processing machinery to meet dynamic market demands and maintain a competitive edge.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $12.5 Billion |

| Market Forecast in 2032 | $18.4 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group, Buhler AG, SPX FLOW Inc., JBT Corporation, The Middleby Corporation, Marel hf, tna solutions Pty Ltd., Heat and Control Inc., Alfa Laval, Krones AG, ProMach, Reading Bakery Systems (a Markel Food Group Company), Ishida Co. Ltd., A.STELLA S.R.L., Starlinger & Co. GmbH, TOMRA Food, Dinnissen Process Technology, Flo-Mech Ltd., PFM Packaging Machinery, FPS Food Process Solutions |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Snacks Processing Machinery Market Key Technology Landscape

The Snacks Processing Machinery market is characterized by a rapidly evolving technological landscape, driven by the twin demands for increased efficiency and enhanced product quality. Automation remains a cornerstone, with advanced Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) enabling precise control over complex production processes, reducing human error, and improving consistency. The integration of Internet of Things (IoT) sensors is becoming increasingly prevalent, allowing for real-time monitoring of machinery performance, ingredient levels, temperature, and other critical parameters. This connectivity facilitates data collection that can be analyzed to optimize operations, predict maintenance needs, and enhance overall line efficiency.

Artificial Intelligence (AI) and machine learning are emerging as transformative technologies, particularly in areas like predictive maintenance, quality control, and process optimization. AI algorithms can analyze vast amounts of data from IoT sensors to identify anomalies, forecast equipment failures, and even suggest adjustments to processing parameters for optimal yield and product characteristics. Computer vision systems, powered by AI, are revolutionizing sorting and inspection processes, quickly identifying defects or foreign materials with greater accuracy than traditional methods. Robotics is also gaining traction, especially in repetitive tasks like packaging, palletizing, and even some intricate food handling, thereby improving speed, hygiene, and reducing labor dependency.

Beyond digitalization, there is a strong focus on sustainable and energy-efficient designs. Manufacturers are developing machinery that consumes less water and energy, reduces waste, and allows for easier cleaning and maintenance, aligning with global sustainability goals. Modular and flexible systems are also key, enabling snack producers to quickly adapt their lines for different product types, flavors, and packaging formats, catering to dynamic consumer preferences and smaller, more frequent production runs. These technological advancements collectively contribute to a more agile, cost-effective, and environmentally responsible snack manufacturing ecosystem, driving continuous innovation across the industry.

Regional Highlights

- North America: This region represents a mature yet highly innovative market for snacks processing machinery. The demand is driven by the continuous pursuit of automation to counter high labor costs, stringent food safety regulations, and a constant drive for new product development. Manufacturers here focus on integrating advanced technologies like AI, IoT, and robotics to enhance efficiency, achieve greater product customization, and ensure compliance. The region also sees a strong emphasis on healthier snack options, prompting investment in baking, roasting, and air-frying technologies. The United States and Canada are key markets, characterized by significant R&D spending and early adoption of cutting-edge machinery, catering to both large-scale industrial operations and niche craft snack producers.

- Europe: The European market for snacks processing machinery is characterized by a strong emphasis on sustainability, energy efficiency, and high-quality production standards. Strict regulatory frameworks regarding food safety and environmental impact compel manufacturers to invest in advanced machinery that minimizes waste, reduces energy consumption, and ensures hygienic operations. Western European countries, such as Germany, Italy, and the UK, are at the forefront of technological innovation, offering sophisticated, integrated solutions. There is also a growing trend towards gourmet and artisanal snacks, fostering demand for flexible and modular equipment that supports diverse, smaller batch productions, while Eastern European countries are witnessing increasing demand due to rising disposable incomes and changing dietary habits.

- Asia Pacific (APAC): APAC stands as the fastest-growing and largest market for snacks processing machinery, primarily fueled by rapid urbanization, rising disposable incomes, and the increasing adoption of processed snack consumption. Countries like China, India, Japan, and Southeast Asian nations are witnessing significant investments in new snack manufacturing facilities and the modernization of existing ones. The sheer population size and evolving consumer preferences for Western-style snacks, alongside traditional Asian snacks, create immense opportunities. The focus here is on scalable, high-capacity machinery to meet mass production demands, coupled with increasing interest in automation to improve efficiency and consistency in a competitive market.

- Latin America: This region presents significant growth potential, driven by economic development, increasing urbanization, and the expanding presence of multinational food companies. Countries such as Brazil, Mexico, and Argentina are key markets, where rising middle-class populations are driving demand for convenience foods, including a wide variety of snacks. Investments in snacks processing machinery are focused on improving production capabilities, enhancing product quality, and meeting growing domestic consumption. While automation is a growing trend, there is still substantial demand for semi-automatic and robust, cost-effective machinery solutions suitable for diverse operational scales and local market conditions.

- Middle East and Africa (MEA): The MEA region is an emerging market for snacks processing machinery, with growth largely attributed to expanding populations, increasing Western influence on dietary habits, and ongoing infrastructure development. Countries in the GCC (Gulf Cooperation Council) and South Africa are leading the way, with rising disposable incomes supporting higher consumption of processed snacks. There is a strong demand for machinery that can cater to both traditional local snacks and international varieties. Investments are increasingly directed towards establishing modern processing plants, improving food safety standards, and adopting more efficient production technologies to serve both domestic markets and potential export opportunities within the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Snacks Processing Machinery Market.- GEA Group

- Buhler AG

- SPX FLOW Inc.

- JBT Corporation

- The Middleby Corporation

- Marel hf

- tna solutions Pty Ltd.

- Heat and Control Inc.

- Alfa Laval

- Krones AG

- ProMach

- Reading Bakery Systems (a Markel Food Group Company)

- Ishida Co. Ltd.

- A.STELLA S.R.L.

- Starlinger & Co. GmbH

- TOMRA Food

- Dinnissen Process Technology

- Flo-Mech Ltd.

- PFM Packaging Machinery

- FPS Food Process Solutions

Frequently Asked Questions

What are the key drivers of the snacks processing machinery market?

The market is primarily driven by the increasing global demand for convenience foods, rising disposable incomes, rapid urbanization, and a continuous focus on enhancing food safety and hygiene standards. Technological advancements and product diversification by snack manufacturers also significantly contribute to market expansion.

How is automation transforming snack production?

Automation is revolutionizing snack production by significantly improving efficiency, reducing labor costs, ensuring consistent product quality, and minimizing human error. It enables higher throughput, better process control, and advanced traceability, which are crucial for meeting modern consumer demands and regulatory requirements.

What role does sustainability play in snack machinery?

Sustainability is a growing concern, prompting manufacturers to develop energy-efficient machinery that minimizes water usage, reduces waste, and employs eco-friendly materials. Sustainable practices and equipment help snack producers lower their environmental footprint and operational costs, aligning with consumer and corporate social responsibility goals.

Which regions offer the most growth potential?

Asia Pacific is identified as the region with the most significant growth potential, driven by its large population, increasing disposable incomes, and the rapid adoption of processed snack consumption. Emerging markets in Latin America and the Middle East and Africa also present substantial opportunities due to ongoing urbanization and economic development.

What are the major challenges faced by manufacturers?

Manufacturers in the snacks processing machinery market face challenges such as high initial capital investment, the complexity of integrating advanced technologies, a shortage of skilled labor for operating and maintaining sophisticated machinery, and volatility in raw material prices. Adhering to diverse and stringent global food safety regulations also presents ongoing hurdles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager