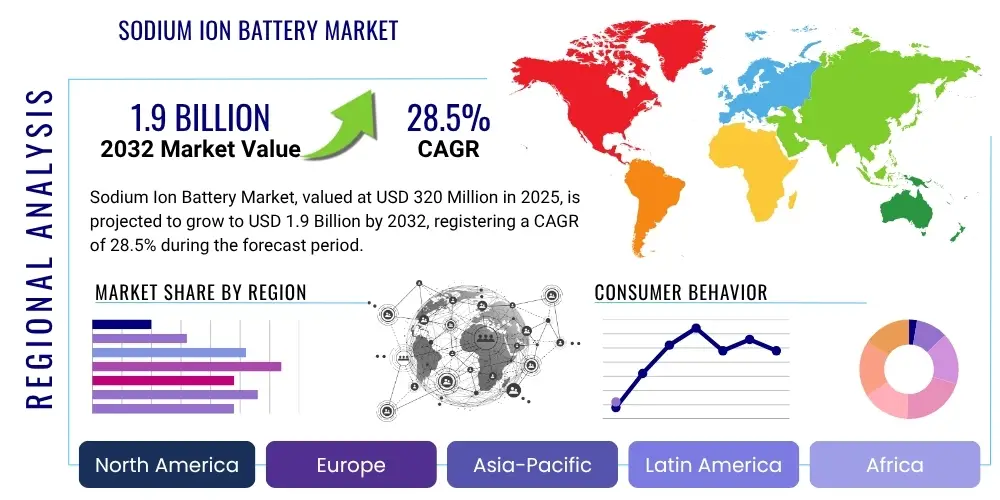

Sodium Ion Battery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428881 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Sodium Ion Battery Market Size

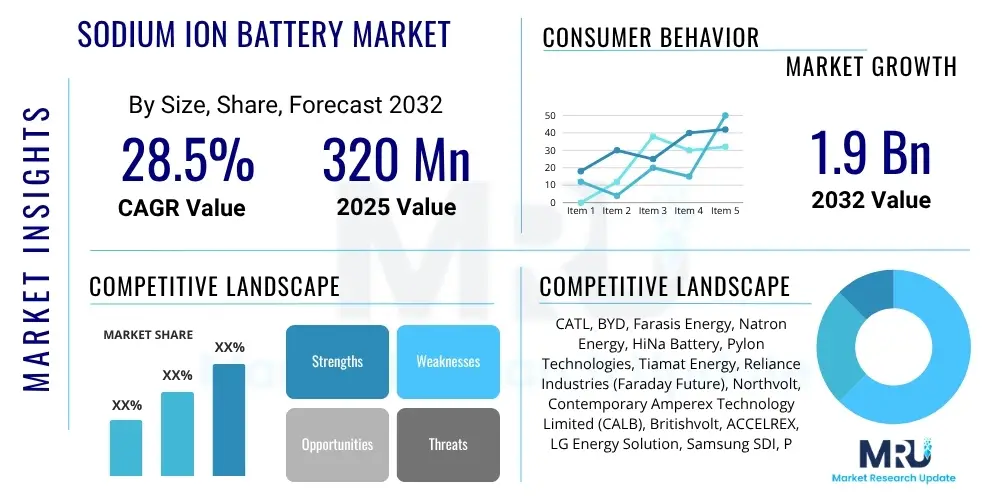

The Sodium Ion Battery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 28.5% between 2025 and 2032. The market is estimated at $320 Million in 2025 and is projected to reach $1.9 Billion by the end of the forecast period in 2032.

Sodium Ion Battery Market introduction

The Sodium Ion Battery Market is rapidly emerging as a compelling alternative to traditional lithium-ion technology, driven by the increasing demand for sustainable and cost-effective energy storage solutions. Sodium ion batteries (NIBs) utilize sodium ions as charge carriers, leveraging the earth's abundant and widely distributed sodium resources, which significantly reduces raw material costs and supply chain risks compared to lithium. This market encompasses the development, manufacturing, and deployment of NIBs across various applications, from grid-scale energy storage to electric vehicles and consumer electronics. Their distinct electrochemical properties and material compositions offer specific advantages in certain use cases, positioning them as a vital component in the global transition towards a more diversified and resilient energy landscape.

The product description of sodium ion batteries centers on their foundational components, including sodium-based cathode materials, carbon-based or sodium-alloy anodes, a sodium-salt electrolyte, and a separator. Unlike lithium-ion batteries that rely on scarce and geographically concentrated lithium, cobalt, and nickel, NIBs employ materials like sodium iron phosphate or sodium layered oxides for cathodes, and hard carbon for anodes. These materials are not only more abundant but also less toxic, contributing to a more environmentally friendly battery lifecycle. The operational principle involves the intercalation and de-intercalation of sodium ions between the cathode and anode during charge and discharge cycles, facilitating energy storage and release. Continuous research and development efforts are focused on enhancing their energy density, cycle life, and charging efficiency to broaden their applicability.

Major applications for sodium ion batteries are diverse and expanding. They are particularly well-suited for stationary energy storage systems, such as grid-scale renewable energy integration and backup power for commercial and industrial facilities, where their lower cost and inherent safety advantages outweigh the current energy density limitations compared to premium lithium-ion solutions. Furthermore, NIBs are finding increasing relevance in lower-speed electric vehicles, two-wheelers, and electric rickshaws, as well as in specific consumer electronics and off-grid solutions where robustness and cost are critical factors. The primary benefits include superior raw material abundance and lower cost, improved safety due to less reactive components, and better low-temperature performance. These advantages, coupled with a growing emphasis on localized supply chains, are driving significant interest and investment into the sodium ion battery market, marking them as a pivotal technology for future energy independence.

Sodium Ion Battery Market Executive Summary

The Sodium Ion Battery Market is experiencing dynamic growth, propelled by the urgent need for diversified and sustainable energy storage technologies. Key business trends indicate a surge in strategic partnerships between material suppliers, battery manufacturers, and automotive or energy utility companies, aiming to accelerate commercialization and scale production. Investments in research and development are robust, focusing on improving energy density, cycle life, and manufacturing efficiencies to make NIBs competitive across a wider range of applications. Several start-ups are emerging with innovative cell designs and chemistries, while established battery giants are dedicating significant resources to develop their own NIB product lines, indicating a strong market entry and expansion phase for this technology. The emphasis on localized supply chains is also a significant trend, reducing reliance on geographically concentrated raw materials and fostering regional manufacturing hubs.

Regional trends highlight Asia Pacific, particularly China and India, as leading epicenters for NIB development and deployment, driven by government support for new energy technologies, extensive domestic raw material availability, and large manufacturing capacities. China, in particular, boasts numerous companies actively developing and commercializing NIBs for various applications, from EVs to grid storage. Europe and North America are also witnessing increased investment and research, motivated by energy security concerns, climate change mitigation goals, and a desire to build resilient domestic battery industries. These regions are focusing on establishing pilot plants and collaborative research initiatives to catch up with the advanced manufacturing capabilities seen in Asia, aiming to integrate NIBs into their respective renewable energy infrastructures and electric transportation ecosystems. Government incentives and regulatory frameworks supporting sustainable energy are crucial in shaping these regional developments.

Segmentation trends within the Sodium Ion Battery Market reveal a clear emphasis on specific chemistries and applications. Sodium iron phosphate (NFP) and sodium layered oxide cathodes are currently dominant, offering a balance of performance, cost, and safety, making them attractive for stationary storage and entry-level electric vehicles. Advancements in anode materials, particularly hard carbon, are critical for improving energy density and charging rates. From an application perspective, grid-scale energy storage systems (ESS) are projected to be a primary growth driver, given the excellent suitability of NIBs for long-duration, high-power cycling requirements where space and weight are less constraining than in mobility. The electric vehicle segment, especially for urban mobility and two-wheelers, is another key area, benefiting from the cost-effectiveness and safety profile of NIBs. These evolving trends underscore the market's strategic focus on leveraging NIBs’ inherent advantages in specific, high-volume segments before broader market penetration.

AI Impact Analysis on Sodium Ion Battery Market

User questions regarding the impact of Artificial Intelligence on the Sodium Ion Battery Market frequently revolve around how AI can accelerate material discovery, optimize battery design, enhance manufacturing processes, and improve battery management systems. Users are keen to understand if AI can overcome current NIB limitations such as energy density and cycle life, reduce development timelines, and contribute to faster commercialization. Concerns often touch upon the complexity of integrating AI into existing R&D and manufacturing workflows, the availability of sufficient data for AI training, and the potential for AI-driven innovations to drastically alter competitive landscapes. The general expectation is that AI will play a transformative role, enabling more efficient and cost-effective battery development and deployment, ultimately accelerating the widespread adoption of sodium ion battery technology. There is also interest in AI's potential for predictive maintenance and real-time performance optimization in deployed NIB systems.

- AI accelerates the discovery and screening of novel sodium-ion electrode materials and electrolytes by predicting properties and simulating performance.

- AI optimizes battery cell design, including electrode thickness, porosity, and separator characteristics, to enhance energy density and power output.

- AI improves manufacturing processes by enabling predictive maintenance, fault detection, and quality control, leading to higher yields and reduced costs.

- AI-driven Battery Management Systems (BMS) enhance battery safety, extend cycle life, and optimize charging/discharging profiles through real-time data analysis.

- AI facilitates the development of sophisticated thermal management strategies to ensure stable operation and longevity of NIBs in diverse conditions.

- AI contributes to supply chain optimization, predicting raw material availability and demand fluctuations, thereby improving procurement and logistics for NIB components.

DRO & Impact Forces Of Sodium Ion Battery Market

The Sodium Ion Battery Market is significantly influenced by a confluence of driving factors, restraints, and opportunities, all shaped by broader impact forces. A primary driver is the global emphasis on energy security and sustainability, pushing for alternatives to lithium-ion chemistries due to geopolitical concerns over raw material sourcing and the environmental footprint of mining. The abundance and low cost of sodium, coupled with its widespread distribution, make NIBs an attractive solution for grid-scale energy storage, driving substantial investment and research. Furthermore, the increasing demand for cost-effective energy storage in emerging markets and for applications where energy density is not the paramount concern, such as urban electric vehicles and stationary storage, provides a strong market pull. Regulatory support and government incentives for renewable energy and electric mobility also act as powerful accelerators, creating a favorable policy environment for NIB adoption and commercialization.

Despite these strong tailwinds, the market faces several notable restraints. The relatively lower energy density of current NIB technologies compared to advanced lithium-ion batteries limits their immediate adoption in high-performance applications like long-range electric vehicles and compact portable electronics, where size and weight are critical. Cycle life and charging rates, while improving, still require further development to match the established performance benchmarks of mature lithium-ion systems. A significant restraint is the need for greater manufacturing scale and infrastructure development. The existing battery manufacturing ecosystem is heavily geared towards lithium-ion, and transitioning or expanding to NIB production requires substantial capital investment and specialized expertise. Market skepticism and the inherent conservatism of large-scale adopters, who prefer proven technologies, also pose a challenge, requiring extensive validation and demonstration projects to build confidence.

However, these restraints are accompanied by substantial opportunities that promise to reshape the market. Continuous advancements in material science, particularly in developing high-performance cathode and anode materials, are expected to significantly improve energy density and cycle life, broadening NIB applicability. The growing demand for stationary energy storage, driven by the expansion of renewable energy sources and the need for grid modernization, presents a vast addressable market where NIBs’ cost-effectiveness and safety are highly valued. Opportunities also lie in niche applications such as low-speed electric vehicles, two-wheelers, and off-grid power solutions in developing regions. Impact forces like stringent environmental regulations, increasing consumer awareness about sustainable technologies, and geopolitical shifts favoring localized supply chains further amplify the opportunities for sodium ion batteries to establish a significant foothold. Technological breakthroughs in solid-state electrolytes and advanced cell designs could also unlock entirely new market segments for NIBs, positioning them for long-term growth and widespread integration into the global energy infrastructure.

Segmentation Analysis

The Sodium Ion Battery Market is segmented across various dimensions, providing a granular view of its structure and growth dynamics. These segments help in understanding the distinct requirements of different end-user applications and the varying performance characteristics derived from specific battery chemistries and components. The market can be broadly categorized by battery type, application, component, and end-use industry, each with its own set of technological advancements and market drivers. Analyzing these segments is crucial for stakeholders to identify promising growth areas, tailor product development, and formulate targeted market entry strategies. The inherent versatility of NIB technology allows for diverse product offerings that can address a wide spectrum of energy storage needs, from large-scale grid stabilization to smaller, cost-sensitive electronic devices, reflecting a nuanced market landscape.

Key segmentations often include the specific cathode and anode materials employed, which directly influence a battery's performance metrics like energy density, power capability, and cycle life. For example, layered oxides and Prussian blue analogs are prominent cathode materials, each offering unique advantages for different applications. Anode materials such as hard carbon are widely researched for their excellent sodium storage capabilities. Furthermore, the market is segmented by the battery's form factor, ranging from cylindrical cells to pouch and prismatic designs, which are optimized for integration into different devices and systems. This granular segmentation allows for a precise evaluation of market trends, technological preferences, and competitive dynamics within the nascent but rapidly evolving sodium ion battery ecosystem. Understanding these distinctions is fundamental to predicting future market shifts and identifying areas ripe for innovation and investment.

- By Type:

- Sodium Nickel Manganese Cobalt Oxide (NMC)

- Sodium Iron Phosphate (NFP)

- Sodium Layered Oxide

- Prussian Blue Analogs (PBA)

- Other Types (e.g., Sodium Vanadate, Sodium Sulfide)

- By Component:

- Cathode Material

- Anode Material (Hard Carbon, Soft Carbon, Alloys)

- Electrolyte

- Separator

- Battery Housing and Others

- By Application:

- Electric Vehicles (EVs)

- Two-Wheelers

- Low-Speed EVs

- Passenger EVs (Emerging)

- Commercial Vehicles

- Energy Storage Systems (ESS)

- Grid-Scale Storage

- Commercial and Industrial (C&I) Storage

- Residential Storage

- Backup Power

- Consumer Electronics

- Industrial Equipment

- Other Applications (e.g., Marine, Aerospace, Medical)

- Electric Vehicles (EVs)

- By End-Use Industry:

- Automotive

- Energy & Power

- Telecommunications

- Industrial

- Consumer Goods

- Healthcare

Value Chain Analysis For Sodium Ion Battery Market

The value chain for the Sodium Ion Battery Market begins with the upstream analysis, which encompasses the sourcing and processing of raw materials. This segment involves the extraction and refinement of abundant elements such as sodium salts, iron, manganese, and various carbon sources (like hard carbon from biomass or petroleum coke) for anode materials. Unlike lithium-ion batteries, NIBs leverage readily available and low-cost materials, significantly de-risking the supply chain from geopolitical influences and price volatility associated with scarce minerals like lithium and cobalt. Key players in this stage include chemical suppliers, mining companies for other metals, and specialized material processors who purify and prepare these raw materials to battery-grade specifications, ensuring consistency and quality essential for high-performance NIB production.

Moving downstream, the value chain progresses through the manufacturing of battery components, cell assembly, and module/pack integration. Component manufacturers specialize in producing cathode and anode active materials, electrolytes (typically sodium salts dissolved in organic solvents), and separators. Cell manufacturers then assemble these components into individual sodium ion cells, which are subsequently integrated into larger modules and battery packs by pack assemblers. This stage involves complex engineering to ensure thermal management, safety, and efficient energy delivery. The distribution channel for these finished battery packs is multifaceted, involving both direct and indirect sales. Direct sales often occur for large-scale projects, where battery manufacturers supply directly to automotive OEMs, grid operators, or large industrial clients, often accompanied by comprehensive technical support and long-term service agreements.

Indirect distribution involves a network of distributors, integrators, and value-added resellers who cater to a broader range of smaller and medium-sized enterprises (SMEs) or specific application niches. These intermediaries often provide customization, installation, and maintenance services, bridging the gap between large-scale manufacturers and diverse end-users. The choice between direct and indirect channels is influenced by factors such as market size, geographical reach, product complexity, and customer relationship requirements. The entire value chain is characterized by a high degree of collaboration, from material innovation at the upstream end to system integration and after-sales support at the downstream end. Continuous innovation in materials science and manufacturing processes, coupled with strategic partnerships across the chain, is crucial for improving cost-effectiveness, performance, and overall market penetration of sodium ion battery technologies.

Sodium Ion Battery Market Potential Customers

The Sodium Ion Battery Market targets a diverse array of potential customers across multiple sectors, each driven by specific requirements for energy storage. A significant segment comprises electric vehicle manufacturers, particularly those focusing on lower-speed, short-to-medium range vehicles such as two-wheelers, three-wheelers, and urban passenger cars. These OEMs are attracted to NIBs primarily due to their cost-effectiveness, enhanced safety profiles, and better performance in colder climates compared to some lithium-ion chemistries. As the push for affordable electric mobility intensifies in emerging markets, NIBs offer a viable pathway to electrify transportation without the premium cost associated with high-end lithium-ion batteries, making them ideal for mass-market adoption and fleet operations where total cost of ownership is a critical consideration for buyers.

Another major segment of potential customers includes grid operators and renewable energy developers who require large-scale, stationary energy storage systems to stabilize electricity grids, integrate intermittent renewable sources like solar and wind, and provide ancillary services. For these applications, the inherent safety, long cycle life, and cost advantage of NIBs, especially for multi-hour storage durations, make them highly attractive. Commercial and industrial (C&I) facilities also represent key buyers, utilizing NIBs for peak shaving, demand charge management, and reliable backup power solutions, reducing operational costs and ensuring business continuity. These customers prioritize robustness, reliability, and economic viability over ultra-high energy density, perfectly aligning with the current strengths of sodium ion battery technology. Energy storage system integrators, who design and deploy bespoke solutions, also serve as critical intermediaries for these end-users.

Furthermore, the consumer electronics industry, particularly for devices where form factor and ultra-high energy density are not the absolute top priorities but cost and safety are important, presents a burgeoning customer base. This includes manufacturers of portable power stations, certain IoT devices, and perhaps even entry-level laptops or tools. Industrial equipment manufacturers, especially for applications like forklifts, automated guided vehicles (AGVs), and material handling equipment, are exploring NIBs for their durability and cost benefits over traditional lead-acid batteries. The telecommunications sector also shows interest for remote base station power and backup systems. Overall, the end-users and buyers of sodium ion batteries are primarily those seeking reliable, safe, and economically viable energy storage solutions, with a particular focus on large-scale stationary applications and cost-sensitive electric mobility, positioning NIBs as a cornerstone of the future energy ecosystem.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $320 Million |

| Market Forecast in 2032 | $1.9 Billion |

| Growth Rate | 28.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CATL, BYD, Farasis Energy, Natron Energy, HiNa Battery, Pylon Technologies, Tiamat Energy, Reliance Industries (Faraday Future), Northvolt, Contemporary Amperex Technology Limited (CALB), Britishvolt, ACCELREX, LG Energy Solution, Samsung SDI, Panasonic Energy, Sumitomo Electric, Ambri, Altris, Aqua Power Systems, Li-Fun Technology |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sodium Ion Battery Market Key Technology Landscape

The Sodium Ion Battery Market's technology landscape is characterized by intense research and development focused on enhancing electrode materials, optimizing electrolyte compositions, and innovating cell architectures. A central area of technological advancement is the cathode material, where layered transition metal oxides (like NaMO2 where M=Ni, Mn, Co or Fe) and Prussian blue analogs (PBA) are leading candidates. Researchers are striving to improve their capacity, voltage stability, and cycling performance to close the gap with high-performance lithium-ion cathodes. Significant efforts are also directed towards developing iron and manganese-rich cathode materials to further reduce costs and reliance on more expensive or scarce elements. The stability and integrity of these cathode structures during repeated sodium ion insertion and extraction are paramount to achieving a long cycle life, driving innovations in doping and surface coatings.

For anode materials, hard carbon remains the most promising technology due to its excellent sodium storage capabilities, affordability, and relatively straightforward manufacturing. However, ongoing research is exploring alternative anode materials such as disordered carbon, phosphorus-based compounds, and various alloys that can offer higher specific capacities and improved rate capabilities. The development of advanced binders and conductive additives is also critical to ensure the structural integrity and electrical conductivity of both anode and cathode electrodes, directly impacting the overall battery performance. The electrolyte plays a vital role in sodium ion transport; innovations in developing non-flammable, wide operating temperature range, and stable electrolytes (both liquid and solid-state) are key to improving both safety and performance characteristics of NIBs, addressing current limitations such as dendrite formation at the anode.

Furthermore, significant technological progress is being made in battery cell design and manufacturing processes. This includes optimizing cell form factors (cylindrical, pouch, prismatic) for specific applications, improving packaging techniques, and developing efficient thermal management systems to ensure stable and safe operation. Advancements in dry electrode manufacturing, which can reduce energy consumption and environmental impact, are also being explored. The integration of advanced Battery Management Systems (BMS) equipped with sophisticated algorithms is essential for maximizing battery life, ensuring safety, and optimizing performance under various operating conditions. Overall, the key technology landscape is defined by a holistic approach to innovation across materials science, electrochemistry, and engineering, all aimed at enhancing the energy density, power, safety, and cycle life of sodium ion batteries while maintaining their fundamental cost advantages and resource abundance.

Regional Highlights

- Asia Pacific (APAC): The APAC region, particularly China, is at the forefront of the Sodium Ion Battery Market, driven by extensive government support, robust domestic raw material supply chains, and significant investments in research and manufacturing. China hosts numerous leading NIB developers and manufacturers, with rapid advancements in commercialization for both electric vehicles and grid-scale storage. India is also emerging as a key player, focusing on NIBs for two-wheelers, three-wheelers, and renewable energy integration, aiming to reduce reliance on imported lithium. South Korea and Japan are actively engaged in material R&D and strategic partnerships to secure a foothold in this evolving market, leveraging their established battery expertise. The region benefits from a large domestic market for energy storage and electric mobility, making it a critical hub for NIB innovation and deployment.

- Europe: Europe is demonstrating increasing strategic interest in sodium ion batteries as part of its broader efforts to achieve energy independence and decarbonization goals. Countries like France, Sweden, and the UK are witnessing significant investments in NIB research, pilot production facilities, and strategic collaborations. The focus is on establishing robust domestic battery supply chains, reducing reliance on external sources for critical materials, and integrating NIBs into renewable energy grids and electric vehicle ecosystems. European regulatory frameworks and funding initiatives, such as the European Battery Alliance, are providing strong impetus for the development and commercialization of NIB technology within the continent.

- North America: North America is experiencing a growing impetus for sodium ion battery development, primarily driven by the need for enhanced grid stability, renewable energy integration, and diversifying battery supply chains. The United States, in particular, is seeing increased government funding for NIB research through agencies like the Department of Energy, alongside private sector investments in start-ups focused on NIB commercialization. Companies are exploring applications in stationary storage, heavy-duty vehicles, and specialized industrial uses. The region aims to leverage its scientific expertise and industrial capacity to become a significant contributor to the global NIB market, with a strong emphasis on domestic manufacturing capabilities to secure critical energy technologies.

- Latin America: Latin America is anticipated to show gradual adoption of sodium ion battery technologies, primarily in grid modernization projects, off-grid energy solutions, and potentially in the electrification of public transport fleets in urban centers. Countries with significant renewable energy potential, such as Brazil and Chile, are exploring NIBs as a cost-effective solution for energy storage to complement

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager