Soft Gripper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431153 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Soft Gripper Market Size

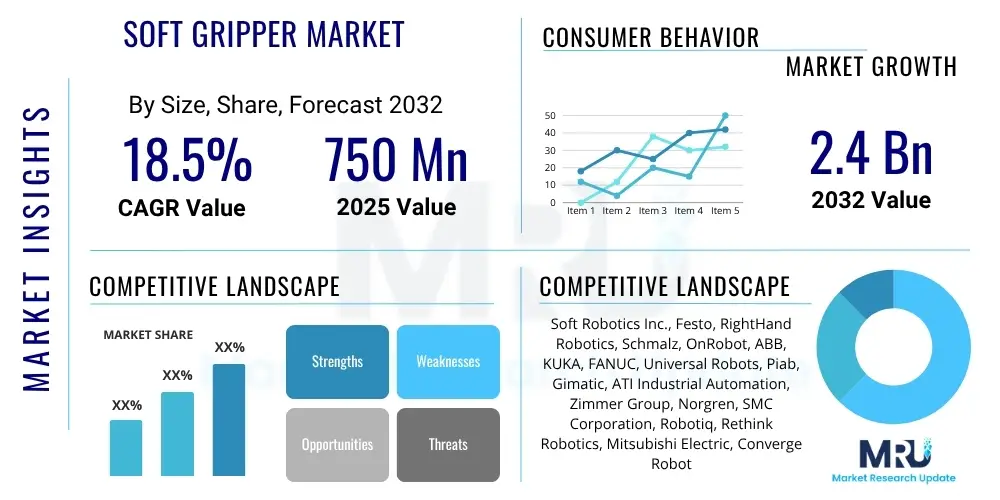

The Soft Gripper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at USD 750 million in 2025 and is projected to reach USD 2.4 billion by the end of the forecast period in 2032.

Soft Gripper Market introduction

The Soft Gripper Market encompasses advanced robotic end effectors designed for delicate and variable object handling. These grippers utilize compliant materials and adaptive designs, enabling them to conform to diverse shapes and textures without causing damage, a significant improvement over rigid conventional grippers. Their primary function involves safe and efficient manipulation of fragile, irregularly shaped, or sensitive items across various industrial settings, driving enhanced automation and operational efficiency. The market is experiencing robust expansion fueled by the increasing adoption of collaborative robots and the escalating demand for automated solutions in sectors requiring precise and gentle object interaction.

Soft grippers, often inspired by biological systems, employ principles of compliant robotics and pneumatic or electric actuation to achieve their flexible gripping capabilities. Products range from multi-finger designs to bellows-style suction cups and adaptive pouches, fabricated from materials like silicone, rubber, or specialized thermoplastic elastomers. Major applications span critical industries such as food and beverage processing, pharmaceuticals, electronics manufacturing, and logistics, where high-mix, low-volume production and stringent handling requirements are commonplace. The inherent adaptability of soft grippers minimizes the need for frequent tooling changes and reduces product damage, thereby optimizing production lines and improving overall throughput. This versatility makes them indispensable in modern automated environments.

The benefits derived from integrating soft grippers are substantial, including enhanced product safety, reduced operational costs due to minimized product damage, and improved workflow flexibility. They are particularly advantageous in scenarios involving fragile or irregularly shaped items where traditional rigid grippers are unsuitable or cause damage. Key driving factors propelling market growth include the global surge in industrial automation, accelerated expansion of e-commerce necessitating efficient parcel handling, persistent labor shortages in manufacturing and logistics, and continuous technological advancements in soft robotics and artificial intelligence. These drivers collectively contribute to the increasing demand for flexible and intelligent gripping solutions that can adapt to the complexities of modern production and supply chain environments, ultimately enhancing productivity and reducing waste.

Soft Gripper Market Executive Summary

The Soft Gripper Market is characterized by dynamic business trends centered on automation, robotics integration, and increased customization to meet diverse industrial needs. Manufacturers are focusing on developing more versatile, easy-to-integrate, and cost-effective solutions, especially for collaborative robot applications. The trend towards modular designs and standardized interfaces is also gaining momentum, facilitating quicker deployment and broader adoption across small and medium-sized enterprises. Furthermore, strategic partnerships between soft gripper manufacturers and robot integrators are becoming more common, aiming to provide comprehensive automation packages and expand market reach. This collaborative approach is accelerating innovation and market penetration, addressing specific industry challenges and requirements effectively.

Regional trends indicate significant growth in the Asia Pacific (APAC) region, driven by extensive manufacturing activities, rapid industrialization, and substantial investments in automation technologies, particularly in countries like China, Japan, and South Korea. North America and Europe also demonstrate robust growth, fueled by technological innovation, the adoption of advanced robotics in diverse sectors, and a strong emphasis on smart factories and Industry 4.0 initiatives. Latin America, the Middle East, and Africa are emerging markets, showing increasing potential as industrial infrastructure develops and automation solutions become more accessible. Each region presents unique challenges and opportunities, with varying levels of automation maturity and specific industry demands shaping market dynamics and investment priorities.

Segment trends highlight a strong demand for soft grippers in material handling, especially for delicate pick-and-place operations in the food and beverage, pharmaceutical, and electronics industries. The need for flexible packaging solutions and intricate assembly tasks is also driving innovation within the market. By type, pneumatic and electric soft grippers dominate, offering a balance of power, precision, and control. In terms of payload capacity, lightweight grippers (up to 5 kg) are witnessing significant demand due to their compatibility with collaborative robots, making automation feasible for smaller, more sensitive tasks. The continuous evolution of materials and actuation mechanisms is expanding the applicability of soft grippers into new and niche markets, further diversifying the demand landscape and fostering segment-specific growth.

AI Impact Analysis on Soft Gripper Market

Users frequently inquire about how Artificial Intelligence (AI) can enhance the adaptability and performance of soft grippers, particularly in dynamic and unstructured environments. Key themes revolve around AI's role in improving object recognition, enabling more sophisticated decision-making for grasping strategies, and facilitating predictive maintenance. Concerns often touch upon the complexity of AI integration, the computational resources required, and the need for robust data sets for effective training. Expectations are high regarding AI's potential to transform soft grippers into highly intelligent, autonomous, and self-optimizing end effectors capable of handling unprecedented levels of variability and task complexity without extensive human programming or oversight.

- AI-powered vision systems enable superior object recognition and precise localization, even for irregularly shaped or transparent items.

- Machine learning algorithms allow soft grippers to learn optimal grasping forces and approaches through trial and error, adapting to new objects autonomously.

- Predictive maintenance driven by AI analyzes gripper performance data, forecasting potential failures and optimizing maintenance schedules.

- Reinforcement learning facilitates real-time adjustment of gripping parameters, enhancing robustness in dynamic and unstructured environments.

- AI integration supports complex task planning and execution, enabling soft grippers to perform intricate assembly or sorting operations more efficiently.

- Enhanced human-robot collaboration through AI ensures safer and more intuitive interaction, particularly in cobot applications requiring responsive gripping.

- AI-driven data analysis improves energy efficiency by optimizing gripper actuation patterns based on task requirements and environmental feedback.

DRO & Impact Forces Of Soft Gripper Market

The Soft Gripper Market is significantly influenced by a confluence of driving factors, restraints, and opportunities, all shaped by various impact forces. The primary drivers include the escalating demand for automation across diverse industries to address labor shortages and enhance productivity, coupled with the inherent capability of soft grippers to handle delicate, irregularly shaped, and variable objects without damage. The rapid expansion of e-commerce, requiring efficient and gentle handling of numerous parcel types, further propels market growth. Continuous technological advancements in soft robotics, materials science, and AI integration are also pivotal in expanding the applicability and performance of these grippers, making them more attractive for industrial deployment.

Despite robust growth prospects, the market faces certain restraints. The relatively high initial investment cost associated with advanced soft gripper systems, including the gripper itself and its integration into existing robotic setups, can be a barrier for some small and medium-sized enterprises. The complexity of integrating these sophisticated grippers with diverse robotic platforms and control systems, requiring specialized expertise, also poses a challenge. Furthermore, compared to traditional rigid grippers, many soft grippers have limitations in terms of maximum payload capacity and speed for heavy-duty applications, which restricts their adoption in certain industrial environments where brute force or extreme speed is paramount. Addressing these limitations through innovation and cost reduction strategies is crucial for broader market penetration.

Significant opportunities abound within the Soft Gripper Market, driven by the increasing need for customization to cater to specific application requirements and the continuous development of novel smart materials with enhanced properties. The growing trend of collaborative robotics presents a vast opportunity, as soft grippers are inherently safer for human-robot interaction and perfectly suited for cobot applications. Untapped potential also exists in niche markets such as medical devices, biotechnology, and agricultural automation, where delicate and adaptive handling is critical. Impact forces, including global economic growth, favorable government policies promoting industrial automation, and the rising awareness of product damage reduction benefits, collectively create a conducive environment for market expansion and innovation, encouraging new entrants and strategic investments.

Segmentation Analysis

The Soft Gripper Market is comprehensively segmented to provide a detailed understanding of its diverse components and growth dynamics. This segmentation facilitates targeted market analysis, allowing stakeholders to identify key trends, emerging opportunities, and competitive landscapes across various product types, payload capacities, application areas, and end-user industries. Such granular analysis is essential for strategic planning, product development, and market entry decisions, reflecting the multifaceted nature of demand for compliant robotic end effectors across the global industrial ecosystem.

- By Type

- Pneumatic Soft Grippers

- Electric Soft Grippers

- Vacuum Soft Grippers

- Hydraulic Soft Grippers

- Smart Material Soft Grippers

- By Payload Capacity

- Up to 1 kg

- 1 kg to 5 kg

- 5 kg to 10 kg

- Above 10 kg

- By Application

- Pick and Place

- Assembly

- Packaging

- Inspection

- Material Handling

- Sorting

- Machine Tending

- Quality Control

- By End-User Industry

- Food and Beverage

- Pharmaceuticals and Healthcare

- Electronics and Semiconductors

- Automotive

- Logistics and E-commerce

- Consumer Goods

- Textiles

- Chemicals

- Others

- By Material

- Silicone

- Rubber

- Thermoplastic Elastomers (TPE)

- Fabric Composites

- Hydrogels

- Shape Memory Polymers

- Others

Value Chain Analysis For Soft Gripper Market

The value chain for the Soft Gripper Market begins with upstream activities focused on the procurement and processing of specialized raw materials. This segment includes suppliers of advanced polymers such as silicone, various rubbers, and thermoplastic elastomers, which are crucial for the flexibility and durability of grippers. Additionally, component manufacturers provide essential pneumatic or electric actuation systems, sensors, control electronics, and custom fabrication services. Research and development institutions also play a vital upstream role in innovating new materials, design principles, and manufacturing processes. The efficiency and cost-effectiveness in this stage directly influence the final product's quality, performance, and overall market competitiveness, emphasizing the importance of robust supplier relationships and material science advancements.

Moving downstream, the value chain progresses through the manufacturing and assembly of soft grippers, often involving sophisticated additive manufacturing techniques like 3D printing and precise molding processes. Following production, these grippers are supplied to robotic system integrators, original equipment manufacturers (OEMs), and directly to end-user businesses. System integrators play a critical role in custom engineering complete robotic solutions that incorporate soft grippers, ensuring seamless integration with existing automation infrastructure and specific application needs. OEMs, particularly those manufacturing collaborative robots, often bundle soft grippers as part of their comprehensive offerings, providing turnkey solutions to their clients. This downstream interaction emphasizes customization and solution delivery to address unique customer requirements.

Distribution channels for soft grippers are varied, encompassing both direct and indirect approaches. Direct channels involve sales directly from manufacturers to large industrial clients, system integrators, or OEMs, often through dedicated sales teams and technical support. Indirect channels primarily involve a network of distributors, value-added resellers (VARs), and online marketplaces, which extend market reach to a broader customer base, including small and medium-sized enterprises. These channels also provide localized sales, technical support, and after-sales services, which are critical for customer satisfaction and market penetration. The choice of distribution strategy often depends on the target market, geographical reach, and the level of technical support required by the end-users, ensuring product accessibility and effective market coverage.

Soft Gripper Market Potential Customers

The primary end-users and buyers in the Soft Gripper Market span a wide array of industries that necessitate the delicate, adaptable, and damage-free handling of objects. Industries such as food and beverage processing represent significant demand, particularly for handling fresh produce, baked goods, and packaged foods that are often fragile or have irregular shapes. The pharmaceutical and healthcare sectors are crucial customers, utilizing soft grippers for manipulating sterile medical devices, fragile vials, and delicate laboratory samples, where precision and hygiene are paramount. The electronics and semiconductors industry also heavily relies on soft grippers for handling sensitive components, circuit boards, and finished products without causing electrostatic discharge or physical damage during assembly and testing processes.

Beyond these, the automotive industry employs soft grippers for handling various components during assembly, especially those with painted or polished surfaces that are susceptible to scratches. Logistics and e-commerce companies are increasingly adopting soft grippers to automate parcel sorting, picking, and packaging processes, addressing the challenges of handling diverse items with varying weights and geometries efficiently and without breakage. Additionally, the consumer goods sector benefits from soft grippers for packaging and assembly tasks involving products with diverse textures and fragility. These end-users prioritize solutions that enhance throughput, minimize waste, reduce labor costs, and improve overall product quality and safety throughout their operational workflows.

The versatility of soft grippers also extends to niche applications and emerging markets. Research and development institutions, educational facilities, and custom automation providers are also significant potential customers, often seeking highly flexible and programmable grippers for prototyping, experimental setups, and specialized robotic projects. Furthermore, industries like textiles, agriculture, and chemical processing are beginning to recognize the benefits of soft grippers for handling delicate fabrics, fruits, vegetables, or hazardous materials with greater safety and efficiency. This broad appeal underscores the market's potential for continued expansion as more industries discover the advantages of compliant robotic manipulation for their specific production and handling challenges.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 750 million |

| Market Forecast in 2032 | USD 2.4 billion |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Soft Robotics Inc., Festo, RightHand Robotics, Schmalz, OnRobot, ABB, KUKA, FANUC, Universal Robots, Piab, Gimatic, ATI Industrial Automation, Zimmer Group, Norgren, SMC Corporation, Robotiq, Rethink Robotics, Mitsubishi Electric, Converge Robotics, Empire Robotics (acquired by Soft Robotics). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Soft Gripper Market Key Technology Landscape

The Soft Gripper Market is underpinned by a rapidly evolving technological landscape, driven by advancements in materials science, actuation systems, and intelligent control mechanisms. A core technology involves the development of novel soft robotic materials, primarily advanced polymers such as specialized silicones, rubbers, and thermoplastic elastomers (TPEs), which offer superior compliance, durability, and biocompatibility. These materials are engineered to exhibit specific mechanical properties that allow the grippers to conform precisely to object geometries without applying excessive force, ensuring gentle handling. Further innovations include hydrogels and shape memory polymers, which introduce responsive and self-healing capabilities, enhancing gripper resilience and functionality in challenging environments.

Actuation technologies are another critical component of the soft gripper landscape, dictating how these compliant structures are controlled to perform gripping actions. Pneumatic actuation remains a dominant technology, utilizing compressed air to inflate or deflate internal chambers within the gripper, resulting in controlled deformation. Electric actuation, often through small motors or electroactive polymers, is gaining traction for its precision, quieter operation, and ease of integration with robotic systems, eliminating the need for external air compressors. Vacuum-based systems are also prevalent, employing suction cups or bellows made of soft materials to create a secure grip. The combination of these actuation methods with advanced sensor feedback loops allows for highly responsive and adaptable gripping strategies.

Beyond materials and actuation, the integration of artificial intelligence (AI), machine learning (ML), and advanced vision systems is transforming soft grippers into intelligent end effectors. AI algorithms enable grippers to learn optimal grasping strategies for unknown objects, adapt to dynamic environments, and perform complex tasks autonomously. Vision systems provide real-time feedback on object position, orientation, and characteristics, feeding data to AI models for precise manipulation. Furthermore, advancements in embedded sensing, such as force sensors and tactile feedback systems, allow soft grippers to "feel" objects, adjust their grip in real time, and detect slippage. This confluence of technologies creates highly versatile, efficient, and intelligent gripping solutions essential for the next generation of industrial automation.

Regional Highlights

- North America: This region is a significant hub for technological innovation and early adoption of advanced robotics, driving demand for soft grippers in sectors like electronics, pharmaceuticals, and logistics. The presence of major robot manufacturers and a strong emphasis on automation to combat labor shortages contribute to robust market growth. The United States and Canada are leading countries due to substantial R&D investments and a mature industrial base.

- Europe: Europe exhibits strong growth, particularly in Germany, Italy, and France, driven by the widespread adoption of Industry 4.0 principles and a focus on collaborative robotics in automotive, manufacturing, and food processing industries. Stringent quality control requirements and a push towards sustainable and efficient production processes further boost the demand for precise handling solutions.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market, primarily fueled by rapid industrialization, extensive manufacturing activities, and significant government investments in automation and robotics in countries like China, Japan, South Korea, and India. The burgeoning e-commerce sector and high-volume production lines demanding delicate handling are key drivers.

- Latin America: This region is an emerging market for soft grippers, with increasing automation adoption in industries such as food and beverage, automotive, and agriculture. Brazil and Mexico are leading the way, driven by foreign investments in manufacturing and a growing awareness of the benefits of advanced robotic solutions for improving productivity and safety.

- Middle East and Africa (MEA): The MEA market is still in its nascent stages but shows considerable potential. Investments in industrial diversification, smart city initiatives, and the development of logistics hubs are gradually increasing the demand for automation technologies, including soft grippers, particularly in the UAE, Saudi Arabia, and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Soft Gripper Market.- Soft Robotics Inc.

- Festo

- RightHand Robotics

- Schmalz

- OnRobot

- ABB

- KUKA

- FANUC

- Universal Robots

- Piab

- Gimatic

- ATI Industrial Automation

- Zimmer Group

- Norgren

- SMC Corporation

- Robotiq

- Mitsubishi Electric

- Converge Robotics

- Realisable

- Bionic Robotics GmbH

Frequently Asked Questions

What are soft grippers and how do they differ from traditional grippers?

Soft grippers are robotic end effectors made from compliant, flexible materials that can adapt to various object shapes and textures, enabling delicate, damage-free handling. Unlike traditional rigid grippers, which often require precise alignment and can damage fragile items, soft grippers conform to objects, offering superior versatility and gentleness for diverse applications.

Which industries benefit most from integrating soft grippers?

Industries handling delicate, irregularly shaped, or sensitive items benefit significantly. This includes food and beverage for fresh produce and baked goods, pharmaceuticals for vials and medical devices, electronics for sensitive components, and e-commerce/logistics for diverse parcel handling.

What are the key advantages of using soft grippers in automation?

Key advantages include reduced product damage, enhanced flexibility for handling diverse objects without tooling changes, safer operation alongside human workers (especially with collaborative robots), and improved overall efficiency in delicate pick-and-place or assembly tasks.

How does AI influence the performance and future of soft grippers?

AI enhances soft grippers by enabling intelligent object recognition, adaptive grasping strategies through machine learning, and predictive maintenance. This allows grippers to operate more autonomously, learn from experience, and adapt to unstructured environments, significantly boosting their versatility and efficiency.

What are the primary challenges limiting the widespread adoption of soft grippers?

Primary challenges include the relatively higher initial investment costs compared to traditional grippers, the complexity involved in integrating them with existing robotic systems, and current limitations in terms of maximum payload capacity and operational speed for very heavy or high-speed applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager