Sol-Gel Coatings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429300 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Sol-Gel Coatings Market Size

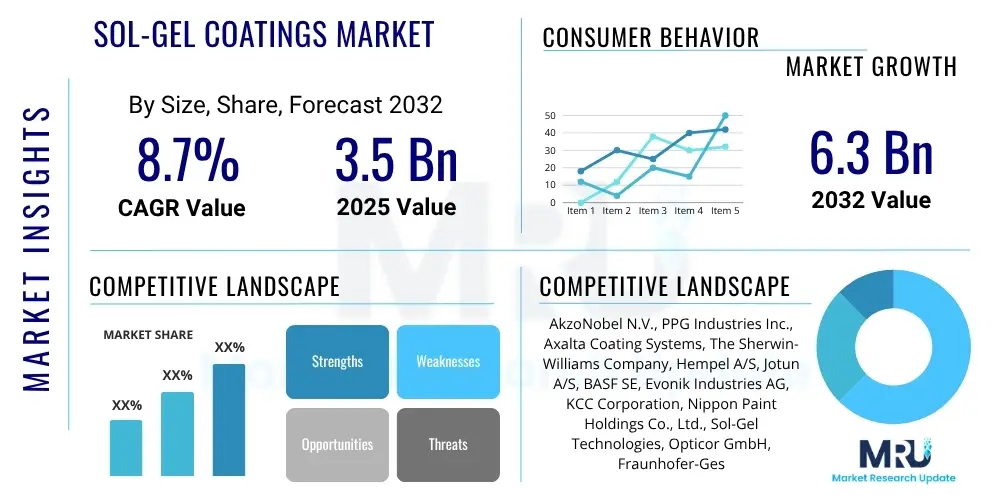

The Sol-Gel Coatings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2025 and 2032. The market is estimated at USD 3.5 Billion in 2025 and is projected to reach USD 6.3 Billion by the end of the forecast period in 2032. This substantial growth is primarily driven by the increasing demand for high-performance, multi-functional coatings across various industrial sectors, coupled with continuous advancements in sol-gel chemistry and processing technologies. The market's expansion is further supported by the growing need for sustainable and environmentally friendly coating solutions that offer superior protection and enhanced material properties.

Sol-Gel Coatings Market introduction

The Sol-Gel Coatings Market encompasses a specialized segment within the advanced materials industry, focusing on the production and application of thin films and coatings derived from sol-gel processing. Sol-gel is a wet-chemical technique involving the conversion of a colloidal suspension (sol) into a gel, which then undergoes further processing to form a dense material or thin film. This innovative approach allows for the creation of coatings with exceptional characteristics such as superior hardness, corrosion resistance, anti-reflection, self-cleaning, and biocompatibility, often at lower processing temperatures compared to traditional methods. The versatility of sol-gel chemistry enables the incorporation of various functional components, leading to multi-functional coatings tailored for specific performance requirements.

Major applications for sol-gel coatings span a broad spectrum of industries, including automotive for enhanced durability and aesthetics, aerospace for thermal protection and erosion resistance, medical devices for biocompatibility and antimicrobial properties, electronics for dielectric layers and protective barriers, and construction for self-cleaning and energy-efficient windows. The inherent benefits of these coatings, such as their ability to form uniform films on complex geometries, tunable properties, and often-reduced environmental footprint compared to solvent-based alternatives, make them increasingly attractive. Key driving factors for market growth include the escalating demand for high-performance materials in critical applications, stringent environmental regulations pushing for eco-friendly coating solutions, and ongoing research and development leading to novel formulations and expanded application areas.

Sol-Gel Coatings Market Executive Summary

The Sol-Gel Coatings Market is currently experiencing robust growth, propelled by significant business trends such as increasing investments in research and development aimed at creating advanced hybrid sol-gel formulations, strategic collaborations between raw material suppliers and end-use industries, and a growing emphasis on sustainable manufacturing practices. Innovations in nanotechnology integration within sol-gel matrices are opening new avenues for ultra-performance coatings, enhancing properties like scratch resistance, hydrophobicity, and electrical conductivity. Consolidation activities through mergers and acquisitions are also observed as companies seek to expand their technological capabilities, geographic reach, and product portfolios, ensuring a competitive edge in a rapidly evolving market landscape.

Regionally, the Asia Pacific continues to dominate the sol-gel coatings market, driven by its burgeoning automotive, electronics, and construction sectors, particularly in countries like China, India, and South Korea, where industrial expansion and infrastructure development are robust. North America and Europe also represent significant markets, characterized by stringent environmental regulations that favor sol-gel technology and strong demand from the aerospace, medical, and advanced manufacturing industries. Segment-wise, the anti-corrosion and anti-scratch coating applications are witnessing substantial demand due to their critical role in extending product lifespan and improving durability across various end-use sectors, while the medical and healthcare segment is showing promising growth for biocompatible and antimicrobial coatings, fueled by an aging global population and advancements in medical technology.

AI Impact Analysis on Sol-Gel Coatings Market

Common user questions regarding AI's impact on the Sol-Gel Coatings Market often revolve around how artificial intelligence can accelerate material discovery, optimize synthesis processes, predict coating performance, and enhance manufacturing efficiency. Users are interested in AI's potential to reduce development cycles, improve quality control, and enable the design of novel, multi-functional coatings with unprecedented precision. Concerns also exist regarding the complexity of integrating AI, the need for vast datasets, and the expertise required to leverage these technologies effectively within the specialized field of sol-gel chemistry.

- Accelerated Material Discovery: AI algorithms can rapidly screen and predict optimal precursor combinations and synthesis parameters for novel sol-gel formulations, significantly reducing the time and cost associated with traditional trial-and-error R&D.

- Process Optimization and Control: Machine learning models can monitor and adjust sol-gel processing conditions in real-time, such as temperature, humidity, and curing times, to ensure consistent coating quality and optimize energy consumption in manufacturing.

- Predictive Performance Modeling: AI can analyze vast datasets of material properties and performance characteristics to predict how specific sol-gel coatings will behave under various environmental stressors, enabling the design of coatings with tailored functionality for specific applications.

- Enhanced Quality Control: Computer vision and AI-powered sensors can detect microscopic defects and inconsistencies in sol-gel films during production, vastly improving quality assurance and reducing waste compared to manual inspection methods.

- Customization and Personalization: AI can facilitate the rapid design and formulation of highly customized sol-gel coatings to meet niche application requirements, adapting quickly to specific end-user demands for tailored properties like optical clarity, specific adhesion, or unique surface textures.

- Supply Chain Optimization: AI-driven analytics can improve the forecasting of raw material needs, optimize inventory management, and streamline logistics for sol-gel coating manufacturers, leading to cost savings and increased operational efficiency.

- Robotics and Automation Integration: AI complements robotic systems for automated sol-gel coating application, enabling precision coating deposition on complex geometries and high-throughput manufacturing, further enhancing productivity and consistency.

DRO & Impact Forces Of Sol-Gel Coatings Market

The Sol-Gel Coatings Market is influenced by a dynamic interplay of Drivers, Restraints, Opportunities, and broader Impact Forces. A primary driver is the escalating demand for high-performance, multi-functional coatings across diverse industries such as automotive, aerospace, electronics, and medical, where superior properties like corrosion resistance, scratch resistance, and optical clarity are paramount. Environmental regulations worldwide, which increasingly restrict the use of volatile organic compounds (VOCs) and hazardous materials in traditional coatings, are also significantly pushing the adoption of eco-friendly sol-gel alternatives. Furthermore, continuous technological advancements in sol-gel chemistry, including the development of hybrid organic-inorganic materials and nanoparticle incorporation, are expanding the range of applications and performance capabilities of these coatings.

However, the market faces notable restraints. The relatively high production cost associated with some advanced sol-gel precursors and the energy-intensive curing processes can hinder wider adoption, especially in price-sensitive markets. The complexity of the sol-gel process, requiring precise control over synthesis parameters, also poses a technical challenge that can limit scalability and consistent quality for some manufacturers. Additionally, a lack of widespread awareness and understanding of sol-gel technology's full capabilities and benefits among potential end-users, especially compared to more established coating technologies, can slow market penetration in certain segments. These factors collectively create a competitive landscape where innovation and cost-efficiency are critical.

Despite these challenges, significant opportunities exist for market expansion. Emerging applications in renewable energy (e.g., solar panels, wind turbine blades), smart textiles, and advanced packaging offer new growth avenues for sol-gel coatings that can provide unique protective and functional properties. Continued research into novel, low-cost precursors and energy-efficient curing methods, alongside the development of user-friendly application techniques, can help overcome current cost and complexity restraints. The growing global emphasis on sustainability and the circular economy further positions sol-gel coatings as a future-proof solution, driving investment and innovation towards greener manufacturing processes and product lifecycles. Broader impact forces, such as global economic trends, geopolitical stability affecting supply chains, and rapid digitalization driving demand for advanced electronics, will continue to shape the market's trajectory, emphasizing the need for adaptable and resilient supply chain strategies.

Segmentation Analysis

The Sol-Gel Coatings Market is extensively segmented to provide a detailed understanding of its various components and target applications. This segmentation allows for a granular analysis of market dynamics, identifying key growth drivers, challenges, and opportunities within specific product types, applications, end-use industries, and geographic regions. Understanding these distinct segments is crucial for stakeholders to develop targeted strategies, innovate new products, and effectively penetrate underserved markets, thereby maximizing their competitive advantage and fostering sustained market growth across the diverse landscape of advanced coating solutions.

- By Type: Inorganic Sol-Gel Coatings, Organic-Inorganic Hybrid Sol-Gel Coatings

- By Application: Anti-Corrosion Coatings, Anti-Scratch Coatings, Anti-Reflective Coatings, Self-Cleaning Coatings, Biocompatible Coatings, Others (e.g., Electrical Insulation, Gas Barriers)

- By End-Use Industry: Automotive, Aerospace & Defense, Electronics & Semiconductors, Medical & Healthcare, Building & Construction, Energy (Solar, Wind), Optics & Eyewear, Consumer Goods, Marine, Industrial

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East & Africa (MEA)

Value Chain Analysis For Sol-Gel Coatings Market

The value chain for the Sol-Gel Coatings Market commences with upstream activities focused on the sourcing and production of critical raw materials. This segment includes manufacturers of metal alkoxides, inorganic salts, silanes, and various organic precursors that serve as the fundamental building blocks for sol-gel formulations. These suppliers play a pivotal role in ensuring the purity, consistency, and cost-effectiveness of these specialized chemicals, which directly impacts the performance and economic viability of the final coating product. Research and development institutions also contribute significantly upstream by innovating new precursor chemistries and optimizing synthesis methods.

Midstream in the value chain, specialized coating manufacturers leverage these raw materials to formulate and produce a wide array of sol-gel coatings tailored for specific applications. This stage involves complex chemical engineering, formulation expertise, and quality control processes to ensure the coatings meet stringent performance specifications. Coating manufacturers often employ direct sales teams or utilize established distribution channels to reach their diverse customer base. Downstream activities involve the application of these coatings by end-use industries, such as automotive OEMs, aerospace manufacturers, electronics companies, and medical device producers. These end-users integrate sol-gel coatings into their manufacturing processes to enhance product durability, functionality, and aesthetic appeal, ultimately adding significant value to their final products.

Distribution channels for sol-gel coatings are diverse, encompassing both direct and indirect approaches. Direct sales are common for highly specialized or customized coating solutions, where technical support and close collaboration between the manufacturer and the end-user are essential. Indirect channels involve distributors, agents, and third-party logistics providers who facilitate market access, particularly for standardized products or in geographically dispersed markets. These channels are crucial for efficient inventory management, timely delivery, and providing localized technical assistance, thereby ensuring broad market penetration and customer satisfaction across the global Sol-Gel Coatings Market.

Sol-Gel Coatings Market Potential Customers

The potential customers for sol-gel coatings are remarkably diverse, encompassing a wide array of end-user industries that seek advanced material properties and enhanced performance for their products. The automotive industry represents a significant customer base, utilizing sol-gel coatings for scratch-resistant clear coats, anti-corrosion protection on chassis components, and anti-glare coatings on internal displays. Aerospace and defense manufacturers are key buyers, leveraging these coatings for thermal barrier applications, erosion protection on turbine blades and airframes, and anti-icing solutions due to their lightweight and durable characteristics, which are critical in demanding operational environments.

The electronics and semiconductor sector is another major consumer, employing sol-gel films for dielectric layers, protective coatings for sensitive components, and anti-reflective surfaces for optical devices, driven by the need for miniaturization, improved performance, and reliability. In the medical and healthcare domain, sol-gel coatings are increasingly sought after for creating biocompatible surfaces on implants, antimicrobial layers on surgical instruments, and drug-delivery systems, addressing critical needs for patient safety and device functionality. Furthermore, the building and construction industry utilizes sol-gel coatings for self-cleaning windows, protective layers on facades, and energy-efficient glazing solutions, contributing to sustainable urban development and reducing maintenance costs over time.

Beyond these primary sectors, other significant potential customers include optics and eyewear manufacturers for anti-reflective and anti-scratch lenses, renewable energy companies for improving the efficiency and durability of solar panels and wind turbine blades, and various industrial applications requiring specialized protective barriers against harsh chemicals, extreme temperatures, or abrasion. The broad applicability of sol-gel technology, offering customizable properties, ensures a continuously expanding base of potential customers seeking innovative solutions to enhance product longevity, functionality, and environmental compliance across a multitude of manufacturing and service industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.5 Billion |

| Market Forecast in 2032 | USD 6.3 Billion |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AkzoNobel N.V., PPG Industries Inc., Axalta Coating Systems, The Sherwin-Williams Company, Hempel A/S, Jotun A/S, BASF SE, Evonik Industries AG, KCC Corporation, Nippon Paint Holdings Co., Ltd., Sol-Gel Technologies, Opticor GmbH, Fraunhofer-Gesellschaft, Picosun Oy, Beneq Oy, ICM Products Inc., Materion Corporation, Covestro AG, 3M Company, AGC Inc., NanoXplore Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sol-Gel Coatings Market Key Technology Landscape

The Sol-Gel Coatings Market is characterized by a dynamic and evolving technology landscape, with continuous innovation driving new applications and performance enhancements. The fundamental technology revolves around the careful selection and manipulation of precursors, primarily metal alkoxides and inorganic salts, in a solvent to form a colloidal suspension (sol) through hydrolysis and condensation reactions. Subsequent processing, often involving dip coating, spray coating, spin coating, or doctor blading, deposits a thin film that then converts into a dense, functional gel upon drying and curing. Advancements in precursor chemistry, including the development of hybrid organic-inorganic precursors, are critical, enabling the creation of coatings with a wider range of tailored properties such as improved flexibility, enhanced thermal stability, and superior chemical resistance, thus pushing the boundaries of traditional material limitations.

Beyond the core sol-gel chemistry, the market's technological progress is significantly influenced by advanced deposition techniques and post-processing methods. Techniques like atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) are increasingly being integrated with sol-gel processes to create ultra-thin, highly uniform, and defect-free films, particularly vital for microelectronics and optical applications. Furthermore, the incorporation of nanotechnology, involving the dispersion of various nanoparticles (e.g., SiO2, TiO2, ZnO, graphene) within the sol-gel matrix, is a crucial trend. These nanoparticles impart multi-functional characteristics such as enhanced hardness, UV protection, photocatalytic self-cleaning properties, and improved electrical conductivity, enabling the development of "smart" coatings with active functionalities.

The drive towards sustainability also shapes the technology landscape, with a growing focus on developing water-based or solvent-free sol-gel systems to reduce volatile organic compound (VOC) emissions and minimize environmental impact. Innovations in low-temperature curing methods and UV-curable sol-gel formulations are also gaining traction, offering energy efficiency benefits and compatibility with heat-sensitive substrates. The integration of artificial intelligence and machine learning for predictive material design and process optimization, as well as advanced characterization techniques for real-time quality control, are further solidifying the technological foundation of the sol-gel coatings market, ensuring high-performance, cost-effective, and environmentally responsible solutions for a broad range of industrial demands.

Regional Highlights

- North America: This region is a significant market for sol-gel coatings, driven by robust demand from the aerospace and defense, automotive, and medical device industries. Stringent regulations regarding environmental protection and the emphasis on high-performance materials in critical applications fuel innovation and adoption. The presence of leading research institutions and a strong industrial base contribute to technological advancements and widespread commercialization. Companies in the U.S. and Canada are actively investing in R&D to develop advanced hybrid sol-gel formulations for specialized applications.

- Europe: Europe stands as a mature market with a high adoption rate of sol-gel coatings, particularly in Germany, France, and the UK. The region benefits from stringent environmental norms encouraging eco-friendly coating solutions, as well as a strong automotive sector, advanced manufacturing capabilities, and a thriving aerospace industry. There is a significant focus on sustainable solutions and smart coatings, with a push towards reducing energy consumption during coating application and curing processes, supported by EU-funded research initiatives.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for sol-gel coatings, primarily propelled by rapid industrialization, massive infrastructure development, and a booming manufacturing sector, especially in China, India, Japan, and South Korea. The expanding automotive and electronics industries, coupled with increasing disposable incomes leading to higher demand for consumer goods, are key drivers. Investments in smart cities and renewable energy projects further contribute to the demand for high-performance and functional coatings in the region.

- Latin America: The sol-gel coatings market in Latin America is witnessing steady growth, albeit from a smaller base, driven by increasing industrial activities in countries like Brazil and Mexico. Expansion in the automotive, construction, and oil and gas sectors generates demand for protective and durable coatings. Economic development and urbanization are fostering opportunities for sol-gel applications in infrastructure and consumer goods, with a growing awareness of advanced coating benefits.

- Middle East and Africa (MEA): The MEA region presents emerging opportunities for sol-gel coatings, particularly in sectors such as oil and gas, construction, and automotive. Investments in infrastructure projects and diversification efforts away from oil economies are creating new avenues. Countries like UAE and Saudi Arabia are focusing on advanced materials for corrosion protection in harsh environments and for architectural applications, indicating a gradual but consistent growth in the adoption of these specialized coatings.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sol-Gel Coatings Market.- AkzoNobel N.V.

- PPG Industries Inc.

- Axalta Coating Systems

- The Sherwin-Williams Company

- Hempel A/S

- Jotun A/S

- BASF SE

- Evonik Industries AG

- KCC Corporation

- Nippon Paint Holdings Co., Ltd.

- Sol-Gel Technologies

- Opticor GmbH

- Fraunhofer-Gesellschaft

- Picosun Oy

- Beneq Oy

- ICM Products Inc.

- Materion Corporation

- Covestro AG

- 3M Company

- AGC Inc.

- NanoXplore Inc.

Frequently Asked Questions

What are the primary benefits of sol-gel coatings over traditional coatings?

Sol-gel coatings offer superior properties such as enhanced corrosion resistance, exceptional hardness and scratch resistance, advanced optical properties like anti-reflection or anti-glare, and often boast biocompatibility. They are also known for their environmental friendliness due to lower VOC emissions and lower processing temperatures compared to many traditional solvent-based or high-temperature coating methods.

Which industries are the largest consumers of sol-gel coatings?

The largest consumers of sol-gel coatings include the automotive industry for exterior protection and interior aesthetics, aerospace and defense for high-performance thermal and erosion barriers, electronics and semiconductors for dielectric and protective layers, and the medical and healthcare sector for biocompatible and antimicrobial surfaces on devices.

How is environmental sustainability influencing the sol-gel coatings market?

Environmental sustainability is a significant driver, pushing for the development of water-based or solvent-free sol-gel systems. These formulations reduce volatile organic compound (VOC) emissions, aligning with stricter environmental regulations and consumer demand for greener products, making sol-gel technology a preferred choice for eco-conscious applications.

What role does nanotechnology play in the advancement of sol-gel coatings?

Nanotechnology plays a crucial role by enabling the incorporation of various nanoparticles (e.g., SiO2, TiO2) into the sol-gel matrix. This integration imparts multi-functional properties like enhanced hardness, UV protection, photocatalytic self-cleaning, and improved electrical conductivity, leading to the development of "smart" coatings with active and superior functionalities.

What are the key challenges facing the growth of the sol-gel coatings market?

Key challenges include the relatively high production cost of certain advanced sol-gel precursors, the technical complexity involved in precise process control during synthesis and application, and a comparative lack of widespread awareness among potential end-users regarding the full benefits and capabilities of sol-gel technology versus conventional coating solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager