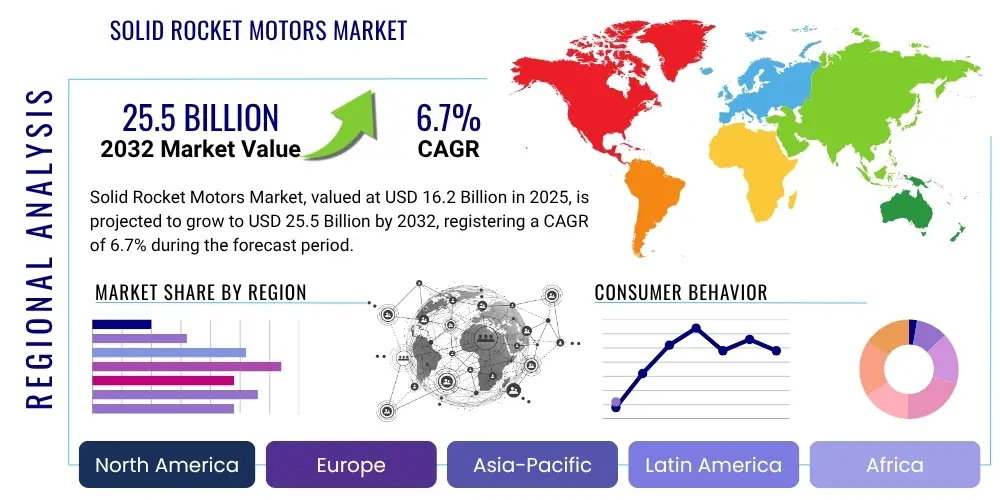

Solid Rocket Motors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429057 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Solid Rocket Motors Market Size

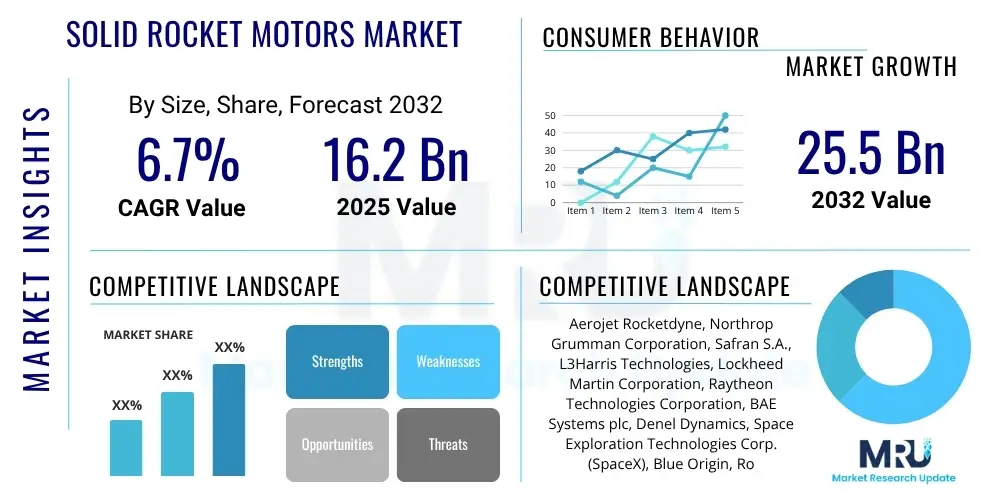

The Solid Rocket Motors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 16.2 Billion in 2025 and is projected to reach USD 25.5 Billion by the end of the forecast period in 2032.

Solid Rocket Motors Market introduction

The Solid Rocket Motors (SRM) market encompasses the design, development, manufacturing, and deployment of rocket propulsion systems utilizing solid propellant. These motors are characterized by their inherent simplicity, high thrust-to-weight ratio, long shelf life, and operational reliability, making them indispensable across various critical applications. Primarily, SRMs convert solid chemical propellant into hot gas, which is then expelled through a nozzle to generate thrust. Their robust nature and instantaneous readiness for launch offer significant operational advantages over liquid propellant systems in specific scenarios. Key benefits driving their continued adoption include their ease of storage and handling, minimal maintenance requirements, and ability to deliver immense power within compact designs. The driving factors for this market are intrinsically linked to escalating global defense expenditures, ambitious space exploration initiatives, and the rapidly expanding commercial satellite launch sector, all demanding dependable and efficient propulsion solutions. As technological advancements continue to refine propellant compositions and structural integrity, the utility and versatility of solid rocket motors are further solidified across both military and commercial domains.

Solid Rocket Motors Market Executive Summary

The Solid Rocket Motors market is poised for robust expansion, driven by a confluence of geopolitical dynamics and technological advancements. Business trends indicate a strong emphasis on research and development into advanced propellant formulations, lightweight composite casing materials, and enhanced manufacturing techniques, including additive manufacturing, to improve performance metrics such as thrust, specific impulse, and burn time while reducing overall system weight and cost. The industry is also witnessing a shift towards modular and scalable SRM designs to cater to diverse mission profiles, from tactical missiles to small satellite launchers. Regional trends highlight North America and Asia Pacific as dominant forces, fueled by substantial defense budgets, ongoing space programs, and increasing commercial space investments. In North America, modernization efforts by military forces and a vibrant private space sector are primary growth catalysts. Meanwhile, in Asia Pacific, countries like China and India are significantly expanding their space capabilities and defense readiness, leading to heightened demand for SRMs. Segment trends indicate a pronounced increase in demand for SRMs within the military and defense sector for tactical and strategic missile systems due to escalating global security concerns, alongside a burgeoning requirement from the commercial space sector, particularly for small satellite launch vehicles and orbital maneuvering systems that leverage the reliability and cost-effectiveness of solid propulsion.

AI Impact Analysis on Solid Rocket Motors Market

Common user questions related to the impact of AI on the Solid Rocket Motors Market frequently revolve around how artificial intelligence can enhance the design, manufacturing, and operational efficiency of these complex propulsion systems. Users are keen to understand how AI might optimize propellant formulation for better performance and safety, streamline the additive manufacturing processes for SRM components, and improve predictive maintenance to extend motor lifespan and reliability. There is also significant interest in AI's role in advanced simulation for performance prediction, mission planning, and failure analysis, ultimately leading to more robust and cost-effective solid rocket motor solutions. The overarching themes reflect expectations for AI to deliver unprecedented levels of precision, automation, and data-driven insights across the entire lifecycle of solid rocket motors.

AI's influence is transforming the design and engineering phases of solid rocket motors by enabling sophisticated computational fluid dynamics (CFD) and finite element analysis (FEA) with enhanced accuracy and speed. Machine learning algorithms can analyze vast datasets of material properties, design parameters, and performance metrics from previous motor tests to identify optimal configurations and predict the behavior of new designs under various operational conditions. This significantly reduces the reliance on costly physical prototypes and extensive trial-and-error, accelerating the development cycle. Furthermore, AI-driven generative design tools are exploring novel geometries for motor casings, nozzles, and propellant grains that were previously difficult or impossible to conceive, leading to lighter, more efficient, and structurally resilient motors.

In manufacturing, AI is revolutionizing production processes through automation, quality control, and predictive maintenance. AI-powered vision systems are employed for real-time inspection of propellant mixing, casting, and curing, identifying defects with greater precision than human operators and ensuring consistency. Robotic systems, guided by AI, can handle hazardous materials and perform intricate assembly tasks, enhancing worker safety and manufacturing throughput. Predictive maintenance algorithms, fed by sensor data from manufacturing equipment, can forecast potential machinery failures, allowing for proactive interventions that minimize downtime and optimize production schedules. This integration of AI not only boosts efficiency and reduces waste but also contributes to the higher reliability and safety standards of the final solid rocket motor products.

- AI-driven design optimization for propellant formulation and motor structure.

- Enhanced predictive modeling and simulation for performance and failure analysis.

- Automated quality control and inspection during manufacturing processes.

- Optimization of additive manufacturing for SRM components, reducing waste and lead times.

- Predictive maintenance for manufacturing equipment, minimizing downtime.

- AI-assisted mission planning and trajectory optimization for launch vehicles using SRMs.

- Improved data analytics for post-flight analysis and continuous product improvement.

DRO & Impact Forces Of Solid Rocket Motors Market

The Solid Rocket Motors market is significantly shaped by a dynamic interplay of drivers, restraints, and opportunities, alongside various impacting forces that collectively determine its trajectory. Key drivers include escalating global defense budgets influenced by geopolitical instability and the need for military modernization, the intensifying global space race particularly concerning new satellite constellations and lunar missions, and the increasing demand for commercial launch services for small satellites. However, the market faces significant restraints such as the exceptionally high research and development costs associated with advanced propellant technologies and complex motor designs, stringent regulatory frameworks governing the production and export of propulsion systems, environmental concerns related to the chemical composition of certain propellants and their combustion byproducts, and challenges related to aging manufacturing infrastructure that requires substantial capital investment for upgrades. Opportunities abound in the burgeoning commercial space sector, which increasingly seeks reliable and cost-effective propulsion for various missions, the development of advanced reusable rocket technologies incorporating solid boosters, and the exploration of new propulsion concepts like hybrid and green propellants, especially in emerging economies demonstrating increasing space and defense ambitions. External impact forces such as supply chain disruptions affecting raw material availability, rapid technological advancements from competing propulsion systems, the availability of government funding for defense and space programs, and international treaties limiting missile technology proliferation, all exert considerable influence on market growth and strategic direction.

Segmentation Analysis

The Solid Rocket Motors market is meticulously segmented to provide a granular understanding of its diverse applications, technological variations, and operational requirements. This segmentation allows for precise market analysis, identifying key growth areas and niche demands across various end-user industries. The classification typically involves motor type, application, thrust class, and end-user, each influencing design specifications, performance parameters, and procurement strategies. Understanding these distinct segments is crucial for manufacturers to tailor their product offerings and for stakeholders to identify strategic investment opportunities within this complex and technologically intensive market.

- By Type

- Composite Propellant (HTPB, GAP, etc.)

- Double-Base Propellant

- Single-Base Propellant

- Others (e.g., Hybrid Propellants, Metallized Propellants)

- By Application

- Space Exploration

- Launch Vehicles (Boosters, Upper Stages)

- Sounding Rockets

- Orbital Maneuvering Systems

- Military and Defense

- Tactical Missiles (Air-to-Air, Surface-to-Air, Anti-Tank)

- Strategic Missiles (ICBMs, SLBMs)

- Rockets and Artillery

- Boosters and Decelerators

- Commercial

- Small Satellite Launch Vehicles

- Payload Delivery Systems

- Suborbital Flights

- Space Exploration

- By Thrust Type

- Low Thrust (Below 50 kN)

- Medium Thrust (50 kN to 500 kN)

- High Thrust (Above 500 kN)

- By End-User

- Government and Defense Agencies

- Commercial Space Companies

- Research and Academic Institutions

Value Chain Analysis For Solid Rocket Motors Market

The value chain for the Solid Rocket Motors market is a complex ecosystem beginning with raw material extraction and extending through highly specialized manufacturing to final deployment by sophisticated end-users. At the upstream analysis stage, the chain involves the procurement of critical raw materials such as chemical propellants (e.g., oxidizers like ammonium perchlorate, binders like HTPB), metallic components for casings and nozzles (e.g., high-strength steel, aluminum alloys, titanium), and advanced composite materials (e.g., carbon fiber, fiberglass) for lightweight structures. Suppliers in this segment are highly specialized chemical manufacturers and advanced materials providers, subject to strict quality control and regulatory compliance. The subsequent manufacturing phase involves intricate processes including propellant mixing and casting, casing fabrication, nozzle assembly, and integration of igniters and thrust vector control systems, typically performed by a limited number of expert aerospace and defense contractors with specialized facilities and intellectual property.

Moving downstream, the value chain encompasses the integration of solid rocket motors into larger systems, such as launch vehicles, missile systems, or space probes. This involves significant system engineering and integration capabilities, often carried out by prime contractors in the aerospace and defense sectors who design and assemble the complete weapon system or spacecraft. These integrators are crucial intermediaries, translating end-user requirements into technical specifications for SRM manufacturers. Their role includes extensive testing and qualification processes to ensure the SRM performs flawlessly within the larger system. The final stage involves the distribution and delivery of these integrated systems to the ultimate end-users, which are predominantly government defense agencies, national space organizations, or, increasingly, commercial space companies.

Distribution channels in the Solid Rocket Motors market are primarily direct, characterized by long-term contracts and direct procurement between SRM manufacturers or system integrators and the government or major commercial clients. Due to the strategic and sensitive nature of the product, indirect channels are rare for finished motors but may exist for specific sub-components or raw materials where specialized distributors handle logistics and compliance. Direct sales ensure tight control over product specifications, security, and intellectual property, while also facilitating direct technical support and customization. This direct engagement model also reinforces the strong relationship-based nature of business in this highly specialized and regulated industry, emphasizing trust and long-term partnership.

Solid Rocket Motors Market Potential Customers

The Solid Rocket Motors market caters to a highly specialized and discerning customer base, primarily comprised of entities with critical defense, space exploration, and advanced scientific objectives. The predominant end-users and buyers of these sophisticated propulsion systems are national defense ministries and government agencies responsible for military capabilities. These customers procure solid rocket motors for a wide array of applications, including tactical missiles (such as air-to-air, surface-to-air, and anti-tank systems), strategic ballistic missiles, and various forms of military rockets and artillery, where reliability, instantaneous readiness, and high thrust are paramount for national security and defense strategies.

Alongside defense sectors, national and international space agencies (e.g., NASA, ESA, Roscosmos, ISRO, CNSA) represent a significant segment of potential customers. They utilize solid rocket motors as boosters for large launch vehicles, upper stages for orbital insertion, and propulsion for sounding rockets and planetary probes, capitalizing on their power and reliability for successful mission accomplishment. Furthermore, the burgeoning commercial space industry, encompassing private space launch providers, satellite constellation operators, and companies offering suborbital flight services, is rapidly emerging as a crucial customer segment. These commercial entities seek cost-effective and dependable solid propulsion solutions for small satellite launch vehicles, orbital transfer vehicles, and other commercial payload delivery missions, driven by the increasing accessibility and economic viability of space.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 16.2 Billion |

| Market Forecast in 2032 | USD 25.5 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aerojet Rocketdyne, Northrop Grumman Corporation, Safran S.A., L3Harris Technologies, Lockheed Martin Corporation, Raytheon Technologies Corporation, BAE Systems plc, Denel Dynamics, Space Exploration Technologies Corp. (SpaceX), Blue Origin, Rocket Lab, Mitsubishi Heavy Industries, IHI Corporation, ArianeGroup, Exquadrum Inc., Sierra Nevada Corporation, Rafael Advanced Defense Systems Ltd., Nammo AS, HDT Global, Chinese Aerospace Science and Technology Corporation (CASC) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Solid Rocket Motors Market Key Technology Landscape

The Solid Rocket Motors market is continuously evolving through significant technological advancements aimed at enhancing performance, safety, and cost-efficiency. One of the primary areas of innovation lies in advanced propellant formulations, focusing on higher specific impulse, improved density, reduced smoke signatures, and extended shelf life. This includes the development of energetic plasticizers for composite propellants (such as HTPB and GAP-based formulations), and research into "green" propellants that minimize environmental impact while maintaining or exceeding performance characteristics of traditional propellants. These advancements are crucial for achieving longer ranges, higher payloads, and meeting increasingly stringent environmental regulations, making motors more versatile and compliant for future missions.

Another pivotal technological landscape involves the widespread adoption of advanced materials and manufacturing processes. The use of lightweight, high-strength composite materials (e.g., carbon fiber reinforced polymers) for motor casings, nozzles, and igniter components is becoming standard, significantly reducing the overall weight of the motor and improving its thrust-to-weight ratio. Additive manufacturing, or 3D printing, is revolutionizing the production of complex SRM components, allowing for intricate geometries, reduced lead times, and lower manufacturing costs. This technology is particularly beneficial for creating optimized nozzle designs, internal insulation, and specialized igniter structures that are difficult to achieve with traditional manufacturing methods, thereby pushing the boundaries of motor design and performance envelope.

Furthermore, the integration of smart technologies and sophisticated control systems is transforming the operational capabilities of solid rocket motors. This includes advanced thrust vector control (TVC) systems that utilize electromechanical actuators or flexible nozzles for precise steering and trajectory adjustments, moving away from more complex hydraulic systems. Digital twin technology is gaining traction, enabling virtual simulation, testing, and optimization of SRMs throughout their lifecycle, from design to mission execution. Coupled with robust non-destructive testing (NDT) techniques like advanced ultrasonics and X-ray computed tomography, these technologies ensure higher reliability, enable proactive maintenance, and provide critical data for continuous improvement, securing the future operational effectiveness and safety of solid rocket motors in diverse applications.

Regional Highlights

- North America: Dominates the Solid Rocket Motors market due to substantial defense budgets, extensive government-funded space programs (NASA), and a thriving private commercial space industry. The region benefits from key players like Aerojet Rocketdyne and Northrop Grumman, robust R&D capabilities, and strong demand for both military and commercial applications. Ongoing modernization of military assets and the growth of small satellite launch services are key market drivers.

- Europe: Represents a significant market driven by collaborative space efforts (ESA) and national defense initiatives. Countries like France, the UK, and Germany contribute substantially through their aerospace and defense industries. Investment in advanced propulsion technologies, missile defense systems, and commercial satellite launches underpins market growth.

- Asia Pacific (APAC): Emerging as the fastest-growing market, propelled by increasing defense expenditures, ambitious national space programs (China, India, Japan, South Korea), and a rising demand for satellite communication and earth observation services. The region is witnessing significant investment in domestic manufacturing capabilities and technological development to reduce reliance on foreign suppliers for critical propulsion systems.

- Latin America: A developing market with nascent space programs and military modernization efforts in countries like Brazil and Argentina. While smaller in scale compared to other regions, there is growing interest in developing indigenous capabilities and collaborating on space technology, indicating future potential for SRM demand.

- Middle East and Africa (MEA): Characterized by strong defense spending due to regional geopolitical tensions, driving demand for missile systems and rockets. Space exploration initiatives are emerging in some countries, albeit at an early stage. The market is primarily influenced by imports of defense technology, with increasing efforts towards localized manufacturing in some nations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Solid Rocket Motors Market.- Aerojet Rocketdyne

- Northrop Grumman Corporation

- Safran S.A.

- L3Harris Technologies

- Lockheed Martin Corporation

- Raytheon Technologies Corporation

- BAE Systems plc

- Denel Dynamics

- Space Exploration Technologies Corp. (SpaceX)

- Blue Origin

- Rocket Lab

- Mitsubishi Heavy Industries

- IHI Corporation

- ArianeGroup

- Exquadrum Inc.

- Sierra Nevada Corporation

- Rafael Advanced Defense Systems Ltd.

- Nammo AS

- HDT Global

- Chinese Aerospace Science and Technology Corporation (CASC)

Frequently Asked Questions

What are the primary applications of solid rocket motors?

Solid rocket motors (SRMs) are primarily utilized in military and defense for tactical and strategic missile propulsion, including air-to-air, surface-to-air, anti-tank, and intercontinental ballistic missiles. In the space sector, they serve as boosters for large launch vehicles, upper stages for orbital insertion, and propulsion for sounding rockets and small satellite launchers. Their reliability, high thrust, and long shelf life make them ideal for missions requiring immediate readiness and robust performance across these critical applications.

How do solid rocket motors differ from liquid propellant engines?

Solid rocket motors differ from liquid propellant engines in several key aspects. SRMs use a pre-mixed, solid propellant charge that provides high thrust-to-weight ratio, simplicity, and instant readiness for launch, making them highly reliable and easy to store. However, their thrust is typically difficult to throttle or stop once ignited. Liquid propellant engines, conversely, use separate liquid oxidizer and fuel tanks, allowing for precise thrust control, throttling, and multiple restarts, but they are more complex, require intricate plumbing, and have higher maintenance requirements. The choice between them depends on specific mission profiles and operational needs.

What are the main technological advancements driving the solid rocket motor market?

Key technological advancements driving the solid rocket motor market include the development of advanced composite materials for lightweight and stronger casings, leading to improved performance ratios. Innovations in propellant formulations are yielding higher specific impulse, reduced smoke, and environmentally friendlier "green" propellants. Furthermore, additive manufacturing (3D printing) is revolutionizing component production, enabling complex geometries, reduced costs, and faster development cycles. Enhanced thrust vector control systems and digital twin technology for simulation and testing also contribute significantly to increased reliability and efficiency.

What are the key challenges faced by manufacturers in the solid rocket motor industry?

Manufacturers in the solid rocket motor industry face several significant challenges. These include the exceptionally high research and development costs associated with developing new propellant technologies and advanced motor designs, requiring substantial investment. Stringent government regulations and export controls add complexity and time to development and deployment. Environmental concerns related to propellant components and combustion byproducts necessitate continuous innovation in greener technologies. Additionally, managing an aging manufacturing infrastructure and navigating a specialized, often limited, supply chain for critical raw materials pose ongoing operational hurdles.

Which regions are leading the growth in the solid rocket motor market?

North America is currently leading the growth in the solid rocket motor market, primarily driven by robust defense spending, extensive government space programs, and a dynamic commercial space sector. The Asia Pacific region is rapidly emerging as the fastest-growing market, propelled by increasing military modernization efforts, ambitious national space programs in countries like China and India, and a burgeoning demand for commercial satellite launch capabilities. Europe also maintains a significant market presence through collaborative space initiatives and national defense projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager