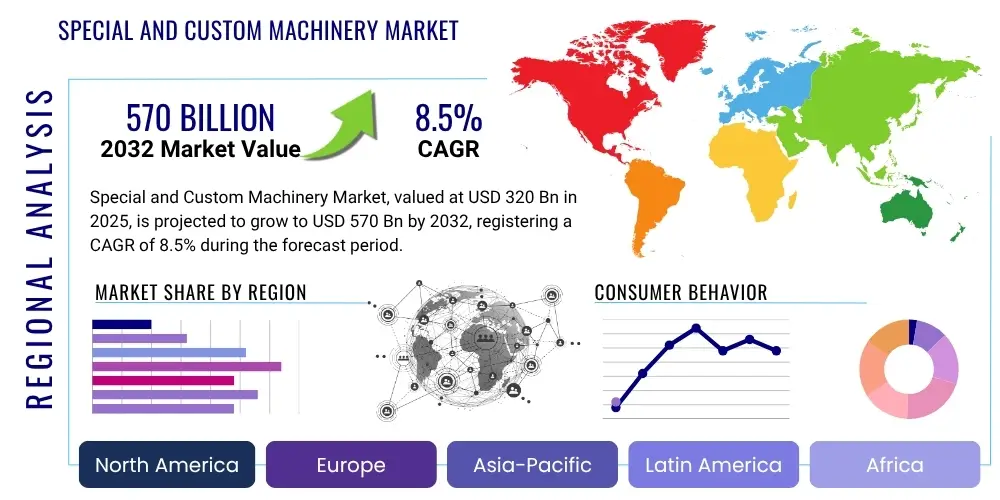

Special and Custom Machinery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430167 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Special and Custom Machinery Market Size

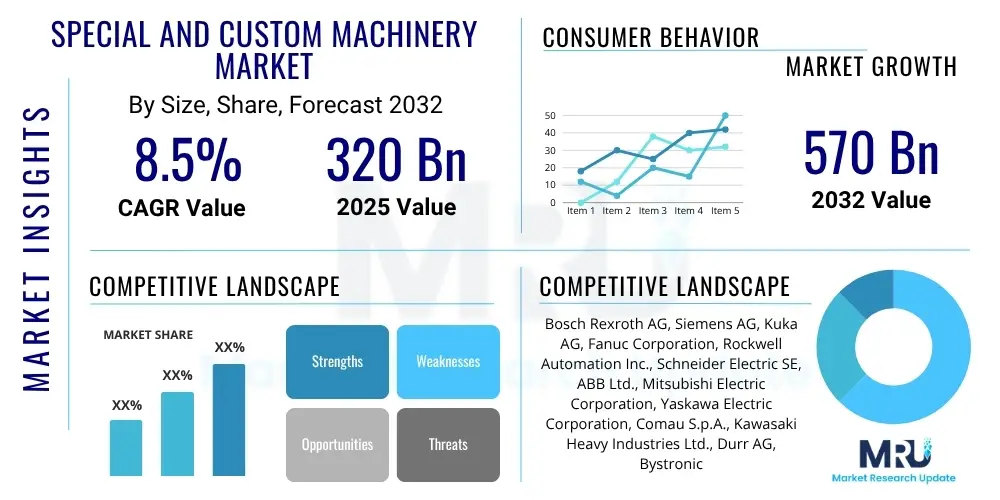

The Special and Custom Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 320 billion in 2025 and is projected to reach USD 570 billion by the end of the forecast period in 2032.

Special and Custom Machinery Market introduction

The Special and Custom Machinery Market encompasses the design, development, and manufacturing of machinery tailored to specific, unique industrial requirements that cannot be met by off-the-shelf solutions. These specialized machines are engineered to perform precise tasks, optimize production processes, and handle unique materials or product specifications across a diverse range of industries. Products in this market include bespoke automation systems, highly specialized processing equipment, unique assembly lines, and precision testing apparatus, all designed with a high degree of flexibility and customization. Major applications span critical sectors such as automotive, aerospace, medical device manufacturing, pharmaceuticals, food and beverage, electronics, and defense, where stringent quality control, high throughput, and specialized handling are paramount. The primary benefits derived from these machines include significantly enhanced operational efficiency, superior product quality consistency, substantial cost reductions through optimized resource utilization, and a crucial competitive advantage stemming from unique capabilities. Key driving factors propelling market growth include the escalating global demand for industrial automation, the pervasive adoption of Industry 4.0 paradigms, the increasing complexity of manufacturing processes, persistent labor shortages in skilled trades, and the strategic imperative for manufacturers to produce highly differentiated and bespoke products efficiently.

Special and Custom Machinery Market Executive Summary

The Special and Custom Machinery Market is experiencing robust growth, driven by an accelerating shift towards advanced manufacturing and tailored production solutions. Key business trends indicate a strong emphasis on integrating smart technologies, such as artificial intelligence, the Internet of Things, and advanced robotics, to enhance machine intelligence, predictive maintenance capabilities, and overall operational autonomy. There is also a notable trend towards modular design and agile manufacturing, allowing for quicker adaptation to evolving market demands and product specifications. Regionally, Asia Pacific continues its dominance, fueled by rapid industrialization, significant investments in manufacturing infrastructure, and the widespread adoption of automation technologies, particularly in countries like China, Japan, and South Korea. North America demonstrates strong innovation, with substantial R&D expenditure and a focus on high-value, complex machinery for aerospace and medical sectors, while Europe maintains its leadership in precision engineering and sustainable manufacturing practices, driven by stringent regulatory frameworks and a push for energy efficiency. Within market segments, the demand for highly automated assembly and processing machinery is surging, alongside an increasing preference for machines capable of handling new and advanced materials. Furthermore, the market is seeing a growing emphasis on lifecycle services, including installation, training, maintenance, and software updates, transforming the supplier-customer relationship into a long-term partnership focused on maximizing machine uptime and performance.

AI Impact Analysis on Special and Custom Machinery Market

Users frequently inquire about how Artificial Intelligence will revolutionize the design, operation, and maintenance of special and custom machinery, seeking to understand its tangible benefits and potential challenges. Common themes center around questions concerning the precision and adaptability AI offers in bespoke manufacturing, its role in improving efficiency, reducing downtime through predictive analytics, and its capacity to empower machines with autonomous decision-making. There is significant interest in AI's application in optimizing complex process parameters, enhancing quality control through advanced vision systems, and facilitating rapid prototyping and iterative design processes. Concerns often include data security, the ethical implications of autonomous systems, and the initial investment required for AI integration, alongside the need for a skilled workforce capable of managing these intelligent systems. Overall, the expectation is that AI will significantly augment human capabilities, making custom machinery more intelligent, efficient, and responsive to dynamic industrial needs.

- Enhanced predictive maintenance: AI algorithms analyze operational data to forecast equipment failures, minimizing unplanned downtime.

- Optimized design and engineering: AI assists in generative design, simulating performance, and automating iterative design processes for specialized components.

- Improved quality control: Machine vision and deep learning identify defects with unparalleled accuracy and speed in complex manufacturing workflows.

- Autonomous operation and decision-making: AI enables machines to adapt to process variations, self-optimize, and perform tasks with minimal human intervention.

- Increased flexibility and adaptability: AI-driven systems can be reconfigured rapidly for new product variants or production demands, crucial for custom manufacturing.

- Resource optimization: AI algorithms optimize energy consumption, material usage, and production scheduling, leading to significant cost savings.

- Advanced robotics integration: AI enhances robotic precision, collaboration, and learning capabilities for complex and delicate tasks in custom setups.

DRO & Impact Forces Of Special and Custom Machinery Market

The Special and Custom Machinery Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaped by powerful impact forces. Key drivers propelling market expansion include the escalating global demand for advanced industrial automation to boost productivity and mitigate labor costs, the relentless pursuit of high-precision and bespoke manufacturing capabilities for differentiated products, and the pervasive adoption of Industry 4.0 technologies like IoT, AI, and robotics that demand specialized equipment integration. Furthermore, persistent skilled labor shortages across various manufacturing sectors compel companies to invest in highly automated, custom-built solutions. However, the market faces notable restraints, primarily the substantial initial capital investment required for designing, developing, and deploying bespoke machinery, which can be a significant barrier for smaller and medium-sized enterprises. The inherent complexity in developing unique solutions necessitates extensive research and development, prolonged lead times, and a highly specialized workforce for operation and maintenance, adding to operational complexities and costs. Moreover, global economic uncertainties, geopolitical instabilities, and disruptions in the supply chain for critical components pose considerable risks to project timelines and profitability. Despite these challenges, vast opportunities exist within emerging industrial sectors, particularly in developing economies rapidly industrializing and upgrading their manufacturing capabilities. The integration of advanced materials, such as composites and alloys, into product designs creates a need for specialized processing machinery, opening new avenues for innovation. Additionally, the growing emphasis on sustainable and energy-efficient manufacturing processes presents an opportunity for custom machinery manufacturers to develop green solutions that align with environmental regulations and corporate responsibility goals. The primary impact forces shaping this market include rapid technological advancements, which constantly redefine manufacturing possibilities and drive innovation cycles. The evolving global regulatory landscape, particularly concerning environmental protection, worker safety, and product standards, mandates adaptation in machine design and functionality. The increasing globalization of supply chains and manufacturing operations necessitates machinery capable of operating across diverse geographical and operational contexts, while intense competitive pressures compel manufacturers to continuously innovate and offer superior, differentiated solutions to maintain market share and profitability.

Segmentation Analysis

The Special and Custom Machinery Market is meticulously segmented to provide a granular understanding of its diverse landscape, categorized primarily by machine type, application, end-user industry, and operational function. This segmentation highlights the specialized nature of demand and the tailored solutions required across various manufacturing environments. Each segment represents a distinct set of technical requirements, operational challenges, and market dynamics, offering a comprehensive view of where customization and innovation are most critical.

- By Machine Type:

- Automated Assembly Machines

- Precision Machining Centers

- Specialized Welding and Joining Equipment

- Custom Material Handling Systems

- Robotic Work Cells

- Inspection and Testing Machinery

- Additive Manufacturing Systems (Custom Built)

- By Application:

- Material Processing

- Component Assembly

- Packaging and Palletizing

- Quality Control and Inspection

- Surface Treatment

- Logistics and Internal Transport

- Specialized Fabrication

- By End-User Industry:

- Automotive

- Aerospace and Defense

- Medical Devices and Pharmaceuticals

- Electronics and Semiconductors

- Food and Beverage

- Energy and Utilities

- Heavy Industry

- Consumer Goods

- By Operational Function:

- Continuous Production

- Batch Production

- Prototyping and R&D

- High-Volume Customization

- By Technology:

- PLC-based Systems

- CNC-based Systems

- AI and Vision Integrated Systems

- IoT and Connectivity Enabled Machines

Value Chain Analysis For Special and Custom Machinery Market

The value chain for the Special and Custom Machinery Market is complex and highly integrated, commencing with robust upstream activities that lay the foundational groundwork for specialized manufacturing. Upstream analysis involves raw material suppliers providing high-grade metals, plastics, and specialized composites, alongside critical component manufacturers who supply advanced sensors, precision motors, control systems, and robotic arms, all tailored to meet stringent performance and reliability specifications. These suppliers often engage in co-development to ensure components are optimized for custom applications. Moving downstream, the value chain encompasses the sophisticated processes of system integration, where bespoke machinery components are assembled, programmed, and rigorously tested to ensure seamless operation and adherence to client specifications. This also includes comprehensive installation services, extensive operator training, and ongoing technical support and maintenance, often involving predictive analytics and remote diagnostics to maximize uptime. Distribution channels in this market are predominantly direct, given the highly customized nature of the products; engineering firms and machine builders directly collaborate with end-user clients from concept to commissioning. Indirect channels may exist for standardized modules or components integrated into larger custom systems, often through specialized distributors or value-added resellers. The prevalence of direct engagement ensures that intricate client requirements are accurately translated into machine design and functionality, fostering strong, long-term relationships centered on engineering expertise and customized solutions.

Special and Custom Machinery Market Potential Customers

Potential customers and end-users of Special and Custom Machinery represent a broad spectrum of manufacturing industries that require highly specific, high-precision, or unique production capabilities unattainable through standard equipment. These buyers are typically characterized by their need for optimized processes, increased automation, enhanced quality control, and the ability to produce highly differentiated or complex products efficiently. Key sectors include the automotive industry, which demands custom assembly lines and specialized tooling for diverse vehicle models and electric vehicle components; the aerospace and defense sector, requiring ultra-precision machining, complex material handling, and stringent inspection systems for critical aircraft and defense components; and the medical device and pharmaceutical industries, where bespoke machinery ensures sterile manufacturing, precise dosage, and intricate assembly for life-critical products. Additionally, the electronics and semiconductor industry relies heavily on custom machinery for micro-assembly, precise etching, and advanced testing of integrated circuits and electronic components. The food and beverage sector utilizes custom solutions for unique packaging, specialized processing of ingredients, and high-speed sorting. Emerging industries focusing on advanced materials, renewable energy, and industrial automation also represent significant potential customers, all seeking innovative, tailored solutions to gain a competitive edge and address unique production challenges.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 320 billion |

| Market Forecast in 2032 | USD 570 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Rexroth AG, Siemens AG, Kuka AG, Fanuc Corporation, Rockwell Automation Inc., Schneider Electric SE, ABB Ltd., Mitsubishi Electric Corporation, Yaskawa Electric Corporation, Comau S.p.A., Kawasaki Heavy Industries Ltd., Durr AG, Bystronic AG, TRUMPF GmbH + Co. KG, DMG MORI AG, Mazak Corporation, Amada Co. Ltd., Okuma Corporation, Heller GmbH, Chiron Group SE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Special and Custom Machinery Market Key Technology Landscape

The Special and Custom Machinery Market is continuously shaped by an evolving and sophisticated technology landscape, driven by the imperative for enhanced precision, efficiency, flexibility, and autonomy in manufacturing. At the forefront is the pervasive integration of Artificial Intelligence and Machine Learning, which enables predictive maintenance, optimizes process parameters, enhances robotic capabilities, and facilitates intelligent quality control through advanced machine vision systems. The Internet of Things (IoT) plays a crucial role by connecting machines, sensors, and control systems, allowing for real-time data collection, remote monitoring, and comprehensive operational analytics, thereby creating smart factories. Advanced Robotics and Cobots (collaborative robots) are essential for automating complex, repetitive, or hazardous tasks with high precision and adaptability, often integrated with AI for greater dexterity and learning. Additive Manufacturing, or 3D printing, especially for tooling and intricate components, allows for rapid prototyping and the production of complex geometries that are often integral to custom machinery design. Digital Twin technology creates virtual replicas of physical machines and processes, enabling simulations, performance optimization, and proactive problem-solving before real-world implementation. Advanced Sensor Technologies, including LiDAR, ultrasonic, force, and tactile sensors, provide critical data for machine operation, safety, and precise control. Furthermore, sophisticated software platforms for CAD/CAM, simulation, and Human-Machine Interface (HMI) are fundamental for designing, programming, and interacting with these complex systems. Cloud Computing and Edge Computing solutions are increasingly utilized for data processing, storage, and enabling distributed intelligence, ensuring secure and efficient operation of connected custom machinery.

Regional Highlights

- North America: The North American market is characterized by high investment in advanced manufacturing technologies and a strong demand for specialized machinery in high-value industries. The United States, in particular, leads in innovation, driven by robust R&D spending and a focus on aerospace, defense, medical devices, and sophisticated electronics manufacturing. Canada also contributes significantly with its automotive and resource processing sectors. The region emphasizes automation to counteract rising labor costs and improve competitive positioning.

- Europe: Europe is a powerhouse for precision engineering and advanced custom machinery, with Germany, Switzerland, and Italy leading the way. The region is known for its stringent quality standards, focus on sustainable manufacturing, and early adoption of Industry 4.0 concepts. Strong automotive, machine tool, and pharmaceutical industries drive demand for bespoke, highly efficient, and environmentally compliant machinery.

- Asia Pacific (APAC): The APAC region represents the largest and fastest-growing market for special and custom machinery globally. Driven by rapid industrialization, extensive manufacturing bases, and significant government initiatives supporting automation, countries like China, Japan, South Korea, and India are key contributors. China’s vast manufacturing output and its "Made in China 2025" initiative heavily rely on advanced custom machinery, while Japan and South Korea excel in robotics, semiconductors, and precision engineering.

- Latin America: The Latin American market is emerging, with increasing investments in industrial modernization, particularly in countries such as Brazil and Mexico. The automotive, food and beverage, and mining sectors are significant demand drivers for custom machinery, aiming to enhance productivity, reduce operational costs, and meet global quality standards. Infrastructure development and foreign direct investment continue to stimulate market growth.

- Middle East and Africa (MEA): The MEA region is experiencing gradual growth, primarily fueled by diversification efforts from oil-dependent economies towards manufacturing, logistics, and infrastructure development. Countries like Saudi Arabia and the UAE are investing heavily in advanced manufacturing capabilities, including automation and specialized production lines. South Africa also plays a crucial role in heavy industry and mining, creating demand for robust custom machinery solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Special and Custom Machinery Market.- Bosch Rexroth AG

- Siemens AG

- Kuka AG

- Fanuc Corporation

- Rockwell Automation Inc.

- Schneider Electric SE

- ABB Ltd.

- Mitsubishi Electric Corporation

- Yaskawa Electric Corporation

- Comau S.p.A.

- Kawasaki Heavy Industries Ltd.

- Durr AG

- Bystronic AG

- TRUMPF GmbH + Co. KG

- DMG MORI AG

- Mazak Corporation

- Amada Co. Ltd.

- Okuma Corporation

- Heller GmbH

- Chiron Group SE

Frequently Asked Questions

What defines special and custom machinery?

Special and custom machinery refers to industrial equipment specifically designed and manufactured to meet unique production requirements, process specific materials, or perform tasks that cannot be accomplished by standard, off-the-shelf machines. These solutions are tailored to optimize efficiency, precision, and output for highly specialized applications.

Which industries are the primary beneficiaries of custom machinery?

Key industries benefiting from custom machinery include automotive, aerospace, medical device manufacturing, pharmaceuticals, electronics and semiconductors, food and beverage, and heavy industry. These sectors often have stringent quality demands, complex product geometries, or unique process flows necessitating bespoke equipment.

How does custom machinery contribute to manufacturing efficiency?

Custom machinery significantly boosts efficiency by perfectly aligning with specific production workflows, reducing manual intervention, minimizing material waste, and increasing throughput. Its tailored design ensures optimal performance for niche tasks, leading to higher output quality, reduced cycle times, and lower operational costs.

What role does Artificial Intelligence play in custom machinery?

AI enhances custom machinery through predictive maintenance, optimizing operational parameters, enabling advanced machine vision for quality control, and empowering robotic systems with greater autonomy and adaptability. This leads to more intelligent, self-optimizing, and highly flexible manufacturing solutions.

What are the main challenges in adopting special and custom machinery?

The primary challenges include high initial capital investment, the technical complexity of design and integration, longer lead times for development, and the requirement for a highly skilled workforce for operation and maintenance. Economic uncertainties and supply chain disruptions can also impact project timelines and costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager