Spin on Carbon Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430980 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Spin on Carbon Market Size

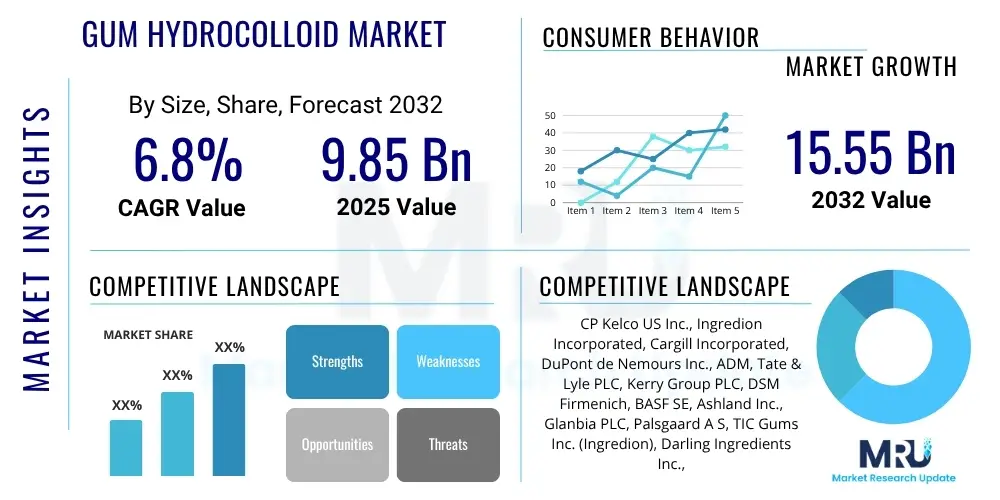

The Spin on Carbon Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 25.5% between 2025 and 2032. The market is estimated at $150 Million in 2025 and is projected to reach $713 Million by the end of the forecast period in 2032.

Spin on Carbon Market introduction

The Spin on Carbon Market represents an innovative and rapidly expanding sector focused on the development and application of advanced carbon materials produced through sophisticated spinning or deposition techniques. These materials, often encompassing specialized forms of carbon nanotubes, graphene, carbon nanofibers, and other precisely structured carbon allotropes, are engineered to possess exceptional properties such as superior electrical and thermal conductivity, high mechanical strength, lightweight characteristics, and chemical stability. The underlying technology typically involves processes like chemical vapor deposition, electrospinning, or solution processing, which allow for the precise control over the morphology and structural integrity of the carbon material, enabling tailored performance for diverse high-tech applications. This market is driven by an escalating global demand for materials that can deliver enhanced performance, miniaturization, and efficiency across multiple industries, positioning Spin on Carbon as a critical enabler for next-generation products and solutions.

The product description for Spin on Carbon materials emphasizes their unique architecture and intrinsic properties. These can include thin films, fibers, or coatings that exhibit unparalleled electrical conductivity for advanced circuitry, remarkable thermal dissipation capabilities for cooling systems, and exceptional strength-to-weight ratios ideal for structural components. Major applications span critical sectors such as high-performance electronics, including flexible displays, advanced sensors, and next-generation semiconductors, as well as energy storage devices like supercapacitors and high-density batteries. Furthermore, these materials are increasingly adopted in aerospace and automotive industries for lightweight composites, in biomedical devices for biocompatible implants and drug delivery systems, and in environmental technologies for filtration and catalysis. The versatility and superior performance profile of Spin on Carbon materials underscore their transformative potential across an array of industrial landscapes.

The benefits derived from integrating Spin on Carbon materials are substantial, ranging from significant improvements in product durability and operational efficiency to enabling entirely new functionalities. For instance, their use allows for the creation of smaller, more powerful electronic components, lighter and more fuel-efficient vehicles, and longer-lasting, faster-charging energy storage solutions. Key driving factors propelling this market forward include relentless innovation in material science, increasing research and development investments by both public and private entities, growing governmental support for advanced manufacturing initiatives, and a burgeoning demand for sustainable and high-performance alternatives to conventional materials. The global push towards electrification, smart technologies, and sustainable development further amplifies the market’s growth trajectory, making Spin on Carbon a pivotal area of technological advancement and economic opportunity.

Spin on Carbon Market Executive Summary

The Spin on Carbon market is characterized by dynamic business trends, marked by significant investment in research and development, particularly by technology giants and specialized material science companies. Strategic collaborations and partnerships between academic institutions, startups, and established industrial players are becoming commonplace, aimed at accelerating material synthesis, characterization, and application development. There is a discernible trend towards market consolidation through mergers and acquisitions, as larger corporations seek to acquire innovative technologies and expand their intellectual property portfolios within the advanced carbon materials space. Additionally, venture capital funding continues to pour into promising startups that demonstrate scalable production capabilities and novel application breakthroughs. The competitive landscape is intensely focused on intellectual property, with companies striving to secure patents for unique synthesis methods and material compositions, thereby establishing strong market positions.

Regionally, the market exhibits varied growth patterns and focuses. Asia Pacific, particularly China, South Korea, and Japan, stands out as a dominant force due to its robust manufacturing infrastructure, extensive electronics industry, and substantial government backing for advanced materials research. This region serves as both a major production hub and a significant consumer market for Spin on Carbon materials, especially in consumer electronics and renewable energy applications. North America and Europe are pivotal for innovation, leading in fundamental research, application development in aerospace, defense, and high-end medical devices. These regions are also characterized by stringent regulatory environments that, while challenging, foster the development of high-quality, compliant materials. Latin America, the Middle East, and Africa are emerging markets, showing increasing interest and investment, particularly in energy and infrastructure projects, but still rely heavily on imports of these specialized materials.

Segment-wise, the market sees particular vibrancy in certain application areas. The electronics segment, driven by the demand for faster processors, flexible electronics, and efficient thermal management solutions, continues to hold a substantial share and is projected for rapid expansion. Energy storage, including advanced battery components and supercapacitors, is another high-growth segment, fueled by the global transition to electric vehicles and renewable energy systems. The aerospace and defense sector shows steady demand for lightweight, high-strength composites, which directly benefit from Spin on Carbon innovations. Emerging trends include the integration of these materials into biomedical devices for enhanced biocompatibility and functionality, as well as their application in smart textiles and infrastructure. The continuous evolution of these segments underscores the broad applicability and transformative potential of Spin on Carbon materials, driving sustained market growth.

AI Impact Analysis on Spin on Carbon Market

User inquiries regarding Artificial Intelligence's influence on the Spin on Carbon market frequently revolve around its potential to accelerate material discovery, optimize manufacturing processes, and enable the development of novel applications. Key themes include the expectation that AI will significantly reduce the time and cost associated with synthesizing new carbon structures by predicting material properties and designing optimal reaction pathways. Concerns often touch upon the initial investment required for AI integration, data privacy issues surrounding proprietary material data, and the potential for job displacement in traditional R&D and manufacturing roles. Users anticipate that AI will facilitate a deeper understanding of structure-property relationships in complex carbon materials, leading to more targeted and efficient material development. They also express interest in AI's role in improving quality control and predictive maintenance within advanced carbon material production lines, ultimately enhancing product reliability and reducing waste.

- AI-driven acceleration of material discovery and design, significantly shortening R&D cycles.

- Optimization of synthesis parameters for various Spin on Carbon materials, leading to improved yield and reduced energy consumption.

- Enhanced quality control through real-time data analysis and anomaly detection in manufacturing processes.

- Predictive modeling for material performance and degradation, enabling longer product lifespans and better reliability.

- Development of autonomous laboratories for high-throughput experimentation and characterization of new carbon structures.

- Personalized material customization based on specific application requirements, enabled by AI algorithms.

- Streamlined supply chain management and inventory optimization for raw materials and finished Spin on Carbon products.

DRO & Impact Forces Of Spin on Carbon Market

The Spin on Carbon Market is significantly propelled by several key drivers that reflect a global shift towards high-performance and sustainable materials. Foremost among these is the escalating demand for lightweight yet robust materials across industries such as aerospace, automotive, and consumer electronics, where weight reduction directly translates into improved fuel efficiency, enhanced performance, and extended battery life. The miniaturization trend in electronic devices and sensors further necessitates materials with superior electrical and thermal properties that can be integrated into increasingly compact form factors without compromising functionality. Additionally, the growing focus on energy efficiency and the development of next-generation energy storage solutions, including advanced batteries and supercapacitors, heavily relies on the unique characteristics offered by Spin on Carbon materials. Continuous advancements in manufacturing techniques and a deeper understanding of carbon material science also serve as crucial drivers, expanding the potential applications and commercial viability of these innovative products.

Despite the promising growth trajectory, the Spin on Carbon market faces several notable restraints. The high production cost associated with advanced carbon materials, particularly for achieving industrial scale while maintaining purity and structural integrity, remains a significant barrier to broader adoption. This often limits their application to niche, high-value sectors, impeding market penetration in more cost-sensitive industries. Scalability challenges in manufacturing, moving from laboratory-scale synthesis to mass production, also present a substantial hurdle, requiring significant capital investment and process optimization. Furthermore, a lack of universally accepted standardization for characterization and performance metrics for various Spin on Carbon materials can hinder market development, making it difficult for end-users to compare products and assure quality. These restraints necessitate ongoing research into cost-effective production methods and collaborative efforts towards establishing industry standards to unlock the market's full potential.

Opportunities within the Spin on Carbon market are abundant and varied, stemming from both technological advancements and evolving global needs. The emergence of new application areas, such as flexible electronics, smart textiles, advanced medical implants, and environmental remediation technologies, opens vast unexplored market segments. The global push for green technologies and sustainable solutions positions Spin on Carbon materials favorably, given their potential for energy savings and resource efficiency in various applications. Strategic partnerships between material producers, equipment manufacturers, and end-users can foster innovation and accelerate the commercialization of novel Spin on Carbon products. Furthermore, increasing government funding for advanced materials research and development, coupled with supportive policies aimed at fostering domestic manufacturing capabilities, creates a conducive environment for market expansion. The ongoing evolution of additive manufacturing techniques also presents a significant opportunity for integrating Spin on Carbon materials into complex, customized structures, further broadening their appeal and utility. The interplay of these drivers, restraints, and opportunities, alongside external impact forces such as geopolitical stability, raw material supply chain resilience, and shifts in consumer preferences towards high-tech and sustainable products, collectively shapes the dynamic landscape of the Spin on Carbon market.

Segmentation Analysis

The Spin on Carbon Market is intricately segmented based on various factors including material type, application, and manufacturing method, each offering unique growth dynamics and market opportunities. This segmentation allows for a comprehensive understanding of the market's structure, highlighting specific areas of innovation, investment, and demand. The diverse range of carbon forms and their tailored properties cater to a broad spectrum of industries, from high-tech electronics to advanced composites, underscoring the versatility and critical role of these materials in modern technological advancements. Analyzing these segments provides strategic insights for market players to focus their research, development, and commercialization efforts.

- By Material Type:

- Carbon Nanotubes (CNTs)

- Single-Walled Carbon Nanotubes (SWCNTs)

- Multi-Walled Carbon Nanotubes (MWCNTs)

- Graphene

- Graphene Oxide (GO)

- Reduced Graphene Oxide (rGO)

- Graphene Nanoplates (GNPs)

- Carbon Nanofibers (CNFs)

- Activated Carbon Fibers (ACFs)

- Amorphous Carbon Films

- Diamond-like Carbon (DLC) Coatings

- Carbon Nanotubes (CNTs)

- By Application:

- Electronics and Semiconductors

- Flexible Displays

- Sensors

- Transistors

- Thermal Management

- Energy Storage

- Batteries (Li-ion, Solid-state)

- Supercapacitors

- Fuel Cells

- Aerospace and Defense

- Lightweight Composites

- Structural Components

- EMI Shielding

- Automotive

- Lightweight Panels

- Battery Components

- Tires

- Medical and Healthcare

- Implants

- Drug Delivery Systems

- Biosensors

- Water and Air Filtration

- Sports Equipment

- Textiles and Wearables

- Electronics and Semiconductors

- By Manufacturing Method:

- Chemical Vapor Deposition (CVD)

- Electrospinning

- Solution Spinning

- Arc Discharge

- Laser Ablation

- Exfoliation

- Additive Manufacturing (3D Printing)

- By End-Use Industry:

- Consumer Electronics

- Automotive & Transportation

- Aerospace & Defense

- Energy & Power

- Medical & Healthcare

- Environmental

- Others (Sports, Textiles)

Value Chain Analysis For Spin on Carbon Market

The value chain for the Spin on Carbon market initiates with the upstream analysis, primarily focusing on the sourcing and processing of raw materials. This critical stage involves suppliers of carbon precursors such as various hydrocarbons (e.g., methane, acetylene, ethylene), polymers, and other organic compounds that serve as the foundational elements for advanced carbon material synthesis. The quality, purity, and availability of these raw materials directly impact the final properties and cost-effectiveness of the Spin on Carbon products. Key activities in this segment include chemical synthesis, purification, and the development of specialized feedstock tailored for specific spinning or deposition techniques. The efficiency and environmental impact of these upstream processes are increasingly scrutinized, driving innovation towards more sustainable and cost-efficient raw material procurement and preparation.

Moving downstream, the value chain encompasses the manufacturing and processing of Spin on Carbon materials, which includes intricate steps like chemical vapor deposition (CVD), electrospinning, solution spinning, and various post-processing treatments. This stage transforms the precursors into highly structured carbon forms such as nanotubes, graphene sheets, or nanofibers with precise control over their morphology, diameter, thickness, and functionalization. Following material synthesis, further value addition occurs through integration into components and sub-systems by intermediate manufacturers. This could involve fabricating carbon-reinforced composites, coating substrates for electronic devices, or incorporating these materials into battery electrodes. The downstream activities are characterized by high technological complexity and proprietary processes, representing a significant portion of the total value addition.

The distribution channel plays a crucial role in connecting manufacturers with end-users. This segment includes both direct and indirect sales channels. Direct sales are often employed for large industrial clients or highly specialized applications where direct technical support and customization are paramount. This allows for closer collaboration between the Spin on Carbon material producer and the end-user, ensuring specific requirements are met. Indirect channels involve specialized distributors, agents, and value-added resellers who possess expertise in handling and marketing advanced materials to a broader customer base, including small and medium-sized enterprises. These intermediaries often provide logistics, technical consultation, and inventory management services, thereby extending market reach. The entire value chain is characterized by a strong emphasis on research and development at every stage, from precursor development to final application integration, as continuous innovation is vital for competitive advantage in this rapidly evolving market.

Spin on Carbon Market Potential Customers

The Spin on Carbon market caters to a diverse array of end-users and buyers who seek advanced materials to enhance the performance, efficiency, and sustainability of their products. Among the primary potential customers are major electronics manufacturers, including those producing smartphones, laptops, flexible displays, and next-generation semiconductors. These companies are constantly in pursuit of materials that offer superior electrical conductivity, improved thermal management capabilities, and mechanical flexibility to meet the demands of miniaturization and high-speed data processing. The unique properties of Spin on Carbon materials, such as graphene's conductivity or carbon nanotube's strength, make them ideal for these applications, enabling breakthroughs in device performance and durability. Additionally, specialized sensor developers and manufacturers of advanced imaging systems represent a growing customer base, leveraging these materials for enhanced sensitivity and precision.

Another significant segment of potential customers includes manufacturers in the energy sector, particularly those involved in the production of electric vehicle batteries, consumer electronics batteries, and grid-scale energy storage solutions. Companies specializing in supercapacitors, fuel cells, and solar panels are also key buyers, as Spin on Carbon materials can drastically improve energy density, charging speeds, cycle life, and overall efficiency of these devices. The aerospace and automotive industries constitute a crucial customer group, driven by the imperative for lightweighting to improve fuel economy and reduce emissions. Automotive OEMs and aerospace component suppliers are increasingly integrating carbon fiber composites and advanced carbon films into vehicle bodies, structural components, and aircraft parts, seeking materials that offer unparalleled strength-to-weight ratios and fatigue resistance. These industries demand materials that can withstand extreme operational conditions while contributing to significant performance gains and operational cost reductions.

Furthermore, the medical and healthcare sector presents a substantial opportunity for Spin on Carbon materials, with potential customers including manufacturers of medical implants, diagnostic devices, and drug delivery systems. The biocompatibility, strength, and electrical properties of certain carbon materials make them suitable for applications such as nerve regeneration, prosthetic interfaces, and advanced biosensors. Companies involved in water purification and environmental remediation are also emerging as key buyers, utilizing activated carbon fibers and graphene-based membranes for highly efficient filtration and adsorption processes. The sports equipment and protective gear industries also represent a niche but growing customer base, seeking materials to develop lighter, stronger, and more durable products. The broad applicability of Spin on Carbon materials across such varied sectors highlights their transformative potential and the extensive market reach for their innovative properties, making them indispensable for next-generation product development across numerous industrial verticals.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $150 Million |

| Market Forecast in 2032 | $713 Million |

| Growth Rate | 25.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | NanoXplore Inc., Applied Graphene Materials plc, Graphenea SA, Versarien plc, Haydale Graphene Industries plc, Sixth Element (Changzhou) Materials Technology Co. Ltd., XG Sciences Inc., Cabot Corporation, Showa Denko K.K., Arkema S.A., Osaka Gas Chemical Co. Ltd., Toray Industries Inc., Teijin Limited, Cytec Solvay Group, Hexcel Corporation, Nippon Graphite Fiber Corporation, LG Chem, Samsung Advanced Institute of Technology, BASF SE, Universal Display Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Spin on Carbon Market Key Technology Landscape

The technological landscape of the Spin on Carbon market is characterized by a sophisticated array of manufacturing, synthesis, and characterization techniques designed to produce carbon materials with tailored properties and structures. Chemical Vapor Deposition (CVD) stands as a foundational technology, widely employed for growing high-quality graphene films and carbon nanotubes directly onto substrates. Variants of CVD, such as plasma-enhanced CVD (PECVD) and atmospheric pressure CVD (APCVD), offer distinct advantages in terms of growth rates, crystallinity, and substrate compatibility, crucial for applications in electronics and sensors. Electrospinning and solution spinning techniques are pivotal for producing continuous carbon nanofibers and yarns from polymer precursors, which are subsequently carbonized to yield materials with high strength, electrical conductivity, and porosity, finding utility in composites, energy storage, and filtration applications. These methods allow for precise control over fiber diameter and alignment, critical for performance optimization.

Beyond these primary synthesis methods, the market also leverages advanced exfoliation techniques for producing graphene from bulk graphite, including mechanical exfoliation, liquid-phase exfoliation, and electrochemical exfoliation, each offering different scales of production and material quality. Laser-induced deposition and additive manufacturing (3D printing) with carbon-based inks or filaments are emerging technologies that enable the fabrication of complex, customized Spin on Carbon structures and devices with unprecedented geometric freedom and resolution. These advancements are particularly significant for prototyping and developing bespoke components for medical devices, microelectronics, and advanced composite structures. The continuous evolution of these manufacturing processes focuses on improving scalability, reducing production costs, enhancing material quality, and enabling more precise control over the atomic and nanoscale architecture of the carbon products.

The efficacy and commercial viability of Spin on Carbon materials are heavily reliant on advanced characterization technologies that can precisely analyze their structural, electrical, mechanical, and chemical properties. Techniques such as Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), and Atomic Force Microscopy (AFM) are essential for visualizing nanoscale morphology and structural defects. Raman spectroscopy, X-ray Diffraction (XRD), and X-ray Photoelectron Spectroscopy (XPS) provide critical insights into material purity, crystallinity, and chemical composition, which are vital for quality control and performance validation. Electrical and thermal conductivity measurements, along with mechanical testing (e.g., tensile strength, Young's modulus), complete the comprehensive evaluation spectrum. The synergy between these advanced synthesis and characterization technologies drives continuous innovation in the Spin on Carbon market, enabling the development of next-generation materials with superior and highly controllable attributes for an expanding range of high-performance applications.

Regional Highlights

- North America: A significant hub for advanced materials research and development, particularly in the aerospace, defense, and high-tech electronics sectors. The United States and Canada exhibit robust innovation ecosystems, with substantial private and public investments in Spin on Carbon technologies. Demand is driven by the need for lightweight composites, high-performance electronics, and advanced energy storage solutions.

- Europe: Characterized by strong automotive and medical device industries, alongside significant research activities in nanotechnology and advanced materials. Countries like Germany, the UK, and France are key players, focusing on sustainable manufacturing processes and applications in electric vehicles, renewable energy infrastructure, and biomedical devices. Regulatory frameworks promoting green technologies also stimulate market growth.

- Asia Pacific (APAC): The largest and fastest-growing market, primarily fueled by extensive manufacturing capabilities, rapid industrialization, and high demand from the consumer electronics and automotive sectors. China, Japan, South Korea, and India are leading the charge with significant government support for R&D, large-scale production facilities, and a booming market for advanced batteries and flexible electronics.

- Latin America: An emerging market with increasing interest in Spin on Carbon materials for infrastructure development, renewable energy projects, and selective high-tech manufacturing. Brazil and Mexico are showing potential, driven by growing industrial bases and a focus on sustainable development. However, market adoption is still in nascent stages compared to developed regions.

- Middle East and Africa (MEA): This region is slowly but steadily adopting advanced carbon materials, particularly in energy-related applications such as solar power and oil & gas, and in diversifying economies beyond traditional industries. Investments in sustainable technologies and smart city initiatives are expected to boost demand, though infrastructure and technological expertise are still developing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Spin on Carbon Market.- NanoXplore Inc.

- Applied Graphene Materials plc

- Graphenea SA

- Versarien plc

- Haydale Graphene Industries plc

- Sixth Element (Changzhou) Materials Technology Co. Ltd.

- XG Sciences Inc.

- Cabot Corporation

- Showa Denko K.K.

- Arkema S.A.

- Osaka Gas Chemical Co. Ltd.

- Toray Industries Inc.

- Teijin Limited

- Cytec Solvay Group

- Hexcel Corporation

- Nippon Graphite Fiber Corporation

- LG Chem

- Samsung Advanced Institute of Technology

- BASF SE

- Universal Display Corporation

Frequently Asked Questions

What is Spin on Carbon material?

Spin on Carbon refers to a class of advanced carbon-based materials, such as carbon nanotubes, graphene, or carbon nanofibers, produced using precise deposition or spinning techniques. These methods allow for fine control over the material's structure and properties, leading to superior electrical conductivity, mechanical strength, and lightweight characteristics for high-performance applications in electronics, energy, and aerospace.

What are the primary applications of Spin on Carbon materials?

Spin on Carbon materials are primarily utilized in high-performance electronics for flexible displays and advanced sensors, energy storage devices like batteries and supercapacitors, aerospace and automotive components for lightweight composites, and in medical devices for implants and drug delivery systems. Their unique properties enable significant enhancements in product efficiency and functionality across diverse industries.

What are the main drivers of growth for the Spin on Carbon Market?

The key drivers for the Spin on Carbon Market include the increasing global demand for lightweight and high-strength materials, the ongoing trend of miniaturization in electronic devices, and the escalating need for efficient energy storage solutions. Additionally, continuous advancements in material science research and manufacturing technologies, alongside supportive government initiatives for advanced materials, significantly contribute to market expansion.

What challenges does the Spin on Carbon Market face?

Despite its potential, the Spin on Carbon Market faces significant challenges such as high production costs, which limit widespread adoption, and difficulties in scaling up manufacturing processes from laboratory to industrial levels. A lack of universal standardization for material characterization and performance metrics also poses a hurdle, complicating product comparison and quality assurance for end-users.

Which regions are leading in the Spin on Carbon Market?

The Asia Pacific region, particularly countries like China, Japan, and South Korea, currently leads the Spin on Carbon Market due to its robust manufacturing infrastructure, strong electronics industry, and substantial government investments in advanced materials. North America and Europe are also significant players, primarily driving innovation and application development in high-value sectors such as aerospace, defense, and medical.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- SOC (Spin on Carbon) Hardmasks Market Statistics 2025 Analysis By Application (3D Microchip, MEMS & NEMS Deep Etching, Others), By Type (Hot-Temperature Spin on Carbon Hardmask, Normal Spin on Carbon Hardmask), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- SOH (Spin on Hardmasks) Market Statistics 2025 Analysis By Application (Semiconductors & ICS, LCDs, Others), By Type (Spin on Carbon Hardmasks (SOC), Spin on Metal Oxide Hardmasks (MHM), Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- SOH (Spin on Hardmasks) Market Statistics 2025 Analysis By Application (Semiconductors (excl. Memory), DRAM, NAND, LCDs, The semiconductiors hold an important share in terms of applications, and account for 50% of the market share.), By Type (Spin on Carbon Hardmasks (SOC), Spin on Metal Oxide Hardmasks (MHM)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager