Steam Autoclaves Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428111 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Steam Autoclaves Market Size

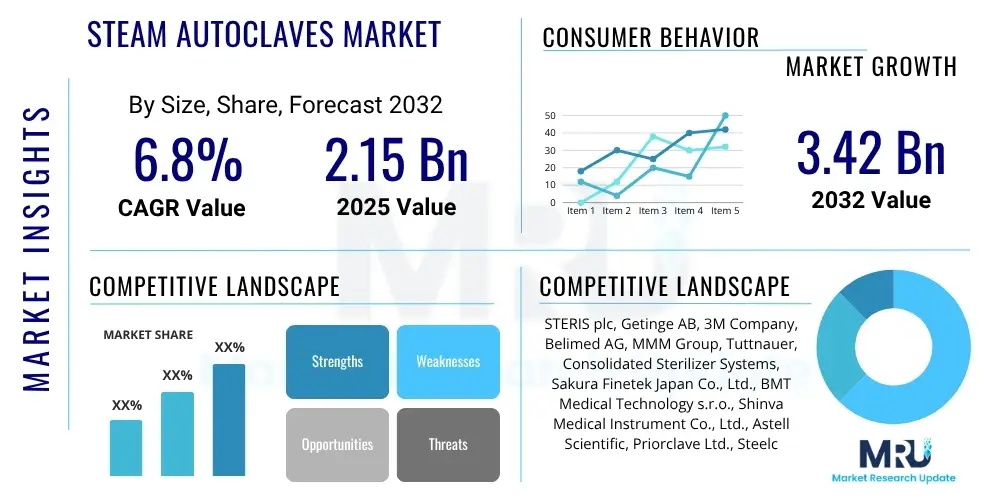

The Steam Autoclaves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 2.15 Billion in 2025 and is projected to reach USD 3.42 Billion by the end of the forecast period in 2032.

Steam Autoclaves Market introduction

The Steam Autoclaves Market encompasses the global industry involved in the manufacturing, distribution, and application of steam sterilization equipment. Steam autoclaves are essential devices utilized across various sectors for effective sterilization of instruments, media, and other materials by employing saturated steam under pressure. This process is critical for eliminating all forms of microbial life, including spores, thereby ensuring safety and preventing contamination in sensitive environments. The primary function revolves around the principles of heat and moisture, where high temperature steam penetrates materials, coagulating proteins and denaturing enzymes in microorganisms, leading to their inactivation. These devices vary significantly in size, capacity, and automation levels, from compact benchtop models used in dental clinics to large industrial autoclaves found in pharmaceutical manufacturing plants and research institutions.

Product descriptions for steam autoclaves typically highlight features such as chamber volume, operating temperature and pressure ranges, sterilization cycles (e.g., gravity, pre-vacuum, liquid), drying capabilities, and advanced control systems for cycle monitoring and validation. Modern autoclaves often incorporate sophisticated safety mechanisms, user-friendly interfaces, and connectivity options for data logging and remote diagnostics. Key applications span a wide spectrum, including healthcare (hospitals, clinics, laboratories for surgical instruments, medical waste), pharmaceuticals (sterilization of media, equipment, and solutions), biotechnology (culture media, fermenters), research and academic institutions (laboratory glassware, reagents), and even industrial settings for certain types of materials requiring high-level decontamination. The versatility and critical function of steam autoclaves underscore their indispensable role in maintaining aseptic conditions across these diverse industries.

The benefits derived from the widespread adoption of steam autoclaves are numerous and profound. They include superior sterilization efficacy, cost-effectiveness compared to some other sterilization methods, environmental friendliness as they primarily use water and heat, and compliance with stringent regulatory standards imposed by health and safety authorities worldwide. Driving factors for market growth are primarily linked to the escalating demand for sterilization in the healthcare sector due to rising surgical procedures and increasing hospital-acquired infections (HAIs), the rapid expansion of the pharmaceutical and biotechnology industries requiring aseptic processing, and growing awareness regarding public health and safety protocols. Technological advancements leading to more efficient, automated, and energy-saving autoclaves also significantly contribute to market expansion, making these devices more accessible and appealing to a broader range of users.

Steam Autoclaves Market Executive Summary

The Steam Autoclaves Market is experiencing robust growth driven by an interplay of evolving business trends, significant regional developments, and dynamic segment-specific shifts. From a business trends perspective, there is a clear move towards automation and integration, with manufacturers developing smart autoclaves that offer enhanced connectivity, remote monitoring, and automated cycle validation, reducing human error and improving operational efficiency. Furthermore, sustainability is becoming a key focus, leading to innovations in energy-efficient models and autoclaves that minimize water consumption. The market is also witnessing a surge in demand for customizable solutions, allowing end-users to tailor autoclave features and capacities to their specific operational requirements. Strategic partnerships and mergers among key players are common, aimed at expanding product portfolios, enhancing distribution networks, and gaining a competitive edge in specialized niches, particularly within the advanced healthcare and life sciences sectors. The increasing adoption of rental and leasing models for autoclaves also represents an emerging business trend, especially for smaller clinics and research labs.

Regional trends indicate that North America and Europe continue to hold significant market shares due to well-established healthcare infrastructures, stringent regulatory frameworks promoting sterilization, and a high concentration of pharmaceutical and biotechnology companies. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate during the forecast period. This growth is attributable to burgeoning economies, increasing healthcare expenditure, rapid expansion of medical tourism, and a growing number of research and development activities in countries like China, India, and Japan. Latin America and the Middle East & Africa (MEA) are also emerging as promising markets, driven by improving healthcare access, increasing investments in medical facilities, and rising awareness about infection control. Local manufacturing capabilities are also developing in these regions, catering to specific regional needs and contributing to market diversification.

Segmentation trends highlight the dominance of the healthcare segment, including hospitals, clinics, and diagnostic centers, which accounts for the largest share of autoclave usage due to the critical need for sterilizing surgical instruments and medical devices. The pharmaceutical and biotechnology sectors are also significant contributors, showing consistent growth fueled by increasing drug discovery, vaccine production, and sterile manufacturing requirements. In terms of product type, vertical and horizontal autoclaves continue to be popular, while benchtop autoclaves see increasing demand from smaller clinics and laboratories for space efficiency and convenience. Advancements in automated and large-capacity autoclaves are catering to industrial-scale sterilization needs, reflecting a trend towards specialized solutions for diverse end-user applications. The market is also seeing a shift towards autoclaves with advanced validation and data logging capabilities to meet evolving regulatory compliance standards, pushing innovation in control systems and software integration.

AI Impact Analysis on Steam Autoclaves Market

The integration of Artificial Intelligence (AI) into the Steam Autoclaves Market is a topic of growing interest, sparking numerous user questions centered around efficiency, predictive maintenance, and enhanced sterilization processes. Common inquiries revolve around how AI can optimize sterilization cycles to reduce energy and water consumption, leading to cost savings and environmental benefits. Users are also keenly interested in AI's role in predictive maintenance, asking if AI algorithms can anticipate equipment failures, schedule maintenance proactively, and minimize downtime, thereby improving operational reliability. Another significant area of concern and expectation is AI's ability to enhance process validation and compliance, with questions focusing on whether AI can automate data analysis, detect anomalies in sterilization cycles, and ensure adherence to stringent regulatory standards more effectively than traditional methods. Furthermore, there's curiosity about AI's potential to personalize sterilization protocols based on specific load types and material sensitivities, moving beyond standardized cycles to more adaptive and intelligent sterilization. The overarching theme is the pursuit of smarter, more autonomous, and highly reliable sterilization solutions.

From the perspective of AI's direct influence, stakeholders anticipate a transformation in how autoclaves are managed and operated. AI-powered systems could significantly enhance the precision of sterilization, optimizing parameters like temperature, pressure, and exposure time based on real-time data analysis of the load's characteristics. This could lead to more effective microbial inactivation while simultaneously preserving the integrity of sensitive materials, an ongoing challenge in medical and pharmaceutical settings. The ability of AI to learn from vast datasets of sterilization cycles and outcomes would enable continuous improvement in performance, adjusting algorithms to prevent under-sterilization or over-processing, which are critical for patient safety and equipment longevity. Such intelligence would move autoclaves beyond mere machines executing fixed programs to adaptive systems capable of autonomous decision-making within defined safety parameters, significantly elevating the standard of sterilization practices.

The market expects AI to introduce a new paradigm of efficiency and reliability, especially concerning remote diagnostics and operational oversight. AI algorithms could monitor multiple autoclaves across different locations, identify potential issues before they escalate into significant problems, and even suggest corrective actions, reducing the need for on-site expert intervention. This could be particularly beneficial for large healthcare networks or multinational pharmaceutical companies with numerous sterilization units. Moreover, AI could streamline regulatory reporting by automatically collecting, analyzing, and formatting compliance data, easing the burden of manual documentation and ensuring audit readiness. The future of steam autoclaves, therefore, envisions devices that are not only robust in their physical sterilization capabilities but also intelligent in their operational management, maintenance, and compliance, making them indispensable assets in critical hygiene and manufacturing environments.

- AI-driven optimization of sterilization cycles for energy and water efficiency.

- Predictive maintenance capabilities to minimize downtime and extend equipment lifespan.

- Automated data analysis and anomaly detection for enhanced process validation and regulatory compliance.

- Personalized sterilization protocols based on load characteristics and material types.

- Enhanced remote monitoring and diagnostics, reducing the need for on-site technical support.

- Improved safety mechanisms through real-time risk assessment and adaptive controls.

- Streamlined data logging and reporting for simplified audits and quality assurance.

DRO & Impact Forces Of Steam Autoclaves Market

The Steam Autoclaves Market is significantly shaped by a confluence of drivers, restraints, opportunities, and pervasive impact forces that dictate its growth trajectory and competitive landscape. Key drivers include the ever-increasing global emphasis on infection control and patient safety, particularly within the healthcare sector where hospital-acquired infections (HAIs) pose a severe threat. This necessitates stringent sterilization protocols and the widespread adoption of effective equipment like steam autoclaves. Furthermore, the expansion of the pharmaceutical and biotechnology industries, fueled by continuous R&D activities, drug discovery, and vaccine production, demands sterile manufacturing environments, thereby boosting the demand for autoclaves. Rising surgical volumes, an aging global population requiring more medical interventions, and growing investments in healthcare infrastructure in developing economies also serve as significant market accelerators. Technological advancements, leading to more automated, energy-efficient, and user-friendly autoclaves, also act as a strong driver by enhancing product appeal and operational efficiency.

However, the market also faces notable restraints. The high initial capital investment required for purchasing advanced steam autoclaves can be a deterrent, especially for smaller clinics, laboratories, or emerging market players. Operational costs, including energy consumption, water usage, and maintenance, can also contribute to the overall economic burden, impacting adoption rates. The availability of alternative sterilization methods, such as ethylene oxide, hydrogen peroxide gas plasma, and dry heat sterilization, presents a competitive challenge, particularly for heat-sensitive materials that cannot withstand high temperatures. Stringent regulatory approval processes and compliance requirements for medical devices and sterilization equipment can also lead to delays in product launch and increased development costs for manufacturers. Moreover, the need for skilled personnel to operate and maintain sophisticated autoclaves can be a limiting factor in some regions, posing training and workforce development challenges.

Opportunities for growth in the market are abundant and diverse. The increasing demand for sterile packaging and medical device reprocessing services offers a fertile ground for autoclave manufacturers. The advent of personalized medicine and advanced therapies necessitates highly controlled and sterile environments, opening new avenues for specialized autoclave designs. Furthermore, the growing focus on environmental sustainability is creating opportunities for the development and adoption of 'green' autoclaves that minimize resource consumption and waste generation. Emerging markets in Asia Pacific, Latin America, and the Middle East & Africa present significant untapped potential due to rapidly expanding healthcare sectors and increasing industrialization. Strategic collaborations between autoclave manufacturers and healthcare providers or research institutions to develop tailored solutions also represent a valuable opportunity for innovation and market penetration. The continuous evolution of regulatory standards, while a restraint in some aspects, also presents an opportunity for manufacturers to innovate and differentiate their products through superior compliance and safety features. These dynamic forces collectively dictate the strategic choices and investment priorities within the Steam Autoclaves Market, steering its evolution towards more efficient, compliant, and technologically advanced sterilization solutions.

Segmentation Analysis

The Steam Autoclaves Market is segmented to provide a granular understanding of its diverse components, offering insights into varying product types, end-user applications, and capacity considerations. This segmentation allows for a detailed analysis of market dynamics, identifying specific growth areas, competitive landscapes, and consumer preferences within each defined category. Understanding these segments is crucial for manufacturers to tailor their product development strategies, for distributors to optimize their supply chains, and for investors to identify lucrative opportunities. The market is primarily bifurcated by product type, which distinguishes between various designs and functionalities of autoclaves, and by end-user, identifying the primary industries and institutions that utilize these sterilization devices. Further segmentation often includes capacity, differentiating between small, medium, and large-volume units, and chamber type, such as horizontal or vertical configurations, each suited for different operational needs and spatial constraints.

The product type segmentation typically includes categories such as horizontal autoclaves, which are widely used for bulk sterilization in hospitals and pharmaceutical industries due to their larger chamber capacities and ease of loading, and vertical autoclaves, often preferred in laboratories and research settings for their space-saving design and efficiency in handling smaller loads. Benchtop autoclaves, characterized by their compact size, are increasingly popular in dental clinics, veterinary practices, and small laboratories where space is at a premium and lower volumes of instruments require rapid sterilization. Advanced autoclaves may also include features like automatic door opening, integrated drying systems, and sophisticated programmable logic controllers (PLCs) for precise cycle control and data recording. Each product type caters to distinct market demands, influenced by factors such as volume of materials to be sterilized, available space, specific regulatory requirements, and budget constraints of the end-user.

End-user segmentation is equally critical, highlighting the primary sectors driving demand. Hospitals and clinics constitute the largest end-user segment, driven by the constant need to sterilize surgical instruments, medical devices, and laboratory equipment to prevent infections. The pharmaceutical and biotechnology industries form another significant segment, requiring autoclaves for sterilizing media, glassware, and process equipment in drug manufacturing, research, and quality control. Academic and research institutions extensively use autoclaves for laboratory equipment, culture media, and waste sterilization. Other industrial applications, though smaller, include certain food processing applications, material science laboratories, and dental clinics, each with unique sterilization demands. The growth within these end-user segments is often correlated with healthcare expenditure, R&D investments, and regulatory emphasis on hygiene and safety standards, making them key indicators for market forecasting and strategic planning.

- By Product Type:

- Horizontal Autoclaves

- Vertical Autoclaves

- Benchtop Autoclaves

- High-Pressure Autoclaves

- Pass-Through Autoclaves

- By End User:

- Hospitals and Clinics

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Dental Clinics

- Other Industrial Applications

- By Capacity:

- Small Capacity (Below 100 Liters)

- Medium Capacity (100-300 Liters)

- Large Capacity (Above 300 Liters)

- By Technology:

- Pre-Vacuum/Pulsating Autoclaves

- Gravity Displacement Autoclaves

- Flash Autoclaves

Value Chain Analysis For Steam Autoclaves Market

The value chain for the Steam Autoclaves Market outlines the sequential activities involved in bringing the product from raw materials to the end-user, highlighting crucial stages from upstream supply to downstream distribution and after-sales support. Upstream analysis focuses on the procurement of raw materials and components necessary for autoclave manufacturing. This includes high-grade stainless steel for chambers and casings, heating elements, pressure sensors, control units (PLCs, microcontrollers), pumps, valves, gaskets, and insulation materials. Suppliers of these specialized components play a critical role, as the quality and availability of these inputs directly impact the reliability, durability, and cost-effectiveness of the final autoclave product. Manufacturers often engage in long-term relationships with trusted suppliers to ensure consistent quality and manage supply chain risks, with an increasing emphasis on sustainable sourcing and ethical labor practices.

Midstream activities involve the design, manufacturing, assembly, and testing of steam autoclaves. This stage incorporates research and development efforts to innovate new features, improve energy efficiency, enhance safety mechanisms, and comply with evolving regulatory standards such as FDA, CE, and ISO certifications. Manufacturing processes include precision metal fabrication, welding, assembly of electrical and mechanical components, and rigorous quality control checks to ensure performance, safety, and longevity. This stage often requires significant capital investment in advanced machinery, skilled labor, and specialized engineering expertise. After manufacturing, products undergo thorough testing, including pressure testing, cycle validation, and calibration, to guarantee they meet specified performance parameters and international sterilization guidelines before being released for distribution.

Downstream analysis encompasses the distribution, sales, installation, and after-sales services. Distribution channels for steam autoclaves are typically multifaceted, involving both direct and indirect approaches. Direct channels include manufacturers selling directly to large hospitals, pharmaceutical companies, or government institutions, often through a dedicated sales force. This allows for closer customer relationships and customized solutions. Indirect channels involve a network of authorized distributors, dealers, and resellers who possess local market knowledge, provide installation services, and offer regional support. These intermediaries are crucial for reaching smaller clinics, laboratories, and academic institutions, as well as for extending market reach into diverse geographical areas. Post-sale services, including installation, commissioning, training, maintenance contracts, repairs, and spare parts supply, are integral to customer satisfaction and product longevity, significantly contributing to the overall value proposition and often representing a recurring revenue stream for manufacturers and distributors alike. The efficiency of this downstream segment directly impacts customer experience and market penetration.

Steam Autoclaves Market Potential Customers

The potential customers for the Steam Autoclaves Market are broadly defined by any entity requiring robust and reliable sterilization of instruments, materials, or waste to maintain aseptic conditions and comply with health and safety regulations. These end-users or buyers span a wide array of industries, each with specific requirements for autoclave capacity, cycle types, and validation capabilities. Hospitals represent a foundational customer segment, ranging from large university hospitals with multiple operating theaters and extensive laboratory facilities to smaller community hospitals. Their demand is driven by the continuous need to sterilize surgical instruments, medical devices, reusable patient care equipment, and pathological waste, making them high-volume users of both large-capacity horizontal and pass-through autoclaves.

Beyond traditional hospital settings, clinics of various specialties also form a significant customer base. This includes dental clinics that must sterilize handpieces and instruments, veterinary clinics maintaining hygiene for animal care, ophthalmology clinics, and specialized outpatient surgical centers. These smaller facilities often opt for compact benchtop or vertical autoclaves that efficiently handle moderate volumes of instruments without requiring extensive space. The growing trend of outpatient procedures and specialized medical practices directly contributes to the increasing demand from this segment, as each new facility requires sterilization equipment to meet regulatory and patient safety standards.

Furthermore, the pharmaceutical and biotechnology industries are critical buyers, utilizing autoclaves for a myriad of applications from research and development to large-scale production. This includes sterilizing culture media for microbial growth, fermentation tanks, glassware, process equipment, and final product containers to ensure sterility in drug manufacturing and vaccine production. Academic and research institutions, encompassing universities, public health laboratories, and private research organizations, also constitute a substantial customer segment, relying on autoclaves for sterilizing laboratory tools, reagents, biological waste, and maintaining sterile environments for experiments. Other potential customers include certain food processing plants for sterilizing packaging or specific ingredients, cosmetic manufacturers, and environmental testing laboratories, all of whom have specific needs for high-temperature steam sterilization to ensure product safety, quality, and regulatory compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.15 Billion |

| Market Forecast in 2032 | USD 3.42 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | STERIS plc, Getinge AB, 3M Company, Belimed AG, MMM Group, Tuttnauer, Consolidated Sterilizer Systems, Sakura Finetek Japan Co., Ltd., BMT Medical Technology s.r.o., Shinva Medical Instrument Co., Ltd., Astell Scientific, Priorclave Ltd., Steelco S.p.A., Fazzini S.r.l., Matachana, S.A., Miele & Cie. KG, Melag Medizintechnik, Prestige Medical, SciCan Ltd., Labtron Equipment Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Steam Autoclaves Market Key Technology Landscape

The technology landscape of the Steam Autoclaves Market is characterized by continuous innovation aimed at enhancing efficiency, safety, user-friendliness, and compliance with increasingly stringent regulatory standards. One prominent technological trend is the advancement in control systems. Modern autoclaves are equipped with sophisticated Programmable Logic Controllers (PLCs) and microprocessors that offer precise control over sterilization cycles, including temperature, pressure, and exposure time. These systems allow for multiple customizable programs, automated cycle validation, and real-time monitoring of critical parameters, often displayed on intuitive touch-screen interfaces. This shift from manual to automated control not only reduces human error but also ensures consistent and repeatable sterilization outcomes, which is vital for quality assurance in medical and pharmaceutical settings.

Another significant area of technological development lies in improving energy and water efficiency. Manufacturers are integrating features such as advanced insulation, optimized heating elements, and efficient vacuum pumps to reduce power consumption. Water recirculation systems and steam generators that minimize water usage are also becoming standard, addressing environmental concerns and lowering operational costs for end-users. Furthermore, the incorporation of advanced drying systems, including vacuum drying and heated jackets, ensures that sterilized items are thoroughly dried, preventing contamination post-sterilization and preparing them immediately for use or storage. These innovations are crucial for maintaining the integrity of instruments and media, particularly in high-throughput environments where rapid turnaround times are essential.

Connectivity and data management represent another vital technological advancement. Many contemporary autoclaves now offer network connectivity, allowing for remote monitoring, diagnostic checks, and software updates. Data logging capabilities are highly sophisticated, automatically recording all cycle parameters, user information, and error messages, which is indispensable for audit trails and regulatory compliance. This data can be easily exported, stored, and integrated with hospital or laboratory information systems, streamlining documentation and enhancing traceability. Furthermore, the development of ergonomic designs, quieter operation, and enhanced safety features, such as automatic door locking mechanisms and intelligent error detection, contribute to an improved user experience and safer working environments. These technological strides collectively position steam autoclaves as highly advanced and indispensable tools in modern sterilization practices, continually evolving to meet complex and dynamic industrial demands.

Regional Highlights

The global Steam Autoclaves Market exhibits distinct regional dynamics, influenced by varying healthcare infrastructures, regulatory landscapes, economic development, and technological adoption rates across different geographies. North America, comprising the United States and Canada, represents a mature market characterized by advanced healthcare systems, high healthcare expenditure, and stringent regulatory frameworks from bodies like the FDA. The region benefits from a robust presence of leading pharmaceutical and biotechnology companies, extensive R&D activities, and a high volume of surgical procedures, all contributing to a consistent demand for high-quality sterilization equipment. Early adoption of advanced technologies, coupled with a strong focus on patient safety and infection control, further solidifies its dominant position. Innovation in smart and automated autoclaves finds a ready market here, driven by the need for operational efficiency and labor cost reduction. The prevalence of chronic diseases and an aging population also continue to fuel the demand for sterile medical equipment.

Europe stands as another significant market for steam autoclaves, with countries such as Germany, the UK, France, and Italy leading the way. The European market is propelled by well-established medical device manufacturing sectors, advanced research capabilities, and comprehensive healthcare systems. Regulatory bodies like the European Medicines Agency (EMA) and national health authorities enforce strict sterilization standards, ensuring a steady demand for compliant and certified autoclaves. Investments in upgrading hospital infrastructure and the expanding biotechnology sector contribute significantly to market growth. There is also a strong emphasis on energy efficiency and sustainable practices, driving the adoption of eco-friendly autoclave models. Eastern European countries are also showing increasing potential due as they modernize their healthcare facilities and align with Western European standards. The robust pharmaceutical industry in countries like Switzerland and Ireland also creates a high demand for advanced sterilization solutions.

The Asia Pacific (APAC) region is projected to be the fastest-growing market for steam autoclaves during the forecast period. This growth is predominantly driven by rapidly developing economies such as China, India, and Japan, which are experiencing substantial investments in healthcare infrastructure, a booming pharmaceutical industry, and increasing medical tourism. The rising prevalence of infectious diseases, coupled with growing awareness about hygiene and infection control, is further boosting market demand. Governments in these countries are increasing healthcare expenditure and implementing policies to improve public health, which in turn stimulates the demand for sterilization equipment. Latin America and the Middle East & Africa (MEA) are emerging markets, characterized by improving economic conditions, growing investments in healthcare facilities, and increasing awareness of disease prevention. Brazil, Mexico, Saudi Arabia, and UAE are notable countries in these regions where healthcare modernization and expansion are creating new opportunities for autoclave manufacturers, albeit with challenges related to market access and affordability. These regions are increasingly adopting global sterilization standards, which necessitates investment in modern steam autoclaves.

- North America (U.S., Canada): Dominant market due to advanced healthcare, stringent regulations, high R&D investment.

- Europe (Germany, UK, France): Strong market fueled by well-established healthcare, medical device manufacturing, and focus on sustainability.

- Asia Pacific (China, India, Japan): Fastest-growing market due to developing economies, increasing healthcare expenditure, and expanding pharmaceutical sector.

- Latin America (Brazil, Mexico): Emerging market with improving healthcare access and infrastructure investments.

- Middle East and Africa (Saudi Arabia, UAE, South Africa): Growing market driven by medical tourism and increasing healthcare development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Steam Autoclaves Market.- STERIS plc

- Getinge AB

- 3M Company

- Belimed AG

- MMM Group

- Tuttnauer

- Consolidated Sterilizer Systems

- Sakura Finetek Japan Co., Ltd.

- BMT Medical Technology s.r.o.

- Shinva Medical Instrument Co., Ltd.

- Astell Scientific

- Priorclave Ltd.

- Steelco S.p.A.

- Fazzini S.r.l.

- Matachana, S.A.

- Miele & Cie. KG

- Melag Medizintechnik

- Prestige Medical

- SciCan Ltd.

- Labtron Equipment Ltd.

Frequently Asked Questions

Analyze common user questions about the Steam Autoclaves market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a steam autoclave and how does it work?

A steam autoclave is a sterilization device that uses saturated steam under high pressure and temperature to kill microorganisms, including bacteria, viruses, fungi, and spores. It works by raising the temperature inside a sealed chamber, causing steam to penetrate materials and denature proteins in microbial cells, effectively sterilizing the contents. This process is highly effective for heat-resistant materials.

What are the primary applications of steam autoclaves?

Steam autoclaves are primarily used in hospitals, clinics, and laboratories for sterilizing surgical instruments, medical devices, laboratory glassware, and culture media. They are also essential in pharmaceutical and biotechnology industries for sterile manufacturing and quality control, as well as in academic institutions for research and waste disposal.

What are the key factors driving the growth of the Steam Autoclaves Market?

Market growth is driven by increasing global focus on infection control and patient safety, expansion of the pharmaceutical and biotechnology sectors, rising number of surgical procedures, and growing investments in healthcare infrastructure in emerging economies. Technological advancements in automation and energy efficiency also contribute significantly to market expansion.

What challenges does the Steam Autoclaves Market face?

Key challenges include the high initial capital investment required for purchasing advanced autoclaves, ongoing operational costs (energy, water), competition from alternative sterilization methods for heat-sensitive materials, and stringent regulatory approval processes that can increase development time and costs for manufacturers.

How is AI impacting the future of steam autoclaves?

AI is expected to significantly impact steam autoclaves by enabling predictive maintenance, optimizing sterilization cycles for efficiency, automating data analysis for compliance, and offering personalized sterilization protocols. This leads to smarter, more reliable, and cost-effective sterilization processes, enhancing safety and operational consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager