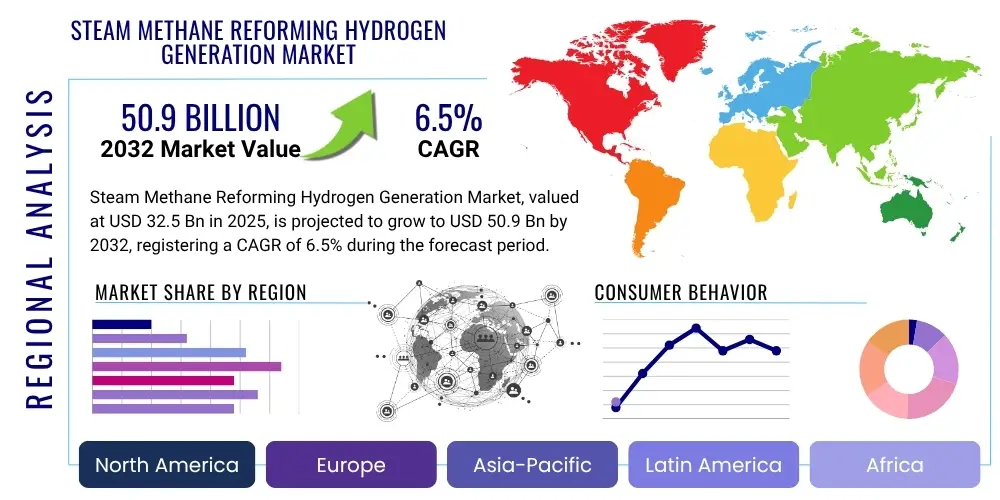

Steam Methane Reforming Hydrogen Generation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430265 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Steam Methane Reforming Hydrogen Generation Market Size

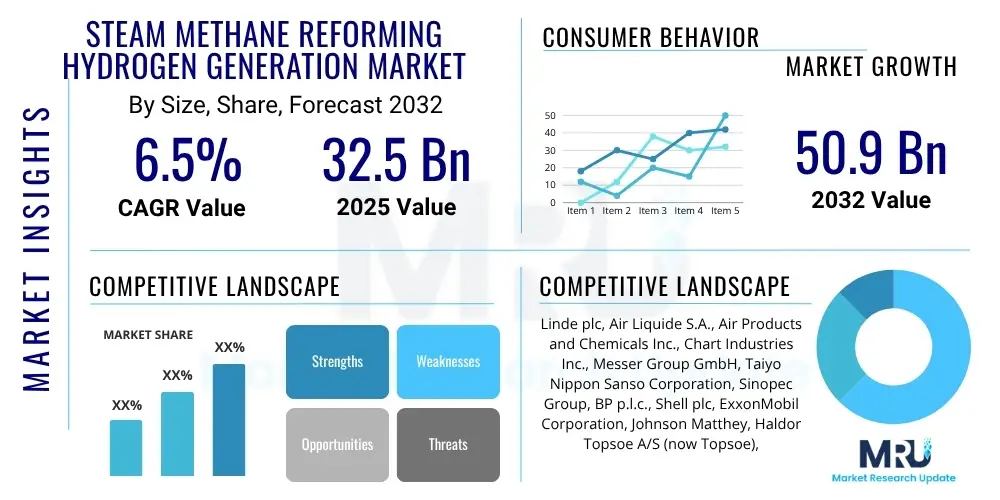

The Steam Methane Reforming Hydrogen Generation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at $32.5 Billion in 2025 and is projected to reach $50.9 Billion by the end of the forecast period in 2032.

Steam Methane Reforming Hydrogen Generation Market introduction

The Steam Methane Reforming (SMR) Hydrogen Generation Market encompasses the industrial production of hydrogen through the reaction of natural gas (methane) with steam. This mature and widely adopted technology serves as the primary method for large-scale hydrogen production globally, catering to diverse industrial requirements. The SMR process involves reacting methane and steam at high temperatures and pressures over a catalyst, typically producing hydrogen and carbon monoxide, followed by a water gas shift reaction to convert carbon monoxide into additional hydrogen and carbon dioxide. This method offers a cost-effective and energy-efficient solution for generating high purity hydrogen on demand, making it an indispensable component of numerous industrial value chains.

Hydrogen produced via SMR finds extensive applications across a multitude of sectors, driven by its versatility and essential role in chemical processes and energy transitions. Key applications include feedstock for ammonia production, a critical component in fertilizer manufacturing, and methanol synthesis, which is vital for plastics and various chemical intermediates. Furthermore, hydrogen is indispensable in petroleum refining for hydrotreating and hydrocracking processes, enhancing fuel quality and reducing sulfur content. Beyond traditional industrial uses, the increasing focus on decarbonization and the emergence of the hydrogen economy are expanding its use in fuel cells for transportation and stationary power generation, as well as a potential clean energy carrier. The product description emphasizes its reliability, scalability, and established infrastructure, which continue to underpin its market dominance.

The market's sustained growth is largely propelled by the escalating global demand for hydrogen across its major applications, alongside governmental and industrial initiatives promoting hydrogen as a cleaner energy vector. The benefits of SMR hydrogen generation include its relatively low production cost compared to other methods, especially when integrated with existing natural gas infrastructure, and the ability to produce hydrogen at a scale necessary for industrial consumption. While concerns about associated carbon emissions persist, advancements in carbon capture, utilization, and storage (CCUS) technologies are presenting pathways for "blue hydrogen" production, positioning SMR as a transitional technology towards a low-carbon hydrogen future. These driving factors, coupled with continuous process optimization and catalyst improvements, solidify SMR's critical role in the evolving energy landscape.

Steam Methane Reforming Hydrogen Generation Market Executive Summary

The Steam Methane Reforming Hydrogen Generation Market is experiencing dynamic shifts, characterized by evolving business trends focused on sustainability and efficiency. Major companies are investing in carbon capture and storage (CCS) technologies to mitigate the environmental impact of SMR, thereby producing "blue hydrogen" that aligns with decarbonization goals. There is also a growing trend towards modular and decentralized SMR units, enabling on-site hydrogen production closer to demand centers and reducing transportation costs. Furthermore, digital transformation, including the adoption of advanced process control and predictive maintenance, is becoming central to optimizing SMR plant operations, enhancing reliability, and improving overall cost-effectiveness. The market is witnessing strategic partnerships aimed at developing integrated hydrogen hubs that combine production, storage, and distribution, reflecting a collaborative approach to accelerating the hydrogen economy.

Regional trends reveal varied growth trajectories and strategic priorities. The Asia Pacific region continues to be a dominant force, driven by robust industrial growth in countries like China and India, which fuels high demand for hydrogen in refining, ammonia, and methanol production. North America benefits from abundant and cost-effective natural gas resources, alongside significant government incentives for CCUS projects, positioning it as a key region for blue hydrogen development. Europe, with its ambitious decarbonization targets and supportive regulatory frameworks, is investing heavily in green hydrogen, but also recognizes blue hydrogen from SMR with CCS as an important transitional solution. The Middle East and Africa are emerging as significant players, leveraging their vast natural gas reserves and strategic geographic locations to become potential exporters of low-carbon hydrogen. These regional dynamics underscore a global commitment to hydrogen as a future energy carrier, albeit with diverse approaches to production methods.

Segment trends within the SMR hydrogen generation market highlight the sustained importance of its traditional applications while also indicating growth in emerging areas. The refining and chemical sectors remain the largest consumers, accounting for the bulk of hydrogen demand. However, the energy sector, particularly with the advent of fuel cell electric vehicles (FCEVs) and hydrogen-powered industrial processes, is poised for substantial growth. There is an increasing focus on larger capacity SMR units to meet industrial scale demands, coupled with a nuanced consideration for smaller, decentralized systems that serve niche markets or enable on-site generation for specific industrial parks. The push for cleaner production methods is driving investment in SMR with integrated CCUS solutions, creating a new "blue hydrogen" segment that is critical for industries seeking to reduce their carbon footprint without immediately transitioning to more expensive green hydrogen alternatives. This multifaceted growth across segments reflects both continuity and innovation in the market.

AI Impact Analysis on Steam Methane Reforming Hydrogen Generation Market

Users frequently inquire about the transformative potential of Artificial Intelligence (AI) in optimizing the Steam Methane Reforming (SMR) hydrogen generation process. Common questions revolve around how AI can enhance efficiency, reduce operational costs, and mitigate the environmental impact of SMR plants. There is significant interest in AI's role in predictive maintenance to minimize downtime, its application in optimizing reactor performance and catalyst life, and its ability to improve energy consumption and CO2 capture rates. Users also express expectations regarding AI's contribution to process automation, real-time monitoring, and data-driven decision-making, ultimately aiming for a more reliable, economical, and environmentally sound blue hydrogen production. The core themes center on AI as a catalyst for intelligent operations and improved sustainability within a mature industrial process.

- AI enables real-time monitoring and anomaly detection for SMR plant operations.

- Predictive maintenance schedules are optimized using AI, reducing unplanned downtime and maintenance costs.

- AI algorithms enhance catalyst performance and extend catalyst lifespan through optimized operating conditions.

- Process parameters like temperature, pressure, and steam-to-carbon ratio are dynamically optimized by AI for maximum hydrogen yield and energy efficiency.

- Integration of AI with Carbon Capture, Utilization, and Storage (CCUS) systems improves CO2 capture efficiency.

- AI facilitates better process control and automation, leading to more stable and safer operations.

- Energy consumption within SMR plants is reduced through AI-driven optimization of heating and cooling cycles.

- Digital twin technology, powered by AI, allows for simulation and optimization of SMR processes before physical implementation.

- Supply chain logistics for methane feedstock and hydrogen distribution are optimized using AI, reducing overall operational costs.

- AI supports advanced analytics for identifying trends, predicting equipment failures, and improving overall plant reliability.

DRO & Impact Forces Of Steam Methane Reforming Hydrogen Generation Market

The Steam Methane Reforming Hydrogen Generation Market is influenced by a complex interplay of drivers, restraints, opportunities, and inherent impact forces. Key drivers include the ever-increasing global demand for hydrogen across diverse industrial applications, ranging from petroleum refining and chemical manufacturing to emerging clean energy sectors. The established nature, cost-effectiveness, and scalability of SMR technology make it a preferred choice for large-scale hydrogen production. Furthermore, the growing momentum behind decarbonization initiatives, particularly the concept of "blue hydrogen" where SMR is coupled with Carbon Capture, Utilization, and Storage (CCUS), is providing a significant impetus for continued investment and technological refinement in this sector. The abundance of natural gas feedstock in several regions also supports the continued viability of SMR as a primary hydrogen source, ensuring a stable and relatively affordable supply.

Despite its advantages, the market faces notable restraints. The primary concern revolves around the substantial carbon dioxide emissions associated with conventional SMR, which runs counter to global efforts to combat climate change. This environmental drawback positions SMR in competition with "green hydrogen" produced from renewable energy via electrolysis, which offers a truly zero-emission pathway. High capital investment requirements for new SMR plants, especially those integrating advanced CCUS technologies, can also pose a barrier to entry or expansion for some players. Additionally, the fluctuating prices of natural gas, a primary feedstock, can introduce volatility into production costs, affecting overall market stability and profitability. Regulatory uncertainties and evolving policy landscapes surrounding carbon pricing and hydrogen production incentives also present challenges for long-term planning and investment decisions within the SMR market.

Significant opportunities exist for the SMR hydrogen generation market, particularly through the widespread adoption of Carbon Capture, Utilization, and Storage (CCUS) technologies. This integration allows SMR to produce "blue hydrogen," which can serve as a crucial bridge to a fully decarbonized hydrogen economy, especially for hard-to-abate industrial sectors. There is also an opportunity for process optimization through digital technologies like AI, machine learning, and advanced sensor networks, leading to enhanced efficiency, reduced operational costs, and improved reliability of SMR plants. The development of modular and smaller-scale SMR units opens avenues for decentralized hydrogen production, reducing distribution costs and enabling on-site generation for various end-users. Impact forces such as stringent environmental regulations, technological advancements in catalysis and separation, and the increasing global emphasis on energy security and sustainability will continue to shape the market landscape, pushing for cleaner and more efficient SMR solutions while navigating competition from other hydrogen production methods.

Segmentation Analysis

The Steam Methane Reforming Hydrogen Generation Market is meticulously segmented across various dimensions to provide a granular understanding of its structure and dynamics. These segmentations typically include analyses by application, end-user industry, production capacity, and technology type, each offering insights into specific market drivers and consumer behaviors. Understanding these segments is crucial for stakeholders to identify key growth areas, tailor their strategies, and allocate resources effectively within the evolving hydrogen economy. The market's diverse applications and end-user base underscore the widespread utility of SMR-generated hydrogen, reflecting its foundational role in numerous industrial and emerging energy processes.

- By Application

- Refining

- Ammonia Production

- Methanol Production

- Chemical Processing

- Metal Production

- Electronics

- Fuel Cells & Energy Storage

- Others

- By End-User Industry

- Oil & Gas

- Chemical

- Power Generation

- Metallurgy

- Electronics

- Food & Beverage

- Pharmaceuticals

- By Production Capacity

- Small-Scale (Below 5,000 Nm3/hr)

- Medium-Scale (5,000-20,000 Nm3/hr)

- Large-Scale (Above 20,000 Nm3/hr)

- By Technology Type

- Conventional SMR

- SMR with Carbon Capture, Utilization, and Storage (CCUS)

- Autothermal Reforming (ATR)

- Partial Oxidation (POX)

Value Chain Analysis For Steam Methane Reforming Hydrogen Generation Market

The value chain for the Steam Methane Reforming Hydrogen Generation Market is comprehensive, beginning with the sourcing of raw materials and extending through complex production processes to the ultimate delivery and application of hydrogen. The upstream analysis primarily focuses on the procurement and supply of natural gas, which serves as the principal feedstock for SMR. This segment involves natural gas exploration, extraction, processing, and transportation via extensive pipeline networks or LNG carriers. Additionally, the upstream segment includes the manufacturing of critical components such as catalysts, refractory materials, and specialized alloys required for constructing SMR reactors and associated equipment. Reliable and cost-effective access to these upstream resources is fundamental to the economic viability and operational stability of hydrogen production facilities.

Midstream activities encompass the core SMR hydrogen generation process itself, including the design, engineering, construction, and operation of SMR plants. This involves the selection and integration of various units such as reformers, shift converters, purification units (e.g., Pressure Swing Adsorption - PSA), and potentially Carbon Capture, Utilization, and Storage (CCUS) facilities for blue hydrogen production. Downstream analysis then concentrates on the handling, storage, and distribution of the produced hydrogen to end-users. This segment includes hydrogen compression, liquefaction, and transportation via pipelines, tube trailers, or specialized tankers for liquid hydrogen. The efficiency and safety of these downstream logistics are crucial for delivering hydrogen effectively to diverse industrial and energy applications, impacting the overall cost and accessibility of the product.

The distribution channels for SMR-generated hydrogen are varied, catering to the specific needs and scale of different customers. Direct distribution typically involves large industrial gas suppliers or integrated chemical companies producing hydrogen for captive use or selling directly to major industrial consumers such as refineries, ammonia plants, and methanol producers through dedicated pipelines or bulk deliveries. Indirect channels involve distributors or smaller logistics companies that serve a broader base of smaller-to-medium sized customers, including those in the food processing, electronics, or specialty chemical sectors, often through packaged gas cylinders or smaller tube trailers. The strategic choice of distribution channel significantly impacts market reach, cost-efficiency, and customer service, influencing the competitive landscape within the Steam Methane Reforming Hydrogen Generation Market.

Steam Methane Reforming Hydrogen Generation Market Potential Customers

Potential customers and end-users of Steam Methane Reforming (SMR) hydrogen are broadly diverse, encompassing a wide array of industrial sectors that rely on hydrogen as a critical feedstock or energy carrier. The largest consumers traditionally come from heavy industries where hydrogen is indispensable for various chemical reactions and processing steps. These include the massive petroleum refining sector, where hydrogen is essential for hydrotreating and hydrocracking to remove impurities and upgrade crude oil into cleaner fuels. The ammonia production industry is another major buyer, as hydrogen is a primary component in the Haber-Bosch process for fertilizer manufacturing, serving global agricultural demands. Similarly, methanol production, a versatile chemical intermediate, heavily depends on hydrogen for its synthesis, underpinning a vast array of downstream products like plastics and adhesives.

Beyond these established industrial giants, the SMR hydrogen market also serves numerous other significant end-users. The broader chemical industry utilizes hydrogen in various synthesis processes, including the production of specialty chemicals and pharmaceuticals. In the metals sector, hydrogen is employed for annealing, reducing atmospheres, and in certain metal refining processes due to its strong reducing properties. The electronics industry uses ultra-high purity hydrogen in the manufacturing of semiconductors and other electronic components. Furthermore, with the accelerating transition towards a hydrogen economy, new potential customers are emerging in the energy sector, including operators of fuel cell electric vehicles (FCEVs), hydrogen fueling stations, and power generation facilities exploring hydrogen as a clean fuel for turbines or combined cycle plants. These diverse applications highlight the pervasive and fundamental role of SMR-produced hydrogen across the global economy.

The increasing focus on decarbonization is also creating a new category of potential customers interested in "blue hydrogen," which is SMR hydrogen coupled with Carbon Capture, Utilization, and Storage (CCUS). Industries committed to reducing their carbon footprint but unable to immediately transition to green hydrogen, such as steel production, cement manufacturing, and heavy transport, are increasingly considering blue hydrogen as a viable interim or long-term solution. These customers are driven by regulatory pressures, corporate sustainability goals, and the need for a reliable, large-scale supply of low-carbon hydrogen. The flexibility and scalability of SMR, especially when integrated with CCUS, positions it as a crucial technology to meet the hydrogen demands of these traditional and emerging industrial sectors, ensuring a broad and expanding customer base for the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $32.5 Billion |

| Market Forecast in 2032 | $50.9 Billion |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Linde plc, Air Liquide S.A., Air Products and Chemicals Inc., Chart Industries Inc., Messer Group GmbH, Taiyo Nippon Sanso Corporation, Sinopec Group, BP p.l.c., Shell plc, ExxonMobil Corporation, Johnson Matthey, Haldor Topsoe A/S (now Topsoe), Thyssenkrupp AG, Woodside Energy Group Ltd, KBR Inc., Saipem S.p.A., Technip Energies, Fluor Corporation, Mitsubishi Heavy Industries Ltd., Siemens Energy AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Steam Methane Reforming Hydrogen Generation Market Key Technology Landscape

The Steam Methane Reforming (SMR) Hydrogen Generation Market relies on a well-established yet continuously evolving technological landscape designed to maximize hydrogen yield, minimize energy consumption, and address environmental concerns. The core of this landscape is the SMR process itself, which involves reacting natural gas (methane) with steam at high temperatures (700-1,100 °C) and pressures over a nickel-based catalyst. This initial endothermic reaction produces syngas, a mixture of hydrogen, carbon monoxide, and carbon dioxide. Subsequent steps, such as the water-gas shift reaction, further convert carbon monoxide into additional hydrogen and carbon dioxide, significantly increasing overall hydrogen purity and yield. The design of reformer furnaces, catalyst selection, and heat recovery systems are critical areas of ongoing innovation, focusing on improving thermal efficiency and reducing operational costs. Advanced catalyst formulations, for instance, aim to enhance activity, selectivity, and resistance to coking, thereby extending operational cycles and reducing maintenance requirements.

Beyond the fundamental SMR reaction, the technology landscape encompasses several critical downstream processes and supplementary technologies vital for producing high-purity hydrogen suitable for various applications. Hydrogen purification is typically achieved through Pressure Swing Adsorption (PSA) units, which selectively adsorb impurities like CO2, CO, and unreacted methane, yielding hydrogen with purity levels often exceeding 99.99%. Membrane separation technologies are also being explored and adopted for pre-purification or as an alternative to PSA, offering potential advantages in energy consumption and modularity. Another significant area of technological development involves integrating Carbon Capture, Utilization, and Storage (CCUS) systems with SMR plants. This integration transforms conventional SMR into "blue hydrogen" production, where post-combustion CO2 capture using amine scrubbing or other advanced absorption technologies prevents greenhouse gas emissions from entering the atmosphere. These CCUS technologies are crucial for SMR to align with global decarbonization efforts and remain competitive in a low-carbon energy future.

Moreover, the SMR technology landscape is expanding to include variants such as Autothermal Reforming (ATR) and Partial Oxidation (POX), which offer different operational characteristics and suitabilities for specific applications or feedstocks. ATR combines aspects of SMR and POX, using both oxygen and steam to reform methane, often resulting in a more compact design and higher thermal efficiency for larger-scale operations. POX, on the other hand, reacts methane with a limited amount of oxygen, producing syngas with a lower H2/CO ratio, often preferred for chemical synthesis applications like methanol. The ongoing research and development in these alternative reforming technologies, coupled with innovations in digitalization, process intensification, and modular plant design, are continually enhancing the flexibility, efficiency, and environmental performance of the SMR hydrogen generation market. This diverse technological toolkit ensures that SMR remains a highly adaptable and economically viable method for hydrogen production, capable of meeting evolving industry demands.

Regional Highlights

- North America: This region is a significant market for SMR hydrogen generation, primarily driven by abundant and cost-effective natural gas resources, particularly from shale formations. The United States and Canada are leading in developing "blue hydrogen" projects, integrating Carbon Capture, Utilization, and Storage (CCUS) with SMR facilities due to government incentives and a strong focus on industrial decarbonization. Demand from refining, ammonia, and methanol production remains robust, with increasing investments in hydrogen infrastructure.

- Europe: European countries are actively pursuing decarbonization strategies, which includes a dual approach to hydrogen. While there is a strong emphasis on green hydrogen production from renewables, blue hydrogen from SMR with CCUS is recognized as an essential transitional solution. Policy support, such as the European Hydrogen Strategy, drives investments, particularly in countries like Germany, the Netherlands, and the UK, aiming to reduce industrial emissions and establish a hydrogen economy.

- Asia Pacific (APAC): The APAC region represents the largest and fastest-growing market for SMR hydrogen, fueled by rapid industrialization and escalating demand from chemical, refining, and manufacturing sectors, especially in China, India, and Southeast Asian nations. While conventional SMR dominates, there's a growing interest and investment in blue hydrogen projects as countries in the region set ambitious climate targets and seek to diversify their energy mix.

- Latin America: The market in Latin America is characterized by emerging opportunities, particularly in countries with significant natural gas reserves such as Argentina and Brazil. The region is exploring the potential for hydrogen production to support domestic industrial growth and potentially for export. Investments are nascent but growing, with an eye towards leveraging SMR technology, possibly with future CCUS integration, to create local hydrogen hubs.

- Middle East and Africa (MEA): MEA holds immense potential due to its vast hydrocarbon resources and strategic location. Countries like Saudi Arabia, UAE, and Qatar are actively investing in blue hydrogen projects, leveraging their natural gas abundance and significant capital. These nations aim to become global leaders in low-carbon hydrogen production and export, contributing to the global energy transition while diversifying their economies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Steam Methane Reforming Hydrogen Generation Market.- Linde plc

- Air Liquide S.A.

- Air Products and Chemicals Inc.

- Chart Industries Inc.

- Messer Group GmbH

- Taiyo Nippon Sanso Corporation

- Sinopec Group

- BP p.l.c.

- Shell plc

- ExxonMobil Corporation

- Johnson Matthey

- Haldor Topsoe A/S (now Topsoe)

- Thyssenkrupp AG

- Woodside Energy Group Ltd

- KBR Inc.

- Saipem S.p.A.

- Technip Energies

- Fluor Corporation

- Mitsubishi Heavy Industries Ltd.

- Siemens Energy AG

Frequently Asked Questions

What is Steam Methane Reforming (SMR) in hydrogen generation?

Steam Methane Reforming (SMR) is a mature industrial process that produces hydrogen by reacting natural gas (primarily methane) with steam at high temperatures and pressures over a catalyst, yielding hydrogen, carbon monoxide, and carbon dioxide. It is currently the most widely used method for large-scale hydrogen production globally.

What are the primary applications of SMR-generated hydrogen?

SMR-generated hydrogen is predominantly used as a feedstock in various industrial processes, including petroleum refining (for hydrotreating), ammonia production (for fertilizers), and methanol synthesis. It also finds applications in the chemical industry, metal processing, and, increasingly, in fuel cells for clean energy.

What is "blue hydrogen" and how is it related to SMR?

Blue hydrogen refers to hydrogen produced from fossil fuels, typically through Steam Methane Reforming (SMR), where the carbon dioxide emissions generated during the process are captured and stored (CCUS) or utilized. This significantly reduces the carbon footprint compared to conventional SMR, making it a lower-carbon hydrogen option.

How does the cost of SMR hydrogen compare to other production methods?

SMR hydrogen is generally the most cost-effective method for large-scale hydrogen production, especially when natural gas prices are low. Its established technology and infrastructure contribute to lower capital and operational costs compared to green hydrogen (electrolysis using renewable energy), although the cost gap is narrowing.

What are the environmental concerns associated with SMR and how are they addressed?

The primary environmental concern with conventional SMR is the emission of carbon dioxide, a potent greenhouse gas. This is being addressed by integrating Carbon Capture, Utilization, and Storage (CCUS) technologies into SMR plants, transforming it into "blue hydrogen" production, which significantly reduces atmospheric carbon emissions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager