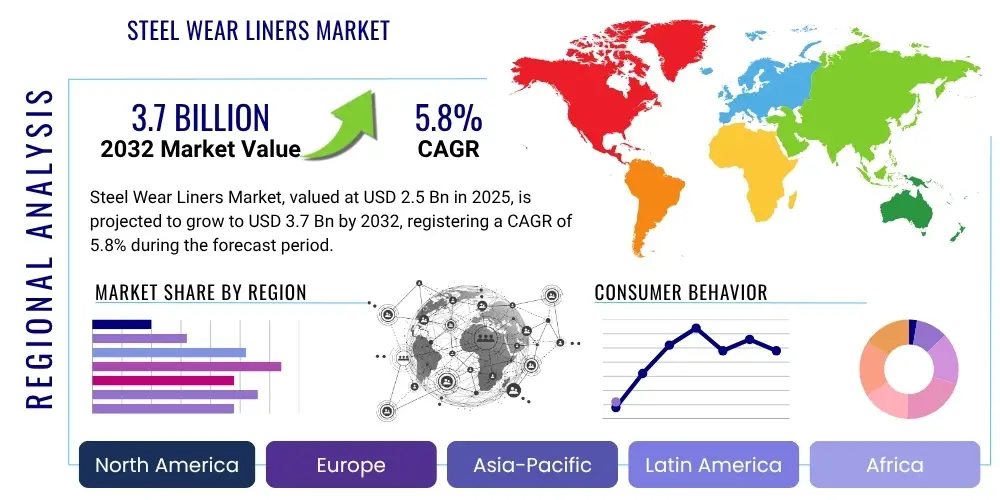

Steel Wear Liners Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430241 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Steel Wear Liners Market Size

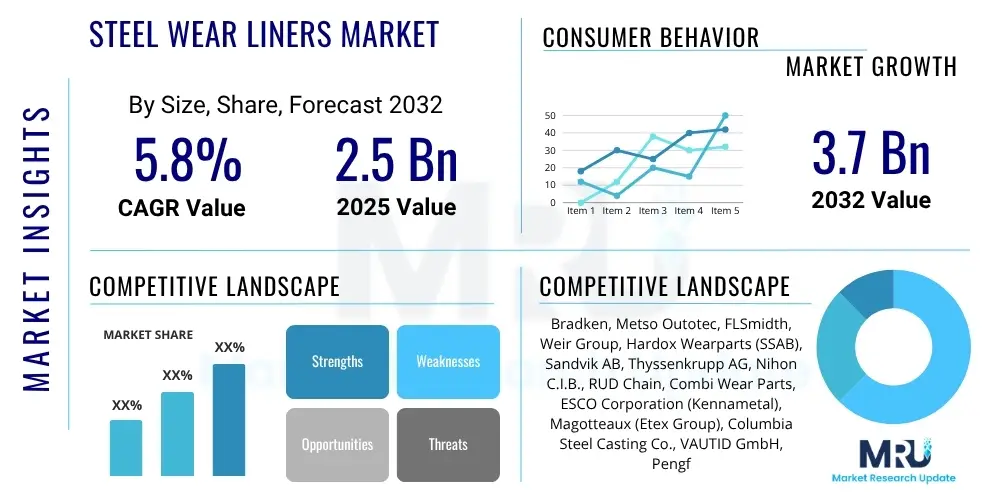

The Steel Wear Liners Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 2.5 billion in 2025 and is projected to reach USD 3.7 billion by the end of the forecast period in 2032.

Steel Wear Liners Market introduction

The Steel Wear Liners market comprises products essential for protecting heavy machinery and equipment from abrasion, impact, and corrosion in demanding industrial environments. These liners are crucial components in industries where raw materials are processed, moved, or crushed, significantly extending the operational lifespan of equipment and reducing maintenance costs. The product primarily consists of specialized steel alloys, including high-chromium cast iron, manganese steel, and various alloy steels, engineered for superior hardness, toughness, and wear resistance.

Major applications of steel wear liners span across ball mills, SAG mills, rod mills, crushers, chutes, hoppers, and excavators, primarily serving the mining and mineral processing, cement and aggregate, construction, and power generation sectors. The primary benefit of employing these liners is enhanced operational efficiency due to reduced downtime for repairs and replacements, leading to significant cost savings. Key driving factors for market growth include the increasing demand for minerals and construction materials, expanding global infrastructure development, and the continuous need for optimized operational expenditure in heavy industries.

Steel Wear Liners Market Executive Summary

The Steel Wear Liners market is experiencing robust growth, driven by escalating demand from critical end-use industries and the global push for operational efficiency and sustainability. Business trends indicate a strong focus on advanced material science, with manufacturers investing in research and development to produce liners with superior wear resistance and extended service life. Strategic partnerships and mergers among key players are common, aiming to expand product portfolios and geographical reach, while supply chain resilience remains a significant operational consideration amidst fluctuating raw material costs.

Regionally, the Asia Pacific market is poised for significant expansion, fueled by rapid industrialization, extensive mining activities, and large-scale infrastructure projects, particularly in China and India. North America and Europe demonstrate a mature market with steady demand, emphasizing technological innovation and stringent safety standards, driving the adoption of high-performance and environmentally compliant wear solutions. Latin America, the Middle East, and Africa are emerging as promising markets due to increasing investments in mining and construction sectors.

Segment-wise, high-chromium cast iron liners are expected to maintain a dominant share due to their exceptional hardness and abrasion resistance, while manganese steel liners offer a balance of toughness and work-hardening properties suitable for high-impact applications. The mining and mineral processing industry continues to be the largest end-user, with increasing global commodity demand necessitating more efficient and durable wear solutions. The market is also witnessing a trend towards customized liner solutions designed for specific equipment and operational conditions to maximize performance.

AI Impact Analysis on Steel Wear Liners Market

User questions related to the impact of AI on the Steel Wear Liners Market frequently revolve around how artificial intelligence can optimize the design, manufacturing, and maintenance of these critical components. Common inquiries concern AI's role in predictive maintenance for wear detection, enhancing material composition for improved durability, automating production processes, and optimizing inventory management for wear parts. Users are keen to understand if AI can lead to more cost-effective solutions, reduce operational downtime, and contribute to more sustainable industrial practices through extended product life and reduced waste. The overarching theme is the expectation that AI will bring about a new era of efficiency, precision, and intelligence in a traditionally materials-heavy industry.

- AI can enable predictive maintenance through sensor data analysis, forecasting liner wear and scheduling replacements optimally.

- AI-driven material design optimization can lead to the development of new, high-performance alloy compositions for enhanced wear resistance.

- Automated quality control and inspection systems utilizing computer vision can improve manufacturing consistency and defect detection.

- Supply chain management can be optimized through AI algorithms for demand forecasting, inventory management, and logistics.

- AI can facilitate customized liner designs by simulating wear patterns and performance under specific operational conditions.

- Robotics and automation, often AI-powered, can enhance the precision and efficiency of liner installation and replacement processes.

- Data analytics platforms can provide insights into equipment performance and liner lifespan, supporting operational decision-making.

DRO & Impact Forces Of Steel Wear Liners Market

The Steel Wear Liners market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaping its growth trajectory and competitive landscape. A primary driver is the increasing global demand for minerals and raw materials, necessitating robust and efficient processing equipment that relies heavily on wear-resistant components. Additionally, the continuous investment in infrastructure development projects worldwide, including roads, buildings, and energy facilities, fuels the demand for cement and aggregate, consequently boosting the need for durable wear liners in crushing and grinding machinery. The imperative for operational cost reduction and enhanced equipment lifespan across heavy industries further accelerates the adoption of high-quality steel wear liners.

However, the market faces notable restraints, particularly the volatile pricing of raw materials such as steel, iron, and various alloying elements, which can significantly impact production costs and profit margins for manufacturers. The high initial investment required for advanced wear liner materials and specialized installation can also be a barrier for some end-users, especially smaller operations. Moreover, the increasing adoption of alternative wear-resistant materials, such as ceramics and composites, in niche applications presents a competitive challenge to traditional steel liners.

Despite these restraints, substantial opportunities exist for market players to innovate and expand. The growing focus on sustainable mining practices and circular economy principles opens avenues for developing recyclable and longer-lasting wear liners. The integration of smart technologies, such as IoT sensors for predictive maintenance and AI for design optimization, offers a significant growth pathway. Furthermore, untapped potential in emerging economies with burgeoning industrial sectors and ongoing infrastructure development provides fertile ground for market expansion and new product penetration. The continuous need for improved performance in harsh operating environments ensures a persistent demand for innovative wear solutions.

Segmentation Analysis

The Steel Wear Liners market is broadly segmented based on various critical parameters, including the type of material, the specific application it serves, and the end-use industry utilizing these products. This comprehensive segmentation allows for a detailed analysis of market dynamics, identifying key growth areas and understanding the varied demands from different industrial sectors. Each segment addresses distinct operational requirements and performance criteria, reflecting the diverse challenges faced in abrasive and high-impact environments.

The material type segmentation differentiates between various steel alloys, each offering unique properties tailored to specific wear mechanisms. Application-based segmentation highlights the different machinery or points where liners are installed, demonstrating the versatility of these components. Finally, the end-use industry segmentation provides insight into the major consumers of steel wear liners, indicating market concentration and potential for specialized product development. Understanding these segments is crucial for strategic planning and product development within the market.

- By Type

- High Chromium Cast Iron Liners

- Manganese Steel Liners

- Alloy Steel Liners

- Others (e.g., Ceramic Composite Liners, Rubber Backed Steel Liners)

- By Application

- Ball Mills

- SAG Mills (Semi-Autogenous Grinding Mills)

- Rod Mills

- Crushers (Jaw, Cone, Impact)

- Chutes

- Hoppers

- Excavators and Buckets

- Conveyor Systems

- By End-Use Industry

- Mining and Mineral Processing

- Cement and Aggregate

- Construction

- Power Generation (e.g., Coal Mills)

- Pulp and Paper

- Others (e.g., Recycling, Agriculture, Foundries)

Value Chain Analysis For Steel Wear Liners Market

The value chain for the Steel Wear Liners market begins with upstream activities involving the sourcing and processing of raw materials such as iron ore, chromium, manganese, and other alloying elements, which are critical for producing the specialized steel alloys. Steel manufacturers transform these raw materials into various steel forms suitable for wear liner production, including plates, bars, and castings. This stage emphasizes material quality, metallurgical expertise, and cost efficiency in raw material procurement and primary processing, setting the foundation for the final product's performance and durability.

Midstream activities involve the manufacturing and fabrication of the wear liners themselves. This includes casting, forging, machining, heat treatment, and surface finishing processes to achieve the desired mechanical properties and precise dimensions. Companies often specialize in specific material types or manufacturing techniques, leveraging advanced production capabilities and quality control measures. Design and engineering services also play a crucial role here, customizing liners for specific equipment models and operational environments to optimize wear life and performance.

Downstream activities encompass the distribution, installation, and after-sales support for steel wear liners. Distribution channels can be direct, where manufacturers sell directly to large end-users or through their own sales networks, or indirect, involving distributors, agents, and service providers who cater to a wider range of customers. Installation services, technical support, and wear monitoring are essential components of the downstream value chain, ensuring proper application and maximizing the benefits for end-users. The efficiency of the distribution network and the quality of support services significantly impact customer satisfaction and market reach.

Steel Wear Liners Market Potential Customers

Potential customers for steel wear liners are predominantly found in heavy industries that extensively use machinery subjected to severe abrasion, impact, and material handling challenges. These end-users are constantly seeking solutions to extend equipment lifespan, reduce maintenance costs, and minimize operational downtime, making durable wear liners an indispensable investment. The procurement decisions are often driven by factors such as material performance, cost-effectiveness over the product lifecycle, and supplier reliability.

The primary buyers include large-scale mining corporations involved in extracting minerals like iron ore, copper, gold, and coal, as well as cement and aggregate producers who operate crushing, grinding, and conveying equipment. Furthermore, construction companies utilizing heavy earthmoving equipment and material processing plants, and power generation facilities relying on robust components for coal handling, represent significant customer segments. These industries require high-quality, specialized wear solutions to maintain continuous and efficient operations, making them the core demographic for steel wear liner manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.5 billion |

| Market Forecast in 2032 | USD 3.7 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bradken, Metso Outotec, FLSmidth, Weir Group, Hardox Wearparts (SSAB), Sandvik AB, Thyssenkrupp AG, Nihon C.I.B., RUD Chain, Combi Wear Parts, ESCO Corporation (Kennametal), Magotteaux (Etex Group), Columbia Steel Casting Co., VAUTID GmbH, Pengfei Group, Shanxi Masteel, Dalian Dajin Heavy Industry, Trelleborg AB, Austbreck, Moly-Cop |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Steel Wear Liners Market Key Technology Landscape

The Steel Wear Liners market is characterized by a dynamic technology landscape focused on enhancing material performance, optimizing manufacturing processes, and integrating digital solutions. Advanced metallurgical techniques are continuously employed to develop new steel alloys with superior hardness, toughness, and abrasion resistance. These include specialized heat treatment processes, alloying element optimization, and the incorporation of carbides or ceramic particles to create composite materials that offer extended service life in extremely harsh environments. The goal is to maximize the life-to-weight ratio and improve overall efficiency.

Manufacturing technologies have also evolved significantly, with precision casting, forging, and machining techniques ensuring tighter tolerances and improved fitment, which is crucial for uniform wear and structural integrity. Robotic welding and automated production lines are increasingly being adopted to enhance consistency, reduce labor costs, and improve safety. Furthermore, non-destructive testing (NDT) methods are routinely used for quality assurance, ensuring the absence of defects and verifying material properties before deployment. The pursuit of higher performance and reliability drives continuous investment in these production advancements.

Digital technologies are rapidly transforming the wear liner sector. Computational tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are extensively used for simulating wear patterns and optimizing liner designs, predicting performance under various operational loads, and reducing prototype development time. The integration of IoT sensors into equipment for real-time wear monitoring, combined with data analytics and AI for predictive maintenance, is a burgeoning technological trend. This allows for proactive replacement scheduling, minimizing unexpected downtime and maximizing asset utilization for end-users, representing a significant leap towards smart industrial operations.

Regional Highlights

- Asia Pacific (APAC): This region is the largest and fastest-growing market for steel wear liners, driven by extensive mining activities in Australia, China, and India, coupled with massive infrastructure development and a booming construction sector. Countries like China and India are also major producers and consumers of cement and aggregates, fueling demand for wear solutions in their respective industries.

- North America: A mature market characterized by technological advancements and stringent environmental regulations. Demand is robust from the mining (e.g., iron ore, copper) and construction sectors. Focus on high-performance, durable, and energy-efficient wear liners is prominent.

- Europe: This region exhibits steady demand, with a strong emphasis on product innovation, quality, and sustainability. Key industries include mining (e.g., Scandinavia), cement, and industrial minerals. Manufacturers here often lead in developing advanced material compositions and recycling initiatives.

- Latin America: This region is a significant market due to its rich mineral resources and extensive mining operations, particularly in countries like Chile (copper), Brazil (iron ore), and Peru. Investments in mining infrastructure are a primary growth driver.

- Middle East and Africa (MEA): Emerging market with considerable growth potential. Driven by increasing investments in mining projects (e.g., South Africa, Saudi Arabia) and ongoing large-scale construction and infrastructure development initiatives across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Steel Wear Liners Market.- Bradken

- Metso Outotec

- FLSmidth

- Weir Group

- Hardox Wearparts (SSAB)

- Sandvik AB

- Thyssenkrupp AG

- Nihon C.I.B.

- RUD Chain

- Combi Wear Parts

- ESCO Corporation (Kennametal)

- Magotteaux (Etex Group)

- Columbia Steel Casting Co.

- VAUTID GmbH

- Pengfei Group

- Shanxi Masteel

- Dalian Dajin Heavy Industry

- Trelleborg AB

- Austbreck

- Moly-Cop

Frequently Asked Questions

What are steel wear liners used for?

Steel wear liners are protective plates or segments made from specialized steel alloys designed to safeguard heavy machinery and equipment from abrasive wear, impact, and corrosion. They are predominantly used in industries like mining, cement, aggregate, and construction to extend the lifespan of equipment such as mills, crushers, chutes, and hoppers.

What types of steel are commonly used for wear liners?

Common types of steel used for wear liners include high chromium cast iron, known for its extreme hardness and abrasion resistance; manganese steel, valued for its work-hardening properties under impact; and various alloy steels customized for specific combinations of toughness and wear resistance. The selection depends on the application's unique operational conditions.

How does AI impact the Steel Wear Liners market?

AI impacts the Steel Wear Liners market by enabling predictive maintenance through data analysis, optimizing material design for enhanced durability, automating quality control in manufacturing, and streamlining supply chain logistics. These applications lead to improved operational efficiency, reduced downtime, and more cost-effective wear solutions for end-users.

Which industries are the primary consumers of steel wear liners?

The primary consumers of steel wear liners are industries characterized by severe abrasive and impact conditions. These include mining and mineral processing, cement and aggregate production, general construction, and power generation (particularly coal-fired plants). These sectors rely on wear liners to protect critical processing and material handling equipment.

What factors drive the growth of the Steel Wear Liners market?

The growth of the Steel Wear Liners market is driven by increasing global demand for minerals and construction materials, continuous infrastructure development projects worldwide, and the persistent industrial need for improved operational efficiency, reduced maintenance costs, and extended equipment lifespan in harsh environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager