Striking Tools Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427223 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Striking Tools Market Size

The Striking Tools Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 16.5 billion in 2025 and is projected to reach USD 22.8 billion by the end of the forecast period in 2032.

Striking Tools Market introduction

The Striking Tools Market encompasses a diverse range of hand tools primarily designed for applying impact or force to an object or surface. This category includes essential implements such as hammers, mallets, axes, chisels, punches, and various impact drivers, each crafted for specific tasks across a multitude of industries and applications. These tools are fundamental to construction, woodworking, metalworking, automotive repair, and general maintenance, serving as indispensable assets for both professional tradespeople and do-it-yourself (DIY) enthusiasts.

Products within this market are characterized by their robust construction, often utilizing high-strength materials like forged steel, hardened alloys, durable wood, and resilient composites to ensure longevity and effective force transmission. The design of striking tools prioritizes ergonomics, aiming to reduce user fatigue and enhance safety through features such as anti-vibration handles and balanced weight distribution. Major applications span from driving nails and breaking materials in construction to shaping wood, splitting timber, and performing precision tasks in specialized crafts.

The core benefits derived from these tools include their reliability, portability, and the ability to deliver precise, controlled force without reliance on external power sources. Key driving factors propelling market growth include sustained global infrastructure development, increasing residential and commercial construction activities, the expansion of manufacturing and industrial sectors, and a consistent demand from the burgeoning DIY segment. Furthermore, continuous innovations in material science and ergonomic design contribute to enhanced product performance and user satisfaction, solidifying the markets trajectory.

Striking Tools Market Executive Summary

The Striking Tools Market is experiencing steady expansion, driven by robust global construction spending, industrialization in emerging economies, and persistent demand from the DIY segment. Current business trends highlight a significant emphasis on product innovation, particularly in enhancing ergonomics, durability, and multi-functionality. Manufacturers are increasingly integrating advanced material science, such as specialized alloy steels and composite handles, to improve tool performance, reduce vibration, and extend product lifespan. E-commerce platforms are also playing a crucial role in market penetration, offering wider product accessibility and competitive pricing, thereby influencing traditional distribution channels and driving consumer purchasing habits toward online retail.

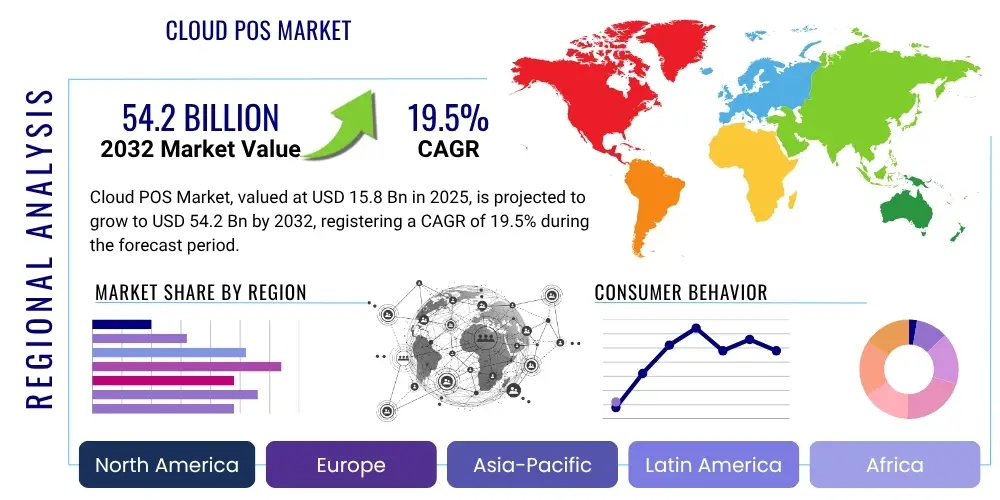

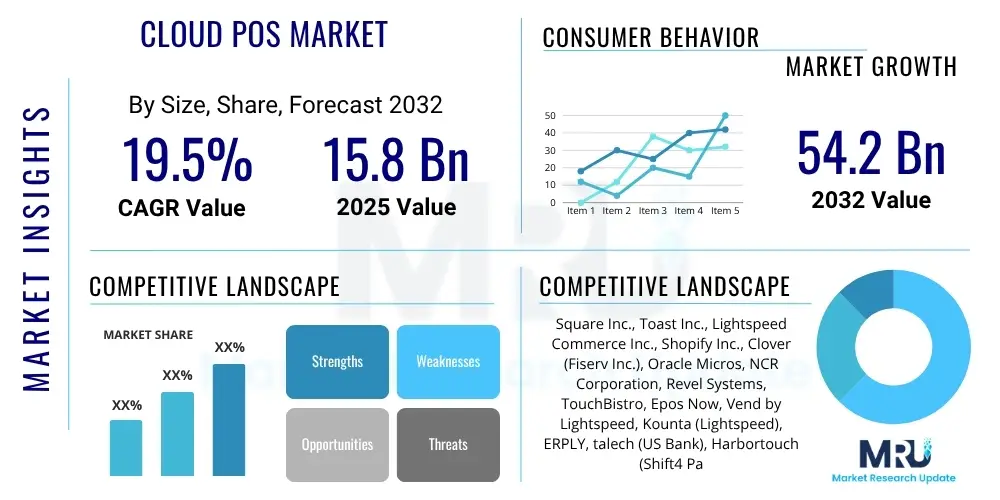

Regional trends indicate that Asia-Pacific remains the fastest-growing market, primarily fueled by rapid urbanization, substantial infrastructure projects, and a burgeoning manufacturing sector in countries like China and India. North America and Europe, while mature markets, demonstrate consistent demand, with a focus on premium, specialized, and ergonomically superior tools. These regions are also leading in the adoption of sustainable manufacturing practices and recycling initiatives within the tool industry. Latin America, the Middle East, and Africa are showing promising growth, attributed to increasing foreign investments in construction and the expansion of local industries, although market penetration remains lower compared to developed regions.

Segmentation trends reveal a sustained demand across both professional and residential applications. The professional segment, encompassing construction, automotive, and industrial uses, commands a larger market share due to the requirement for high-performance and application-specific tools. Concurrently, the DIY segment continues its upward trajectory, bolstered by rising home improvement activities and the availability of user-friendly, affordable toolkits. Furthermore, there is a growing interest in specialized tools designed for niche applications, such as fine woodworking or precision metalworking, which are driving demand for high-quality, often artisanal, striking instruments. This dual-segment growth underscores the markets resilience and adaptability to diverse consumer needs.

AI Impact Analysis on Striking Tools Market

The impact of Artificial Intelligence (AI) on the Striking Tools Market, while perhaps not immediately obvious for traditionally manual implements, is primarily envisioned through enhanced manufacturing processes, material innovation, predictive maintenance, and potentially, the development of smart tool ecosystems. User questions frequently revolve around how AI can make "dumb" tools smarter, the potential for AI to optimize design for better performance and safety, and how it might influence the lifecycle and even the usage of these tools. Key themes include concerns about whether AI integration could lead to over-complication or increased cost for simple tools, balanced against expectations for significant improvements in manufacturing efficiency and product longevity. There is also curiosity about AIs role in creating more sustainable production methods and personalized tool recommendations.

AIs influence is largely upstream and behind-the-scenes, impacting areas like generative design for tool heads and handles, where algorithms can simulate various shapes and material combinations to achieve optimal weight distribution, impact absorption, and ergonomic comfort. This allows manufacturers to develop lighter, stronger, and more user-friendly tools with reduced material waste and faster design iterations. Furthermore, AI-driven analytics can process vast datasets from material stress tests, identifying the most durable alloys and composites, thereby enhancing the overall quality and lifespan of striking tools. This predictive capability extends to quality control on the production line, where AI-powered vision systems can detect microscopic flaws that human inspection might miss, ensuring consistent product excellence.

In the future, AI could also play a role in the "Internet of Tools" concept, where tools might feature embedded sensors to monitor usage patterns, impact force, and wear and tear. AI algorithms could then analyze this data to provide insights into optimal striking techniques for specific materials, recommend timely maintenance, or even predict tool failure before it occurs. While these features are more prevalent in power tools currently, the principles could eventually trickle down to professional-grade manual striking tools, offering enhanced safety, improved efficiency, and personalized user feedback. This integration could revolutionize how striking tools are designed, manufactured, and ultimately used, pushing the boundaries of what is possible in a seemingly traditional market.

- AI-driven Generative Design: Optimizes tool head geometry and handle ergonomics for improved performance, balance, and user comfort, reducing material use and manufacturing costs.

- Predictive Maintenance for Manufacturing Equipment: AI algorithms analyze production data to predict failures in forging, casting, or machining equipment, minimizing downtime and increasing efficiency.

- Advanced Material Science: AI accelerates the discovery and development of new alloys and composites with superior strength, durability, and vibration-damping properties for tool construction.

- Automated Quality Control: AI-powered vision systems detect microscopic defects and inconsistencies in tool components during the manufacturing process, ensuring higher product quality and reliability.

- Supply Chain Optimization: AI enhances logistics, inventory management, and demand forecasting for raw materials and finished goods, improving market responsiveness and reducing waste.

- Smart Tool Integration (Future): Potential for embedded sensors to monitor usage, impact force, and wear, with AI providing performance analytics and predictive maintenance alerts to users.

- Personalized Tool Recommendation Engines: AI can analyze user preferences, project types, and historical purchases to recommend the most suitable striking tools, enhancing customer satisfaction.

- Robotics in Manufacturing: AI guides robotic systems for precision forging, assembly, and finishing of striking tools, improving consistency and reducing labor-intensive tasks.

- Environmental Impact Analysis: AI models can assess the environmental footprint of different manufacturing processes and materials, guiding decisions towards more sustainable production of tools.

DRO & Impact Forces Of Striking Tools Market

The Striking Tools Market is influenced by a complex interplay of drivers, restraints, and opportunities, all contributing to its overall impact forces. Key market drivers include the sustained global growth in the construction and infrastructure sectors, particularly in developing economies, which necessitates a consistent demand for foundational hand tools. Additionally, increasing industrialization, expansion of manufacturing facilities, and the ongoing popularity of DIY and home improvement projects globally further fuel the market. Technological advancements, though subtle for traditional tools, in material science and ergonomic design, contribute to product innovation, enhancing durability and user safety, which in turn drives consumer adoption of newer, more efficient tools. These factors collectively create a robust demand environment, stimulating production and sales across various segments.

However, the market also faces significant restraints that can impede its growth trajectory. Economic slowdowns and fluctuating raw material prices, especially for steel and specialized alloys, can directly impact manufacturing costs and product affordability, leading to price volatility. The increasing availability and preference for power tools in specific applications, where they offer higher efficiency and reduced manual effort, pose a competitive challenge to traditional striking tools. Furthermore, stringent environmental regulations regarding manufacturing processes and material sourcing can increase operational costs for manufacturers, potentially affecting market competitiveness. The presence of counterfeit products and low-quality imitations also undermines brand reputation and market value, presenting a persistent challenge for legitimate manufacturers.

Amidst these challenges, numerous opportunities exist for market expansion and innovation. The emergence of new construction technologies and specialized applications creates a niche for highly specialized striking tools designed for precision and unique material handling. Expanding into untapped or rapidly developing emerging markets offers significant growth potential, as these regions undergo extensive urbanization and infrastructure build-outs. Moreover, a growing global emphasis on sustainable and eco-friendly manufacturing practices presents an opportunity for companies to differentiate themselves by developing tools with recycled materials or through energy-efficient production. Continued investment in research and development to enhance ergonomics, incorporate smart features (even basic ones like integrated sensors for professional tools), and improve material performance will be crucial for capturing future market share and sustaining long-term growth.

Segmentation Analysis

The Striking Tools Market is extensively segmented to reflect the diverse range of products, applications, and end-user requirements that characterize this essential industry. Understanding these segments provides critical insights into market dynamics, consumer preferences, and strategic growth areas for manufacturers and distributors. Segmentation by product type, material, application, and end-user allows for a granular analysis of demand patterns and competitive landscapes. This detailed breakdown aids stakeholders in tailoring product development, marketing strategies, and distribution channels to effectively reach specific target audiences and capitalize on distinct market niches. Each segment represents a unique set of challenges and opportunities, influencing market penetration and revenue generation across various geographical regions.

- By Product Type:

- Hammers (Claw, Ball-peen, Sledge, Framing, Rubber Mallets, etc.): The largest and most diverse category, used for driving, prying, shaping, and demolition across all sectors.

- Axes and Hatchets: Primarily for chopping wood, forestry, and some demolition tasks, with variations for splitting, felling, and carving.

- Chisels (Wood, Cold, Masonry): Used for cutting, carving, and shaping materials like wood, metal, and stone, requiring different edge types and material compositions.

- Punches and Awls: For creating holes, marking, aligning, or starting fasteners in various materials.

- Mallets (Rubber, Wooden, Plastic, Dead Blow): Used for striking surfaces without causing damage, often in woodworking, automotive, and assembly applications.

- Demolition Tools (Crowbars, Pry Bars): Lever-based tools used for breaking, prying, and disassembling structures.

- Specialty Striking Tools: Including impact drivers, brick hammers, geological picks, and other highly specialized instruments for niche applications.

- By Material:

- Steel (Forged, Alloy): Dominant for heads due to strength and durability, often heat-treated for specific hardness.

- Wood (Hickory, Ash): Traditional handle material, offering natural shock absorption.

- Fiberglass: Common for handles, providing durability, weather resistance, and good vibration dampening.

- Rubber/Plastic: Used for mallets, protective caps, and ergonomic handle grips to enhance comfort and prevent slippage.

- Composites: Advanced materials used in handles or entire tools for lightweight strength and superior vibration absorption.

- By Application:

- Construction: Driving nails, demolition, shaping wood, breaking concrete, a primary consumer segment.

- Woodworking and Carpentry: Fine shaping, joinery, assembly, and general wood manipulation.

- Automotive and Mechanical: Repair, assembly, disassembly, and panel work.

- Industrial and Manufacturing: Assembly lines, maintenance, heavy-duty tasks in factories.

- DIY and Residential: Home improvement, minor repairs, gardening, and general household tasks.

- Forestry and Agriculture: Tree felling, splitting logs, land clearing.

- Mining and Quarrying: Breaking rocks, geological sampling.

- By End-User:

- Professional/Commercial: Tradespeople, contractors, industrial workers, mechanics, artisans who require durable, high-performance tools for daily use.

- Residential/DIY: Homeowners, hobbyists, individuals undertaking personal projects, often seeking versatile and user-friendly tools.

- By Distribution Channel:

- Offline (Hardware Stores, Specialty Stores, Supermarkets, Wholesale Distributors): Traditional retail channels providing physical access and expert advice.

- Online (E-commerce Platforms, Brand Websites): Growing segment offering convenience, wider selection, and competitive pricing.

Striking Tools Market Value Chain Analysis

The value chain for the Striking Tools Market is a complex network of interconnected activities, beginning with the sourcing of raw materials and culminating in the delivery of finished products to end-users. This chain encompasses upstream activities involving material extraction and processing, through midstream manufacturing and assembly, to downstream distribution and sales. Effective management of each stage is critical for ensuring product quality, cost efficiency, and timely market delivery, ultimately influencing profitability and competitive positioning. Understanding the flow of value through this chain helps stakeholders identify areas for optimization, risk mitigation, and strategic advantage, from leveraging global supply networks to enhancing direct consumer engagement.

Upstream analysis focuses on the acquisition and processing of fundamental raw materials. This primarily includes iron ore and other metals for steel production, essential for creating the durable heads of hammers, axes, and chisels. Wood species like hickory and ash are sourced for traditional handles, while petroleum derivatives are processed into plastics, rubber, and fiberglass for ergonomic grips, mallets, and composite handles. Suppliers of these raw materials play a crucial role, as their pricing, quality, and reliability directly impact manufacturing costs and the final products performance. Manufacturers often maintain long-term relationships with reputable suppliers to ensure consistent material flow and adhere to quality standards, which is a significant factor in a market where tool durability is paramount.

The downstream segment of the value chain involves the distribution and sale of finished striking tools to end-users. This segment is characterized by a mix of direct and indirect distribution channels. Direct sales often occur for large industrial clients or government contracts, where manufacturers might sell in bulk. However, the majority of striking tools reach consumers through indirect channels, including wholesalers, distributors, large retail chains (e.g., home improvement stores, hardware stores), and, increasingly, e-commerce platforms. Wholesalers and distributors aggregate products from various manufacturers and supply them to retailers, managing logistics and inventory. Retailers, both brick-and-mortar and online, serve as the final touchpoint for customers, providing product access, information, and after-sales support. The rise of online platforms has significantly broadened market reach, allowing smaller brands to compete and offering consumers greater choice and price transparency.

Striking Tools Market Potential Customers

The Striking Tools Market caters to an exceptionally broad and diverse range of potential customers, spanning multiple industries, professional trades, and individual users. These end-users are defined by their specific needs for applying impact force, whether for construction, repair, fabrication, or artistic endeavors. Understanding the varied requirements and purchasing behaviors of these customer segments is crucial for manufacturers and retailers to develop targeted products and marketing strategies. The demand for striking tools is fundamental and persistent, as they are often indispensable for basic tasks that cannot be effectively performed by other types of equipment, making the customer base both stable and expansive.

One of the largest segments of potential customers comprises professionals in the construction and infrastructure industries. This includes general contractors, carpenters, masons, electricians, plumbers, and demolition crews who rely heavily on a wide array of hammers, chisels, and pry bars for daily operations. Their purchasing decisions are primarily driven by durability, ergonomic design to reduce fatigue, safety features, and task-specific functionality, often favoring premium-grade tools that can withstand rigorous use. Government bodies and large construction firms frequently purchase in bulk for major projects, focusing on tools that meet stringent safety and performance standards. This professional segment values reliability and efficiency, as tool failure can lead to significant project delays and safety hazards.

Another substantial customer base is the DIY (Do-It-Yourself) and residential market, encompassing homeowners, hobbyists, and individuals undertaking home improvement or maintenance tasks. This segment typically seeks versatile, easy-to-use, and affordable striking tools for general household repairs, gardening, and small-scale projects. While price sensitivity is often higher in this segment, there is also a growing appreciation for quality and ergonomic features that enhance user experience and safety. Additionally, specialized professionals such as automotive mechanics, metal fabricators, woodworkers, and even artists represent important niche customer groups, requiring tools tailored for precision, specific material handling, or aesthetic applications. Manufacturing and industrial maintenance personnel also constitute a significant customer group, using striking tools for assembly, disassembly, and heavy-duty repair tasks within factory settings.

Striking Tools Market Key Technology Landscape

The technology landscape of the Striking Tools Market, while rooted in traditional craftsmanship, is continuously evolving through advancements in material science, manufacturing processes, and ergonomic design. These technological innovations are aimed at enhancing tool performance, durability, user comfort, and safety, thereby extending product lifespan and improving overall user experience. The integration of cutting-edge materials and sophisticated production techniques allows manufacturers to create tools that are not only more effective but also lighter and less prone to vibration, addressing common challenges associated with repetitive impact tasks. This ongoing evolution is crucial for maintaining relevance in a market that increasingly values efficiency and long-term value.

A significant aspect of the technological landscape is the development and application of advanced materials. Traditional carbon steel has been augmented by specialized alloy steels, such as chromium-vanadium steel, known for their superior hardness, tensile strength, and resistance to wear and corrosion. Heat treatment processes have become more precise, allowing for differential hardening of tool heads to provide a resilient striking face and a softer, more impact-absorbing neck. Furthermore, composite materials like fiberglass and advanced plastics are increasingly being used for handles, offering excellent vibration dampening, weather resistance, and lighter weight compared to traditional wood, contributing to reduced user fatigue and increased safety during prolonged use.

Manufacturing technologies also play a pivotal role in the quality and consistency of striking tools. Precision forging and casting techniques ensure that tool heads are formed with optimal grain structure, maximizing strength and minimizing flaws. Computer Numerical Control (CNC) machining is employed for precise shaping, finishing, and ensuring tight tolerances, especially for specialized tools like chisels and punches. Surface treatments, such as anti-corrosion coatings and polishing, not only improve aesthetics but also extend the tools working life. While less common than in power tools, some professional-grade striking tools may incorporate rudimentary sensor technologies to monitor impact force or integrate with digital measurement tools, hinting at a future where even manual tools become part of a connected ecosystem. Ergonomic engineering, though a design principle, is deeply technological, utilizing biomechanical studies to optimize handle shape, grip texture, and weight distribution for maximum efficiency and minimal strain.

Regional Highlights

- North America: This region represents a mature and highly developed market for striking tools, characterized by robust demand from established construction sectors, automotive industries, and a strong DIY culture. Innovation in ergonomic design and advanced materials, along with a preference for high-quality, durable tools, drives market dynamics. The United States and Canada lead in consumption, with a significant presence of leading global manufacturers and a well-established distribution network.

- Europe: The European market demonstrates consistent demand, with a strong emphasis on precision, safety, and adherence to stringent quality standards. Countries like Germany, the UK, and France are key contributors, driven by stable construction activities, skilled craftsmanship traditions, and a growing focus on sustainable manufacturing practices. The professional segment dominates, favoring specialized and ergonomically advanced tools.

- Asia-Pacific: Poised for the fastest growth, the Asia-Pacific region is propelled by rapid urbanization, massive infrastructure development projects, and expanding manufacturing bases in countries such as China, India, and Southeast Asian nations. The demand spans across both professional and emerging DIY segments, with a growing shift towards higher-quality and more durable tools as economic conditions improve. Cost-effectiveness remains a significant factor for many consumers.

- Latin America: This region presents significant growth potential, fueled by increasing investments in construction, mining, and industrial sectors across countries like Brazil, Mexico, and Argentina. While still developing, the market is experiencing a gradual shift towards better quality tools as economic stability improves and professional standards rise. Local manufacturing is growing, alongside imports from global players.

- Middle East & Africa (MEA): The MEA region is an emerging market for striking tools, driven by large-scale construction projects, particularly in the Gulf Cooperation Council (GCC) countries, and ongoing infrastructure development across various African nations. Demand is increasing for a wide range of tools to support these ambitious projects, with a focus on durability in challenging environments. Market penetration is steadily rising, attracting both established and new market entrants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Striking Tools Market.- Stanley Black & Decker, Inc.

- Apex Tool Group, LLC

- Klein Tools, Inc.

- Estwing Manufacturing Company Inc.

- Vaughan & Bushnell Manufacturing Co.

- Fiskars Group

- Makita Corporation

- Robert Bosch GmbH

- The Home Depot, Inc. (as a major retailer and private label producer)

- Ace Hardware Corporation (as a major retailer and private label producer)

- Craftsman (a brand under Stanley Black & Decker)

- Tekton

- Wilton Tools

- Snap-on Incorporated

- Milwaukee Tool (a brand under Techtronic Industries Co. Ltd.)

- Channellock, Inc.

- NASHUA Corporation

- Husqvarna AB

- Hultafors Group AB

- Stabila Messgeräte Gustav Ullrich GmbH

Frequently Asked Questions

What are the primary factors driving the growth of the Striking Tools Market?

The Striking Tools Market growth is primarily driven by global infrastructure development, sustained expansion in residential and commercial construction sectors, increasing industrialization, and a consistent demand from the do-it-yourself (DIY) and home improvement segments worldwide. Additionally, ongoing innovations in material science and ergonomic design contribute significantly to market expansion.

Which geographical region is expected to exhibit the fastest growth in the Striking Tools Market?

The Asia-Pacific region is projected to experience the fastest growth in the Striking Tools Market. This acceleration is attributed to rapid urbanization, substantial investments in infrastructure projects, and the robust expansion of manufacturing industries in key economies such as China and India.

How is AI impacting the manufacturing and design of striking tools?

AI primarily influences the Striking Tools Market through advanced manufacturing processes and design optimization. This includes generative design for improved ergonomics and performance, AI-driven material science for enhanced durability, and automated quality control systems, leading to more efficient production and superior product quality without direct user interaction with AI in the tool itself.

What are the key types of striking tools and their main applications?

Key types of striking tools include various hammers (claw, sledge, ball-peen), axes, chisels, mallets, and punches. Their main applications range from driving nails, demolition, and shaping materials in construction and woodworking, to mechanical repairs, forestry, and general home maintenance tasks, providing versatile utility across diverse industries.

What are the major challenges faced by the Striking Tools Market?

Major challenges include volatility in raw material prices, economic slowdowns impacting construction spending, increasing competition from power tools for certain applications, and stringent environmental regulations. Additionally, the prevalence of counterfeit products poses a significant threat to market integrity and brand value for established manufacturers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager