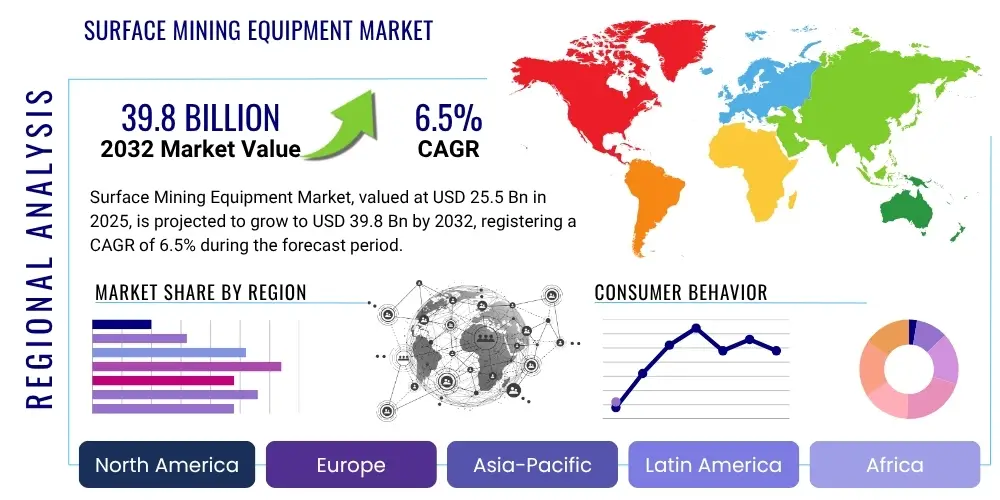

Surface Mining Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431161 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Surface Mining Equipment Market Size

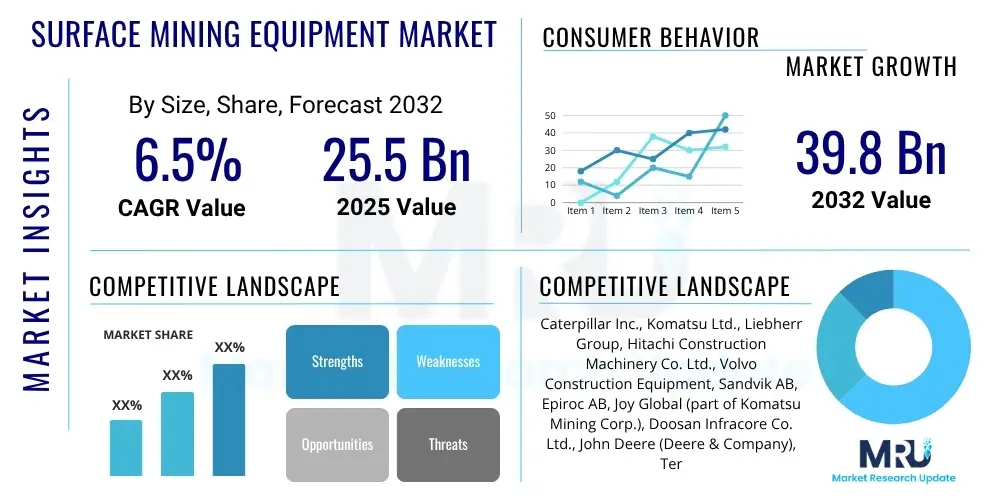

The Surface Mining Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at $25.5 Billion in 2025 and is projected to reach $39.8 Billion by the end of the forecast period in 2032.

Surface Mining Equipment Market introduction

The Surface Mining Equipment Market encompasses a broad range of heavy machinery specifically designed for extracting minerals, metals, and other valuable geological materials from the earth's surface. This includes operations such as open-pit mining, strip mining, and quarrying. The primary objective of these sophisticated machines is to enhance operational efficiency, ensure worker safety, and minimize environmental impact in resource extraction activities. The equipment spectrum ranges from large excavators and haul trucks to specialized drilling rigs and crushing plants, each playing a critical role in the mining workflow from overburden removal to material transportation.

Products within this market are engineered for extreme durability, high performance, and reliability under harsh operating conditions. Major applications span across critical sectors including coal mining, where immense volumes of material are moved, metal mining for iron ore, copper, gold, and other precious metals, and non-metal mining for industrial minerals like limestone, aggregates, and phosphates crucial for construction and chemical industries. The benefits derived from advanced surface mining equipment include significant improvements in productivity, reduced operational costs through automation and fuel efficiency, enhanced safety protocols protecting personnel, and increased precision in material handling and processing. Key driving factors for this market's expansion include the escalating global demand for minerals and metals, accelerated infrastructure development, continuous technological advancements in automation and digitalization, and increasing urbanization worldwide.

Surface Mining Equipment Market Executive Summary

The Surface Mining Equipment Market is experiencing dynamic shifts driven by global economic trends, technological innovations, and evolving regulatory landscapes. Business trends highlight a strong emphasis on automation, digitalization, and sustainability. Manufacturers are increasingly investing in research and development to offer intelligent mining solutions, including autonomous haulage systems, remote operation centers, and data analytics platforms to optimize mine planning and operations. The shift towards electrification of mining fleets is gaining momentum, aiming to reduce carbon footprints and operational costs associated with traditional fossil fuels. Additionally, there is a growing demand for robust, high-capacity equipment capable of handling larger volumes of material more efficiently.

Regional trends indicate significant growth opportunities in Asia Pacific, propelled by rapid industrialization, infrastructure development, and substantial mineral reserves, particularly in countries like China, India, and Australia. North America and Europe continue to be critical markets, characterized by early adoption of advanced technologies, stringent environmental regulations driving demand for cleaner and more efficient equipment, and a focus on operational safety. Latin America and the Middle East and Africa regions, rich in diverse mineral resources, are also poised for growth as mining investments increase, fostering demand for modern surface mining machinery. These regions are increasingly looking to upgrade their existing fleets and adopt new technologies to enhance productivity and competitiveness.

Segmentation trends reveal a sustained demand for large-scale excavators and haul trucks due to their indispensable role in high-volume surface mining operations. The application segment sees robust activity across metal and coal mining, driven by commodity demand. Technologically, the market is trending towards semi-automated and fully automated solutions, which offer significant advantages in terms of precision, safety, and operational continuity. The integration of IoT, AI, and data analytics is transforming equipment maintenance into predictive models, minimizing downtime and extending asset life. Overall, the market is characterized by innovation, a push for sustainability, and a strategic response to global resource demand.

AI Impact Analysis on Surface Mining Equipment Market

User inquiries regarding Artificial Intelligence (AI) in the Surface Mining Equipment Market frequently revolve around its potential to revolutionize operational efficiency, enhance safety, and drive cost reductions. Key themes include the implementation of autonomous vehicles and equipment, the role of predictive maintenance in minimizing downtime, and the broader implications for workforce management and environmental stewardship. Users are keen to understand how AI can optimize mine planning, improve ore recovery rates, and address the increasing complexity of geological data analysis. There is also significant interest in the ethical considerations, data security challenges, and the potential for job displacement or transformation as AI-driven automation becomes more prevalent in mining operations.

The overarching expectation is that AI will usher in an era of "smart mining," where decisions are data-driven, operations are highly automated, and human intervention is minimized in hazardous areas. Concerns often center on the initial capital investment required for AI integration, the necessity for a skilled workforce capable of managing and interpreting AI systems, and ensuring the reliability and robustness of these technologies in harsh mining environments. Furthermore, discussions frequently touch upon the potential for AI to aid in environmental monitoring and compliance, optimizing energy consumption, and facilitating more sustainable resource extraction practices. The industry is actively exploring solutions to integrate AI seamlessly while addressing these complex challenges and maximizing benefits.

- Enhanced operational efficiency through autonomous haulage and drilling systems.

- Improved safety by removing personnel from hazardous work zones.

- Predictive maintenance capabilities reducing equipment downtime and extending asset life.

- Optimized mine planning and resource utilization via advanced data analytics and machine learning algorithms.

- Real-time monitoring and control of mining processes for better decision-making.

- Reduced fuel consumption and emissions through optimized fleet management and route planning.

- Advanced geological modeling and ore grade detection for increased recovery rates.

- Streamlined supply chain and inventory management for parts and consumables.

- Potential for remote operation centers enabling centralized control and expert oversight.

- Facilitation of sustainable mining practices by optimizing resource use and minimizing waste.

DRO & Impact Forces Of Surface Mining Equipment Market

The Surface Mining Equipment Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively shape its growth trajectory and competitive landscape. Key drivers include the ever-increasing global demand for essential minerals, metals, and energy resources, fueled by rapid industrialization, urbanization, and population growth, particularly in emerging economies. Significant government investments in infrastructure projects worldwide further stimulate the demand for construction aggregates and industrial minerals. Furthermore, continuous technological advancements, such as the integration of automation, AI, and IoT, are enhancing equipment efficiency, safety, and productivity, compelling mining companies to upgrade their fleets. The mining industry's imperative to reduce operational costs and improve profitability also drives the adoption of advanced, more efficient machinery.

However, the market faces notable restraints that can impede its expansion. High capital expenditure associated with purchasing and maintaining heavy mining equipment poses a significant barrier, especially for smaller mining operations. Stringent environmental regulations and growing public pressure for sustainable mining practices necessitate substantial investments in cleaner technologies and compliance measures, which can increase operational costs. Fluctuations in commodity prices introduce market volatility, impacting investment decisions in new equipment. Moreover, a shortage of skilled labor, particularly for operating and maintaining advanced technological equipment, presents a persistent challenge. Geopolitical uncertainties and trade tensions can also disrupt supply chains and investment flows, adding to market unpredictability.

Opportunities for growth are abundant within this evolving market. The increasing focus on electrification and hydrogen fuel cell technologies for mining equipment presents avenues for developing eco-friendly and energy-efficient solutions, aligning with global sustainability goals. The rising adoption of remote operation and autonomous mining systems offers enhanced safety, productivity, and the ability to operate in challenging environments. Furthermore, the expansion into unexplored mineral-rich regions, particularly in parts of Africa and Latin America, presents new market frontiers. Strategic partnerships and collaborations between equipment manufacturers, technology providers, and mining companies are fostering innovation and accelerating the deployment of next-generation solutions. The drive towards digitalization and data-driven decision-making offers considerable potential for operational optimization.

Segmentation Analysis

The Surface Mining Equipment Market is comprehensively segmented to provide a detailed understanding of its various components and their respective dynamics. These segments are primarily categorized by Type, Application, and Technology, reflecting the diverse operational needs and technological advancements within the global mining industry. This granular analysis helps identify specific market trends, competitive landscapes, and growth opportunities across different product categories and end-use sectors. The segmentation allows for a targeted approach to market strategy, product development, and investment decisions by highlighting areas of high demand and emerging innovations.

- By Type

- Excavators (Hydraulic Excavators, Electric Rope Shovels, Wheel Loaders)

- Haul Trucks (Off-Highway Trucks, Articulated Dump Trucks)

- Drills (Rotary Drills, Blast Hole Drills, Surface Miner Drills)

- Loaders (Front End Loaders, Backhoe Loaders)

- Dozers (Track Dozers, Wheel Dozers)

- Crushers (Jaw Crushers, Cone Crushers, Impact Crushers)

- Graders

- Others (e.g., Scrapers, Conveyors, Screening Equipment)

- By Application

- Coal Mining

- Metal Mining (Iron Ore, Copper, Gold, Aluminum, Zinc, Others)

- Non-Metal Mining (Limestone, Aggregates, Phosphate, Potash, Others)

- By Technology

- Conventional

- Semi-Automated

- Automated/Autonomous

Value Chain Analysis For Surface Mining Equipment Market

The value chain for the Surface Mining Equipment Market encompasses a series of interconnected activities, beginning from the sourcing of raw materials to the ultimate delivery and aftermarket support of machinery to end-users. Upstream activities involve the procurement of essential raw materials such as steel, specialized alloys, hydraulic components, engines, tires, and advanced electronic systems. This stage also includes the manufacturing of intricate components by various specialized suppliers, who contribute significantly to the quality and performance of the final equipment. Strong relationships with reliable and technologically advanced upstream suppliers are crucial for ensuring the consistent quality, cost-effectiveness, and timely delivery of components, directly impacting the manufacturing lead times and overall cost structure of mining equipment.

Midstream in the value chain involves the design, assembly, and testing of the sophisticated surface mining equipment. Leading manufacturers invest heavily in research and development to innovate new technologies, improve efficiency, and enhance safety features. This phase is characterized by precision engineering, advanced manufacturing processes, and rigorous quality control. Once manufactured, the equipment proceeds to distribution channels, which are typically a mix of direct and indirect approaches. Direct sales involve manufacturers selling directly to large mining corporations or through their own established sales and service networks. Indirect channels involve a robust network of authorized dealers, distributors, and rental companies that provide equipment to a wider range of customers, including smaller mining operations and construction firms, offering localized support and services.

Downstream activities primarily focus on the end-users, which are predominantly mining companies involved in coal, metal, and non-metal extraction, along with large-scale construction and quarrying operations. After-sales support, including maintenance, spare parts supply, technical assistance, and training, constitutes a critical part of the downstream value chain, ensuring equipment uptime and longevity. The effectiveness of the distribution channel directly impacts market penetration and customer satisfaction. The industry increasingly leverages digital platforms for customer engagement, parts ordering, and predictive maintenance services, enhancing the overall value proposition. Direct sales offer greater control over customer relationships and brand perception, while indirect channels provide extensive market reach and specialized local support, catering to diverse customer needs and geographical specificities.

Surface Mining Equipment Market Potential Customers

The primary potential customers and end-users of surface mining equipment are diverse entities operating within the global extractive industries and related sectors. Large-scale mining corporations, often multinational enterprises, represent a significant customer base. These entities require robust, high-capacity machinery for extensive open-pit mining operations across various commodities such as iron ore, copper, gold, coal, and bauxite. Their purchasing decisions are driven by factors like operational efficiency, total cost of ownership, technological sophistication (e.g., automation, electrification), safety features, and the reliability of after-sales support. These companies often seek integrated solutions and long-term partnerships with equipment manufacturers to optimize their vast and complex mining projects.

Beyond large corporations, smaller independent mining operations also constitute an important segment of potential customers. These entities, while perhaps operating on a smaller scale, still require reliable and efficient equipment for their specific extraction projects, which might involve industrial minerals, aggregates, or specialized metals. Their purchasing criteria often prioritize cost-effectiveness, ease of maintenance, and the availability of localized service and parts. Quarrying companies, which extract aggregates like gravel, sand, and crushed stone for the construction industry, are another major end-user group, requiring excavators, loaders, crushers, and haul trucks tailored for aggregate production. Their demand is closely tied to infrastructure development and urban construction activities.

Furthermore, major construction companies and civil engineering firms that undertake large-scale excavation projects, site preparation, and infrastructure development, particularly for roads, dams, and utilities, also represent a segment of potential buyers. While their primary focus is not mining, the heavy earthmoving and material handling capabilities of surface mining equipment make them suitable for extensive construction tasks. Equipment rental companies form an indirect but vital customer group, purchasing equipment to offer flexible solutions to smaller operators and project-based users who may not wish to invest in direct ownership. The diverse needs of these customer segments necessitate a broad range of equipment types, capacities, and technology levels from manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $25.5 Billion |

| Market Forecast in 2032 | $39.8 Billion |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Caterpillar Inc., Komatsu Ltd., Liebherr Group, Hitachi Construction Machinery Co. Ltd., Volvo Construction Equipment, Sandvik AB, Epiroc AB, Joy Global (part of Komatsu Mining Corp.), Doosan Infracore Co. Ltd., John Deere (Deere & Company), Terex Corporation, Metso Outotec, Hyundai Construction Equipment, Sumitomo Heavy Industries, Atlas Copco, FLSmidth & Co. A/S, Astec Industries Inc., Sany Group, XCMG Group, Zoomlion Heavy Industry Science and Technology Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Surface Mining Equipment Market Key Technology Landscape

The Surface Mining Equipment Market is undergoing a profound technological transformation, driven by the imperative for enhanced safety, efficiency, and environmental sustainability. A central element of this landscape is the widespread adoption of automation and autonomous systems. Autonomous haulage systems (AHS) are becoming increasingly common, allowing haul trucks to operate without human drivers, significantly reducing operational costs, improving safety by removing personnel from hazardous environments, and optimizing routes for fuel efficiency. Similarly, autonomous drills and excavators are improving precision and consistency in drilling and digging operations, leading to better blast fragmentation and more efficient material extraction. These systems rely heavily on advanced sensors, GPS, LiDAR, radar, and sophisticated control algorithms to navigate and operate effectively in dynamic mining environments.

The Internet of Things (IoT) and telematics play a crucial role in collecting vast amounts of operational data from mining equipment. This data, encompassing everything from engine performance and fuel consumption to payload weights and cycle times, is transmitted in real-time to centralized platforms. This enables predictive maintenance, where potential equipment failures are identified and addressed before they occur, significantly reducing unplanned downtime and maintenance costs. Furthermore, data analytics and Artificial Intelligence (AI) are being applied to interpret these complex datasets, providing insights for optimizing mine plans, identifying operational bottlenecks, and improving overall fleet management. Machine learning algorithms are used for tasks like optimizing ore sorting, predicting geological conditions, and enhancing the accuracy of resource modeling.

Electrification and alternative power sources are also reshaping the technology landscape. Manufacturers are developing and deploying electric and hybrid mining equipment, including battery-electric haul trucks and loaders, to reduce reliance on fossil fuels, lower greenhouse gas emissions, and decrease noise pollution, particularly beneficial for underground mining and operations near populated areas. Hydrogen fuel cell technology is also emerging as a promising alternative for heavy-duty applications. Remote operation centers are becoming standard, enabling operators to control multiple machines from a safe, comfortable, and centralized location, improving working conditions and expanding the pool of available skilled labor. These technological advancements collectively contribute to a smarter, safer, and more sustainable future for surface mining operations globally.

Regional Highlights

- North America: This region is a significant market driven by technological innovation, stringent safety regulations, and a strong focus on automation and digitalization. The presence of major mining companies and a high adoption rate of advanced equipment contribute to its market share. Canada and the United States, with vast mineral resources and continuous investment in upgrading mining infrastructure, are key contributors.

- Europe: Characterized by mature mining industries and a strong emphasis on environmental sustainability and emissions reduction. European manufacturers are at the forefront of developing electric and hybrid mining equipment and advanced automation solutions. Regulations push for cleaner, more efficient operations.

- Asia Pacific (APAC): The largest and fastest-growing market due to rapid industrialization, urbanization, and high demand for minerals and metals, especially from China, India, and Australia. Significant investments in infrastructure development and large-scale mining projects are driving robust market expansion. The region is also a major manufacturing hub for mining equipment.

- Latin America: A resource-rich region, particularly for copper, iron ore, and gold. The market here is driven by substantial foreign direct investment in mining projects. While adopting new technologies, cost-effectiveness and ruggedness for challenging terrain are key considerations for equipment procurement. Brazil, Chile, and Peru are prominent markets.

- Middle East and Africa (MEA): This region offers significant growth potential due to untapped mineral reserves and increasing investments in mining projects, particularly for gold, diamonds, and phosphates. Governments are actively promoting the mining sector to diversify economies, leading to a rising demand for modern surface mining equipment. South Africa, Saudi Arabia, and Ghana are key countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Surface Mining Equipment Market.- Caterpillar Inc.

- Komatsu Ltd.

- Liebherr Group

- Hitachi Construction Machinery Co. Ltd.

- Volvo Construction Equipment

- Sandvik AB

- Epiroc AB

- Joy Global (part of Komatsu Mining Corp.)

- Doosan Infracore Co. Ltd.

- John Deere (Deere & Company)

- Terex Corporation

- Metso Outotec

- Hyundai Construction Equipment

- Sumitomo Heavy Industries

- Atlas Copco

- FLSmidth & Co. A/S

- Astec Industries Inc.

- Sany Group

- XCMG Group

- Zoomlion Heavy Industry Science and Technology Co. Ltd.

Frequently Asked Questions

What are the primary drivers for the Surface Mining Equipment Market growth?

The market is primarily driven by increasing global demand for minerals and metals, extensive infrastructure development projects, continuous technological advancements in mining machinery, and the industry's focus on enhancing operational efficiency and safety.

How is Artificial Intelligence impacting surface mining operations?

AI is significantly impacting surface mining by enabling autonomous equipment, predictive maintenance, optimized mine planning, real-time data analysis for improved decision-making, and enhanced safety through remote operations, leading to higher productivity and lower costs.

What are the key technological trends in surface mining equipment?

Key technological trends include the integration of automation and autonomous systems, widespread adoption of IoT and telematics for data collection, advanced analytics and AI for operational optimization, and the increasing shift towards electrification and alternative power sources for equipment.

Which regions offer the most significant growth opportunities for the market?

The Asia Pacific region, particularly countries like China, India, and Australia, offers the most significant growth opportunities due to rapid industrialization, infrastructure development, and high demand for raw materials. Latin America and MEA also present substantial potential.

What are the main challenges faced by the Surface Mining Equipment Market?

The market faces challenges such as high capital investment costs, stringent environmental regulations, volatility in commodity prices, a shortage of skilled labor to operate advanced machinery, and geopolitical uncertainties impacting investment and supply chains.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager