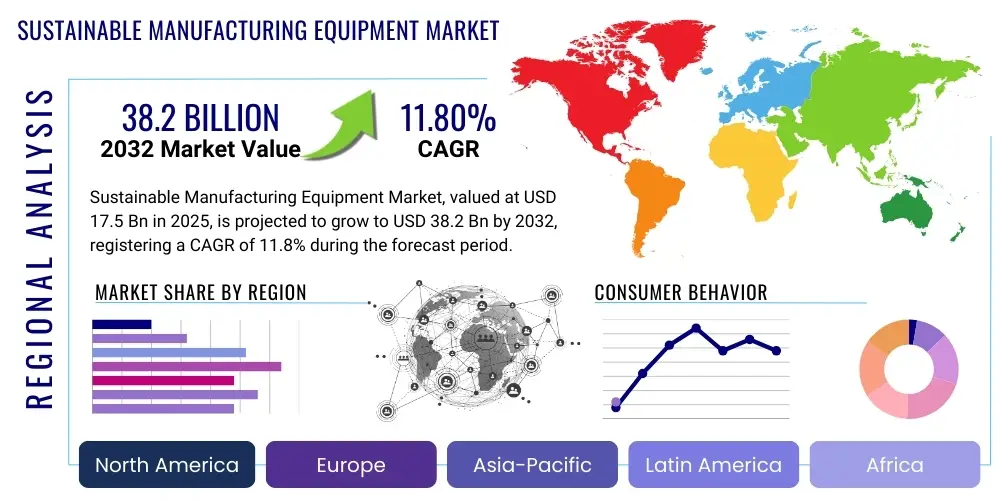

Sustainable Manufacturing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427453 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Sustainable Manufacturing Equipment Market Size

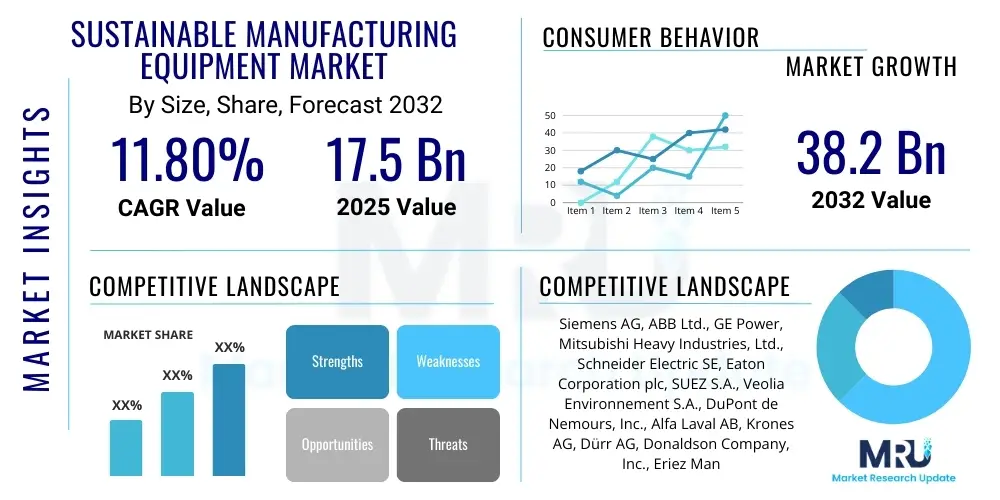

The Sustainable Manufacturing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.8% between 2025 and 2032. The market is estimated at USD 17.5 billion in 2025 and is projected to reach USD 38.2 billion by the end of the forecast period in 2032. This growth trajectory is underpinned by increasing global environmental regulations, corporate sustainability initiatives, and technological advancements that enhance the efficiency and economic viability of eco-friendly production processes. The market encompasses a broad array of machinery designed to minimize resource consumption, reduce waste, and lower carbon emissions across various industrial sectors. Factors such as government incentives, consumer demand for sustainable products, and the rising cost of traditional resources are significant contributors to this robust expansion.

Sustainable Manufacturing Equipment Market introduction

The Sustainable Manufacturing Equipment Market is defined by machinery and technologies engineered to facilitate production processes that minimize environmental impact while optimizing resource utilization. These solutions include energy-efficient machinery, water recycling and treatment systems, waste reduction and recovery equipment, and pollution control devices. Major applications span diverse industries such as automotive, electronics, packaging, textiles, construction, and food & beverage, where they are deployed to reduce operational footprints, enhance material efficiency, and meet stringent regulatory compliance. The primary benefits derived from adopting sustainable manufacturing equipment include reduced energy consumption, lower waste generation, decreased water usage, improved air quality, and significant cost savings over the long term through optimized resource management. Furthermore, these technologies contribute to a companys corporate social responsibility profile, enhancing brand reputation and attracting environmentally conscious consumers and investors. Key driving factors for this market include the escalating global focus on climate change mitigation, the introduction of stricter environmental protection laws, increasing consumer preference for sustainable products, and the economic advantages offered by enhanced operational efficiency and resource recovery.

Sustainable Manufacturing Equipment Market Executive Summary

The Sustainable Manufacturing Equipment Market is experiencing substantial momentum, driven by a confluence of global business trends emphasizing environmental stewardship and operational efficiency. Industries worldwide are increasingly integrating sustainable practices into their core operations to achieve both ecological responsibility and economic competitiveness. Major business trends include the widespread adoption of circular economy principles, the digitalization of manufacturing processes to enable predictive maintenance and resource optimization, and the growing demand for certified green products. These trends compel manufacturers to invest in advanced equipment that supports reduced energy consumption, minimized waste, and lower carbon footprints. From a regional perspective, Europe and North America are leading the adoption due to stringent regulatory frameworks and high consumer awareness, while Asia-Pacific is rapidly emerging as a significant growth hub, fueled by industrialization, increasing environmental concerns, and governmental support for green initiatives. Latin America and the Middle East & Africa are also showing nascent growth, as their industrial sectors gradually embrace sustainable practices. Segment-wise, the market is characterized by strong growth in energy-efficient machinery, waste management and recycling systems, and water treatment technologies. The electronics and automotive sectors are prominent adopters, driven by complex supply chain pressures and a strong push for decarbonization. Emerging segments like additive manufacturing and smart factory solutions further underscore the markets dynamic evolution, promising greater resource efficiency and reduced environmental impact across various production stages.

AI Impact Analysis on Sustainable Manufacturing Equipment Market

The integration of Artificial Intelligence (AI) is profoundly reshaping the sustainable manufacturing equipment landscape, addressing common user questions about how technology can further enhance eco-efficiency and operational intelligence. Users are keenly interested in how AI can optimize energy consumption, predict equipment failures to reduce waste, enable smarter resource allocation, and facilitate advanced process control for minimizing environmental footprints. Key themes emerging from these inquiries include the potential for AI to move beyond reactive sustainability measures towards proactive and predictive environmental management, ensuring that manufacturing processes are not only efficient but also inherently sustainable. There is a strong expectation that AI will unlock new levels of resource optimization, allowing manufacturers to achieve ambitious sustainability targets while simultaneously improving productivity and reducing costs. Concerns often revolve around the initial investment, data privacy, and the complexity of integrating AI systems with existing machinery, yet the overall sentiment leans heavily towards the transformative benefits AI can offer in accelerating the shift towards truly sustainable industrial operations.

AIs influence extends to every facet of sustainable manufacturing, from optimizing individual machine performance to orchestrating entire production lines for maximal eco-efficiency. Machine learning algorithms can analyze vast datasets from sensors embedded in manufacturing equipment, identifying subtle patterns in energy usage, material flow, and waste generation that human operators might miss. This analytical capability allows for real-time adjustments and long-term strategic planning, ensuring that resources like water, energy, and raw materials are consumed only as needed, thereby drastically reducing waste and environmental impact. Predictive analytics, a core AI application, enables proactive maintenance schedules, minimizing unexpected downtime and preventing material spoilage or defective product batches, which directly contributes to a more sustainable production cycle. Furthermore, AI-powered systems can optimize complex processes, such as chemical reactions in waste treatment or material mixing in composite manufacturing, to achieve desired outcomes with the least possible environmental burden.

- AI-driven Predictive Maintenance: Reduces equipment downtime, extends machinery lifespan, and prevents waste from production failures.

- Optimized Energy Management: AI algorithms analyze energy consumption patterns to identify inefficiencies and suggest real-time adjustments for reduction.

- Resource Optimization: Enables intelligent allocation and usage of raw materials, water, and other resources based on demand and availability.

- Advanced Process Control: Enhances precision in manufacturing processes, leading to higher quality products and reduced material waste.

- Automated Waste Sorting and Recycling: AI-powered vision systems improve the efficiency and accuracy of waste segregation for recycling and repurposing.

- Supply Chain Optimization: AI analyzes logistics and inventory to minimize transportation emissions and prevent overproduction or material obsolescence.

- Carbon Footprint Reduction: Supports real-time monitoring and reporting of emissions, guiding strategies for reduction.

- Product Design for Sustainability: AI tools assist in designing products with eco-friendly materials and end-of-life recyclability in mind.

DRO & Impact Forces Of Sustainable Manufacturing Equipment Market

The Sustainable Manufacturing Equipment Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the core impact forces shaping its trajectory. Key drivers include the relentless pressure from evolving environmental regulations and stricter emission standards globally, compelling industries to adopt cleaner production technologies. The rising corporate social responsibility (CSR) initiatives and increasing consumer demand for ethically produced and environmentally friendly goods also significantly push manufacturers towards sustainable practices. Furthermore, the long-term economic benefits associated with sustainable equipment, such as reduced energy consumption, lower waste disposal costs, and optimized resource utilization, provide a strong financial incentive. On the restraint side, the initial high capital investment required for acquiring and implementing advanced sustainable manufacturing equipment poses a significant barrier for many businesses, particularly Small and Medium-sized Enterprises (SMEs). The lack of standardized policies across regions, coupled with the complexity of integrating new sustainable technologies with legacy systems, also presents notable challenges. Opportunities abound in the form of government subsidies, tax incentives, and funding programs aimed at promoting green technology adoption. The continuous innovation in materials science, automation, and digital technologies, particularly AI and IoT, opens avenues for developing even more efficient and cost-effective sustainable solutions. The growing global awareness of climate change and resource scarcity further amplifies the market’s potential, encouraging cross-sector collaborations and the development of circular economy models that integrate sustainable equipment from design to end-of-life. These forces combine to create a dynamic market environment where innovation and strategic investment are crucial for sustained growth and environmental progress.

Segmentation Analysis

The Sustainable Manufacturing Equipment Market is meticulously segmented based on various critical parameters, providing a granular understanding of its diverse components and growth avenues. These segmentations typically include equipment type, application industry, and geographic region, each offering unique insights into market dynamics. Equipment types encompass a wide array of technologies such as energy-efficient machinery (e.g., advanced motors, HVAC systems, industrial boilers), waste management and recycling equipment (e.g., shredders, compactors, separation systems), water treatment and management solutions (e.g., filtration, desalination, wastewater recycling), and pollution control systems (e.g., air scrubbers, catalytic converters). The application industries segment delineates the market across sectors like automotive, electronics, food and beverage, pharmaceuticals, textiles, building and construction, and chemicals, each adopting sustainable equipment tailored to their specific production processes and environmental challenges. Understanding these segments is crucial for stakeholders to identify niche markets, develop targeted strategies, and innovate solutions that address specific industrial needs while promoting overall sustainability goals across the global manufacturing landscape.

Further analysis of these segments reveals distinct growth patterns and technological preferences. For instance, within the energy-efficient machinery segment, the increasing adoption of Industry 4.0 technologies such as IoT sensors and AI-driven control systems is enhancing energy savings and operational transparency. In waste management, theres a growing shift towards advanced recovery systems that not only reduce landfill waste but also convert waste into valuable resources, embodying circular economy principles. The water treatment segment is seeing innovations in membrane technologies and smart water management systems that significantly reduce industrial water footprint and enable reuse. Each industry application, from the precision requirements of electronics manufacturing to the high-volume needs of the automotive sector, drives specific demands for sustainable equipment, necessitating customizable and scalable solutions. The automotive industry, for example, heavily invests in equipment for lightweight material production and efficient paint shops, while the food and beverage sector focuses on hygienic design, water conservation, and waste valorization.

- By Equipment Type:

- Energy-Efficient Manufacturing Systems (e.g., high-efficiency motors, smart HVAC, industrial heat pumps)

- Waste Management and Recycling Equipment (e.g., shredders, balers, material recovery facilities, advanced sorting systems)

- Water Treatment and Management Solutions (e.g., ultrafiltration, reverse osmosis, wastewater recycling units, smart metering)

- Pollution Control Equipment (e.g., air scrubbers, electrostatic precipitators, VOC abatement systems)

- Renewable Energy Integration Equipment (e.g., industrial solar panels, wind turbine components for onsite power generation)

- Additive Manufacturing Equipment (e.g., 3D printers for reduced material waste)

- Automation and Robotics (for optimized resource use and precision manufacturing)

- By Application Industry:

- Automotive Industry

- Electronics and Semiconductor Manufacturing

- Food and Beverage Processing

- Chemical and Petrochemical Industry

- Pharmaceuticals and Biotechnology

- Textile and Apparel Manufacturing

- Building and Construction Materials

- Packaging Industry

- Metals and Mining

- By End-User:

- Large Enterprises

- Small and Medium-sized Enterprises (SMEs)

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, South Korea, ASEAN, Rest of Asia-Pacific)

- South America (Brazil, Argentina, Rest of South America)

- Middle East & Africa (GCC Countries, South Africa, Rest of Middle East & Africa)

Sustainable Manufacturing Equipment Market Value Chain Analysis

The value chain for the Sustainable Manufacturing Equipment Market is characterized by a sequential yet interconnected series of activities, starting from upstream raw material suppliers and extending through manufacturing, distribution, and ultimately to the end-users. Upstream analysis involves raw material extraction and processing, focusing on sustainable sourcing of metals, plastics, and electronic components that minimize environmental impact. This stage also includes the development and production of specialized components like high-efficiency motors, advanced sensors, and control systems. Midstream activities encompass the design, engineering, and assembly of the sustainable manufacturing equipment itself, where innovation in energy efficiency, waste reduction capabilities, and longevity are paramount. Manufacturers integrate cutting-edge technologies like IoT, AI, and advanced robotics to create intelligent and resource-efficient machinery. Downstream analysis focuses on the distribution channels, which include both direct sales and indirect channels through distributors, agents, and system integrators who provide installation, maintenance, and after-sales services. Direct channels often cater to large enterprises with complex, custom requirements, fostering closer relationships between manufacturers and end-users. Indirect channels leverage extensive networks to reach a broader customer base, including SMEs, offering standardized solutions and local support. The entire value chain is increasingly being scrutinized for its environmental footprint, with a growing emphasis on circularity, ensuring that products are designed for disassembly, reuse, and recycling, thereby closing the loop on resource consumption and minimizing waste across the lifecycle of the equipment.

Sustainable Manufacturing Equipment Market Potential Customers

The Sustainable Manufacturing Equipment Market targets a broad spectrum of end-users and buyers across diverse industrial sectors, united by a common objective of enhancing operational sustainability and efficiency. Potential customers primarily include large multinational corporations that are under intense public scrutiny and regulatory pressure to meet stringent environmental targets, as well as forward-thinking Small and Medium-sized Enterprises (SMEs) looking to gain a competitive edge through green production practices. Key industries comprise automotive manufacturers seeking to reduce emissions from vehicle production and assembly lines, electronics companies aiming to minimize waste and energy consumption in chip fabrication and device assembly, and food and beverage processors focused on reducing water usage and managing organic waste efficiently. Additionally, pharmaceutical companies investing in cleaner production processes, textile manufacturers adopting waterless dyeing technologies, and construction material producers pursuing low-carbon manufacturing are significant buyers. Energy-intensive sectors like metals and mining also represent substantial opportunities for equipment that can optimize energy use and reduce environmental impact. Essentially, any manufacturing entity seeking to comply with environmental regulations, improve resource efficiency, reduce operational costs, enhance brand reputation, and contribute positively to climate change mitigation initiatives stands as a potential customer for sustainable manufacturing equipment, reflecting a growing global imperative for responsible industrialization.

Sustainable Manufacturing Equipment Market Key Technology Landscape

The Sustainable Manufacturing Equipment Market is underpinned by a rapidly evolving technology landscape that continuously introduces innovations designed to enhance eco-efficiency and operational performance. Central to this landscape are advanced automation and robotics, which enable precision manufacturing, reduce human error, and optimize material usage, thereby minimizing waste. The Internet of Things (IoT) plays a crucial role by connecting machinery and sensors across the production floor, facilitating real-time data collection on energy consumption, resource flow, and waste generation. This data, when analyzed by Artificial Intelligence (AI) and machine learning algorithms, drives predictive maintenance, optimizes process parameters, and identifies opportunities for significant resource savings. Energy-efficient technologies form another cornerstone, including high-efficiency motors, variable frequency drives (VFDs), smart HVAC systems, and industrial heat pumps, all aimed at reducing energy demand. Furthermore, advanced filtration and membrane technologies are critical for industrial water treatment and recycling, enabling significant reductions in fresh water intake and wastewater discharge. Material recovery and recycling technologies, such as advanced sorting systems, chemical recycling, and waste-to-energy solutions, are integral to achieving circular economy objectives. The integration of additive manufacturing (3D printing) is also gaining traction, allowing for on-demand production, reduced material waste, and localized manufacturing, which lowers transportation emissions. These technologies collectively form a synergistic ecosystem, where digital connectivity and intelligent automation are leveraged to transform traditional manufacturing into highly efficient, low-impact sustainable production systems, driving both environmental benefits and economic competitiveness across industries.

Regional Highlights

The global Sustainable Manufacturing Equipment Market exhibits significant regional variations in adoption and growth, influenced by diverse regulatory environments, industrial landscapes, and economic development stages. North America, particularly the United States and Canada, stands as a mature market driven by stringent environmental regulations, robust corporate sustainability initiatives, and high consumer awareness. The region benefits from substantial investments in R&D and a strong push towards digital transformation in manufacturing, leading to the rapid adoption of advanced energy-efficient and waste reduction technologies. Government incentives and funding programs further bolster the market, encouraging industries to transition towards cleaner production methods. Industries such as automotive, aerospace, and electronics are leading the charge in sustainable equipment integration.

Europe represents another pioneering region, with countries like Germany, the UK, and France at the forefront of sustainable manufacturing. The European Unions ambitious climate targets, comprehensive environmental directives (e.g., circular economy action plan, Green Deal), and strong emphasis on resource efficiency drive continuous innovation and investment in sustainable equipment. The regions industrial base, particularly in machinery, automotive, and chemicals, is actively seeking solutions to reduce its carbon footprint and achieve net-zero targets. Scandinavia, in particular, showcases advanced integration of renewable energy sources and highly efficient industrial processes, serving as a benchmark for sustainable practices. This mature market is characterized by a strong ecosystem of technology providers, research institutions, and end-users committed to environmental stewardship.

Asia-Pacific is projected to be the fastest-growing region, fueled by rapid industrialization, burgeoning manufacturing sectors, and increasing environmental concerns across countries like China, India, Japan, and South Korea. While historically characterized by high industrial pollution, governments in the region are now implementing stricter environmental policies and offering incentives for green manufacturing. The enormous scale of manufacturing output, combined with the drive for energy independence and resource security, provides immense opportunities for sustainable equipment providers. China, as the worlds largest manufacturing hub, is making significant investments in energy efficiency, pollution control, and industrial waste management. Similarly, Japan and South Korea, with their advanced technological capabilities, are focusing on high-tech sustainable solutions, including smart factories and advanced recycling technologies. This regions growth is also propelled by the expansion of the electronics, textile, and automotive industries seeking to meet global sustainability standards.

- North America: Driven by strict environmental regulations, significant R&D investments, and robust corporate sustainability agendas in the U.S. and Canada. High adoption in automotive, aerospace, and electronics.

- Europe: Leading the market with ambitious EU climate targets, comprehensive environmental policies, and a strong focus on circular economy principles; notably in Germany, UK, and Nordic countries.

- Asia-Pacific: Fastest-growing region due to rapid industrial expansion, escalating environmental awareness, and supportive government initiatives, especially in China, India, Japan, and South Korea. High demand from electronics and textiles.

- South America: Emerging market with increasing awareness and policy implementation in countries like Brazil and Argentina, driven by resource management needs in agriculture and mining sectors.

- Middle East & Africa: Nascent market with growing investments in industrial diversification and sustainability initiatives, particularly in GCC countries, focusing on water management and energy efficiency in petrochemicals and construction.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sustainable Manufacturing Equipment Market.- Siemens AG

- ABB Ltd.

- GE Power

- Mitsubishi Heavy Industries, Ltd.

- Schneider Electric SE

- Eaton Corporation plc

- SUEZ S.A.

- Veolia Environnement S.A.

- DuPont de Nemours, Inc.

- Alfa Laval AB

- Krones AG

- Dürr AG

- Donaldson Company, Inc.

- Eriez Manufacturing Co.

- Enviro-Waste Services Group Ltd.

- Terracycle Inc.

- Caterpillar Inc.

- Hitachi Zosen Corporation

- ANDRITZ AG

- Metso Outotec Oyj

Frequently Asked Questions

What is sustainable manufacturing equipment?

Sustainable manufacturing equipment comprises machinery and technologies designed to minimize environmental impact, optimize resource usage, and reduce waste throughout the production process. This includes energy-efficient machines, water recycling systems, waste management solutions, and pollution control devices, all aimed at fostering eco-friendly and cost-effective industrial operations.

Why is there growing demand for sustainable manufacturing equipment?

The demand is driven by stringent environmental regulations, increasing corporate social responsibility, rising consumer preference for sustainable products, and the long-term economic benefits of reduced operational costs and resource efficiency. Global climate change concerns and resource scarcity also compel industries to adopt greener practices.

Which industries are the primary adopters of sustainable manufacturing equipment?

Key industries adopting sustainable manufacturing equipment include automotive, electronics, food and beverage, pharmaceuticals, textiles, and construction. These sectors heavily invest in such equipment to reduce energy consumption, manage waste, conserve water, and comply with industry-specific environmental standards.

How does AI impact the sustainable manufacturing equipment market?

AI significantly impacts the market by enabling predictive maintenance to reduce waste, optimizing energy and resource allocation, enhancing process control for higher efficiency, and automating waste sorting and recycling. AI-driven insights help manufacturers make data-backed decisions for improved environmental performance and cost savings.

What are the main challenges faced by the sustainable manufacturing equipment market?

The primary challenges include the high initial capital investment required for new equipment, the complexity of integrating advanced sustainable technologies with existing legacy systems, and the variability in environmental policies and incentives across different regions globally. Overcoming these requires strategic planning and governmental support.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager