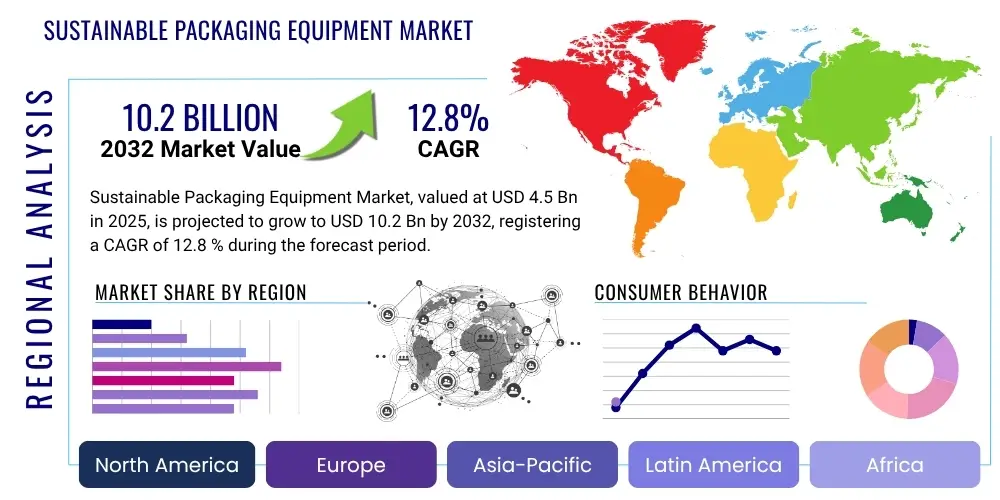

Sustainable Packaging Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427889 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Sustainable Packaging Equipment Market Size

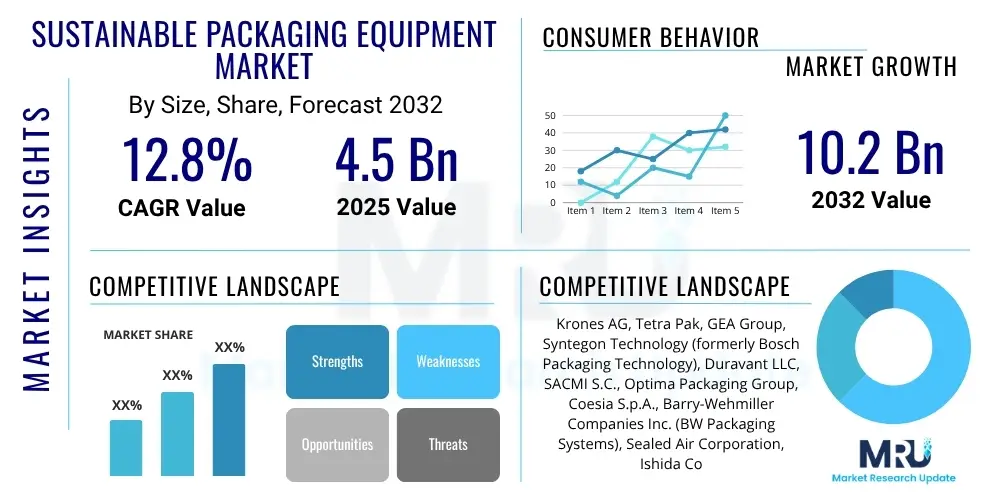

The Sustainable Packaging Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.8% between 2025 and 2032. The market is estimated at USD 4.5 billion in 2025 and is projected to reach USD 10.2 billion by the end of the forecast period in 2032.

Sustainable Packaging Equipment Market introduction

The sustainable packaging equipment market encompasses a comprehensive range of machinery and sophisticated systems engineered to facilitate the creation, filling, sealing, and handling of packaging solutions that inherently minimize environmental impact. This critical sector provides advanced equipment for utilizing a diverse array of eco-friendly materials, including recycled, recyclable, biodegradable, compostable, and renewable substrates, while simultaneously optimizing packaging processes to significantly reduce waste generation and energy consumption. As global environmental concerns intensify and consumer preferences shift unequivocally towards eco-conscious products, industries across nearly every sector are making substantial investments in cutting-edge equipment that actively supports and enables their sustainable packaging initiatives. This transformative shift is predominantly fueled by the emergence of stringent regulatory frameworks, ambitious corporate sustainability goals, and the tangible economic advantages derived from reduced material usage, enhanced operational efficiency, and a strengthened brand reputation.

These highly advanced machines vary widely, spanning automated filling and sealing systems specifically designed to handle innovative eco-materials, to sophisticated labeling and inspection technologies meticulously engineered for the unique demands of recyclable and compostable packaging. Major applications for this equipment are pervasive across vital sectors such as food and beverage, pharmaceuticals, personal care, and a wide range of industrial goods, where the dual imperative of robust product protection and unwavering environmental responsibility holds paramount importance. The machinery plays an indispensable role in empowering manufacturers to effectively transition from conventional packaging paradigms to more environmentally benign alternatives, a process that frequently necessitates either significant adaptations to existing production lines or the strategic investment in entirely new, purpose-built machinery tailored for sustainable practices. The continuous evolution and breakthroughs in material science are directly correlated with the concurrent development of compatible packaging equipment, pushing the boundaries of what is technologically feasible in terms of speed, precision, and material versatility.

The foremost benefits associated with the adoption of sustainable packaging equipment are multifaceted, including a substantial reduction in overall waste generation, a demonstrable decrease in carbon footprints across the supply chain, a significantly improved brand image and consumer perception, and proactive compliance with the rapidly evolving global environmental regulations. These powerful factors are collectively compelling businesses to undertake a thorough re-evaluation of their entire packaging lifecycle, from material sourcing to end-of-life considerations. The primary driving forces behind the vigorous growth of this market include a heightened global consumer awareness regarding climate change and environmental degradation, expansive corporate social responsibility (CSR) initiatives, governmental incentives and subsidies for green technologies, and the relentless technological advancements in automation and material handling. These advancements make sustainable packaging practices not only environmentally imperative but also economically viable and operationally efficient for large-scale mass production. This powerful convergence of environmental necessity, economic advantage, and technological prowess strategically positions the sustainable packaging equipment market for robust and sustained expansion in the foreseeable future, making it a critical component of the global sustainability agenda.

Sustainable Packaging Equipment Market Executive Summary

The sustainable packaging equipment market is currently experiencing a period of profound and dynamic growth, intricately shaped by significant business trends that underscore a global pivot towards automation, smart manufacturing, and the judicious integration of artificial intelligence for unprecedented enhancements in operational efficiency and targeted waste reduction. Corporations are increasingly prioritizing the acquisition of scalable and flexible machinery that demonstrates the capability to adeptly handle a diverse spectrum of eco-friendly materials, ranging from innovative plant-based plastics to advanced, high-performance paperboard solutions. This strategic imperative is fostering a landscape where partnerships between equipment manufacturers and specialized material suppliers are becoming commonplace, with a shared objective to innovate and cultivate comprehensive sustainable packaging ecosystems. From a regional perspective, established markets in Europe and North America currently lead in the adoption of these technologies, driven by their stringent regulatory environments and a highly environmentally conscious consumer base, while the Asia-Pacific region is rapidly emerging as a primary growth engine, propelled by accelerating industrialization and a burgeoning awareness of ecological issues, albeit with varying degrees of regulatory uniformity.

Analysis of segmentation trends within the market reveals a pronounced emphasis on sophisticated end-of-line packaging solutions, including advanced palletizing and stretch wrapping equipment, with a discernible shift towards materials and methodologies that rigorously uphold circular economy principles. The food and beverage sector consistently remains the largest consuming industry, perpetually seeking innovative equipment for applications such as aseptic filling, modified atmosphere packaging (MAP), and superior sealing technologies for perishable goods utilizing sustainable films and containers. Furthermore, there is an escalating demand for equipment specifically tailored for the burgeoning e-commerce sector, with a keen focus on developing lightweight, compact, and protective packaging solutions designed to minimize shipping volumes and mitigate transit-related carbon emissions. Concurrently, the pharmaceutical and personal care industries are demonstrating robust and sustained demand, significantly driven by intensifying regulatory pressures, the imperative for product differentiation through sustainable practices, and evolving consumer preferences for transparent, eco-friendly branding.

Collectively, the market is defined by an exceptionally rapid pace of technological innovation, with equipment manufacturers committing substantial investments to research and development. These efforts are focused on engineering machinery capable of effectively processing challenging sustainable materials with unparalleled efficiency and at increasingly higher operational speeds. The seamless integration of Industry 4.0 principles, such as sophisticated IoT sensors for comprehensive predictive maintenance and real-time data analytics for granular process optimization, is swiftly becoming an industry standard. These multifaceted trends collectively underscore a market that is not merely expanding in its volumetric size but is also undergoing a profound evolution in its inherent complexity and technological sophistication. This dual evolution adeptly addresses both immediate operational demands and overarching global environmental imperatives. The persistent global push for greater resource efficiency and enhanced conservation is anticipated to continue shaping the market's trajectory, driving continuous innovation and the widespread adoption of sustainable packaging solutions across all industrial sectors.

AI Impact Analysis on Sustainable Packaging Equipment Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the sustainable packaging equipment market frequently revolve around how AI can fundamentally enhance efficiency, drastically reduce material waste, and significantly improve the overall sustainability footprint of packaging operations. Common user questions probe the potential of AI for implementing advanced predictive maintenance protocols for machinery, optimizing the precise usage of sustainable materials, elevating quality control standards for new and often challenging sustainable substrates, and automating complex decision-making processes within sophisticated packaging lines. Users are particularly keen to understand AI's pivotal role in enabling highly adaptive packaging solutions, where machinery can dynamically adjust its parameters in real time to accommodate subtle variations in recycled content percentages or the unique properties of biodegradable materials, thereby ensuring consistent output quality and minimizing operational downtime. Recurrent concerns often highlight the substantial initial investment costs associated with AI integration, the critical need for specialized data scientists and AI expertise, and the broader ethical implications inherent in fully autonomous packaging systems and advanced data collection.

The overarching themes identified from user analysis reveal a powerful expectation that AI will emerge as a truly transformative force, enabling unprecedented levels of precision, responsiveness, and agility in sustainable packaging processes. Stakeholders widely anticipate AI to deliver robust solutions for critical challenges such as real-time defect detection across diverse packaging formats, intelligent sorting of complex recyclable materials, and dynamic, intelligent adjustments to machine parameters. These adjustments are particularly crucial for effectively handling the unique characteristics of sustainable packaging materials, which can sometimes exhibit greater fragility or inconsistency compared to their traditional plastic counterparts. The strategic integration of advanced machine learning algorithms is increasingly viewed as indispensable for optimizing energy consumption within the entire packaging line and for providing actionable, data-driven insights into highly effective waste reduction strategies, thereby directly contributing to the long-term economic viability and environmental benefits of sustainable practices. This symbiotic relationship between AI and sustainable packaging underscores a future where efficiency and ecological responsibility are seamlessly intertwined.

Furthermore, users demonstrate a strong interest in understanding precisely how AI can significantly facilitate the traceability and transparency of sustainable packaging throughout the entire supply chain, offering verifiable proof for environmental claims and ensuring regulatory compliance. There is a clear and growing demand for AI-powered vision systems specifically tailored for rigorous quality assurance, designed to guarantee that products packaged in sustainable materials consistently meet stringent industry standards without compromising product integrity, functionality, or safety. This comprehensive analysis strongly suggests a substantial market readiness and eagerness for AI solutions that offer tangible, measurable improvements in key sustainability metrics, deliver significant operational cost savings, and provide a formidable competitive edge in a rapidly evolving and environmentally conscious global marketplace. The capacity of AI to address complex material variability, optimize resource use, and enhance quality control positions it as a cornerstone technology for the future of sustainable packaging equipment.

- Optimized material usage through predictive analytics and smart dispensing mechanisms, minimizing overage.

- Enhanced quality control and real-time defect detection for a wide array of sustainable packaging materials.

- Predictive maintenance of packaging machinery, significantly reducing unplanned downtime and energy waste.

- Automated, adaptive adjustments to machine parameters for varying sustainable material properties and batches.

- Improved supply chain traceability and comprehensive transparency for sustainable packaging components.

- Reduced energy consumption across the packaging line through AI-driven process optimization strategies.

- Development of intelligent sorting and recycling initiatives for post-consumer packaging waste streams.

- Creation of advanced adaptive robotic systems specifically designed for handling delicate sustainable materials.

DRO & Impact Forces Of Sustainable Packaging Equipment Market

The sustainable packaging equipment market is significantly influenced by a compelling interplay of drivers, restraints, and opportunities, all contributing to its unique set of impact forces. Key drivers include the widespread implementation of stringent environmental regulations mandating reduced plastic usage, increased recyclability targets, and the promotion of compostable solutions, coupled with an escalating global consumer demand for eco-friendly products and packaging alternatives. Simultaneously, ambitious corporate sustainability initiatives and firm commitments to circular economy principles further accelerate crucial investment in specialized machinery capable of meeting these evolving demands. However, the market faces notable restraints, such as the often-higher initial capital investment costs associated with advanced sustainable packaging equipment and the inherent research and development challenges involved in ensuring compatibility with new, diverse sustainable materials. These new materials can present unique processing difficulties due to varied physical properties, alongside the persistent challenge of a fragmented or inadequate standardized infrastructure for recycling and composting in numerous global regions. Nevertheless, substantial opportunities exist, particularly in the continuous innovation of machinery capable of efficiently handling a broader spectrum of sustainable materials at increased operational speeds, capitalizing on the rapid growth of e-commerce which demands lightweight and protective sustainable packaging solutions, and leveraging the transformative integration of AI and IoT for enhanced operational performance, precision, and waste reduction. These combined dynamics exert a profound influence on the market's trajectory, driving continuous innovation, fostering new partnerships, and accelerating the global adoption of environmentally responsible packaging solutions across all industrial sectors.

Segmentation Analysis

The sustainable packaging equipment market is characterized by a highly diverse and intricate array of segmentations, which collectively allow for a profound and granular understanding of its various facets, underlying dynamics, and future growth trajectories. These comprehensive segments are instrumental in delineating market behavior, providing critical insights for strategic planning and targeted development based on specific equipment types, material compatibility, distinct end-use industries, and crucial geographic regions. Equipment types span the entire packaging process, ranging from sophisticated primary packaging machines such as advanced filling, precise sealing, and intelligent labeling systems, to robust secondary and tertiary packaging solutions like automated cartoning, precise case packing, and efficient palletizing systems. Each of these equipment categories is undergoing continuous evolution to more effectively and efficiently handle a growing variety of sustainable substrates, reflecting the escalating market demand for enhanced versatility, speed, and precision in sustainable packaging operations.

Material compatibility constitutes a particularly critical segmentation, fundamentally differentiating equipment specifically engineered for processing distinct eco-friendly materials. This includes machinery optimized for recycled plastics (e.g., rPET, rHDPE), innovative bioplastics (e.g., PLA, PHA), versatile paper and paperboard products, durable glass, and various metals (e.g., aluminum, steel). Each of these sustainable materials presents its own unique set of processing challenges and opportunities, directly driving intensive innovation in machine design, tooling, and operational parameters. The diverse landscape of end-use industries forms another vital segment, with the expansive food and beverage sector consistently representing the largest consumer of sustainable packaging equipment. This is closely followed by the pharmaceutical and healthcare, personal care and cosmetics, chemical and industrial, and automotive sectors. Each industry operates under distinct regulatory requirements, possesses unique product characteristics, and has specific production demands that profoundly influence the type and sophistication of sustainable packaging equipment adopted, from aseptic filling in food processing to tamper-evident seals in pharmaceuticals.

Further granular segmentation includes the level of automation integrated into the equipment (ranging from manual, to semi-automatic, to fully automatic solutions), the speed of operation required for different production volumes, and specialized functionalities such as vacuum packaging, Modified Atmosphere Packaging (MAP) for extended shelf life, or advanced shrink wrapping techniques. This detailed, multi-layered analysis of market segments is essential for enabling market players to accurately identify niche opportunities, precisely tailor their product offerings to meet specific client needs, and develop highly targeted marketing and sales strategies. As sustainability continues its ascent to become a core business imperative across virtually all global sectors, the demand for increasingly specialized and innovative equipment that not only supports but also actively drives these sustainability goals will continue to propel significant innovation and diversification within each of these meticulously defined market segments, ensuring a dynamic and responsive industry landscape.

- By Equipment Type:

- Filling Equipment

- Sealing Equipment

- Labeling Equipment

- Form-Fill-Seal Equipment

- Cartoning Equipment

- Case Packing Equipment

- Palletizing Equipment

- Shrink Wrapping Equipment

- Modified Atmosphere Packaging (MAP) Equipment

- Other Packaging & Processing Equipment

- By Material Type:

- Recycled Plastics (rPET, rHDPE, rPP)

- Bioplastics (PLA, PHA, Starch-based)

- Paper & Paperboard

- Glass

- Metals (Aluminum, Steel)

- Compostable & Biodegradable Materials

- Other Sustainable Materials

- By End-Use Industry:

- Food & Beverage

- Pharmaceuticals & Healthcare

- Personal Care & Cosmetics

- Chemicals & Industrial

- Automotive

- E-commerce & Logistics

- Others

- By Automation Level:

- Manual

- Semi-Automatic

- Automatic

Value Chain Analysis For Sustainable Packaging Equipment Market

The value chain for the sustainable packaging equipment market is inherently intricate, encompassing a series of interconnected stages from upstream raw material and component suppliers to sophisticated downstream end-users, with each stage contributing significantly to the final product's value and its effective market delivery. Upstream analysis commences with the specialized providers of crucial components, which include advanced sensors, precision motors, sophisticated control systems, and meticulously engineered parts that are indispensable for the manufacturing of complex packaging machinery. This stage also incorporates suppliers of innovative sustainable material handling mechanisms and custom tooling designed to seamlessly interact with and process a diverse array of eco-friendly substrates. A significant emphasis on research and development activities, often involving strategic partnerships with material science companies and automation specialists, is vital at this initial stage to ensure optimal equipment compatibility, peak performance, and longevity when working with cutting-edge sustainable packaging innovations.

Midstream activities primarily encompass the comprehensive processes of design, manufacturing, precision assembly, rigorous testing, and quality assurance of the sustainable packaging equipment itself. This crucial segment includes Original Equipment Manufacturers (OEMs) who are at the forefront of integrating advanced technologies such as robotics, artificial intelligence, and the Internet of Things (IoT) into their machines. These integrations are strategically aimed at enhancing operational efficiency, minimizing waste generation, and improving the overall flexibility required for effectively handling a wide spectrum of sustainable materials. Throughout the manufacturing process, uncompromising quality control, strict compliance with international safety standards, and rigorous adherence to evolving environmental regulations are absolutely paramount. Distribution channels, operating both directly and indirectly, play a pivotal role in efficiently bringing these technologically advanced and often complex machines to market. Direct channels involve equipment manufacturers selling directly to large corporate clients or through their dedicated sales teams, frequently providing bespoke custom solutions and extensive, personalized after-sales support. Indirect channels, conversely, leverage a broad network of distributors, agents, and value-added resellers who cater to smaller businesses or serve specific regional markets, often providing invaluable localized service, technical expertise, and seamless integration support.

Downstream analysis focuses intently on the critical services provided after the sale, which include expert installation, seamless integration into existing production lines, comprehensive maintenance, and ongoing technical support services extended to end-users across various industries. This encompasses crucial elements such as specialized technical training for operating personnel, reliable spare parts supply, and essential upgrades for existing machinery to ensure continued optimal performance. End-users, including prominent food and beverage manufacturers, leading pharmaceutical companies, and established personal care brands, heavily rely on this robust support infrastructure to maximize the operational lifespan, efficiency, and return on investment of their sustainable packaging lines. Furthermore, strategic partnerships with innovative sustainable packaging material suppliers are frequently crucial downstream, ensuring that the acquired equipment seamlessly processes the chosen eco-friendly films, containers, or substrates without compromise. The entire sustainable packaging equipment value chain is characterized by an unwavering emphasis on sustainability, not only in the actual packaging produced but also inherently in the manufacturing processes of the equipment itself, thus driving efficiency, promoting resource conservation, and reducing environmental impact at every single stage of the value creation journey.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 Billion |

| Market Forecast in 2032 | USD 10.2 Billion |

| Growth Rate | 12.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Krones AG, Tetra Pak, GEA Group, Syntegon Technology (formerly Bosch Packaging Technology), Duravant LLC, SACMI S.C., Optima Packaging Group, Coesia S.p.A., Barry-Wehmiller Companies Inc. (BW Packaging Systems), Sealed Air Corporation, Ishida Co. Ltd., AETNA GROUP, B&R Industrial Automation, Velteko, Cama Group, Massman Automation Designs, Shemesh Automation, IMA S.p.A., ProMach Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sustainable Packaging Equipment Market Potential Customers

The diverse landscape of potential customers for sustainable packaging equipment spans an expansive array of industries, each driven by a unique confluence of increasingly stringent regulatory pressures, evolving corporate environmental stewardship mandates, and the inexorable rise of consumer demand for products packaged with demonstrable environmental responsibility. The largest and most prominent segment of end-users typically comprises manufacturers within the expansive food and beverage industry. These enterprises necessitate high-speed, precision-engineered equipment for the accurate filling, secure sealing, and meticulous labeling of an enormous variety of products, ranging from delicate fresh produce and dairy items to complex processed foods and diverse beverages, all while undergoing a critical transition towards sustainable formats such as compostable films, fully recyclable bottles, and innovative carton-based packaging solutions. Their intense focus on extending shelf life, maintaining impeccable hygiene, and preserving absolute product integrity necessitates advanced machinery capable of adeptly handling often delicate sustainable materials without any compromise on operational performance or product quality.

Pharmaceutical and healthcare companies collectively represent another critically significant customer base, primarily driven by exceptionally strict regulatory requirements pertaining to product safety, tamper-evidence, and end-to-end traceability, alongside a burgeoning and urgent focus on broader sustainability goals. These companies actively seek state-of-the-art equipment for applications such as precise blister packaging, aseptic sterile filling, and robust tamper-evident sealing, all while progressively utilizing sustainable materials like high-grade recycled plastics or advanced paperboard solutions. Concurrently, the rapidly expanding personal care and cosmetics sector is emerging as a formidable customer group, as leading brands increasingly leverage sustainable packaging as a key differentiator in a crowded marketplace. This segment demands highly versatile equipment capable of expertly handling unique product formulations and diverse packaging formats, ranging from elegantly designed refillable containers to innovative biodegradable sachets, reflecting a strong commitment to both aesthetics and ecological integrity.

Beyond these traditionally dominant sectors, other rapidly growing potential customer groups include the chemical and industrial goods industries, which require robust packaging for various hazardous and non-hazardous materials; the automotive sector, focusing on sustainable packaging for parts and components; and, crucially, the burgeoning e-commerce and logistics companies. The e-commerce sector, in particular, is a powerful catalyst, driving intense demand for lightweight, compact, and highly protective sustainable packaging equipment. This emphasis is driven by the dual objectives of significantly reducing shipping costs and minimizing the environmental impact associated with transportation and last-mile delivery. Essentially, any enterprise involved in the manufacturing, processing, or distribution of physical goods that necessitates packaging is a potential customer, provided they are either actively committed to, or legally mandated to, adopt more sustainable and environmentally responsible practices. The pervasive and accelerating global shift towards a comprehensive circular economy model guarantees a continuously expanding and evolving customer base for innovative and high-performance sustainable packaging solutions, underscoring the long-term growth potential of this vital market.

Sustainable Packaging Equipment Market Key Technology Landscape

The sustainable packaging equipment market stands at the vanguard of technological innovation, characterized by the relentless integration of advanced solutions designed to meet the increasingly complex and multifaceted demands of eco-friendly packaging. A pivotal aspect of this dynamic technological landscape involves the continuous development of highly adaptable, precise, and robust machinery capable of seamlessly handling an expansive array of sustainable materials. These materials frequently exhibit significantly different properties, such as tensile strength, flexibility, and heat sensitivity, compared to traditional plastics, necessitating specialized processing techniques. This includes breakthroughs in advanced filling and sealing technologies that can efficiently work with thinner, more delicate biodegradable films or stiffer, recycled paperboard, all while meticulously ensuring product integrity, maintaining rapid production speeds, and minimizing material waste. The widespread adoption of sophisticated robotics and advanced automation systems is fundamental to this evolution, enabling swift and efficient changeovers between diverse packaging formats and material types, thereby further minimizing waste, maximizing operational flexibility, and enhancing overall production efficiency.

Another profoundly significant technological advancement shaping this market is the pervasive integration of Industry 4.0 principles, most notably encompassing the Internet of Things (IoT) and cutting-edge artificial intelligence (AI). IoT sensors, strategically embedded within packaging machines, provide an uninterrupted stream of real-time data on critical operational parameters such as performance metrics, precise energy consumption, and exact material usage. This rich data empowers manufacturers to implement highly effective predictive maintenance strategies, anticipate potential failures before they occur, and proactively optimize overall operational efficiency, thereby drastically reducing unplanned downtime and associated costs. AI-powered vision systems are concurrently becoming indispensable for implementing stringent quality control protocols, capable of accurately detecting even minute defects in challenging sustainable packaging materials or meticulously ensuring proper sealing with novel, sometimes temperamental, substrates. This advanced defect detection capability significantly reduces product recalls, minimizes material waste, and upholds brand reputation. Furthermore, sophisticated machine learning algorithms are continually optimizing production parameters, dynamically adapting to variables like ambient humidity levels, subtle material batch variations, or line speed fluctuations, all to consistently maintain superior output quality and operational stability.

Moreover, the development and integration of highly energy-efficient technologies are paramount, reflecting a deep commitment to reducing the environmental footprint of the packaging process itself. This includes the widespread adoption of advanced servo motors, regenerative drives that capture and reuse energy, and meticulously optimized heating and cooling systems, all specifically engineered to minimize energy consumption. Innovative material handling systems, featuring specialized grippers, vacuum systems, and intelligent conveyors, are also being continually developed to gently yet efficiently process sensitive and often delicate sustainable packaging components without causing damage or waste. The overriding emphasis across this technological landscape is on creating smart, seamlessly connected, and extraordinarily efficient packaging lines that not only meticulously produce sustainable packaging but also operate in an inherently sustainable manner. This dual focus drives down both operational costs and environmental impact concurrently. This holistic and integrated approach to technology underscores the sustainable packaging equipment market's unwavering commitment to achieving comprehensive sustainability across the entire lifecycle of packaging production, from initial design to final disposal.

Regional Highlights

- North America: This region, particularly the United States and Canada, represents a highly mature and influential market characterized by high adoption rates for sustainable packaging equipment. This growth is predominantly driven by ambitious corporate sustainability mandates, a well-informed and robust consumer demand for eco-friendly products, and advanced domestic manufacturing capabilities. The region benefits from established infrastructure for recycling and a strong focus on innovation, fostering significant investment in R&D to develop equipment compatible with a broader range of sustainable materials, including bioplastics and advanced paper-based solutions, alongside the integration of smart factory technologies for enhanced efficiency and traceability.

- Europe: As a global frontrunner, Europe leads the adoption of sustainable packaging equipment, propelled by exceptionally stringent EU directives and national regulations targeting plastic reduction, increased recycling targets, and the proactive promotion of a circular economy. Countries such as Germany, the UK, France, and Italy are distinguished by robust legislative frameworks and a high degree of environmental consciousness among both consumers and businesses. This regulatory and societal pressure drives continuous, substantial investment in advanced filling, sealing, and processing equipment for recyclable, reusable, and compostable packaging solutions across the dominant food, beverage, and pharmaceutical sectors. Europe also serves as a critical hub for packaging machinery innovation, frequently setting global benchmarks in sustainability and operational excellence.

- Asia Pacific (APAC): The Asia Pacific region is unequivocally poised for the most rapid and expansive growth within the sustainable packaging equipment market. This significant surge is primarily attributed to burgeoning industrialization, rapidly rising disposable incomes across key demographics, and an increasingly heightened environmental awareness, particularly evident in economic powerhouses like China, India, Japan, and Southeast Asian nations. While the regulatory environment can exhibit greater fragmentation compared to Europe or North America, there is a clear and accelerating trend towards adopting sustainable practices, often spearheaded by the presence of international brands and proactive local government initiatives. The immense scale of manufacturing and the ongoing modernization of industrial facilities in APAC present vast and compelling opportunities for sustainable packaging equipment manufacturers, especially those capable of offering cost-effective, scalable, and technologically adaptive solutions.

- Latin America: This emerging market is experiencing growth in sustainable packaging equipment adoption, spurred by increasing foreign investment, the expanding presence of multinational corporations with global sustainability commitments, and a gradual but steady shift in consumer preferences towards sustainable goods. Countries like Brazil, Mexico, and Argentina are seeing rising demand for efficient and environmentally responsible packaging solutions, particularly in the food and beverage and personal care sectors, as local industries strive to align with international best practices and regulatory trends. Challenges primarily involve infrastructure development and overcoming initial investment hurdles, though opportunities for localized innovation and market entry are considerable.

- Middle East & Africa (MEA): The MEA region is demonstrating growing awareness and investment in sustainable practices and related equipment, particularly within the fast-moving consumer goods (FMCG), food and beverage, and personal care sectors. Growth is supported by government initiatives aimed at diversification, economic development, and international partnerships that bring advanced technologies and sustainability expertise to the region. While still in nascent stages compared to other regions, the increasing focus on resource efficiency, waste reduction, and the demand for imported sustainable goods are creating new avenues for market development and technological adoption in countries like the UAE, Saudi Arabia, and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sustainable Packaging Equipment Market. The competitive landscape is characterized by a dynamic mix of established global players with extensive market presence and innovative niche providers, all relentlessly striving to deliver cutting-edge solutions tailored for eco-friendly packaging. These prominent companies are making substantial and strategic investments in research and development, with a primary focus on enhancing machine versatility to seamlessly handle an increasingly diverse range of sustainable materials, significantly improving operational efficiency through automation, and critically integrating smart technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) to meticulously optimize entire production lines. Strategic partnerships, collaborative ventures, and targeted acquisitions are becoming increasingly common as firms seek to expand their technological capabilities, broaden their market reach, and consolidate their positions, particularly in high-growth regional markets and specialized application areas within the sustainable packaging ecosystem.These leading key players are continuously at the forefront of innovation, proactively addressing the evolving and often complex challenges inherent in sustainable packaging. Such challenges include maintaining exceptionally high-speed production rates while processing delicate or inherently inconsistent recycled and biodegradable materials, and ensuring seamless integration with diverse supply chains. Their comprehensive product portfolios typically encompass an extensive array of sophisticated machinery, ranging from advanced filling and precision sealing systems to highly automated end-of-line solutions like robotic palletizers, all meticulously designed with a core commitment to sustainability. A strong emphasis is consistently placed on achieving superior energy efficiency, significantly reducing material waste during the actual packaging process, and ensuring the robust capability to process materials that actively support circular economy principles and contribute to resource regeneration. Furthermore, these leading companies frequently provide extensive and crucial after-sales support services, which include expert installation, thorough technical training for operating personnel, proactive maintenance programs, and essential upgrade pathways, collectively ensuring the optimal performance, extended lifespan, and maximum return on investment for their clients' sustainable packaging solutions worldwide.

The market is currently observing a pronounced trend towards the development of highly modular and inherently flexible equipment designs. These innovative designs enable manufacturers to effortlessly adapt their production lines to accommodate new and evolving packaging formats or to seamlessly switch between different material changes without necessitating substantial additional capital expenditure. This unparalleled flexibility is absolutely crucial for businesses that are navigating the rapidly changing landscape of sustainable packaging regulations, dynamic consumer preferences, and emergent material science breakthroughs. Additionally, key companies are intensely focusing on sophisticated digital integration, offering a suite of advanced software solutions for real-time production monitoring, in-depth data analytics for process optimization, and reliable remote diagnostics capabilities. These digital tools further contribute to the unparalleled efficiency, resilience, and overall sustainability of modern packaging operations. The collective, concerted efforts and strategic leadership of these market leaders are instrumental in driving the global transition towards the widespread adoption of more environmentally responsible, economically viable, and technologically advanced packaging practices across virtually all industrial sectors, charting a clear path toward a more sustainable future for packaging.

- Krones AG

- Tetra Pak

- GEA Group

- Syntegon Technology (formerly Bosch Packaging Technology)

- Duravant LLC

- SACMI S.C.

- Optima Packaging Group

- Coesia S.p.A.

- Barry-Wehmiller Companies Inc. (BW Packaging Systems)

- Sealed Air Corporation

- Ishida Co. Ltd.

- AETNA GROUP

- B&R Industrial Automation

- Velteko

- Cama Group

- Massman Automation Designs

- Shemesh Automation

- IMA S.p.A.

- ProMach Inc.

- Sidel (Tetra Laval Group)

Frequently Asked Questions

Analyze common user questions about the Sustainable Packaging Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is sustainable packaging equipment?

Sustainable packaging equipment refers to specialized machinery and sophisticated systems designed to process and create packaging solutions that inherently minimize environmental impact. This encompasses equipment compatible with a wide range of recycled, recyclable, biodegradable, or compostable materials, alongside technologies that actively reduce waste generation, optimize energy consumption, and lower the carbon footprint throughout the entire packaging process. It enables companies to effectively meet their eco-friendly goals and comply with evolving environmental regulations.

How does sustainable packaging equipment contribute to a circular economy?

Sustainable packaging equipment plays a crucial role in fostering a circular economy by facilitating the extensive use of reusable, recyclable, or compostable materials, thereby significantly diverting waste from landfills and incineration. It actively supports closed-loop systems by efficiently processing materials that can be reintegrated into the production cycle multiple times, promoting profound resource efficiency. Additionally, it minimizes virgin material consumption and energy usage during manufacturing, ensuring that packaging is optimally designed for longevity, subsequent reuse, and effective end-of-life recovery or recycling.

What are the key drivers for the sustainable packaging equipment market?

The sustainable packaging equipment market is vigorously driven by several powerful and interconnected factors. These include the implementation of increasingly stringent environmental regulations imposing plastic reduction targets and higher recycling quotas, rapidly growing global consumer demand for environmentally friendly products and their packaging, and expansive corporate sustainability initiatives aiming to significantly reduce environmental footprints across operations. Furthermore, continuous technological advancements enabling the efficient processing of novel sustainable materials and the unprecedented expansion of the e-commerce sector further accelerate market growth and widespread adoption.

What challenges do manufacturers face in adopting sustainable packaging equipment?

Manufacturers frequently encounter significant challenges when adopting sustainable packaging equipment. These challenges include the often-substantial initial investment costs for acquiring new, specialized machinery, technical complexities inherent in adapting existing equipment or processing diverse and sometimes inconsistent sustainable materials, and the critical need for acquiring or developing specialized technical expertise. Additionally, a persistent lack of standardized recycling and composting infrastructure in certain regions, coupled with the imperative to ensure both the aesthetic appeal and uncompromising functional performance of sustainable packaging, can present considerable hurdles.

How is AI impacting the sustainable packaging equipment market?

Artificial Intelligence (AI) is profoundly impacting the sustainable packaging equipment market by enabling dramatically enhanced operational efficiency, unparalleled precision, and significant waste reduction across production lines. AI-powered systems facilitate advanced predictive maintenance, precisely optimize material usage through sophisticated analytics, greatly improve quality control for often-challenging sustainable substrates, and allow for highly adaptive, real-time adjustments to machine parameters. This intelligent integration leads to substantial reductions in downtime, lower energy consumption, and the production of more consistent, higher-quality sustainable packaging output, driving both environmental and economic benefits.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager