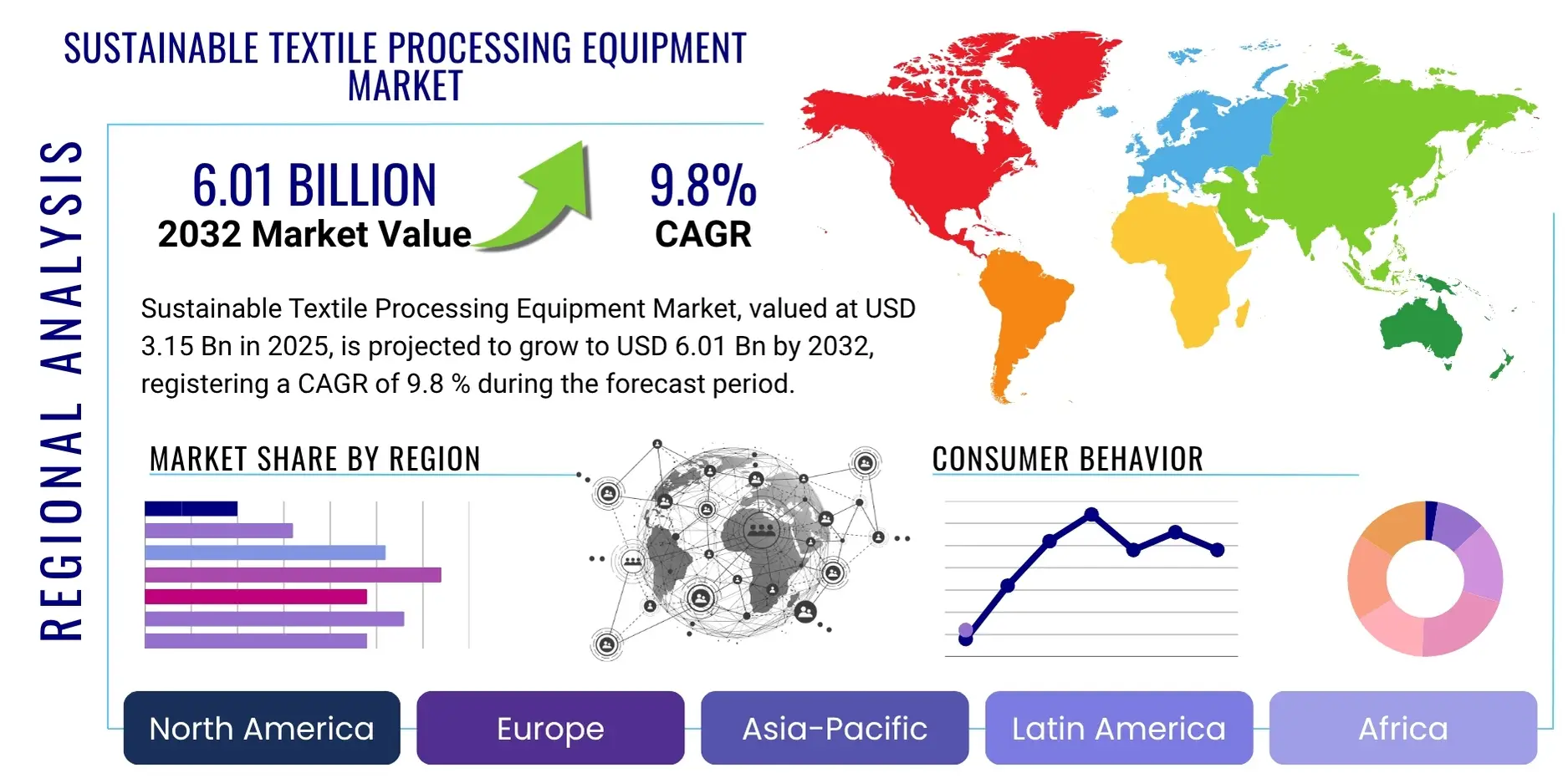

Sustainable Textile Processing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428206 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Sustainable Textile Processing Equipment Market Size

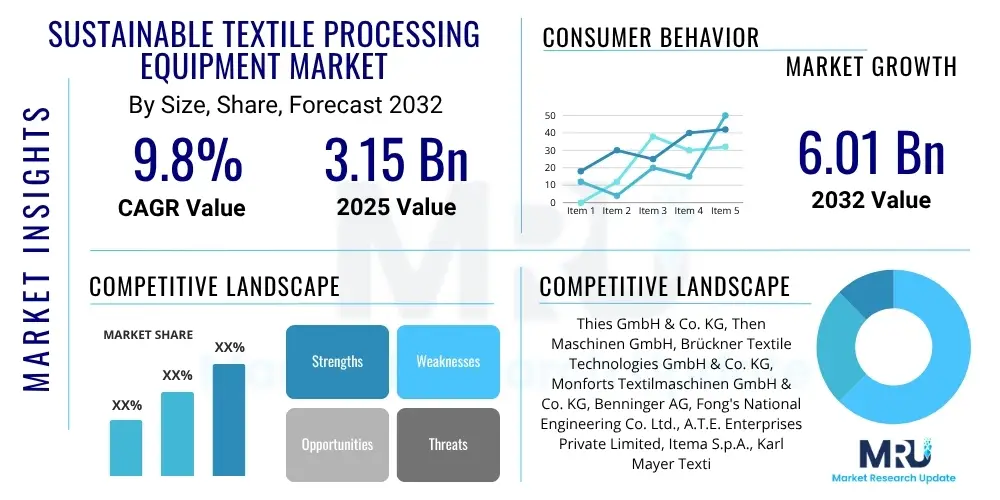

The Sustainable Textile Processing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2025 and 2032. The market is estimated at USD 3.15 billion in 2025 and is projected to reach USD 6.01 billion by the end of the forecast period in 2032. This robust growth trajectory is primarily driven by an escalating global demand for eco-friendly textile production methods, stringent environmental regulations pushing industries towards sustainable practices, and continuous technological advancements fostering more efficient and less resource-intensive equipment.

Sustainable Textile Processing Equipment Market introduction

The Sustainable Textile Processing Equipment Market encompasses machinery and technologies designed to minimize environmental impact throughout the textile manufacturing lifecycle, from fiber preparation to finishing. This includes innovative solutions for water reduction, energy efficiency, chemical optimization, and waste treatment. These technologies address critical industry challenges such as high water consumption, significant energy use, and the discharge of hazardous chemicals, aiming to transform traditional textile production into a more ecologically responsible and economically viable process.

Major applications of this equipment span across various segments of the textile industry, including apparel manufacturing, home textiles, technical textiles, and industrial fabrics. The core benefit derived from adopting sustainable processing equipment is the substantial reduction in environmental footprint, leading to lower operational costs through resource efficiency, enhanced brand reputation, and compliance with evolving global sustainability standards. Key driving factors include increasing consumer awareness regarding eco-friendly products, governmental mandates promoting green manufacturing, and innovations in material science and process engineering that enable more sustainable textile production without compromising quality or performance.

This market is characterized by a strong emphasis on research and development, with manufacturers continuously striving to introduce advanced equipment that offers superior performance in terms of resource conservation. Products range from waterless dyeing machines and advanced wastewater treatment systems to energy-efficient spinning and weaving equipment, and digital printing technologies that reduce dye consumption. The integration of automation and smart controls further optimizes these processes, contributing significantly to the overall sustainability goals of the textile industry.

Sustainable Textile Processing Equipment Market Executive Summary

The Sustainable Textile Processing Equipment Market is experiencing dynamic shifts, primarily influenced by an imperative for environmental stewardship and operational efficiency across the global textile industry. Business trends indicate a strong move towards circular economy principles, prompting manufacturers to invest in equipment that facilitates recycling, reuse, and waste minimization. There is a growing preference for modular and adaptable machinery capable of handling diverse sustainable materials, reflecting a desire for flexibility in production lines. Strategic partnerships between equipment providers and textile manufacturers are becoming more common, aimed at co-developing tailored sustainable solutions and accelerating market adoption of new technologies. Furthermore, the market is witnessing increased mergers and acquisitions as companies seek to expand their technological portfolios and market reach, particularly in areas of advanced digital and automation solutions for sustainable processing.

Regionally, Asia Pacific continues to dominate the market due to its robust textile manufacturing base, coupled with increasing environmental regulations and growing awareness among local manufacturers. Countries like China, India, and Vietnam are not only significant producers but also emerging adopters of sustainable technologies. Europe and North America, while having mature textile industries, are at the forefront of innovation and stringent regulatory frameworks, driving demand for high-end, energy-efficient, and water-saving equipment. Latin America, the Middle East, and Africa are showing nascent but accelerating growth, influenced by global sustainability trends and growing investments in upgrading textile infrastructure, particularly in countries aiming to boost their export competitiveness.

Segment-wise, the market is broadly characterized by innovations in dyeing and finishing equipment, which historically represent the most resource-intensive stages of textile production. The demand for waterless or low-water dyeing technologies, such as supercritical CO2 dyeing and foam dyeing, is rapidly expanding. Pre-treatment and washing segments are also seeing significant advancements aimed at reducing chemical use and water consumption. Digital printing equipment is gaining traction due to its precision, minimal waste generation, and flexibility for small-batch production. The overall trend indicates a holistic approach to sustainability, with integrated systems that optimize multiple processing stages simultaneously being preferred by large-scale textile manufacturers. Additionally, the increasing use of recycled fibers is driving demand for specific equipment designed to process these materials efficiently.

AI Impact Analysis on Sustainable Textile Processing Equipment Market

The integration of Artificial Intelligence (AI) into the Sustainable Textile Processing Equipment Market is fundamentally reshaping operational paradigms and pushing the boundaries of efficiency and resource optimization. Common user questions often revolve around how AI can enhance existing machinery, improve process control, predict maintenance needs, and ultimately contribute to a more sustainable textile value chain. Users are keenly interested in the tangible benefits AI offers, such as precise control over dyeing parameters, intelligent energy management in drying processes, and the optimization of chemical formulations to reduce waste and improve output quality. There is also significant curiosity about AI's role in analyzing complex data sets from production lines to identify bottlenecks and areas for improvement, alongside concerns regarding the initial investment costs, the need for specialized skills to manage AI-driven systems, and data privacy issues. Expectations are high for AI to deliver unprecedented levels of automation, predictive analytics, and real-time decision-making capabilities that enhance sustainability metrics and operational profitability.

- AI-powered systems enable real-time monitoring and precise control of dyeing and finishing processes, optimizing chemical and water usage.

- Predictive maintenance algorithms reduce equipment downtime and extend machinery lifespan by anticipating potential failures, improving operational efficiency.

- Machine learning algorithms analyze vast datasets to identify optimal energy consumption patterns in various processing stages, leading to significant energy savings.

- Computer vision and AI enhance quality control by detecting defects early in the production cycle, minimizing waste and improving product consistency.

- AI facilitates the development of intelligent water recycling and wastewater treatment systems, improving filtration and purification processes.

- Optimization of supply chain and inventory management through AI reduces material waste and transportation emissions, contributing to overall sustainability.

- AI-driven simulation tools allow for virtual prototyping and testing of new sustainable textile processes, accelerating innovation and reducing resource intensive trials.

DRO & Impact Forces Of Sustainable Textile Processing Equipment Market

The Sustainable Textile Processing Equipment Market is significantly shaped by a confluence of driving factors, restrictive elements, abundant opportunities, and overarching impact forces. Key drivers include the stringent and expanding global environmental regulations, particularly those targeting water pollution, carbon emissions, and hazardous chemical usage in textile production. Consumer demand for eco-friendly and ethically produced textiles also plays a crucial role, compelling brands and manufacturers to adopt greener processes. Furthermore, technological advancements leading to more efficient and cost-effective sustainable equipment, coupled with rising operational costs of traditional methods, are propelling market growth. These drivers collectively push the industry towards a more responsible and resource-efficient manufacturing paradigm.

However, the market faces several restraints that temper its growth. The high initial capital investment required for sustainable textile processing equipment can be a significant barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. The complexity of integrating new sustainable technologies into existing production infrastructure, alongside a shortage of skilled labor capable of operating and maintaining these advanced machines, also poses challenges. Moreover, concerns about the performance parity of sustainable methods compared to conventional techniques, especially in terms of speed and color fastness, can hinder adoption, necessitating continuous innovation to bridge this perception gap.

Despite the challenges, numerous opportunities abound within the sustainable textile processing equipment market. Emerging economies with rapidly expanding textile industries present significant growth potential as they look to upgrade their manufacturing capabilities with modern, sustainable solutions. The development of new bio-based and recycled fibers creates demand for specialized processing equipment, opening new niches. Furthermore, the increasing adoption of Industry 4.0 technologies, such as IoT, AI, and automation, can be leveraged to further enhance the efficiency and sustainability of textile processing. The growing focus on circular economy models also provides opportunities for equipment designed for textile recycling and material recovery. Impact forces such as global climate change initiatives, shifting geopolitical trade policies, and volatile raw material prices continuously influence investment decisions and technological priorities within the market, emphasizing resilience and adaptability in sustainable practices.

Segmentation Analysis

The Sustainable Textile Processing Equipment Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in identifying specific growth areas, technological advancements, and end-user preferences across various dimensions. The primary ways to segment this market include equipment type, processing stage, application, and geographical region. Each segment exhibits unique characteristics driven by distinct demands for resource efficiency, environmental compliance, and operational performance.

Understanding these segments allows market participants to tailor their offerings more effectively and identify niche markets with high growth potential. For instance, the demand for waterless dyeing equipment might be particularly high in water-scarce regions, while digital printing equipment sees increased adoption in fast fashion and customized textile production. The continuous evolution of textile materials and processing techniques necessitates flexible and specialized equipment, further refining these market segments. This granular view enables strategic planning and informed decision-making for manufacturers, suppliers, and investors alike.

- By Equipment Type:

- Pre-treatment Equipment

- Dyeing Equipment

- Printing Equipment

- Finishing Equipment

- Washing and Drying Equipment

- Wastewater Treatment Systems

- Energy Recovery Systems

- By Processing Stage:

- Fiber Processing

- Yarn Processing

- Fabric Processing (Weaving, Knitting)

- Wet Processing (Dyeing, Printing, Finishing)

- By Application:

- Apparel

- Home Textiles

- Technical Textiles

- Industrial Textiles

- Others (e.g., Medical Textiles, Geo-textiles)

- By Technology/Process:

- Waterless Dyeing Technologies (Supercritical CO2, Foam Dyeing)

- Digital Printing

- Low-Liquor Ratio Dyeing

- Enzyme-Based Processing

- Biological Wastewater Treatment

- Heat Recovery Systems

Value Chain Analysis For Sustainable Textile Processing Equipment Market

The value chain for the Sustainable Textile Processing Equipment Market begins with the upstream suppliers who provide essential raw materials, components, and intellectual property. This includes manufacturers of specialized metals, plastics, electronics, sensors, and software crucial for constructing advanced machinery. These upstream partners play a vital role in ensuring the quality, durability, and technological sophistication of the final equipment. Innovation at this stage, such as the development of more energy-efficient motors or durable, non-corrosive materials, directly impacts the sustainability and performance attributes of the processing equipment, fostering a foundation for ecological responsibility.

Moving downstream, the value chain involves the manufacturing and assembly of the sustainable textile processing equipment, followed by its distribution to end-users. Manufacturers often engage in direct sales to large textile mills, or utilize a network of distributors and agents to reach a broader market, including small and medium-sized enterprises. Post-sale services, including installation, training, maintenance, and technical support, are critical components of the downstream segment, ensuring optimal performance and longevity of the equipment. These services are particularly important for sustainable machinery, as their efficiency directly contributes to the environmental benefits and return on investment for the textile producers.

The distribution channels employed can be broadly categorized into direct and indirect methods. Direct channels involve manufacturers selling directly to textile companies, often for large, custom-built machinery, allowing for closer client relationships and tailored solutions. Indirect channels involve partnerships with specialized distributors, local agents, or system integrators who have extensive market reach and expertise in specific regions or application areas. The choice of distribution strategy often depends on the scale of operation, geographical scope, and the need for localized support and after-sales services, all aiming to efficiently connect the innovative sustainable equipment with the textile manufacturers striving for greener production.

Sustainable Textile Processing Equipment Market Potential Customers

The potential customers for sustainable textile processing equipment are diverse and span the entire spectrum of the global textile industry, united by a growing imperative to adopt environmentally responsible manufacturing practices. The primary end-users are large-scale textile manufacturers, including integrated mills that handle all stages from fiber to finished fabric. These major players are often driven by economies of scale, stringent international regulations, and brand image enhancement to invest in advanced, resource-efficient machinery, seeking to reduce operational costs associated with water, energy, and chemical consumption, while also meeting the sustainability demands of their global clients.

Medium and small-sized textile enterprises (SMEs), including dyeing houses, printing units, and finishing plants, also represent a significant customer base. While facing potential challenges with initial capital investment, many SMEs are increasingly recognizing the long-term benefits of sustainability, such as access to new markets, compliance with local environmental policies, and improved cost structures. They are often looking for modular, adaptable, and cost-effective sustainable solutions that can be integrated into their existing infrastructure without extensive overhaul, making them crucial targets for equipment providers offering scalable technologies.

Furthermore, specialty textile manufacturers focusing on technical textiles, smart fabrics, and high-performance materials are increasingly adopting sustainable processing equipment. These segments require precise and consistent processing, and sustainable technologies often offer enhanced control and quality, alongside their environmental benefits. Brands and retailers who enforce strict sustainability standards across their supply chains also act as indirect but powerful drivers, influencing their manufacturing partners to invest in sustainable equipment to meet procurement requirements. Research institutions and pilot projects also serve as early adopters and validation grounds for cutting-edge sustainable textile processing innovations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.15 Billion |

| Market Forecast in 2032 | USD 6.01 Billion |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thies GmbH & Co. KG, Then Maschinen GmbH, Brückner Textile Technologies GmbH & Co. KG, Monforts Textilmaschinen GmbH & Co. KG, Benninger AG, Fong's National Engineering Co. Ltd., A.T.E. Enterprises Private Limited, Itema S.p.A., Karl Mayer Textilmaschinenfabrik GmbH, Truetzschler Group, Rieter AG, Lakshmi Machine Works Limited, SSM Textile Machinery, Goller Textilmaschinen GmbH, C. R. Diehl GmbH & Co. KG, Datacolor, EFI Reggiani, Huntsman Corporation, Tonello S.p.A., Brazzoli S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sustainable Textile Processing Equipment Market Key Technology Landscape

The Sustainable Textile Processing Equipment Market is characterized by a vibrant and rapidly evolving technology landscape, driven by the dual objectives of environmental protection and operational efficiency. One of the most significant advancements is in waterless and low-water dyeing technologies, such as supercritical CO2 dyeing, which eliminates the need for water in the dyeing process entirely, and foam dyeing, which drastically reduces water and chemical consumption. These innovations directly address the textile industry's notorious water footprint, offering substantial savings and reducing wastewater discharge. Similarly, advanced digital printing technologies have revolutionized textile coloration by minimizing dye waste, eliminating screen preparation, and allowing for on-demand printing, thereby reducing material consumption and lead times.

Beyond dyeing and printing, the market sees extensive integration of automation, IoT (Internet of Things), and advanced sensor technologies across various processing stages. Smart sensors monitor parameters like temperature, pH levels, and chemical concentrations in real-time, enabling precise control and optimization of processes to reduce resource use and improve consistency. IoT connectivity allows for remote monitoring, predictive maintenance, and data-driven decision-making, transforming traditional textile factories into intelligent, interconnected facilities. These technologies not only enhance sustainability but also boost productivity and product quality, offering a compelling value proposition for textile manufacturers.

Furthermore, biological and membrane-based wastewater treatment systems are pivotal in closing the loop on water usage by enabling efficient recycling of process water, significantly reducing the environmental impact of textile effluents. Energy recovery systems, such as heat exchangers, are increasingly integrated into drying and finishing equipment to capture and reuse waste heat, leading to substantial energy savings and reduced greenhouse gas emissions. The development of enzyme-based pre-treatment and finishing processes offers a greener alternative to traditional chemical methods, reducing the use of harsh chemicals and mitigating their environmental consequences. Collectively, these technological advancements form the backbone of a more sustainable and resource-efficient textile industry.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to its extensive textile manufacturing base, particularly in countries like China, India, Bangladesh, and Vietnam. Rapid industrialization, coupled with growing environmental awareness and increasing governmental emphasis on sustainable manufacturing, is driving significant investments in sustainable textile processing equipment. The region is a hub for both production and consumption of textiles, leading to high demand for resource-efficient technologies to comply with international export standards and local regulations.

- Europe: A leading region in terms of innovation and adoption of advanced sustainable technologies. Driven by stringent environmental regulations (e.g., REACH), strong consumer demand for eco-friendly products, and a mature textile industry focused on high-value, specialized textiles. Countries like Germany, Italy, and Switzerland are key players in manufacturing high-quality, energy-efficient, and low-impact processing equipment, consistently setting global benchmarks for sustainability.

- North America: Characterized by a strong focus on technological advancements, automation, and niche high-performance textiles. The market is propelled by a growing emphasis on circular economy principles, corporate social responsibility initiatives, and a consumer base willing to pay a premium for sustainable products. Investments in R&D and strategic partnerships for developing innovative water-saving and energy-efficient solutions are prominent in the United States and Canada.

- Latin America: An emerging market with growing potential, influenced by increasing textile production capacities and evolving environmental legislations. Countries like Brazil and Mexico are witnessing gradual adoption of sustainable processing equipment, driven by both domestic demand for responsible manufacturing and the need to meet international trade compliance for exports. Local manufacturers are exploring cost-effective sustainable solutions.

- Middle East and Africa (MEA): Showing nascent but accelerating growth in the sustainable textile processing equipment market. The region's textile industries are undergoing modernization, with increasing investments in new technologies to enhance efficiency and address resource scarcity, particularly water. Governments are gradually implementing policies to promote sustainable industrial practices, creating opportunities for suppliers of eco-friendly machinery, especially in countries like Turkey, Egypt, and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sustainable Textile Processing Equipment Market.- Thies GmbH & Co. KG

- Then Maschinen GmbH

- Brückner Textile Technologies GmbH & Co. KG

- Monforts Textilmaschinen GmbH & Co. KG

- Benninger AG

- Fong's National Engineering Co. Ltd.

- A.T.E. Enterprises Private Limited

- Itema S.p.A.

- Karl Mayer Textilmaschinenfabrik GmbH

- Truetzschler Group

- Rieter AG

- Lakshmi Machine Works Limited

- SSM Textile Machinery

- Goller Textilmaschinen GmbH

- C. R. Diehl GmbH & Co. KG

- Datacolor

- EFI Reggiani

- Huntsman Corporation

- Tonello S.p.A.

- Brazzoli S.p.A.

Frequently Asked Questions

Analyze common user questions about the Sustainable Textile Processing Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate for the Sustainable Textile Processing Equipment Market?

The Sustainable Textile Processing Equipment Market is projected to experience a robust Compound Annual Growth Rate (CAGR) of 9.8% between 2025 and 2032. This growth is driven by increasing environmental regulations, consumer demand for eco-friendly products, and continuous technological advancements aimed at minimizing the environmental footprint of textile manufacturing.

What are the primary benefits of adopting sustainable textile processing equipment?

Adopting sustainable textile processing equipment offers multiple benefits, including significant reductions in water and energy consumption, minimized chemical usage, and lower waste generation. These efficiencies lead to substantial operational cost savings, improved compliance with environmental regulations, enhanced brand reputation, and better access to markets that prioritize sustainable products, contributing to a circular economy.

How is AI impacting the Sustainable Textile Processing Equipment Market?

AI is profoundly impacting the market by enabling real-time process optimization, predictive maintenance, and intelligent resource management. It enhances precision in dyeing and finishing, reduces waste through improved quality control, and optimizes energy consumption. AI-driven systems contribute to higher efficiency, extended equipment lifespan, and data-driven decision-making, pushing the industry towards greater sustainability.

What are the main challenges faced by the Sustainable Textile Processing Equipment Market?

Key challenges include the high initial capital investment required for new sustainable machinery, which can be a barrier for many textile manufacturers, particularly SMEs. Other challenges involve the complexity of integrating advanced technologies into existing production lines, the shortage of skilled labor to operate and maintain specialized equipment, and ensuring that sustainable methods match or exceed the performance of conventional processes.

Which regions are leading the adoption of sustainable textile processing equipment?

Asia Pacific currently dominates the market due to its large-scale textile manufacturing base and increasing environmental awareness. Europe and North America are also significant leaders, driven by stringent regulations, strong R&D, and high consumer demand for eco-friendly textiles. These regions are at the forefront of technological innovation and sustainable practices, continuously setting industry standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager