Tamping Rammer Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427536 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Tamping Rammer Machine Market Size

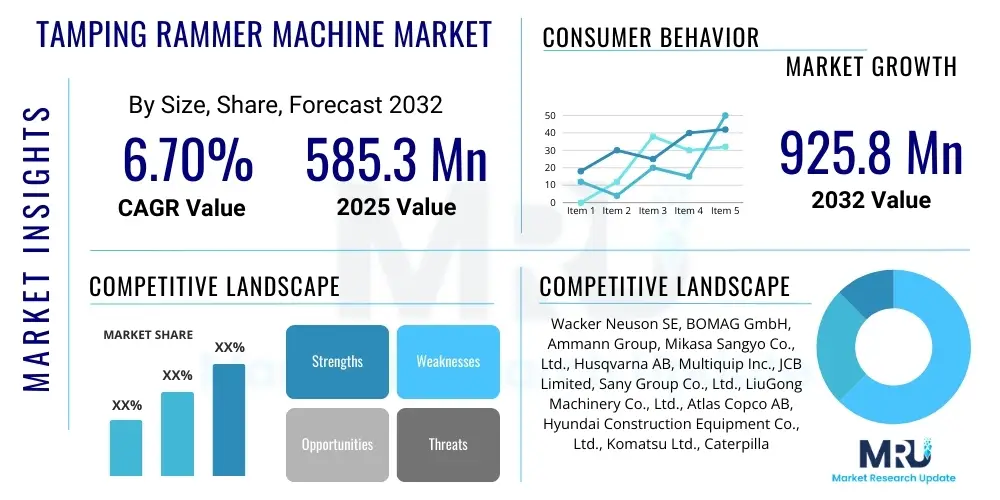

The Tamping Rammer Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 585.3 million in 2025 and is projected to reach USD 925.8 million by the end of the forecast period in 2032.

Tamping Rammer Machine Market introduction

The Tamping Rammer Machine Market encompasses a vital segment of the construction and civil engineering industry, providing essential equipment for soil, gravel, and asphalt compaction. These specialized machines are primarily designed for compacting cohesive and mixed soils in confined areas, such as trenches, foundations, and backfill applications where larger compaction equipment cannot operate efficiently or safely. Their unique impact and vibration mechanism ensures optimal density and stability, crucial for the longevity and structural integrity of various construction projects.

Key applications for tamping rammer machines include the preparation of roadbeds, utility trench backfills, landscaping projects, and the compaction around pillars and abutments. These machines are favored for their ability to achieve high compaction densities in layers, significantly reducing the risk of ground settlement and ensuring a stable base for subsequent construction activities. The robust design and portable nature of tamping rammers make them indispensable tools for a wide range of contractors, from large-scale infrastructure developers to small and medium-sized construction firms.

The markets growth is predominantly driven by increasing global infrastructure development, rapid urbanization, and a consistent demand for maintenance and repair of existing structures. Benefits such as enhanced operational efficiency, superior compaction quality, and improved safety in confined spaces contribute significantly to their widespread adoption. Additionally, continuous technological advancements focused on ergonomic design, fuel efficiency, and reduced emissions are further propelling market expansion and enhancing user experience.

Tamping Rammer Machine Market Executive Summary

The Tamping Rammer Machine Market is experiencing dynamic shifts, influenced by several overarching business, regional, and segment trends. Globally, the market is characterized by a strong emphasis on operational efficiency and environmental sustainability, driving innovations towards more fuel-efficient and electric-powered models. The growing construction and infrastructure sectors, particularly in developing economies, are providing significant impetus, while developed regions focus on equipment upgrades and adherence to stricter emission norms. The rental market for construction equipment is also a significant trend, offering cost-effective solutions for contractors and expanding market reach for manufacturers.

Regionally, Asia-Pacific continues to dominate the market due to robust infrastructure spending, rapid urbanization, and a burgeoning construction industry in countries like China, India, and Southeast Asian nations. North America and Europe demonstrate a mature market, characterized by demand for advanced, operator-friendly, and environmentally compliant machinery, alongside a strong aftermarket and rental sector. Latin America, the Middle East, and Africa are emerging markets, driven by increasing government investments in public works and urban development projects, albeit with a focus on more cost-effective and durable solutions.

Segment-wise, gasoline-powered tamping rammers currently hold the largest share due to their widespread availability and lower initial cost, but the electric/battery-powered segment is projected to witness the highest growth rate as companies prioritize sustainability and reduce operational noise and emissions. The trend towards lighter and more compact machines designed for enhanced maneuverability in increasingly congested urban construction sites is also notable. Furthermore, the market sees a continuous demand across diverse applications, with road and highway construction and utility trenching remaining the primary areas of utilization.

AI Impact Analysis on Tamping Rammer Machine Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Tamping Rammer Machine Market often center on its potential to enhance operational efficiency, improve safety, and automate aspects of compaction processes. Common questions revolve around whether AI can predict maintenance needs, optimize compaction patterns, or even lead to autonomous rammer operations. There is also interest in how AI might contribute to data-driven decision-making on construction sites and reduce reliance on manual operator skill, particularly concerning consistency and quality of compaction work. Users generally express a blend of anticipation for technological advancements and concerns about integration costs and the readiness of the industry for such sophisticated systems.

- AI-powered predictive maintenance can monitor machine performance, anticipate failures, and schedule proactive servicing, minimizing downtime and extending equipment lifespan.

- Integration of AI with sensors can provide real-time compaction data, allowing operators or autonomous systems to optimize tamping patterns for consistent and uniform soil density.

- AI algorithms could analyze site conditions and project requirements to recommend optimal tamping rammer models and operating parameters, enhancing project efficiency and quality.

- Future developments may include AI-driven autonomous tamping rammers for repetitive tasks in controlled environments, improving safety by removing human operators from hazardous zones.

- AI can contribute to enhanced safety features by recognizing potential hazards or unsafe operating conditions and alerting operators or initiating automatic shutdowns.

- Supply chain optimization through AI can improve logistics for parts and new equipment, reducing lead times and improving market responsiveness.

DRO & Impact Forces Of Tamping Rammer Machine Market

The Tamping Rammer Machine Market is shaped by a confluence of driving factors, restraints, and opportunities, alongside significant impact forces. Key drivers include robust global infrastructure development initiatives, rapid urbanization leading to increased residential and commercial construction, and a rising demand for rental equipment due to cost-effectiveness and flexibility. Technological advancements focused on ergonomics, fuel efficiency, and reduced emissions are also propelling market growth. However, the market faces restraints such as the high initial investment cost of advanced machinery, the availability of alternative compaction methods, and the shortage of skilled operators in certain regions. Stringent environmental regulations and varying governmental policies on construction also pose challenges to manufacturers and market penetration.

Opportunities for growth are abundant, particularly in the development of electric and hybrid tamping rammers that align with global sustainability goals and emerging environmental mandates. The expansion into untapped emerging markets, especially in Africa and parts of Asia, presents significant potential. Furthermore, the integration of smart technologies, such as telematics and IoT for remote monitoring and predictive maintenance, offers avenues for differentiation and value addition. The increasing emphasis on operator safety and comfort is also creating opportunities for product innovation in anti-vibration systems and noise reduction features.

The markets competitive landscape is influenced by several impact forces. The intense competitive rivalry among established global players and regional manufacturers drives continuous innovation and pricing strategies. The bargaining power of buyers, comprising large construction firms and rental companies, is moderate to high, influencing product customization and service offerings. Supplier power from engine and component manufacturers is also significant, especially for specialized parts. The threat of substitutes, primarily other compaction equipment like vibratory plate compactors, is present but often mitigated by the tamping rammers specific utility in confined spaces. The threat of new entrants is moderate, as high capital investment, established distribution networks, and strong brand recognition create barriers, yet niche players can emerge with specialized or innovative products.

Segmentation Analysis

The Tamping Rammer Machine Market is intricately segmented based on various attributes, allowing for a detailed understanding of market dynamics, consumer preferences, and growth opportunities across different categories. These segmentations provide a granular view of demand patterns, technological adoption rates, and competitive landscapes, aiding manufacturers and stakeholders in strategic decision-making. Analyzing these segments helps in identifying core market demands and tailoring product development and marketing efforts to specific end-user needs and operational environments.

Understanding the market through its segments is critical for forecasting future trends and assessing the potential impact of new technologies or regulatory changes. The diversity within each segment reflects the wide array of construction applications and operational requirements for compaction equipment, from heavy-duty infrastructure projects to smaller landscaping tasks. This detailed breakdown highlights the nuanced demands across different regions and industries, facilitating targeted market penetration strategies and product portfolio diversification for market participants.

- By Type:

- Gasoline Tamping Rammers

- Diesel Tamping Rammers

- Electric/Battery Tamping Rammers

- By Operating Weight:

- Lightweight (Under 60 kg)

- Medium-weight (60-80 kg)

- Heavyweight (Over 80 kg)

- By Application:

- Road & Highway Construction

- Building & Bridge Construction

- Utilities (Trench Backfill)

- Landscaping and Paving

- Foundations and Residential Projects

- Other Civil Engineering Works

- By End-User:

- Construction Companies

- Equipment Rental Companies

- Municipalities and Government Agencies

- Utility Service Providers

- Landscaping Contractors

- Individual Contractors

- By Sales Channel:

- Direct Sales

- Distributors and Dealers

- Online Retailers

- Rental Fleets

Tamping Rammer Machine Market Value Chain Analysis

The value chain for the Tamping Rammer Machine Market is a complex network of activities that transforms raw materials into finished products and delivers them to the end-users. It begins with upstream activities involving the sourcing of essential raw materials such as steel, aluminum, and various polymers, along with specialized components like engines, gearboxes, and compaction mechanisms. Manufacturers often rely on a global network of suppliers for these critical inputs, emphasizing quality, cost-efficiency, and reliable delivery. Component manufacturers, including engine suppliers like Honda, Robin, and Yanmar, play a pivotal role, setting technological standards and influencing overall machine performance and reliability. Research and development efforts at this stage focus on material science, engine efficiency, and anti-vibration technologies.

Midstream activities involve the manufacturing and assembly of the tamping rammer machines. This stage includes precision engineering, welding, painting, and the integration of various components into a complete unit. Quality control and testing are paramount to ensure the machines meet industry standards for durability, performance, and safety. Manufacturers continuously invest in automation and lean manufacturing processes to optimize production efficiency and reduce costs. Product innovation, particularly in areas like electric motor integration, advanced vibration dampening, and ergonomic design, is a key focus to gain a competitive edge in the market.

Downstream analysis covers the distribution and sales channels, which are crucial for market penetration and customer reach. Tamping rammer machines reach end-users through a combination of direct and indirect channels. Direct sales often occur for large volume orders from major construction companies or government agencies, fostering direct relationships and customized solutions. Indirect channels involve a vast network of authorized distributors, dealers, and equipment rental companies. These intermediaries provide local sales, after-sales service, spare parts, and technical support, which are vital for customer satisfaction and brand loyalty. Rental fleets, in particular, represent a significant distribution avenue, offering accessibility to smaller contractors and project-based users without the burden of capital investment. Marketing and promotional activities, including trade shows, digital campaigns, and product demonstrations, also form a critical part of the downstream value chain, educating potential customers about product features and benefits.

Tamping Rammer Machine Market Potential Customers

The Tamping Rammer Machine Market serves a diverse range of potential customers, primarily operating within the construction, infrastructure, and utility sectors. These end-users typically require robust and efficient compaction solutions for tasks in confined spaces, making tamping rammers indispensable tools. Key customer segments include large-scale general construction contractors involved in commercial and residential building projects, who utilize these machines for foundation preparation, backfilling around structures, and ensuring stable ground for various constructions. Their demand often revolves around reliability, performance, and adherence to project timelines.

Another significant customer base comprises equipment rental companies, which purchase tamping rammers to offer a flexible and cost-effective solution to smaller contractors and projects with varying needs. These companies focus on machine durability, ease of maintenance, and broad applicability across different job sites to maximize their return on investment. Municipal and government agencies, responsible for public works, road maintenance, and utility infrastructure, are also major buyers, using tamping rammers for street repairs, sidewalk construction, and maintaining public utility lines. Their purchasing decisions are often influenced by long-term durability, operational safety, and environmental compliance.

Furthermore, utility service providers, including those in telecommunications, gas, and water, regularly employ tamping rammers for trench backfilling after laying pipes and cables, ensuring proper compaction to prevent future ground settlement and utility damage. Landscaping contractors utilize these machines for preparing grounds for patios, pathways, and other hardscape elements, where precise compaction is crucial for aesthetic and structural integrity. Individual contractors and small businesses also form a vital segment, relying on these machines for a variety of smaller-scale, diverse projects, prioritizing portability and ease of use.

Tamping Rammer Machine Market Key Technology Landscape

The Tamping Rammer Machine Market is continually evolving, driven by advancements in engineering and material science aimed at enhancing performance, efficiency, and user experience. A core technological aspect lies in the development of sophisticated engine systems, predominantly four-stroke gasoline engines for their reliability and power, alongside ongoing research into more efficient two-stroke alternatives. The focus is increasingly shifting towards reducing emissions and improving fuel economy, with manufacturers integrating advanced carburetion and exhaust after-treatment systems to meet stringent environmental regulations. The emergence of electric and battery-powered tamping rammers represents a significant technological leap, addressing concerns about noise, emissions, and operator exposure to exhaust fumes, making them ideal for indoor or environmentally sensitive applications.

Another critical area of innovation is in anti-vibration technology and ergonomics. Prolonged exposure to vibration can lead to operator fatigue and health issues, prompting manufacturers to develop advanced dampening systems, isolated handles, and improved suspension mechanisms. These innovations aim to significantly reduce hand-arm vibration (HAV) levels, enhancing operator comfort and safety during extended use. Furthermore, the design of the compaction foot and the ramming mechanism is continuously refined to optimize impact force, frequency, and jump height, ensuring maximum compaction density and efficiency across various soil types, from granular to cohesive materials. Material science plays a role in developing lighter yet more durable components, improving machine lifespan and portability.

The integration of smart technologies is also shaping the landscape, albeit at an early stage for this specific equipment category. Features such as telematics for GPS tracking, remote diagnostics, and usage monitoring are becoming more common in larger construction machinery and are gradually finding their way into tamping rammers. Sensors capable of measuring compaction density in real-time could revolutionize quality control on site, providing immediate feedback to operators. Connectivity features enable better fleet management for rental companies and large construction firms, allowing for optimized maintenance schedules and improved operational planning. These technological advancements collectively contribute to a more efficient, safer, and environmentally friendly compaction process, aligning with modern construction demands.

Regional Highlights

- North America: Characterized by a mature construction market with a strong emphasis on worker safety, advanced technology adoption, and a robust equipment rental sector. Demand for fuel-efficient and low-emission models is growing. Significant investment in infrastructure upgrades and maintenance drives steady market demand.

- Europe: Driven by strict environmental regulations, leading to a high demand for electric and low-emission tamping rammers. Western European countries exhibit a preference for high-quality, durable equipment with advanced ergonomic features. Eastern Europe is experiencing growth due to increasing infrastructure development and modernization efforts.

- Asia-Pacific: The largest and fastest-growing market due to rapid urbanization, massive infrastructure projects (roads, railways, airports), and robust residential and commercial construction in countries like China, India, and Southeast Asian nations. Cost-effectiveness and product availability are key drivers, alongside an increasing shift towards more efficient and technologically advanced machines.

- Latin America: An emerging market with growing demand influenced by government investments in public works and mining sectors. Brazil and Mexico are key markets, showing increasing adoption of modern construction equipment as economic conditions improve and infrastructure needs expand.

- Middle East & Africa (MEA): Experiencing significant growth due to large-scale development projects, especially in the GCC countries (Saudi Arabia, UAE) and urban expansion across Africa. The demand for durable and robust machinery suited for challenging environmental conditions is high, alongside a rising interest in efficient compaction solutions for new cities and transportation networks.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tamping Rammer Machine Market.- Wacker Neuson SE

- BOMAG GmbH (Fayat Group)

- Ammann Group

- Mikasa Sangyo Co., Ltd.

- Husqvarna AB

- Multiquip Inc.

- JCB Limited

- Sany Group Co., Ltd.

- LiuGong Machinery Co., Ltd.

- Atlas Copco AB

- Hyundai Construction Equipment Co., Ltd.

- Komatsu Ltd.

- Caterpillar Inc.

- Indeco North America

- Weber MT GmbH

Frequently Asked Questions

What is a tamping rammer machine used for?

A tamping rammer machine is primarily used for compacting cohesive and mixed soils in confined areas, such as trenches, foundations, backfill around structures, and small repair jobs where larger compaction equipment cannot reach. It ensures optimal soil density to prevent settlement.

What are the main types of tamping rammers available?

Tamping rammers are mainly categorized by their power source: gasoline-powered, diesel-powered, and increasingly, electric/battery-powered models. Gasoline types are most common, while electric models offer lower emissions and noise for specific environments.

How does a tamping rammer differ from a plate compactor?

Tamping rammers are ideal for cohesive and mixed soils in deep, narrow areas, compacting with a direct, high-impact force. Plate compactors, especially vibratory ones, are better suited for granular soils and asphalt on larger, open surfaces, compacting through high-frequency vibrations.

What factors should be considered when choosing a tamping rammer?

Key factors include the type of soil to be compacted, the size of the working area (confined vs. open), operating weight for optimal compaction, engine power, fuel efficiency, anti-vibration features for operator comfort, and specific job site requirements regarding noise and emissions.

What is the impact of environmental regulations on the tamping rammer market?

Environmental regulations, particularly regarding engine emissions and noise pollution, are driving manufacturers to develop more fuel-efficient, lower-emission gasoline and diesel engines, as well as accelerating the adoption and innovation of electric/battery-powered tamping rammers to meet compliance standards and market demand for sustainable solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager