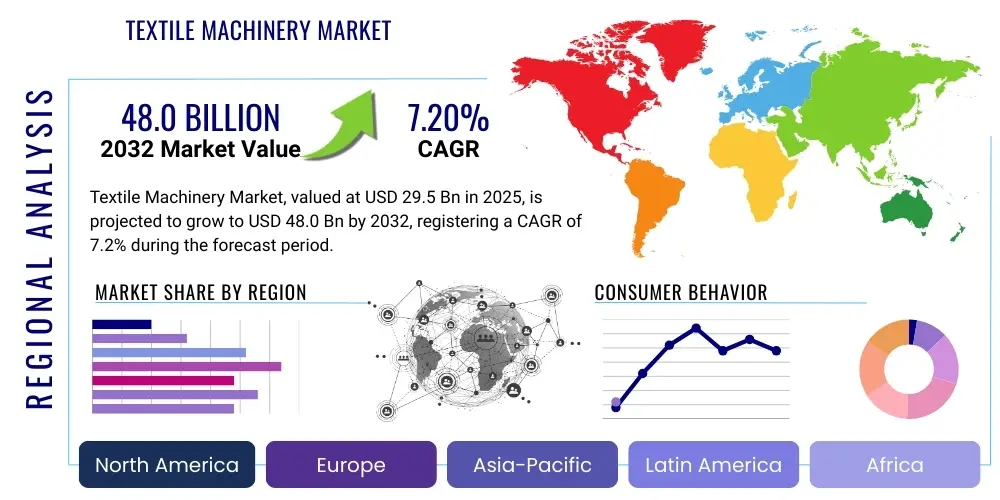

Textile Machinery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427444 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Textile Machinery Market Size

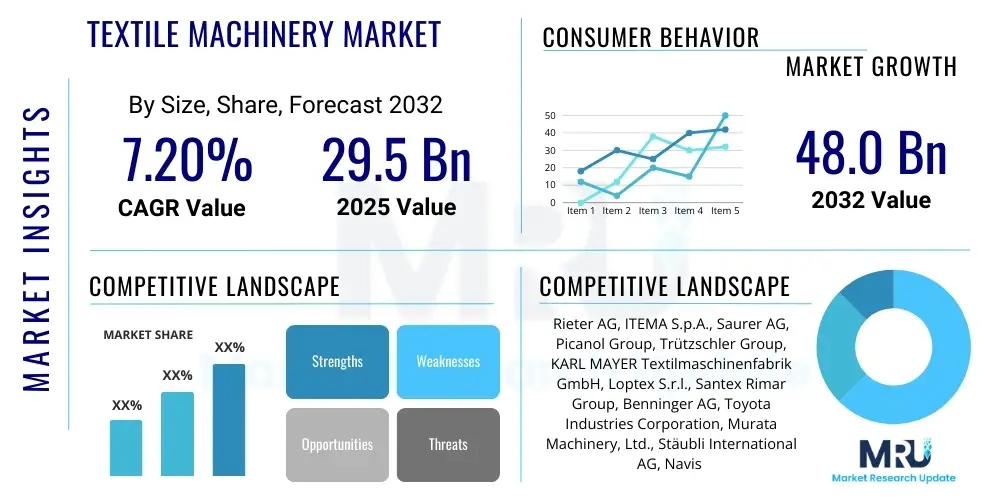

The Textile Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at USD 29.5 Billion in 2025 and is projected to reach USD 48.0 Billion by the end of the forecast period in 2032.

Textile Machinery Market introduction

The global textile machinery market encompasses a broad array of specialized equipment crucial for the entire textile manufacturing process, from fiber preparation to final fabric finishing. This sophisticated machinery is indispensable for spinning, weaving, knitting, non-woven production, dyeing, printing, and various finishing treatments, enabling the transformation of raw fibers into finished textile products. The continuous evolution of these machines significantly impacts the efficiency, quality, and sustainability of textile production worldwide, catering to diverse applications ranging from apparel and home furnishings to high-performance technical textiles. The markets dynamism is driven by technological advancements aimed at enhancing automation, precision, and environmental compliance, addressing the complex demands of a globalized textile industry.

Products within this market segment include, but are not limited to, spinning machines (ring spinning, open-end spinning, air-jet spinning), weaving machines (shuttle, shuttleless, air-jet, water-jet, rapier, projectile looms), knitting machines (circular, flat, warp knitting), dyeing and printing machinery (digital textile printers, rotary screen printers, continuous dyeing ranges), and finishing equipment (sanforizing, calendering, coating, laminating machines). Each category plays a vital role in transforming intermediate textile products into finished goods with specific properties and aesthetics. These machines are increasingly integrated with advanced control systems and sensors to optimize performance and reduce human intervention, fostering a new era of smart manufacturing.

Major applications for textile machinery span a wide spectrum, including the production of apparel fabrics, home textiles (bedding, curtains, upholstery), industrial textiles, medical textiles, automotive textiles, and sports equipment. The benefits derived from modern textile machinery are manifold, encompassing higher production speeds, superior product quality, reduced waste, lower energy consumption, and increased operational flexibility. Key driving factors for market expansion include the burgeoning global demand for textiles, rapid advancements in automation and digitalization, the increasing focus on sustainable production practices, and the growing adoption of technical textiles across various end-use industries. Furthermore, the rising disposable incomes in emerging economies are fueling demand for apparel and home furnishings, thereby indirectly propelling the demand for efficient textile manufacturing capabilities.

Textile Machinery Market Executive Summary

The textile machinery market is currently experiencing significant transformative business trends, largely characterized by an accelerated shift towards automation, digitalization, and sustainable manufacturing practices. Manufacturers are increasingly investing in Industry 4.0 technologies, including the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics, to enhance operational efficiency, reduce labor costs, and improve product quality. There is a strong emphasis on developing machinery that offers greater flexibility for customized production, shorter lead times, and reduced environmental impact through lower energy and water consumption. The competitive landscape is marked by intense innovation, with companies striving to offer integrated solutions that cover multiple stages of textile production, thereby providing a comprehensive ecosystem for textile mills and apparel manufacturers.

Regionally, Asia-Pacific dominates the textile machinery market, primarily due to the presence of large manufacturing hubs in countries like China, India, and Vietnam, coupled with a robust domestic demand for textiles and apparel. These countries benefit from lower labor costs and supportive government policies, making them attractive for textile production and subsequent investment in advanced machinery. Europe, while a mature market, continues to be a hub for research and development, particularly for high-end, specialized machinery and sustainable technologies, with Germany and Italy leading in innovation. North America is characterized by increasing adoption of automation to offset higher labor costs and a growing focus on technical textiles, leading to investment in sophisticated, high-performance machinery. Emerging markets in Latin America and Africa are also showing potential, driven by increasing textile production capacities and a push for localized manufacturing.

From a segmentation perspective, the market is witnessing robust growth across various machinery types, with a particularly strong impetus in weaving and knitting machinery, driven by demand for diverse fabric structures and increasing apparel consumption. Finishing and processing machinery segments are also experiencing significant expansion, propelled by the need for higher quality finishes, advanced printing technologies, and sustainable dyeing solutions that minimize water and chemical usage. The rise of technical textiles is a pivotal trend, stimulating demand for specialized machinery capable of processing high-performance fibers and producing fabrics with unique functionalities. Furthermore, the market for components and parts is growing steadily, supported by the need for maintenance, upgrades, and replacement cycles of existing machinery, ensuring continuous operational efficiency for textile manufacturers globally.

AI Impact Analysis on Textile Machinery Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Textile Machinery Market frequently revolve around how AI can enhance efficiency, reduce operational costs, and contribute to more sustainable manufacturing processes. Common questions explore AIs role in predictive maintenance, improving product quality through automated inspection, optimizing design and production workflows, and revolutionizing supply chain management. Users are particularly interested in the practical applications of AI, such as machine learning algorithms for real-time process adjustments, data analytics for identifying production bottlenecks, and AI-powered robotics for material handling and complex assembly tasks. There is also significant curiosity about the integration challenges, skill requirements, and the potential for AI to drive significant competitive advantages for early adopters, ultimately leading to a more intelligent, adaptive, and autonomous textile manufacturing environment.

- Enhanced Predictive Maintenance: AI algorithms analyze machine performance data to predict potential failures, enabling proactive maintenance and significantly reducing downtime.

- Optimized Production Planning: AI systems can process vast amounts of data to forecast demand, optimize production schedules, and allocate resources more efficiently.

- Improved Quality Control: AI-powered vision systems and sensors detect defects with higher accuracy and speed than human inspection, ensuring consistent product quality.

- Smart Design and Development: AI can assist in fabric design, pattern generation, and material selection by simulating properties and suggesting optimal solutions.

- Automated Supply Chain Management: AI optimizes logistics, inventory management, and raw material sourcing, leading to greater efficiency and cost savings.

- Energy and Resource Optimization: AI monitors and controls energy consumption in real-time, optimizing machine settings to reduce power, water, and chemical usage.

- Real-time Process Adjustment: Machine learning models enable machinery to adapt parameters dynamically based on production conditions, improving yield and quality.

- Customization and Personalization: AI facilitates mass customization by enabling flexible production lines that can quickly switch between different product specifications.

- Robotics and Automation Integration: AI enhances the intelligence and dexterity of robots used in material handling, intricate assembly, and quality inspection within textile factories.

- Workforce Augmentation: AI-driven tools support human operators by providing insights, automating repetitive tasks, and enhancing decision-making, leading to increased productivity.

DRO & Impact Forces Of Textile Machinery Market

The textile machinery market is significantly shaped by a confluence of driving factors, restrictive challenges, and promising opportunities, all contributing to a dynamic set of impact forces. Key drivers include the ever-increasing global demand for textile products across various end-use sectors like apparel, home furnishings, and technical textiles, fueled by population growth and rising disposable incomes, particularly in emerging economies. Technological advancements, such as the integration of Industry 4.0 principles, automation, and digitalization, are further propelling market growth by enhancing productivity, efficiency, and product quality. The growing emphasis on sustainable production methods and environmental compliance also necessitates investment in new, eco-friendly machinery that reduces resource consumption and waste. Additionally, the rapid expansion of technical textiles, which require specialized manufacturing processes, acts as a robust growth catalyst, pushing for innovation in machinery capabilities.

Despite these strong drivers, the market faces several significant restraints. The high initial capital investment required for modern textile machinery poses a substantial barrier, especially for small and medium-sized enterprises (SMEs) that may struggle with financing. Economic downturns and trade protectionism can lead to reduced investment in new machinery, impacting market growth. A shortage of skilled labor proficient in operating and maintaining advanced textile machinery is another critical challenge, particularly as technologies become more complex. Furthermore, intense competition from low-cost machinery manufacturers, predominantly from Asia, can exert downward pressure on pricing and profit margins for established players, necessitating continuous innovation and differentiation to maintain market share. Stringent environmental regulations, while driving sustainability, can also increase operational costs and complexity for machinery manufacturers and textile producers alike.

Opportunities within the textile machinery market are abundant and diverse. The burgeoning demand for technical textiles in sectors such as automotive, medical, construction, and sportswear presents a lucrative avenue for specialized machinery development and sales. The shift towards mass customization and on-demand manufacturing, enabled by digital technologies and AI, offers manufacturers the chance to cater to niche markets and consumer preferences more effectively. Emerging markets in Africa and Latin America, with their developing textile industries, represent untapped potential for market expansion. Moreover, the increasing focus on circular economy principles and textile recycling solutions is creating new opportunities for machinery that can process recycled fibers and enable closed-loop manufacturing systems. Collaborative research and development initiatives between machinery manufacturers, technology providers, and academic institutions are also fostering innovation and the creation of next-generation textile machinery.

Segmentation Analysis

The global textile machinery market is comprehensively segmented based on various attributes, providing a granular view of its diverse landscape. These segmentations are crucial for understanding market dynamics, identifying growth pockets, and formulating targeted business strategies. The primary segmentation criteria include the type of machinery, the specific application or end-use, and the level of automation or technology incorporated. Each segment reflects unique demand patterns, technological requirements, and competitive landscapes, driven by the evolving needs of the global textile industry. Analyzing these segments helps in comprehending how different parts of the market contribute to its overall growth and future trajectory, highlighting areas of high potential and those facing saturation or specific challenges. This structured approach allows stakeholders to make informed decisions regarding product development, market entry, and resource allocation.

- By Type:

- Spinning Machinery (Ring Spinning, Open-End Spinning, Air-Jet Spinning)

- Weaving Machinery (Shuttleless Looms - Rapier, Air-Jet, Water-Jet; Shuttle Looms)

- Knitting Machinery (Circular Knitting, Flat Knitting, Warp Knitting)

- Finishing and Processing Machinery (Dyeing, Printing, Washing, Drying, Calendering, Coating, Laminating)

- Non-Woven Machinery (Spunbond, Meltblown, Needle Punching)

- Other Machinery (Braiding, Embroidery, Auxiliary Equipment, Parts & Accessories)

- By Application:

- Apparel Manufacturing

- Home Textiles (Bedding, Upholstery, Curtains)

- Technical Textiles (Automotive, Medical, Construction, Sports, Protective Wear)

- Industrial Textiles

- Others (Carpets, Ropes, Twines)

- By Technology/Automation:

- Automatic Machinery

- Semi-Automatic Machinery

- Manual Machinery

- By End-Use Industry:

- Small & Medium Enterprises (SMEs)

- Large Enterprises

Textile Machinery Market Value Chain Analysis

The value chain of the textile machinery market is a complex ecosystem involving multiple stages, beginning from raw material procurement to the ultimate deployment and maintenance of machinery in textile manufacturing units. The upstream segment of this value chain involves suppliers of critical components such as specialized metals, electronic parts, motors, sensors, and precision engineering components that are essential for the construction of sophisticated textile machines. These suppliers play a vital role in ensuring the quality, durability, and technological advancement of the final machinery. Relationships with these upstream providers are crucial for machinery manufacturers to maintain cost efficiency, innovation cycles, and consistent production quality, often requiring long-term strategic partnerships and rigorous quality control measures.

The core of the value chain is occupied by the textile machinery manufacturers themselves. These companies are responsible for the research and development, design, engineering, assembly, and testing of various types of textile equipment. They invest heavily in innovation to incorporate advanced technologies like automation, artificial intelligence, and sustainable features into their products, catering to the evolving demands of the textile industry. Following manufacturing, the distribution channel plays a critical role in bringing these machines to end-users. This typically involves a network of direct sales forces, authorized distributors, agents, and sometimes online platforms. Direct sales are often preferred for large, complex machinery requiring extensive installation and after-sales support, while distributors handle sales and service for a broader range of products, often providing local support and market access.

The downstream segment of the value chain consists of the textile producers who are the primary customers for this machinery. This includes textile mills, apparel manufacturers, non-woven fabric producers, and technical textile companies across the globe. These end-users utilize the machinery to process raw fibers, spin yarns, weave fabrics, knit garments, dye, print, and finish textile products. The effectiveness and efficiency of the machinery directly impact their operational costs, product quality, and market competitiveness. After-sales service, including installation, training, maintenance, and spare parts supply, forms a critical part of the downstream value chain, ensuring the longevity and optimal performance of the machinery, and fostering long-term customer relationships. Both direct distribution channels, where manufacturers interact directly with end-users, and indirect channels, involving intermediaries like agents and distributors, are prevalent, catering to different market segments and geographical requirements, ensuring widespread market penetration and comprehensive customer support.

Textile Machinery Market Potential Customers

The primary potential customers for textile machinery are diverse entities within the global textile and apparel manufacturing ecosystem, ranging from large-scale integrated textile mills to specialized boutique production houses. These end-users are constantly seeking machinery that enhances productivity, improves product quality, reduces operational costs, and supports sustainable manufacturing practices. The core customer base includes traditional textile mills involved in spinning, weaving, knitting, and finishing operations, which require a comprehensive suite of equipment to convert raw fibers into finished fabrics. These mills often invest in high-capacity, automated machinery to meet the demands of mass production, focusing on efficiency and consistency across their extensive product lines. Their purchasing decisions are heavily influenced by factors such as machine reliability, energy efficiency, ease of maintenance, and the availability of robust after-sales support and spare parts, crucial for continuous operation.

Another significant segment of potential customers includes apparel manufacturers, particularly those engaged in high-volume production or specializing in complex garment constructions. While some apparel manufacturers focus more on cutting and sewing equipment, larger players and integrated operations also invest in knitting and finishing machinery to control more of their supply chain. The growing trend towards fast fashion and on-demand manufacturing has also driven demand for more agile and digitally integrated machinery that can quickly adapt to changing designs and smaller batch sizes. Beyond apparel, producers of home textiles, such as bedding, upholstery, and curtain manufacturers, form a substantial customer segment. These companies require machinery capable of handling various fabric types and widths, often with a focus on durability, aesthetic finishes, and specific functional properties relevant to household applications.

Furthermore, a rapidly expanding customer base is found within the technical textiles sector. This includes manufacturers specializing in non-woven fabrics, industrial textiles, medical textiles, automotive textiles, geotextiles, and sports textiles. These applications demand highly specialized machinery designed to process advanced materials and produce fabrics with specific performance characteristics like high strength, flame resistance, water repellency, or biodegradability. Companies in this segment often require customized machinery solutions and are willing to invest in cutting-edge technology that enables the production of innovative, high-value-added products. The demand from these diverse end-users collectively drives innovation and growth within the textile machinery market, pushing manufacturers to continuously develop more sophisticated, efficient, and versatile equipment tailored to specific industry needs and emerging market trends.

Textile Machinery Market Key Technology Landscape

The textile machinery market is currently undergoing a profound technological transformation, driven by the principles of Industry 4.0, which emphasizes connectivity, automation, and data-driven decision-making. At the forefront of this landscape is the widespread adoption of the Internet of Things (IoT), where sensors are embedded into machinery to collect real-time data on performance, energy consumption, and operational parameters. This data is then utilized for predictive maintenance, optimizing production processes, and identifying potential bottlenecks before they lead to downtime. Smart machinery integrated with IoT capabilities allows for remote monitoring and control, significantly enhancing operational flexibility and efficiency. Manufacturers are increasingly offering interconnected systems that facilitate seamless communication between different stages of textile production, moving towards fully integrated smart factories where machines, systems, and human operators collaborate intelligently.

Another pivotal technological advancement is the integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms into textile machinery. AI is being deployed for advanced quality control, using computer vision systems to detect even minute defects in fabrics with high precision and speed, far surpassing human capabilities. Machine learning models optimize various processes, from yarn tensioning in spinning to color matching in dyeing, leading to improved product consistency and reduced waste. Robotic process automation (RPA) and advanced robotics are also transforming material handling, intricate assembly tasks, and automated loading/unloading processes, particularly in areas requiring repetitive or high-precision actions. These AI-driven and robotic solutions not only boost productivity but also enhance workplace safety by taking over hazardous or ergonomically challenging tasks, contributing to a more efficient and resilient manufacturing environment.

Sustainability-focused technologies are also shaping the key technology landscape. There is a strong emphasis on developing machinery that minimizes environmental impact through reduced energy consumption, lower water usage in dyeing and finishing, and improved chemical management. Innovations include waterless dyeing technologies, digital printing with minimal water waste, and advanced filtration systems for wastewater treatment. Furthermore, technologies enabling the processing of recycled fibers and the development of biodegradable textiles are gaining prominence, supporting the industrys shift towards a circular economy. Additive manufacturing (3D printing) is emerging for creating complex machine components and even functional textile structures, offering greater design flexibility and faster prototyping. These technological advancements collectively aim to create a more efficient, sustainable, and intelligent textile manufacturing ecosystem, driving competitive advantage and meeting evolving global demands.

Regional Highlights

- Asia-Pacific: This region stands as the undisputed leader in the global textile machinery market, primarily driven by the massive textile and apparel manufacturing bases in countries like China, India, Vietnam, Bangladesh, and Pakistan. China, in particular, is both a major producer and consumer of textile machinery, with significant investments in upgrading its manufacturing capabilities with advanced, automated equipment. India is witnessing robust growth due to government initiatives promoting local manufacturing and increasing domestic consumption. The region benefits from a large labor force, lower operational costs, and growing export-oriented textile industries, leading to continuous demand for efficient and modern machinery. The focus is increasingly on acquiring machinery that offers higher productivity, better energy efficiency, and integrates digital technologies to stay competitive in the global market.

- Europe: Despite being a mature market, Europe remains a critical hub for innovation and the production of high-quality, technologically advanced textile machinery, especially in countries like Germany, Italy, Switzerland, and Belgium. These nations are renowned for their precision engineering, research and development in sustainable textile technologies, and the production of specialized machinery for technical textiles. European manufacturers often lead in areas such as digital textile printing, advanced finishing processes, and automation solutions, catering to the premium segment of the market. The regions growth is driven by the continuous need for process optimization, adherence to stringent environmental regulations, and the demand for machinery capable of producing high-value, specialized textile products.

- North America: The North American textile machinery market is characterized by a strong focus on automation, digitalization, and the production of high-performance technical textiles. Facing higher labor costs, manufacturers in the U.S. and Canada are increasingly investing in automated and intelligent machinery to enhance efficiency and reduce reliance on manual labor. There is significant demand for machinery used in the production of automotive textiles, protective wear, and medical textiles. While the regions overall textile manufacturing footprint might be smaller compared to Asia, the emphasis is on innovation, quality, and specialized applications, driving demand for advanced and sophisticated equipment rather than mass-market solutions.

- Latin America: The Latin American textile machinery market is showing promising growth, albeit from a smaller base, driven by increasing local textile production capacities and government efforts to reduce reliance on imports. Countries like Brazil, Mexico, and Argentina are investing in modernizing their textile industries, leading to demand for a range of machinery, including spinning, weaving, and finishing equipment. The market is influenced by economic stability and trade policies, with a growing interest in more efficient and sustainable machinery to compete regionally and internationally. Opportunities exist for both established global players and regional manufacturers to cater to this evolving market.

- Middle East & Africa: This region presents emerging opportunities for textile machinery, particularly in countries like Turkey, Egypt, and South Africa, which have established textile industries. Investments in textile manufacturing are being driven by a desire for economic diversification, job creation, and meeting local and regional demand. There is a gradual shift towards modernizing existing facilities and establishing new ones, creating demand for cost-effective yet efficient machinery. The focus is often on versatile machinery that can produce a range of products for apparel, home textiles, and increasingly, some technical textile applications. Turkey, in particular, is a significant player with a robust domestic textile industry and a strong export orientation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Textile Machinery Market.- Rieter AG (Switzerland)

- ITEMA S.p.A. (Italy)

- Saurer AG (Switzerland)

- Picanol Group (Belgium)

- Trützschler Group (Germany)

- KARL MAYER Textilmaschinenfabrik GmbH (Germany)

- Loptex S.r.l. (Italy)

- Santex Rimar Group (Italy)

- Benninger AG (Switzerland)

- Toyota Industries Corporation (Japan)

- Murata Machinery, Ltd. (Japan)

- Stäubli International AG (Switzerland)

- Navis TubeTex (USA)

- Jiangsu Jinggong Textile Machine Co., Ltd. (China)

- Shima Seiki Mfg., Ltd. (Japan)

Frequently Asked Questions

What is the projected growth rate for the Textile Machinery Market?

The Textile Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032, reaching an estimated USD 48.0 Billion by 2032.

How is AI impacting the Textile Machinery Market?

AI significantly impacts the Textile Machinery Market by enabling predictive maintenance, enhancing quality control, optimizing production planning, and facilitating smart design, leading to increased efficiency and reduced operational costs.

What are the primary drivers for the Textile Machinery Market?

Primary drivers include rising global demand for textiles, rapid advancements in automation and digitalization, increasing focus on sustainable production practices, and the growing adoption of technical textiles across various industries.

Which region dominates the Textile Machinery Market?

Asia-Pacific currently dominates the Textile Machinery Market, primarily driven by large manufacturing bases and robust demand in countries such as China, India, and Vietnam, coupled with supportive government policies.

What are the key technological trends in textile machinery?

Key technological trends include the integration of Industry 4.0 principles, the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), robotics, and sustainability-focused innovations like waterless dyeing and circular economy solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Textile Machinery Market Statistics 2025 Analysis By Application (Cotton Textile Industry, Woolen Textile Industry, Linen Textile Industry, Others), By Type (Spinning Machinery, Knitting Machinery, Weaving Machinery, Finishing Machinery, Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Textile Machinery Market Statistics 2025 Analysis By Application (Cotton Textile Industry, Woolen Textile Industry, Linen Textile Industry), By Type (Spinning Machinery, Knitting Machinery, Weaving Machinery, Finishing Machinery), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager